Market Overview

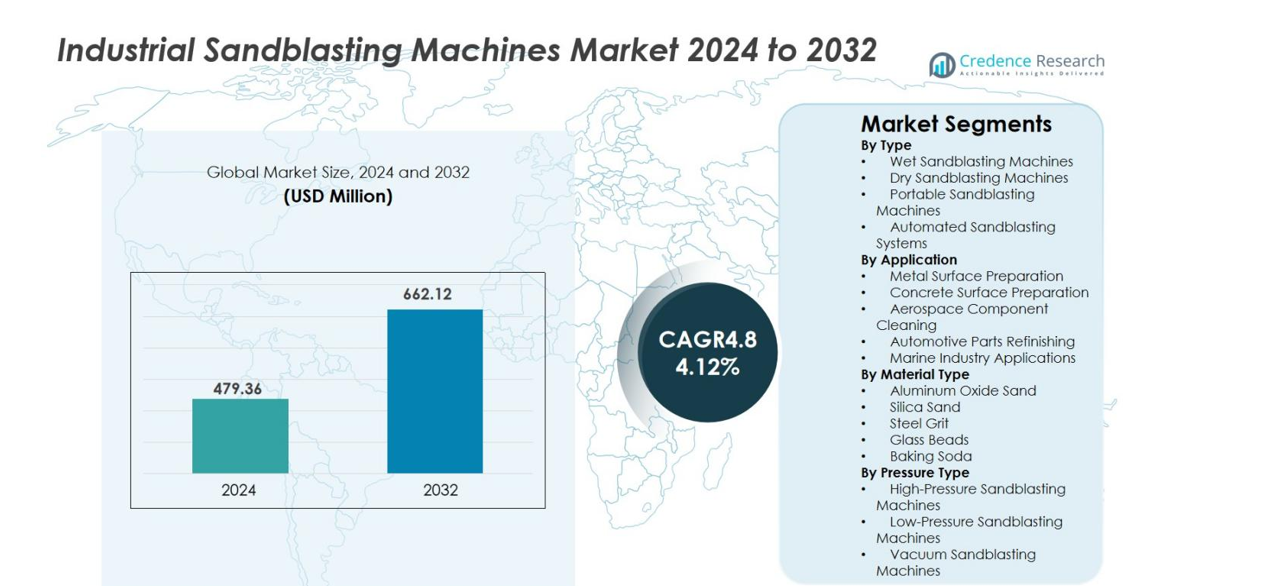

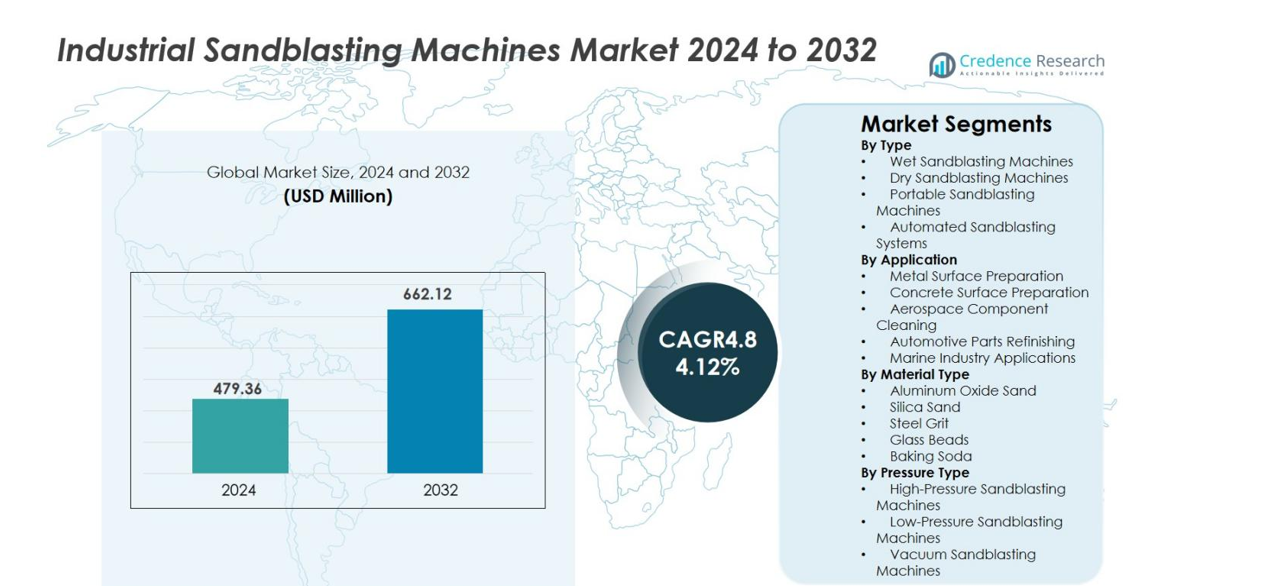

Industrial Sandblasting Machines Market size was valued USD 479.36 Million in 2024 and is anticipated to reach USD 662.12 Million by 2032, at a CAGR of 4.12% during the forecast period.

