Market Overview:

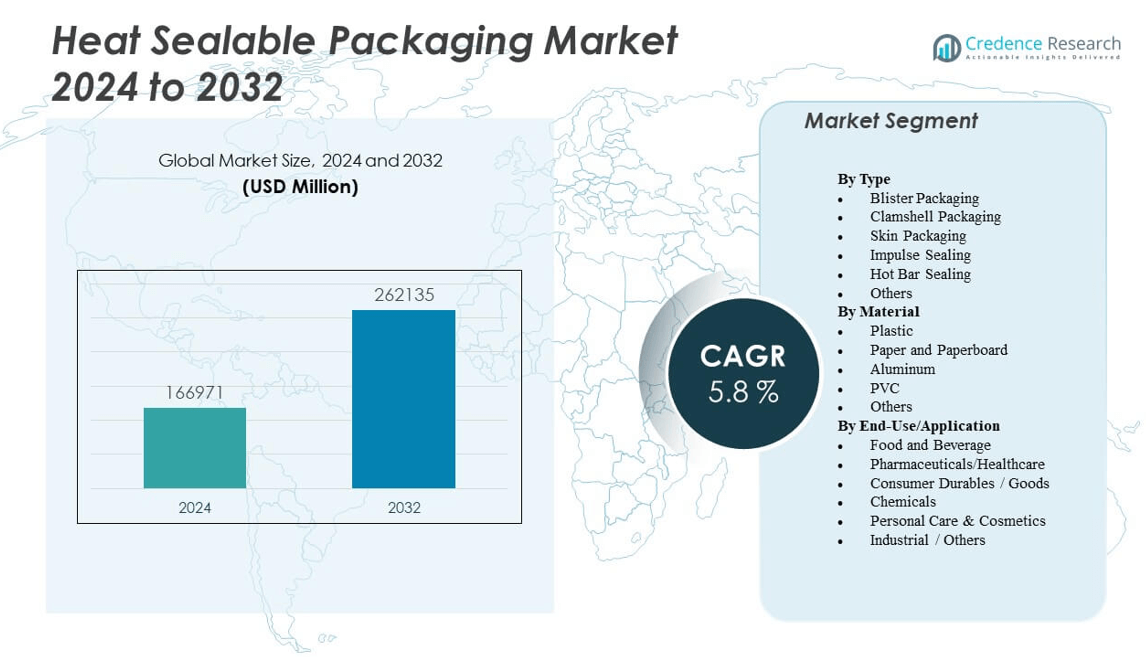

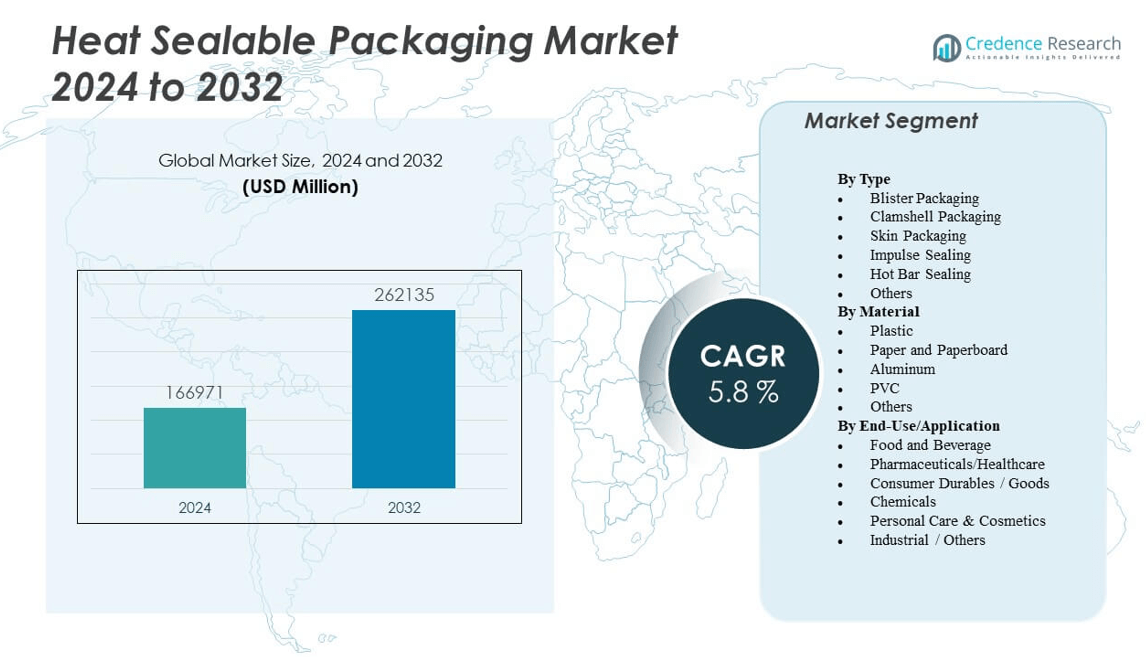

The Heat Sealable Packaging Market is projected to grow from USD 166,971 million in 2024 to an estimated USD 262,135 million by 2032, with a compound annual growth rate (CAGR) of 5.8% from 2024 to 2032.

| REPORT ATTRIBUTE |

DETAILS |

| Historical Period |

2020-2023 |

| Base Year |

2024 |

| Forecast Period |

2025-2032 |

| Heat Sealable Packaging Market Size 2024 |

USD 166,971 million |

| Heat Sealable Packaging Market, CAGR |

5.8% |

| Heat Sealable Packaging Market Size 2032 |

USD 262,135 million |

The market is being driven by growing demand for tamper-evident and secure packaging across food, pharmaceutical, and consumer goods industries. As consumers increasingly prioritize convenience and hygiene, manufacturers are adopting heat sealable films and laminates for flexible packaging. Innovations in biodegradable and recyclable heat sealable materials also support sustainability goals, making them attractive to environmentally conscious brands. The rapid growth of e-commerce and food delivery sectors has further strengthened the need for reliable, leak-proof packaging solutions, contributing to sustained market momentum.

Regionally, Asia Pacific leads the Heat Sealable Packaging Market due to its dominant manufacturing base and rising consumer demand in countries such as China, India, and Indonesia. North America remains a mature market with sustained investments in pharmaceutical and processed food packaging. Europe is witnessing steady adoption, driven by strict regulatory policies and growing preference for eco-friendly materials. Latin America and the Middle East & Africa represent emerging markets, where increasing urbanization, retail expansion, and industrialization are creating new opportunities for heat sealable packaging across diverse end-use sectors.\

Access crucial information at unmatched prices!

Request your sample report today & start making informed decisions powered by Credence Research Inc.!

Download Sample

Market Insights:

- The Heat Sealable Packaging Market is projected to grow from USD 166,971 million in 2024 to USD 262,135 million by 2032, at a CAGR of 5.8%, driven by rising demand across food, pharma, and personal care sectors.

- Strong growth in ready-to-eat meals, e-commerce packaging, and convenience food boosts the need for tamper-evident and airtight sealing solutions.

