Market Overview

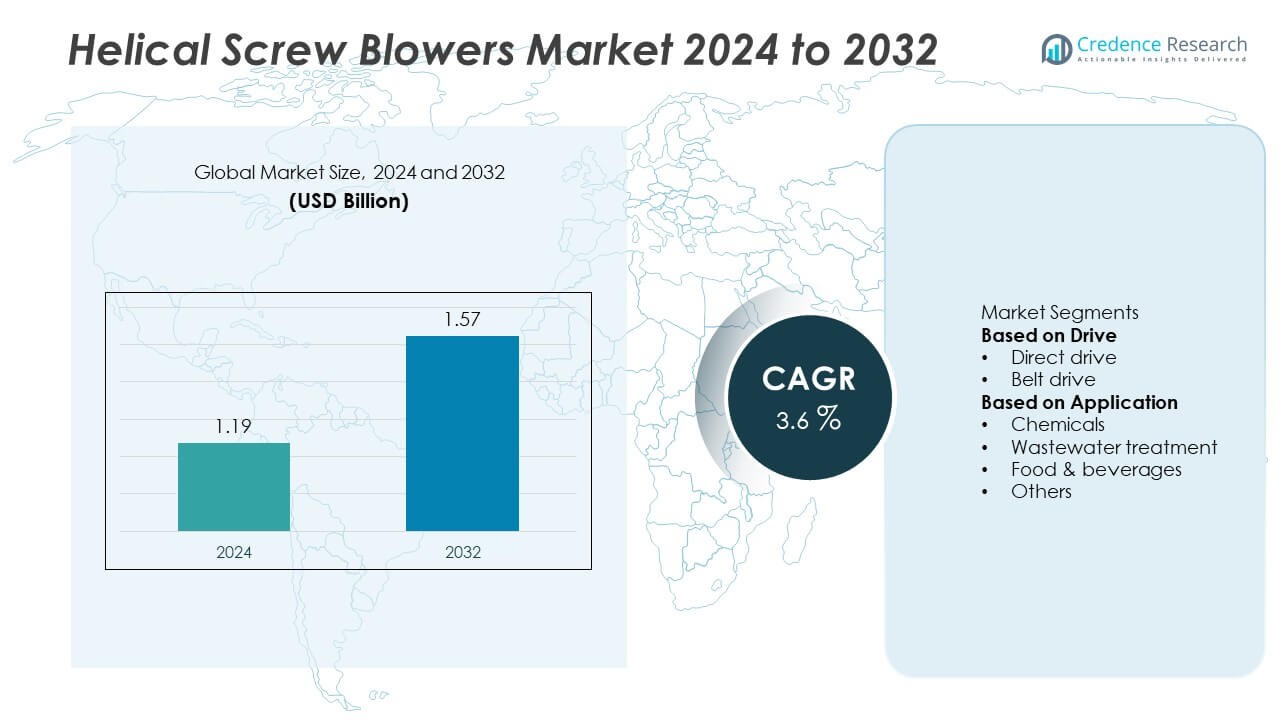

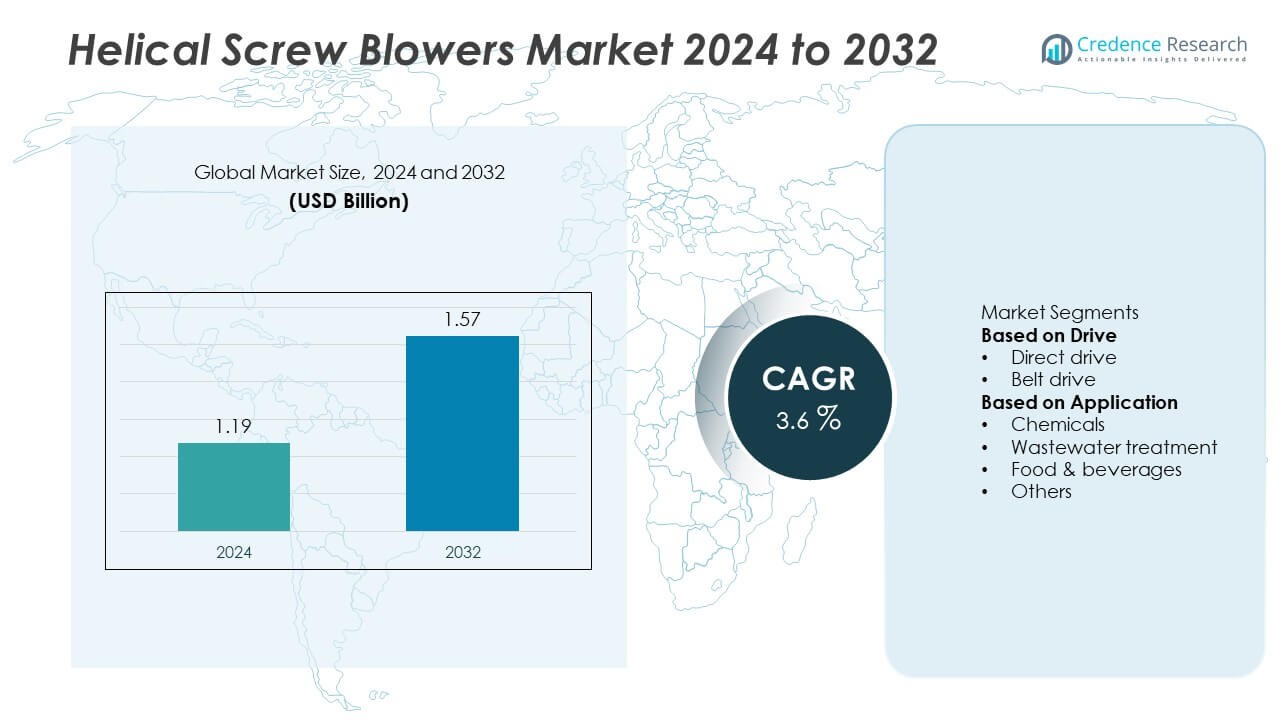

The global helical screw blowers market was valued at USD 1.19 billion in 2024 and is projected to reach USD 1.57 billion by 2032, growing at a CAGR of 3.6% during the forecast period.

| REPORT ATTRIBUTE |

DETAILS |

| Historical Period |

2020-2023 |

| Base Year |

2024 |

| Forecast Period |

2025-2032 |

| Helical Screw Blowers Market Size 2024 |

USD 1.19 Billion |

| Helical Screw Blowers Market, CAGR |

3.6% |

| Helical Screw Blowers Market Size 2032 |

USD 1.57 Billion |

The helical screw blowers market is led by key companies such as Kaeser Kompressoren, Aerzen, Atlas Copco, Gardner Denver, Robuschi, Hilti Corporation, Roots System, ITW Buildex, Chandler VAC, and Performance System III, Inc. These players dominate through advanced technology integration, strong service networks, and product efficiency improvements. They focus on energy-saving solutions, smart control systems, and durable designs to meet industrial demands. North America leads the market with a 34% share, driven by large-scale wastewater and manufacturing applications, while Europe, holding 29%, follows due to strict energy-efficiency regulations. Asia-Pacific, with 28% share, remains the fastest-growing region supported by rapid industrialization and infrastructure expansion.

Access crucial information at unmatched prices!

Request your sample report today & start making informed decisions powered by Credence Research Inc.!

Download Sample

Market Insights

- The global helical screw blowers market was valued at USD 1.19 billion in 2024 and is projected to reach USD 1.57 billion by 2032, expanding at a CAGR of 3.6% during the forecast period.

- Rising demand for energy-efficient air solutions and industrial modernization in wastewater and chemical sectors drives overall market growth, with the direct drive segment holding 58% share due to lower energy losses and higher efficiency.

- Increasing adoption of smart monitoring systems and IoT-enabled performance control represents a key market trend across advanced manufacturing facilities.

- Leading players such as Kaeser Kompressoren, Aerzen, Atlas Copco, and Gardner Denver compete through energy optimization technologies and global service networks.

- North America leads with 34% share, followed by Europe at 29% and Asia-Pacific at 28%, while Latin America (5%) and Middle East & Africa (4%) exhibit steady growth through industrial infrastructure and wastewater management projects.

