Market Overview

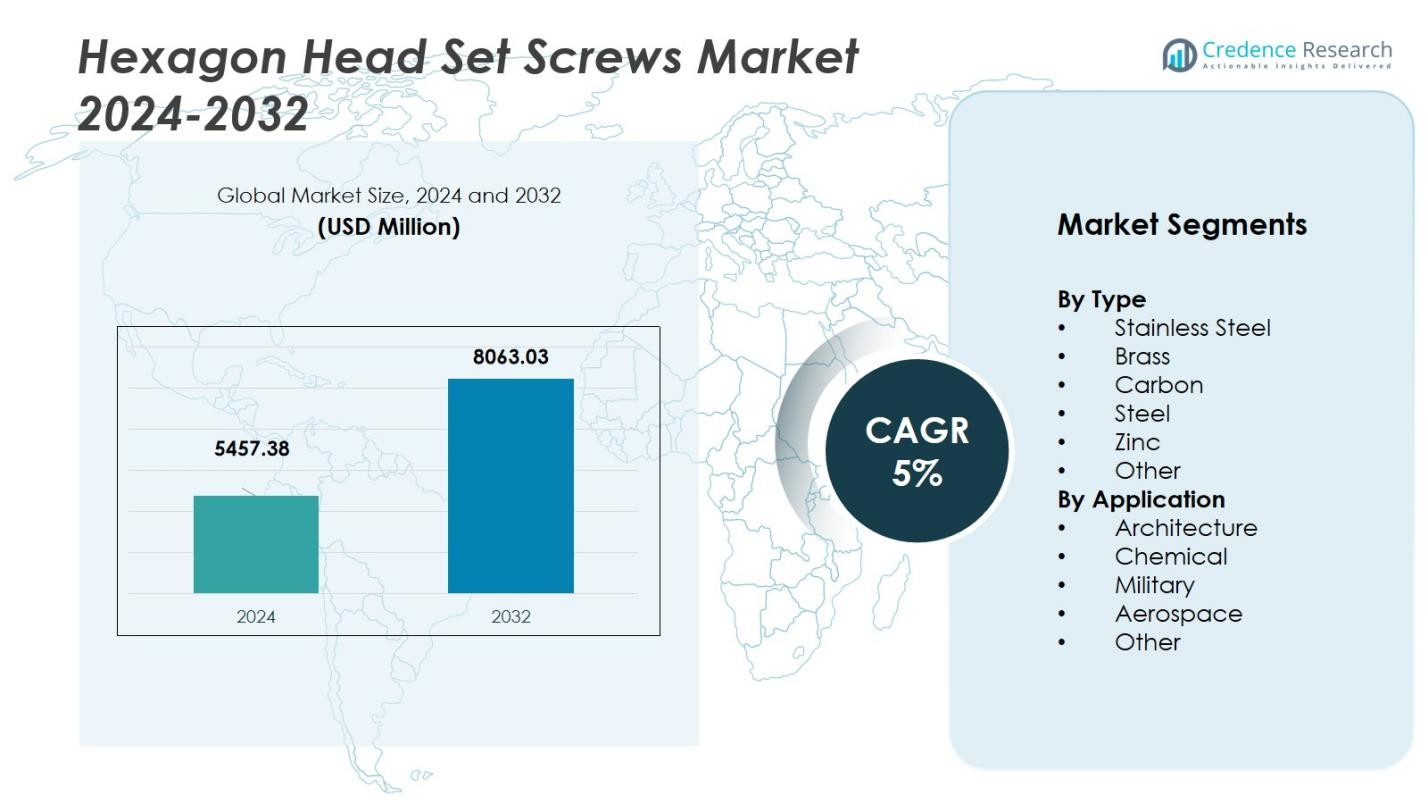

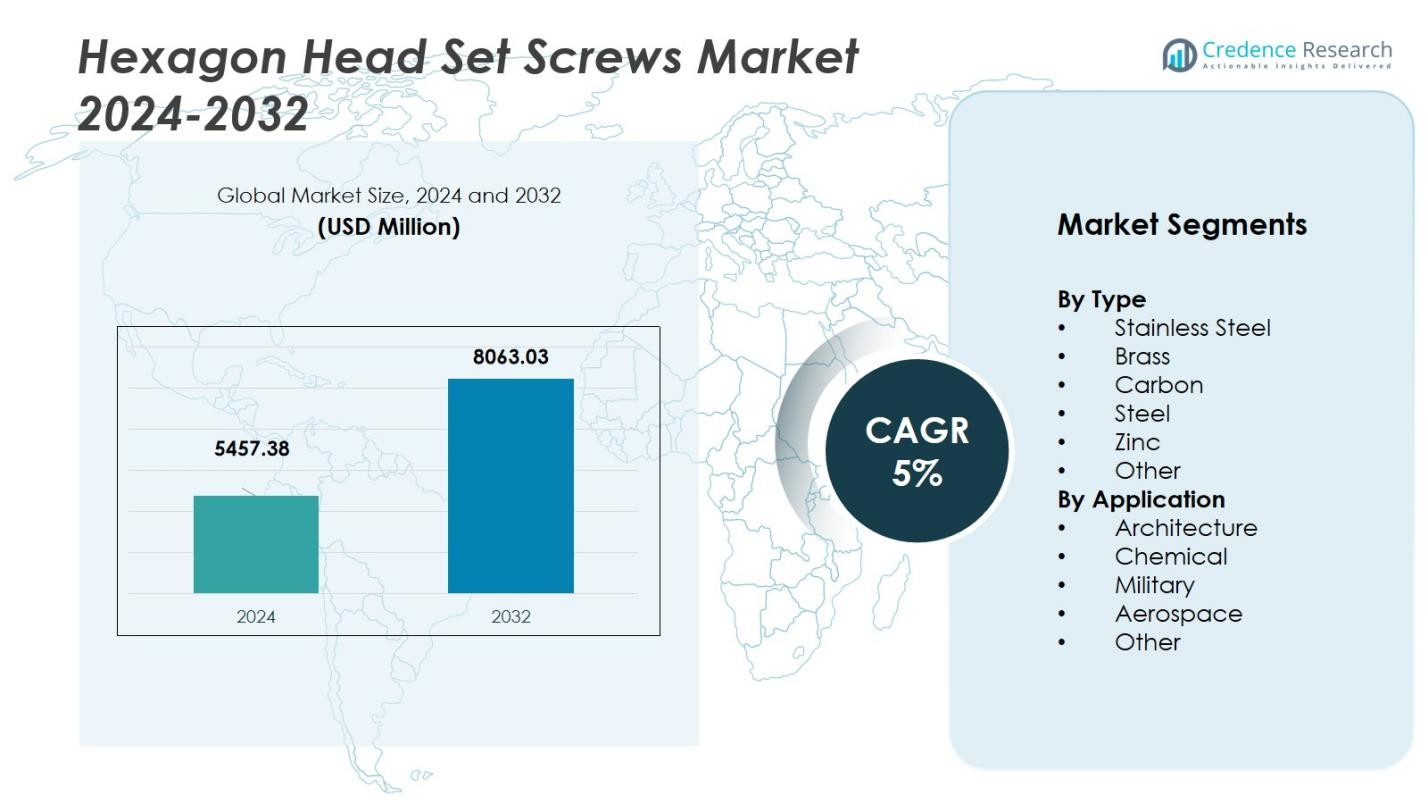

The Hexagon Head Set Screws Market size was valued at USD 5457.38 million in 2024 and is anticipated to reach USD 8063.03 million by 2032, at a CAGR of 5% during the forecast period.

| REPORT ATTRIBUTE |

DETAILS |

| Historical Period |

2020-2023 |

| Base Year |

2024 |

| Forecast Period |

2025-2032 |

| Hexagon Head Set Screws Market Size 2024 |

USD 5457.38 Million |

| Hexagon Head Set Screws Market, CAGR |

5% |

| Hexagon Head Set Screws Market Size 2032 |

USD 8063.03 Million |

The Hexagon Head Set Screws Market is dominated by key players such as Lamons Manufacturing and Service Company, Accurate Screw Machine Corp., Acme Screw Co., L. Huyett, B and G Manufacturing Company, Inc., M. Berg, Inc., DuPage Products Group, Long-Lok Fasteners Corp., Bondhus Corp., and HASM North America. These companies maintain strong market positions through continuous product innovation, expansion into new regions, and the development of specialized fastener solutions. In addition to their strategic growth initiatives, they also focus on enhancing their operational efficiencies and distribution networks. Regionally, the Asia Pacific region holds the largest share of the market, accounting for approximately 34%, driven by industrialization and infrastructure development in emerging economies like China and India. North America follows with a market share of around 28%, thanks to its mature industrial base, while Europe holds a 22% share, fueled by strong automotive and aerospace sectors.