- Pharmaceutical packaging drives adoption of high-barrier films and sterile heat sealing formats for compliance and product integrity.

- Technical challenges related to sealing mixed-material laminates and narrow seal windows can hinder mass-scale implementation.

- Sustainability goals and evolving regulations push manufacturers to transition toward recyclable mono-material heat sealable films.

- Asia Pacific leads with 41% market share, supported by high packaging demand and large-scale local manufacturing.

- North America and Europe show steady growth driven by innovation in seal technologies and sustainability-driven material shifts.

Market Drivers:

Growing Demand for Food Safety and Convenience in Packaged Goods

Consumer preference for hygienic, tamper-evident packaging continues to grow, especially in food and beverage sectors. The shift toward ready-to-eat meals and single-serve portions increases reliance on heat sealable formats. Companies seek packaging that preserves freshness while offering extended shelf life. Heat sealable packaging meets these demands by creating airtight seals that protect contents from contamination. Rising food safety regulations worldwide reinforce the need for compliant and reliable packaging formats. The Heat Sealable Packaging Market benefits from evolving consumer expectations and stricter regulatory controls. It plays a pivotal role in supporting health-centric packaging innovations. The push for improved convenience and portability reinforces its relevance in modern retail settings.

Rising Use of Heat Sealable Films in Pharmaceutical and Healthcare Packaging

The pharmaceutical industry demands packaging solutions that ensure integrity, sterility, and barrier performance. Heat sealable films provide secure seals that safeguard sensitive products from moisture, oxygen, and microbial ingress. It supports unit-dose formats, blister packs, and tamper-evident packaging for high-risk medications. Governments worldwide require serialization and traceability in pharmaceutical supply chains, driving adoption of precise sealing technologies. Medical device packaging also relies on heat sealing for protection and compliance with international standards. Growth in over-the-counter and prescription drug distribution channels fuels this need further. The Heat Sealable Packaging Market aligns with strict healthcare requirements and performance standards. It strengthens product security while streamlining production processes.