Market Segmentation Analysis:

By Drive

The direct drive segment dominated the helical screw blowers market in 2024, holding 58% share. Its leadership is driven by higher energy efficiency, lower maintenance needs, and improved operational reliability compared to belt-driven systems. Direct drive blowers eliminate transmission losses, making them ideal for continuous industrial operations. Their compact design also supports easy installation in confined spaces. Industries such as wastewater treatment and cement are adopting these blowers to reduce energy consumption and operational costs. Manufacturers are developing variable-speed direct drive systems to further optimize performance and reduce lifecycle costs.

- For instance, Kaeser Kompressoren introduced its EBS and FBS series rotary screw blowers equipped with IE4 or IE5 Ultra-Premium Efficiency motors. These units, with a flow range up to 72 m³/min and pressure differentials up to 1,100 mbar, can achieve energy savings of up to 35% compared to conventional rotary lobe blowers.

By Application

The wastewater treatment segment held the largest share of 41% in the helical screw blowers market in 2024. The segment’s dominance stems from the growing need for energy-efficient aeration systems in municipal and industrial plants. Helical screw blowers offer superior efficiency, low noise, and continuous airflow, making them suitable for biological treatment and sludge processing. Increasing investments in wastewater infrastructure and stringent environmental regulations are driving adoption worldwide. Additionally, the food and beverage industry is emerging as a key user segment due to rising demand for clean, oil-free air systems in processing and packaging applications.

- For instance, Atlas Copco deployed its ZS screw blower range in multiple wastewater plants across Germany, providing airflow rates up to 2,600 m³/hour with sound levels below 73 dB(A). Each system achieves energy savings of around 30% compared to lobe blowers and operates continuously for over 50,000 hours without major servicing, supporting long-term wastewater aeration efficiency.

Key Growth Drivers

Rising Demand for Energy-Efficient Blower Systems

The growing emphasis on energy efficiency across industries is a major driver of the helical screw blowers market. These blowers consume significantly less power compared to traditional rotary or lobe blowers, reducing overall operating costs. Their variable frequency control and advanced rotor designs enhance energy savings and system performance. Industries such as wastewater treatment, food processing, and chemicals are rapidly adopting these systems to meet energy efficiency standards and sustainability goals. Government initiatives promoting energy conservation further strengthen market demand globally.

- For instance, ELGi Equipments launched its AB series oil-free screw air compressors equipped with 4/5 lobe rotors and integrated variable frequency drives (VFDs). These units are designed for sensitive applications, including wastewater and cement industries, providing energy savings by matching output with air demand.

Expansion of Wastewater Treatment Infrastructure

Increasing investments in wastewater treatment facilities are boosting the adoption of helical screw blowers worldwide. Their ability to deliver continuous, oil-free, and low-noise air makes them ideal for aeration and sludge treatment processes. Governments in developing regions, including India and China, are modernizing water management systems to comply with stricter discharge regulations. Additionally, rising industrial wastewater generation from manufacturing and food sectors accelerates product deployment. These factors collectively drive the growth of helical screw blowers in environmental and utility applications.

- For instance, Aerzen has installed Delta Hybrid helical screw blowers in numerous wastewater treatment plants across Europe and Asia, with some models offering volume flow rates up to 9,000 m³/hour. These systems deliver significant energy savings, with some modern variants achieving up to 37% more efficiency than older blowers.

Technological Advancements in Blower Design

Ongoing innovations in rotor profiles, sealing systems, and drive mechanisms are transforming the helical screw blowers market. Manufacturers are developing oil-free, low-maintenance models with smart control systems to enhance reliability and energy monitoring. Integration of IoT-enabled sensors allows predictive maintenance, reducing downtime and optimizing efficiency. These technological advancements make screw blowers more adaptable across diverse applications such as cement, mining, and pharmaceuticals. The shift toward intelligent and high-performance solutions continues to expand their global adoption.

Key Trends and Opportunities

Integration of Smart Monitoring and Automation

The adoption of digital control and remote monitoring technologies is reshaping the operational landscape for helical screw blowers. Smart control panels equipped with IoT sensors enable real-time data tracking, predictive maintenance, and performance optimization. These systems help industries minimize energy waste and improve uptime. Automation-driven air management solutions are particularly gaining traction in large-scale wastewater and chemical plants. As industrial digitization progresses, demand for smart, connected blowers with enhanced operational intelligence is expected to grow significantly.