Access crucial information at unmatched prices!

Request your sample report today & start making informed decisions powered by Credence Research Inc.!

Download Sample

Market Insights

- The Hexagon Head Set Screws Market was valued at USD 5457.38 million in 2024 and is expected to reach USD 8063.03 million by 2032, growing at a CAGR of 5% during the forecast period.

- The market is driven by the rising demand for high-performance materials in industries such as aerospace, construction, and chemicals.

- Key trends include the increasing adoption of customized fasteners and technological advancements in manufacturing, such as automation and precision machining.

- The market faces challenges such as fluctuating raw material prices and stringent regulatory standards for fastener quality and safety.

- Regionally, Asia Pacific leads with a 34% market share, followed by North America at 28% and Europe at 22%, with demand growing across the architecture, aerospace, and military sectors.

Market Segmentation Analysis:

By Type

In the Hexagon Head Set Screws Market, the Stainless Steel segment holds the dominant share, accounting for 35% of the market. Stainless steel’s resistance to corrosion, strength, and durability make it ideal for various industrial applications. The growing demand for high-performance materials in harsh environments, particularly in the aerospace and chemical industries, drives the expansion of this segment. Following stainless steel, the Carbon segment also holds a significant share due to its affordability and strength in mechanical applications, contributing to the overall market’s growth.

- For instance, in the Carbon segment, products like DIN931 hex bolts made of high-grade carbon steel are extensively used in mechanical applications due to their cost-efficiency and strength, such as those supplied by Prince Fastener, showing strong demand in construction and general machinery assembly.

By Application

The Architecture segment leads the Hexagon Head Set Screws Market, holding a market share of about 40%. The demand for reliable, long-lasting fasteners for construction and building infrastructure is a key driver for this segment. Hexagon head set screws provide excellent holding power and are used extensively in the fastening of structural components, enhancing their importance in the construction industry. Other growing applications, such as in Military and Aerospace, are also contributing to the increasing demand, with the Aerospace sector expected to witness the highest growth rate during the forecast period.

- For instance, in the architecture sector, Raj Fasteners in India supplies stainless steel hexagonal screws (SS 316) widely used for securing structural components in construction projects due to their excellent corrosion resistance and mechanical strength.

Key Growth Drivers

Rising Demand for High-Performance Materials

The increasing demand for high-performance materials across industries such as aerospace, architecture, and chemical manufacturing drives the growth of the Hexagon Head Set Screws Market. Stainless steel and carbon, commonly used in hexagon head set screws, offer exceptional strength, corrosion resistance, and durability, making them highly sought after for critical applications. As industries prioritize longevity and performance, particularly in harsh environmental conditions, the demand for robust fastening solutions like hexagon head set screws continues to rise, fueling market expansion.

- For instance, hexagon head screws made of Bumax super-duplex stainless steel and titanium are used in aerospace applications to endure high vibration and extreme conditions with excellent corrosion resistance.

Expansion of Infrastructure Development

Infrastructure development, especially in the construction and architectural sectors, significantly contributes to the Hexagon Head Set Screws Market’s growth. The use of these fasteners in residential, commercial, and industrial buildings is accelerating as construction projects demand reliable and durable fastening solutions. With urbanization and increasing investments in infrastructure globally, the demand for high-quality hexagon head set screws to support structural integrity grows, further driving the market. This trend is especially prevalent in emerging markets where urban infrastructure development is on the rise.

- For instance, ETTINGER GmbH, a precision fastener supplier based near Munich, provides hexagon head screws widely used in vehicle construction and agricultural engineering, emphasizing their role in creating stable metal connections essential for infrastructure.