| REPORT ATTRIBUTE |

DETAILS |

| Historical Period |

2020-2023 |

| Base Year |

2024 |

| Forecast Period |

2025-2032 |

| Industrial Sandblasting Machines Market Size 2024 |

USD 479.36 Million |

| Industrial Sandblasting Machines Market, CAGR |

4.12% |

| Industrial Sandblasting Machines Market Size 2032 |

USD 662.12 Million |

Industrial Sandblasting Machines Market is driven by strong participation from leading manufacturers such as Clemco Industries, Airblast, Axxiom Manufacturing, ABShot Tecnics, Applied Concepts, ACE, Trinity Tool, Midwest Finishing Systems, Ningbo Qianfeng Machinery, and Abrasive Blasting Service & Supplies. These companies strengthen market presence through advanced dry, wet, automated, and portable blasting systems designed for industrial precision and high operational efficiency. North America led the global market with a 32.7% share in 2024, supported by strong demand from aerospace MRO, automotive refinishing, marine maintenance, and large-scale infrastructure rehabilitation. Europe and Asia-Pacific follow closely with expanding industrial and manufacturing activities.

Market Insights

- Industrial Sandblasting Machines Market reached USD 479.36 Million in 2024 and is projected to reach USD 662.12 Million by 2032, growing at a 4.12% CAGR through the forecast period, driven by rising industrial surface preparation needs.

- Strong demand for Dry Sandblasting Machines, holding a 41.6% share, supports market expansion as manufacturers prioritize high-efficiency cleaning and coating preparation.

- A major trend shaping the market is the shift toward automated, low-dust, and digitally monitored blasting systems, enhancing precision and safety across aerospace, automotive, and marine applications.

- Key players such as Clemco Industries, Airblast, Axxiom Manufacturing, and ABShot Tecnics expand their portfolios with advanced blasting solutions to meet evolving industrial requirements.

- North America led with a 32.7% share, followed by Europe at 27.3% and Asia-Pacific at 29.8%, while Metal Surface Preparation remained the leading application segment with a 37.4% share in 2024.

Access crucial information at unmatched prices!

Request your sample report today & start making informed decisions powered by Credence Research Inc.!

Download Sample

Market Segmentation Analysis

By Type

The Industrial Sandblasting Machines Market shows strong adoption across type categories, with Dry Sandblasting Machines dominating the segment with a 41.6% share in 2024. Their leadership is driven by high versatility, strong material removal capability, and widespread use in heavy-duty industrial cleaning. Automated Sandblasting Systems also gain momentum due to rising factory automation and precision requirements in aerospace and automotive plants. Portable Sandblasting Machines remain essential for field maintenance and marine applications. Wet Sandblasting Machines benefit from reduced dust emissions, supporting safety compliance, yet remain secondary due to lower stripping efficiency compared to dry systems.

- For instance, Graco’s EcoQuip 2 Vapor Abrasive Blast Equipment reportedly reduces airborne dust by up to 92% compared to equivalent dry blasting operations, making it a strong choice for projects where dust suppression and compliance are critical.

By Application

Within applications, Metal Surface Preparation led the segment with a 37.4% share in 2024, supported by extensive use in fabrication workshops, shipyards, refineries, and automotive part refurbishing. High demand for corrosion removal, coating preparation, and weld cleaning fuels adoption across industrial clusters. Automotive Parts Refinishing and Aerospace Component Cleaning continue to expand due to increasing restoration, lightweight component cleaning, and maintenance operations. Concrete Surface Preparation benefits from infrastructure upgrades, while Marine Industry Applications grow due to rising demand for hull cleaning and anti-fouling surface preparation.

- For instance, Wheelabrator surface preparation systems are used in major shipyards for weld cleaning and scale removal, with documented cases showing productivity gains in steel fabrication lines through automated blast rooms and rollers.