- For instance, Ingersoll Rand introduced its Helix Connect platform with its screw blowers, which uses advanced sensor technology and cloud-based monitoring to provide real-time data. The system’s predictive maintenance capabilities offer actionable insights that help maximize uptime and support energy efficiency in continuous industrial applications.

Sustainability and Environmental Compliance Focus

Rising environmental awareness and strict emission regulations are driving industries toward cleaner air solutions. Helical screw blowers, known for their oil-free compression and low noise, align with global sustainability objectives. Manufacturers are investing in eco-friendly designs that reduce carbon emissions and energy footprints. This shift presents strong opportunities for market expansion in Europe and Asia-Pacific, where regulatory frameworks promote green manufacturing. The focus on sustainability continues to shape product innovation and procurement strategies across multiple industries.

- For instance, Aerzen has developed oil-free helical screw blowers equipped with optional IE5 ultra-efficient motors, which in some models can achieve 96% drive efficiency during partial load operations.

Key Challenges

High Initial Investment and Installation Cost

Despite long-term operational benefits, the high upfront cost of helical screw blowers remains a major challenge. Their precision components, advanced control systems, and specialized materials make them more expensive than conventional blowers. Small and medium enterprises often prefer cheaper alternatives, slowing market penetration. Moreover, the cost of installation and skilled maintenance personnel adds to operational expenses. Manufacturers are addressing this by introducing modular and energy-saving designs to improve affordability and return on investment.

Lack of Awareness and Technical Expertise

Limited awareness about the efficiency and performance benefits of helical screw blowers restrains market growth, especially in developing economies. Many industries continue using traditional lobe blowers due to familiarity and lower perceived risk. Additionally, the absence of skilled technicians for system calibration and maintenance affects adoption rates. Training programs and demonstration projects by manufacturers are helping to bridge this gap. However, widespread education and technical support remain essential to enhance market acceptance and long-term utilization.

Regional Analysis

North America

North America held the largest share of 34% in the helical screw blowers market in 2024. The region’s leadership is supported by widespread adoption across wastewater treatment, food processing, and petrochemical industries. The U.S. Environmental Protection Agency’s energy efficiency programs encourage industries to upgrade to advanced, low-power blowers. Strong industrial automation and the presence of key manufacturers enhance market penetration. Demand for reliable and oil-free air systems in municipal and industrial plants further drives adoption. Continuous infrastructure modernization and environmental compliance efforts sustain North America’s dominant position in the global market.

Europe

Europe accounted for 29% share of the global helical screw blowers market in 2024. The region’s growth is driven by stringent energy efficiency regulations and a strong focus on carbon reduction across industries. Countries such as Germany, France, and the U.K. are investing heavily in upgrading wastewater treatment facilities and industrial automation. European manufacturers are also leading in eco-friendly product development and low-noise blower technologies. Supportive EU directives promoting clean air and sustainable operations further enhance market adoption. The region’s emphasis on industrial efficiency and environmental protection continues to drive steady demand growth.

Asia-Pacific

Asia-Pacific held 28% share of the global helical screw blowers market in 2024 and emerged as the fastest-growing region. Rapid industrialization, urban expansion, and infrastructure development across China, India, and Southeast Asia are fueling market growth. Government initiatives for wastewater management and industrial pollution control are boosting product adoption. Regional manufacturers are offering cost-effective, high-efficiency systems to cater to local demand. Expanding manufacturing sectors such as food processing, chemicals, and pharmaceuticals further support regional consumption. Growing awareness of energy savings and operational efficiency is positioning Asia-Pacific as a key growth hub globally.

Latin America

Latin America captured 5% share of the helical screw blowers market in 2024. The region’s growth is supported by increasing investment in wastewater treatment and food processing industries, particularly in Brazil and Mexico. Governments are implementing stricter regulations for industrial emissions and water treatment efficiency. Rising adoption of energy-efficient technologies by regional manufacturing facilities further drives demand. Although infrastructure limitations persist, ongoing modernization projects are improving market accessibility. The focus on sustainable industrial development and environmental compliance continues to support gradual expansion across Latin America’s industrial landscape.