Advancements in Manufacturing Technologies

Ongoing advancements in manufacturing technologies are positively influencing the Hexagon Head Set Screws Market. With the integration of automation, precision machining, and advanced materials, manufacturers are able to produce high-quality screws at reduced costs and increased efficiency. This has made it easier to meet the diverse needs of industries such as aerospace, automotive, and chemical, where precision and reliability are critical. The continuous innovation in manufacturing processes ensures the availability of more advanced and cost-effective solutions, driving the adoption of hexagon head set screws.

Key Trends & Opportunities

Growing Adoption in Aerospace and Military Applications

The aerospace and military industries represent a significant growth opportunity for the Hexagon Head Set Screws Market. Both sectors demand high-performance fasteners that can withstand extreme conditions, such as high temperatures and pressure, where stainless steel and other specialized materials excel. As global military and aerospace spending increases, there is a growing demand for fastening solutions that ensure structural integrity and safety. This presents a long-term opportunity for manufacturers to develop tailored solutions to meet the evolving needs of these industries.

- For instance, Bossard Aerospace offers a wide range of aerospace-certified hexagon screws and fasteners compliant with AS, NAS, and MS standards, tailored for high-strength, precision applications.

Emergence of Customization in Fasteners

Customization is a key trend gaining traction in the Hexagon Head Set Screws Market. As industries seek more tailored and specific solutions for their applications, demand for customized fasteners that meet unique material and design requirements is increasing. This trend is particularly evident in sectors such as aerospace, military, and chemical processing, where fasteners need to meet exact specifications. Manufacturers are now offering more flexibility in terms of size, material, and coating options, enabling customers to access solutions that are specifically designed for their needs.

- For instance, BUMAX Fasteners offers certified stainless steel fasteners with PED approval and complete traceability, catering to the stringent requirements of chemical processing plants.

Key Challenges

Fluctuating Raw Material Prices

One of the major challenges faced by the Hexagon Head Set Screws Market is the fluctuation in raw material prices. The price of materials such as stainless steel, carbon, and zinc is subject to global supply chain disruptions, geopolitical instability, and changes in demand across industries. These fluctuations can impact production costs, making it challenging for manufacturers to maintain stable pricing and profitability. As raw material prices continue to fluctuate, companies must find ways to mitigate these risks through better supply chain management or alternative material sourcing.

Stringent Regulatory Standards

The Hexagon Head Set Screws Market also faces challenges related to stringent regulatory standards. Industries such as aerospace, military, and chemicals are subject to strict regulations regarding the quality and safety of fastening components. Manufacturers must adhere to international standards, such as ISO and ASTM certifications, which can involve costly testing, quality control, and compliance processes. The complexity of meeting these regulatory requirements can pose challenges, especially for smaller manufacturers, and may hinder the speed at which products can be brought to market.

Regional Analysis

North America

North America commands a market share of around 28% in the Hexagon Head Set Screws Market thanks to its mature industrial base and advanced manufacturing sectors. Growth is driven by heavy investment in aerospace, defence, and automated machinery in the region. The demand for high‑performance fastening solutions remains strong as manufacturers upgrade equipment and retrofit existing systems. Furthermore, construction and infrastructure maintenance activities sustain steady consumption of hexagon head set screws across commercial and industrial projects.

Europe

Europe holds approximately 22% share of the hexagon head set screws market. The region benefits from strong automotive and aerospace industries that demand high‑quality fasteners with exacting tolerance and corrosion resistance. Technological innovation and stringent regulatory standards in manufacturing support adoption of premium fastening solutions. Infrastructure renewal and green building initiatives also contribute to growth, with fastening components playing an integral part in durable construction and industrial installations.

Asia Pacific

The Asia Pacific region leads with a market share of about 34% in the hexagon head set screws segment, propelled by rapid industrialisation and urbanisation. Major economies such as China and India are driving demand across construction, machinery manufacturing and automotive applications. The expansion of manufacturing hubs and infrastructure investment in emerging nations underpins robust growth potential. Competitive manufacturing, expanding supply chains and rising standardisation of fasteners further support market expansion in this region.

Latin America

Latin America accounts for around 8% of the global hexagon head set screws market. Growth in the region is driven by rising infrastructure development, mining operations and expanding industrial activity. However, the pace of growth is moderated by economic volatility and currency fluctuations. Manufacturing investments and regional trade agreements are opening opportunities, yet supply chain limitations and slower adoption of advanced fastener technologies still restrain market size compared with other regions.