Expanding Application in Industrial and Consumer Goods Sectors

Beyond food and pharma, heat sealable materials are gaining momentum in electronics, automotive parts, and home care products. These sectors demand durable, tamper-proof, and transport-resilient packaging. It offers scalable solutions for batch and custom packaging requirements in industrial goods. Retail brands favor heat sealable pouches and films for promoting aesthetics, freshness, and branding. Consumer goods manufacturers integrate resealable options, supported by heat seal layers, to enhance user experience. The Heat Sealable Packaging Market responds to shifting brand preferences and logistics priorities. Flexible production capabilities make it suitable for varying product shapes and sizes. Strong sealing performance improves transit safety and shelf presentation.

- For example, Mondi Group’s 2024 Innovation Brief details that its BarrierPack Recyclable film was integrated into industrial packaging for automotive parts, providing puncture resistance withstanding 160 kPa internal pressure.

Supportive Regulations and Sustainable Packaging Initiatives

Governments and international bodies are pushing industries toward recyclable and biodegradable packaging solutions. Heat sealable films based on bio-based and compostable polymers meet these targets without compromising performance. The Heat Sealable Packaging Market benefits from rising demand for alternatives to plastic-heavy formats. It supports compliance with extended producer responsibility (EPR) and plastic reduction mandates. Advances in solvent-free and low-temperature sealing technologies reduce energy use and emissions. Regulatory alignment across geographies fosters uniformity in packaging specifications. Brand owners seek heat sealable materials that meet evolving sustainability metrics and labeling standards. It offers a path to maintain compliance while delivering packaging efficiency.

- For example, Dow launched INNATE™ TF‑220 Precision Packaging Resin, specifically formulated for recyclable mono‑material BOPE films. It supports circular design, production scale‑up, and collaboration with brand owners like Liby, integrating ~10 % post‑consumer recycled (PCR) resin into flexible packaging formats

Market Trends

Integration of Smart Features and Functional Layers in Heat Seal Films

Manufacturers are embedding smart features like QR codes, NFC tags, and tamper-evident seals into heat sealable films. These features enhance traceability, consumer engagement, and anti-counterfeiting capabilities. It reflects a growing shift toward intelligent packaging that supports supply chain transparency. Functional layers such as antimicrobial coatings and oxygen scavengers are also being integrated. These value-added enhancements allow customization based on product shelf life and distribution conditions. The Heat Sealable Packaging Market embraces multi-functionality to meet complex industry needs. It elevates packaging beyond containment, enabling interactivity and real-time product tracking. This trend expands the role of packaging in customer communication and compliance.

Shift Toward High-Performance and Barrier-Optimized Film Structures

High-barrier films are becoming a preferred option across food, healthcare, and industrial segments. Innovations in multilayer laminates help improve moisture, light, and gas barrier performance. It enables longer shelf lives without using preservatives or refrigeration. Co-extruded and metallized films with sealable coatings offer customizable barrier properties. The Heat Sealable Packaging Market is evolving with demand for performance packaging that suits global logistics. Specialty film grades now cater to high-humidity and high-temperature environments. Brands prioritize performance metrics like seal strength, puncture resistance, and clarity. This trend supports expansion into new application areas and enhances packaging reliability.

- For example, Taghleef Industries’ EXTENDO® ultra-high barrier BOPP films achieve oxygen transmission rates (OTR) below 0.1cm³/m²/day, meeting the strictest requirements for food shelf-life and aroma retention.

Adoption of Mono-Material Heat Sealable Solutions for Recycling Compliance

Brands and converters are shifting to mono-material film structures to improve recyclability. Polyethylene-based heat sealable laminates are replacing multi-material structures that are harder to recycle. The Heat Sealable Packaging Market adopts design-for-recycling principles to align with circular economy goals. Technological advancements now allow mono-material films to match the sealing and barrier performance of complex composites. Regulatory pressure in Europe and parts of Asia accelerates this transition. Brands view mono-material packaging as a competitive differentiator in sustainability reporting. This trend drives investments in compatible sealing technologies and testing infrastructure. Standardization in recyclability labeling further supports consumer acceptance.