Middle East & Africa

The Middle East & Africa accounted for 4% share of the global helical screw blowers market in 2024. Growing infrastructure investments, particularly in water and wastewater treatment, drive market growth in the UAE, Saudi Arabia, and South Africa. The expansion of petrochemical and cement industries also contributes to rising demand for efficient blower systems. Governments are emphasizing energy optimization and environmental standards through national sustainability programs. Increasing public-private partnerships and industrial diversification plans, such as Saudi Vision 2030, further strengthen regional adoption of advanced air management technologies.

Market Segmentations:

By Drive

By Application

- Chemicals

- Wastewater treatment

- Food & beverages

- Others

By Geography

- North America

- Europe

- Germany

- France

- U.K.

- Italy

- Spain

- Rest of Europe

- Asia Pacific

- China

- Japan

- India

- South Korea

- South-east Asia

- Rest of Asia Pacific

- Latin America

- Brazil

- Argentina

- Rest of Latin America

- Middle East & Africa

- GCC Countries

- South Africa

- Rest of the Middle East and Africa

Competitive Landscape

The competitive landscape of the helical screw blowers market is shaped by leading companies such as Kaeser Kompressoren, Aerzen, Hilti Corporation, Roots System, Gardner Denver, Robuschi, Performance System III, Inc., Chandler VAC, ITW Buildex, and Atlas Copco. These players compete through continuous innovation, product diversification, and energy-efficient system development to meet the needs of industrial and municipal applications. Manufacturers focus on enhancing efficiency, durability, and noise reduction while integrating smart monitoring and variable frequency drive technologies. Strategic partnerships, mergers, and service network expansion strengthen their global market presence. European and North American companies lead in technological innovation, while Asia-Pacific firms emphasize cost-efficient manufacturing and regional market penetration. Ongoing R&D in oil-free and high-performance blower designs continues to define competition, with sustainability and lifecycle optimization emerging as key differentiating factors across major industry participants.

Shape Your Report to Specific Countries or Regions & Enjoy 30% Off!

Key Player Analysis

Recent Developments

- In May 2024, Kaeser Kompressoren introduced the FBS and GBS Rotary Screw Blowers. These models were showcased at IFAT 2024 and set new standards in efficiency and compact design.

- In May 2024, Aerzen unveiled the Delta Hybrid Screw Blower at IFAT 2024. It combines the characteristics of a positive displacement blower and a screw compressor, suitable for low-pressure applications up to 1,500 mbar.

- In March 2023, Gardner Denver launched the CycloBlower H.E. Series, a high-efficiency helical screw blower. This series offers significant design advantages, providing quality and dependability across multiple applications.

Report Coverage

The research report offers an in-depth analysis based on Drive, Application and Geography. It details leading market players, providing an overview of their business, product offerings, investments, revenue streams, and key applications. Additionally, the report includes insights into the competitive environment, SWOT analysis, current market trends, as well as the primary drivers and constraints. Furthermore, it discusses various factors that have driven market expansion in recent years. The report also explores market dynamics, regulatory scenarios, and technological advancements that are shaping the industry. It assesses the impact of external factors and global economic changes on market growth. Lastly, it provides strategic recommendations for new entrants and established companies to navigate the complexities of the market.

Future Outlook

- The helical screw blowers market will continue to grow steadily driven by industrial modernization.

- Energy-efficient and low-noise blower technologies will gain strong adoption across industries.

- Wastewater treatment expansion will remain a major contributor to long-term demand.

- Integration of IoT and smart monitoring systems will enhance operational efficiency.

- Manufacturers will focus on oil-free and eco-friendly blower solutions to meet emission standards.

- Asia-Pacific will record the fastest growth supported by rapid industrialization and infrastructure projects.

- North America and Europe will maintain leadership through strong environmental regulations.

- Product innovation and automation will help reduce operating costs and improve reliability.

- Strategic collaborations and mergers will strengthen global supply and service networks.

- Continuous R&D in rotor design and drive systems will shape future technological advancements.