By Material Type

The material type segment is dominated by Aluminum Oxide Sand, holding a 33.9% share in 2024, attributed to its high hardness, recyclability, and suitability for precision blasting in aerospace, metal finishing, and machinery maintenance. Steel Grit also holds strong demand for aggressive cleaning and surface profiling, especially in shipyards and heavy fabrication. Glass Beads gain adoption for peening and cosmetic finishing in automotive and electronics. Silica Sand, though widely used, experiences reduced preference due to regulatory restrictions. Baking Soda continues to grow for delicate cleaning applications due to its non-abrasive, eco-friendly characteristics.

Key Growth Drivers

Rising Demand for Surface Preparation in Manufacturing and Infrastructure

The Industrial Sandblasting Machines Market grows significantly as manufacturers and infrastructure developers prioritize precise and efficient surface preparation. Increasing fabrication of metal structures, pipelines, automotive components, and construction elements boosts demand for abrasive blasting to remove rust, coatings, and impurities. Expanding industrial automation enhances productivity requirements, encouraging industries to adopt high-performance blasting systems. The surge in global infrastructure upgrades, refurbishment activities, and welding applications further accelerates adoption, making sandblasting systems indispensable for achieving consistent material profiling and long-term coating adhesion.

- For instance, Guyson Corporation’s robotic grit-blast surface-preparation systems are used for precision cleaning of aerospace and turbine components enabling consistent, automated blast treatment which supports high throughput in manufacturing or maintenance operations.

Expansion of Aerospace, Automotive, and Marine Maintenance

Growth is strongly driven by rising maintenance, repair, and overhaul (MRO) activities across aerospace, automotive, and marine sectors. Manufacturers rely heavily on advanced blasting systems to clean precision components, refurbish engine parts, strip coatings, and prepare surfaces for repainting. Lightweight materials in aerospace require controlled blasting solutions, while automotive remanufacturing and marine hull cleaning create continuous demand. Increasing adoption of sustainable coatings and anti-corrosion treatments amplifies the need for efficient blasting systems, supporting long-term market expansion across these high-value industries.

- For instance, Boeing-approved MRO facilities use highly controlled, specialized media-blasting systems, such as Plastic Media Blasting (PMB), to safely strip coatings from specific robust aluminum and composite components. This method is carefully governed by strict engineering specifications (e.g., Boeing PS12115) to ensure uniform surface preparation without damaging lightweight structures a critical requirement for specific repairs within modern fleets.

Adoption of Automated and Portable Sandblasting Solutions

Automation and mobility play crucial roles in driving market growth, as industries shift toward high-efficiency blasting processes with reduced labor dependency. Automated sandblasting systems enhance consistency, minimize human error, and support large-scale manufacturing, particularly in aerospace, oil & gas, and heavy engineering. Meanwhile, portable sandblasting machines gain traction in marine maintenance, construction projects, and on-site industrial repairs where mobility and flexibility are vital. This dual demand strengthens overall market penetration, supported by advancements in dust-control technology, operator safety mechanisms, and integrated monitoring systems.

Key Trends & Opportunities

Shift Toward Environmentally Compliant and Low-Dust Blasting Technologies

A major trend shaping the Industrial Sandblasting Machines Market is the shift toward eco-friendly, low-emission blasting systems. Regulatory pressure on silica sand usage and dust generation drives manufacturers to innovate with wet blasting, vacuum blasting, and enclosed automated systems. This transition opens significant opportunities for equipment producers offering advanced dust collectors, closed-loop abrasive systems, and environmentally safe media alternatives. As industries aim to meet stricter safety and environmental standards, demand for modern, compliant technologies grows rapidly across manufacturing, marine, and automotive applications.

- For instance, Clemco’s AEROLYTE DryStrip Systems are widely used in aerospace MRO centers to blast composite and aluminum parts using low-dust plastic media, supporting safe, residue-free coating removal without silica exposure.

Integration of Digital Monitoring, Automation, and Robotics

The integration of digital technologies represents a major opportunity for market players. Smart sandblasting machines equipped with sensors, automated dosing control, and remote monitoring improve precision, reduce abrasive consumption, and enhance operator safety. Robotics-based blasting solutions are increasingly adopted in aerospace and automotive sectors to handle complex geometries and repetitive processes. Predictive maintenance, real-time diagnostics, and data analytics further strengthen operational efficiency. As Industry 4.0 accelerates, sandblasting manufacturers gain new growth avenues by offering intelligent, interconnected blasting systems.