- For instance, SÜDPACK launched its Pure-Line mono-material film in 2025, used for coffee packaging to meet “Made for Recycling” certification—demonstrating validated protection against UV radiation, oxygen, and water vapor with processed volumes exceeding 100million packages per year.

Customization of Heat Seal Parameters for Automation and Precision Packaging

Automation trends in packaging operations require materials with consistent seal integrity and machine compatibility. Heat sealable films are being tailored for specific sealing temperatures, dwell times, and pressure ranges. It improves packaging line efficiency and reduces material waste. The Heat Sealable Packaging Market adapts to robotic and high-speed production environments in FMCG and pharmaceuticals. Manufacturers offer seal curves and validation data to support automated quality checks. This customization minimizes sealing errors and enhances throughput. Temperature-sensitive products also benefit from low-seal-temperature materials. Precision sealing supports lean manufacturing and improved traceability across modern production lines.

Market Challenges Analysis

Material Compatibility Issues and Limited Seal Range Tolerance

Despite its versatility, heat sealable packaging faces challenges related to seal performance across diverse materials. Compatibility between layers like aluminum foil, PET, and PE can limit sealing reliability. It requires exacting conditions of pressure, temperature, and time for effective bonding. Minor deviations during sealing can compromise integrity or cause burn-through. The Heat Sealable Packaging Market must address narrow seal windows and inconsistencies in lamination. Adapting materials for wide-ranging sealing equipment across regions adds complexity. Converters may face higher rejection rates in mass production settings. Customizing sealant layers for mixed substrates often raises costs and time-to-market. It places pressure on innovation in seal coating and material engineering.

Environmental Trade-Offs and Complexity in Sustainable Material Design

Efforts to improve sustainability in heat sealable packaging can introduce new trade-offs. Bio-based materials may lack thermal stability or mechanical strength required for industrial packaging. Recyclable or compostable films may not be compatible with existing sealing infrastructure. The Heat Sealable Packaging Market needs to balance environmental claims with regulatory compliance and operational practicality. Innovation in compostable seal layers is still nascent and often cost-prohibitive. Scaling eco-friendly formats requires end-of-life clarity and uniform global standards. Packaging downgauging can compromise seal integrity or shelf life under transit stress. These challenges hinder the speed of sustainability transitions and require multidisciplinary collaboration.

Market Opportunities

Expansion in Ready-to-Eat and Delivery-Driven Food Markets

The growth of the foodservice and meal-kit industries opens opportunities for heat sealable packaging. Ready-to-eat, frozen, and microwaveable meals require reliable seals that can withstand heating and transit. It plays a critical role in keeping food safe, portioned, and intact during delivery. The Heat Sealable Packaging Market stands to gain from rapid adoption in ghost kitchens and quick commerce. Innovations in dual-ovenable sealant layers support high-performance requirements. Heat sealable lids and trays also suit fast-paced retail and takeaway formats. New entrants and private labels seek economical and scalable packaging solutions. Strong demand across cities and tier-II markets creates room for product variety and regional customization.

Adoption of Bio-Based and Recyclable Heat Seal Films in Emerging Markets

Emerging economies are adopting sustainable packaging to meet export requirements and local consumer preferences. Regional governments promote recyclable and compostable materials through incentives and mandates. The Heat Sealable Packaging Market can capitalize on rising demand for affordable, compliant, and eco-friendly sealing options. Bio-based polymers like PLA and starch blends are finding application in flexible formats. Local manufacturing of eco-materials reduces dependency on imports and supports cost competitiveness. Education campaigns around packaging recyclability boost acceptance in retail and consumer segments. Brands targeting global supply chains rely on packaging that meets evolving ESG criteria. This creates long-term growth potential for sustainable sealable film providers.

Market Segmentation Analysis:

The Heat Sealable Packaging Market is segmented by type, material, and end-use application, each contributing to its broad applicability across industries.

By packaging types, blister packaging leads due to its widespread use in pharmaceuticals and consumer goods, offering tamper evidence and product visibility. Clamshell and skin packaging gain traction in retail and electronics due to their protective properties and shelf appeal. Impulse and hot bar sealing are essential sealing methods across both flexible and rigid formats, supporting high-speed packaging operations. These varied types enable manufacturers to meet specific packaging demands across use cases.