Middle East & Africa

The Middle East & Africa region holds about 8% market share in the global hexagon head set screws market. The region’s growth is supported by oil & gas infrastructure projects, increasing construction activity and industrial diversification efforts. Government‑led investments in renewable energy installations also create demand for high‑performance fastening products. Nonetheless, market expansion is tempered by logistical challenges, lower levels of local manufacturing maturity and competition from imports of lower‑cost fastener solutions.

Market Segmentations:

By Type

- Stainless Steel

- Brass

- Carbon

- Steel

- Zinc

- Other

By Application

- Architecture

- Chemical

- Military

- Aerospace

- Other

By Region

- North America

- Europe

- Germany

- France

- U.K.

- Italy

- Spain

- Rest of Europe

- Asia Pacific

- China

- Japan

- India

- South Korea

- South-east Asia

- Rest of Asia Pacific

- Latin America

- Brazil

- Argentina

- Rest of Latin America

- Middle East & Africa

- GCC Countries

- South Africa

- Rest of the Middle East and Africa

Competitive Landscape

The competitive landscape of the Hexagon Head Set Screws Market is marked by the presence of major players such as Lamons Manufacturing and Service Company, Accurate Screw Machine Corp., Acme Screw Co., L. Huyett, B and G Manufacturing Company, Inc., M. Berg, Inc., DuPage Products Group, Long‑Lok Fasteners Corp., Bondhus Corp., and HASM North America. These firms actively invest in product innovations, broaden their distribution networks, and pursue strategic acquisitions to strengthen their market positioning. The competitive intensity remains high as firms vie for leadership in high‑performance sectors such as aerospace, construction, and chemical processing. Further, the market features a mix of global and regional players, which contributes to both innovation and price competition, keeping pressure on margins and driving differentiation through material quality and service support.

Key Player Analysis

- Accurate Screw Machine Corp.

- DuPage Products Group

- Bondhus Corp.

- Long-Lok Fasteners Corp.

- Huyett

- B and G Manufacturing Company, Inc.

- HASM North America

- Berg, Inc.

- Lamons Manufacturing and Service Company

- Acme Screw Co.

Recent Developments

- In September 2025, Riverspan Partners acquired United Titanium, a manufacturer of precision-engineered fasteners, including hex head bolts and other specialty components.

- In April 2025, L. Huyett launched a new line of over 60,000 industrial threaded fasteners, including set screws, bolts, hex head screws, and other related items.

- In January 2025, Bossard Group completed the acquisition of the German Ferdinand Gross Group, strengthening its fastening‑technology and distribution capabilities.

Shape Your Report to Specific Countries or Regions & Enjoy 30% Off!

Report Coverage

The research report offers an in-depth analysis based on Type, Application and Region. It details leading market players, providing an overview of their business, product offerings, investments, revenue streams, and key applications. Additionally, the report includes insights into the competitive environment, SWOT analysis, current market trends, as well as the primary drivers and constraints. Furthermore, it discusses various factors that have driven market expansion in recent years. The report also explores market dynamics, regulatory scenarios, and technological advancements that are shaping the industry. It assesses the impact of external factors and global economic changes on market growth. Lastly, it provides strategic recommendations for new entrants and established companies to navigate the complexities of the market.

Future Outlook

- The demand for hexagon head set screws will increase due to growth in global infrastructure and industrial sectors.

- Aerospace and defense applications will drive the need for high‑performance materials in hexagon head set screws.

- Emerging economies, particularly in Asia‑Pacific and Latin America, will present new growth opportunities.

- Advanced manufacturing processes, like automation and robotics, will boost demand for precision fasteners.

- Retrofit and maintenance projects will sustain ongoing demand for replacement hexagon head set screws.

- Sustainable materials and coatings will become more prominent due to increasing environmental awareness.

- Customisation and application‑specific fasteners will gain traction in industries like aerospace and chemicals.

- Digital supply chain integration and online distribution will make hexagon head set screws more accessible.

- Competitive pressure will lead manufacturers to offer value‑added services like on‑site inventory management.

- Volatile raw material prices and stringent regulations will drive market consolidation and strategic investments.