- For instance, WestRock’s OptiPak™ blister packaging is widely used for prescription and over-the-counter pharmaceuticals, with the company reporting annual production of over 1.5 billion pharmaceutical blister packs in the U.S. alone.

By material, plastic dominates due to its flexibility, low cost, and compatibility with various sealing techniques. Polyethylene, polypropylene, and PET are preferred for food and healthcare products requiring moisture and oxygen barriers. Paper and paperboard are gaining popularity in sustainable packaging initiatives, while aluminum and PVC serve niche requirements in barrier-sensitive and medical applications. It continues to shift toward recyclable and composite-free materials.

By end-use, food and beverage remain the largest segment, driven by demand for secure, convenient, and tamper-evident packaging formats. Pharmaceuticals and healthcare rely on heat sealable packaging for sterility and compliance, while consumer durables adopt it for protection and shelf differentiation. Personal care, industrial goods, and chemical packaging segments contribute to steady growth, supported by product safety and regulatory adherence. The Heat Sealable Packaging Market addresses varied sectoral needs with material versatility, process adaptability, and strong sealing performance.

- For instance, Sealed Air’s Cryovac® shrink bags handle over 15 billion food packaging units globally per year, providing tamper-evident, leak-proof solutions for meat and poultry processors.

Segmentation:

By Type

- Blister Packaging

- Clamshell Packaging

- Skin Packaging

- Impulse Sealing

- Hot Bar Sealing

- Others

By Material

- Plastic (including types like polyethylene, polypropylene, PET)

- Paper and Paperboard

- Aluminum

- PVC

- Others

By End-Use/Application

- Food and Beverage

- Pharmaceuticals/Healthcare

- Consumer Durables / Goods

- Chemicals

- Personal Care & Cosmetics

- Industrial / Others

By Region

- North America

- Europe

- Germany

- France

- U.K.

- Italy

- Spain

- Rest of Europe

- Asia Pacific

- China

- Japan

- India

- South Korea

- South-east Asia

- Rest of Asia Pacific

- Latin America

- Brazil

- Argentina

- Rest of Latin America

- Middle East & Africa

- GCC Countries

- South Africa

- Rest of the Middle East and Africa

Regional Analysis:

Asia Pacific holds the largest share of the Heat Sealable Packaging Market at 41%, driven by high consumption of packaged foods, rapid urbanization, and strong manufacturing infrastructure. Countries such as China, India, Japan, and South Korea contribute significantly due to their expanding food and pharmaceutical sectors. Rising income levels and growing demand for convenience packaging accelerate adoption of heat sealable films and laminates. Regional players invest in localized production and flexible packaging lines to cater to domestic and export demands. Government initiatives promoting sustainable packaging push innovation in recyclable heat sealable materials. The region remains a key hub for both supply and demand across application industries. It leads the market with scalable capacity and competitive pricing.

North America accounts for 27% of the Heat Sealable Packaging Market, supported by strong demand from food service, healthcare, and industrial packaging sectors. The United States drives regional growth through continuous investment in automated packaging systems and advanced sealant technologies. Heat sealable materials are widely adopted across frozen food, pharmaceutical, and ready-meal segments due to their safety and barrier properties. Brands prioritize high-performance packaging that meets FDA and USDA standards, encouraging material innovations. The region focuses on sustainable mono-material formats to meet environmental regulations and consumer expectations. R&D activities across the U.S. and Canada reinforce product quality and customization. It remains a leading region for technological development and packaging standardization.

Europe holds a 22% share of the Heat Sealable Packaging Market, led by demand from regulated food and healthcare sectors. Countries such as Germany, France, Italy, and the UK drive adoption due to stringent safety and environmental norms. The EU’s circular economy targets encourage the shift to recyclable heat sealable packaging formats. It also sees strong growth in bio-based sealant films supported by regional recycling infrastructure. European packaging firms emphasize low-temperature sealing and solvent-free coatings to reduce energy use and improve compliance. Growing demand for premium and convenience packaging in retail contributes to market momentum. The region combines regulatory pressure and innovation to maintain a competitive edge.

Shape Your Report to Specific Countries or Regions & Enjoy 30% Off!

Key Player Analysis:

- Amcor plc

- Berry Global Inc.

- Constantia Flexibles

- Sealed Air Corporation

- Mondi Group

- Huhtamaki Oyj

- Uflex Ltd.

- Shako Flexipack

- DuPont Teijin Films

- HEAT SEAL, LLC

- Winpak Ltd.

- Glenroy, Inc.

- Plastissimo Film Co. Ltd.

- Bischof & Klein GmbH

- Ampac Holdings LLC

- Schur Flexibles Holding GesmbH

- Supravis Group S.A.

Competitive Analysis:

The Heat Sealable Packaging Market features a competitive landscape dominated by global packaging giants such as Amcor plc, Berry Global Inc., Sealed Air Corporation, and Mondi Group. These companies maintain strong positions through expansive product portfolios, global distribution networks, and consistent investment in sustainable and high-barrier sealant technologies. Regional players like Uflex Ltd., Shako Flexipack, and Supravis Group S.A. provide agile, customized solutions catering to local markets. Strategic partnerships, acquisitions, and R&D initiatives are central to gaining market share. It fosters innovation in recyclable materials and advanced heat sealing technologies. Healthcare and food industry requirements drive competition around performance, compliance, and material efficiency. Companies differentiate by offering seal integrity, automation compatibility, and regulatory adherence.

Recent Developments:

- In March 2025, Amcor plc introduced several new sustainable packaging solutions, such as the industry-first 2oz retort bottle for nutritional shots featuring StormPanel technology and the launch of a refill pouch for laundry and cleaning products.

- In March 2025, Constantia Flexibles completed the acquisition of a majority share in Aluflexpack AG, a leading European flexible packaging producer. This move is set to strengthen Constantia’s leadership in product innovation and sustainability, expanding their capacity to provide a broader range of packaging solutions to the food and pharmaceutical sectors.

- In October 2024, Mondi Group completed the acquisition of a specialty packaging facility in Eastern Europe, expanding its capacity for producing heat-sealable flexible packaging. This acquisition is intended to meet growing demand from the food and personal care industries, supporting Mondi’s long-term growth strategy in the region.

- In March 2024, Sealed Air Corporation (now rebranded as SEE) launched the Liquibox Universal Self-Sealing Cap, a hygienic, recyclable fitment for large-format dairy dispensing systems. This innovative product targets improved hygiene and extended freshness for foodservice applications—key requirements in heat sealable packaging.

Market Concentration & Characteristics:

The Heat Sealable Packaging Market exhibits moderate to high concentration with a mix of multinational corporations and specialized regional firms. It is characterized by rapid innovation, stringent quality standards, and growing emphasis on sustainability. The market responds to evolving regulations and consumer demand for safer, recyclable packaging. Customization, speed-to-market, and material performance define competitive advantages. It emphasizes strong technical expertise and operational scale, particularly in high-growth sectors like pharmaceuticals, food service, and e-commerce. Continuous R&D investment supports advancements in heat sealable materials and coatings. Strategic collaborations across the supply chain enhance product development and market reach.

Report Coverage:

The research report offers an in-depth analysis based on type, material, and end-use application, It details leading market players, providing an overview of their business, product offerings, investments, revenue streams, and key applications. Additionally, the report includes insights into the competitive environment, SWOT analysis, current market trends, as well as the primary drivers and constraints. Furthermore, it discusses various factors that have driven market expansion in recent years. The report also explores market dynamics, regulatory scenarios, and technological advancements that are shaping the industry. It assesses the impact of external factors and global economic changes on market growth. Lastly, it provides strategic recommendations for new entrants and established companies to navigate the complexities of the market.

Future Outlook:

- Demand for recyclable and mono-material heat sealable films is expected to grow due to tightening global sustainability regulations.

- Advancements in bio-based polymers will support the development of compostable heat sealable packaging solutions.

- Adoption of heat sealable formats in e-commerce and direct-to-consumer packaging will expand across various product categories.

- Integration of smart features like tamper-evident seals and traceability tags will enhance packaging functionality.

- Increased investment in automation and precision sealing equipment will improve production efficiency and reduce material waste.

- Growth in cold chain logistics and frozen food sectors will elevate the need for high-barrier and thermally stable sealable packaging.

- Regulatory pressure on single-use plastics will accelerate innovation in alternative sealant materials.

- Emerging markets will drive new demand through urbanization, retail modernization, and rising disposable incomes.

- Collaboration between material science firms and converters will foster development of tailored, application-specific sealing films.

- Healthcare and pharmaceutical industries will continue to lead adoption due to strict hygiene and compliance standards.