- For instance, Wheelabrator’s SmartLine automated blast systems use integrated digital diagnostics and control modules that track machine cycles, wear-part status, and maintenance intervals for continuous operation in manufacturing plants.

Key Challenges

Regulatory Restrictions and Environmental Compliance Pressures

The market faces challenges due to tightening regulations on silica sand usage, particulate emissions, and operator safety standards. Compliance with OSHA, EPA, and EU directives forces companies to invest in advanced dust-control mechanisms and safer abrasive alternatives, increasing operational costs. Many small and medium workshops struggle to upgrade outdated systems, leading to slower adoption. The need for specialized filtration, containment, and protective equipment adds complexity, limiting widespread deployment in cost-sensitive industries and regions with less stringent regulatory frameworks.

High Maintenance Costs and Skilled Operator Shortage

Industrial sandblasting machines require regular maintenance due to abrasive wear on nozzles, hoses, blast cabinets, and turbines, resulting in significant operational expenses. The shortage of skilled operators further complicates efficient machine usage, particularly for high-precision applications in aerospace and energy sectors. Downtime caused by equipment failure, abrasive mismanagement, or improper handling directly impacts productivity. Training requirements and safety protocols increase cost burdens for industries relying on manual or semi-automated blasting processes, posing a persistent challenge to market expansion.

Regional Analysis

North America

North America leads the Industrial Sandblasting Machines Market with a 32.7% share in 2024, driven by strong demand from automotive refurbishing, aerospace MRO, marine maintenance, and large-scale industrial fabrication. The U.S. dominates regional consumption due to high investments in infrastructure rehabilitation, oil & gas asset maintenance, and automated surface treatment technologies. Rising adoption of dust-controlled and environmentally compliant systems supports market advancement. Canada contributes steadily through growth in metal fabrication and shipbuilding industries. Continuous modernization of manufacturing plants further strengthens the region’s reliance on advanced sandblasting equipment.

Europe

Europe accounted for 27.3% of the Industrial Sandblasting Machines Market in 2024, supported by robust demand from aerospace component cleaning, automotive parts refinishing, and marine surface treatment. Germany, Italy, and France lead the region with strong engineering and manufacturing clusters adopting automated blasting systems to meet strict environmental and worker-safety regulations. The region’s push for sustainable abrasive materials and closed-loop blasting technologies accelerates innovation. Shipyards in the Netherlands and Norway create additional demand, while refurbishment of aging industrial infrastructure continues to reinforce steady market growth across Europe.

Asia-Pacific

Asia-Pacific emerged as the fastest-growing region with a 29.8% share in 2024, driven by rapid industrialization, expanding manufacturing hubs, and rising construction activities across China, India, Japan, and South Korea. The region benefits from strong demand for metal and concrete surface preparation in automotive, heavy machinery, and marine industries. China leads in large-volume production and adoption of automated blasting systems, while India sees rising demand in ship repair and infrastructure upgrades. Government investments in industrial modernization and export-oriented manufacturing significantly bolster regional market expansion.

Latin America

Latin America held a 5.9% share of the Industrial Sandblasting Machines Market in 2024, driven by increasing use in oil & gas maintenance, marine vessel refurbishment, and metal fabrication industries. Brazil and Mexico remain the largest contributors due to strong automotive and industrial manufacturing bases. Infrastructure upgrades and offshore platform maintenance support steady demand for surface preparation solutions. The region gradually adopts portable and automated sandblasting technologies to enhance operational efficiency. However, economic fluctuations and limited adoption of advanced blasting systems pose challenges, although continued industrialization supports moderate growth.

Middle East & Africa

The Middle East & Africa region accounted for 4.3% of the Industrial Sandblasting Machines Market in 2024, supported by extensive demand in oil & gas infrastructure maintenance, heavy machinery refurbishment, and marine operations. Gulf countries, particularly Saudi Arabia and the UAE, invest in advanced blasting equipment to support pipeline maintenance, refinery upgrades, and shipyard operations. Africa contributes through mining, construction, and industrial repair activities. Increasing regulatory focus on dust control and operator safety encourages adoption of modern blasting technologies, although budget constraints in developing markets limit penetration of high-end systems.

Market Segmentations

By Type

- Wet Sandblasting Machines

- Dry Sandblasting Machines

- Portable Sandblasting Machines

- Automated Sandblasting Systems

By Application

- Metal Surface Preparation

- Concrete Surface Preparation

- Aerospace Component Cleaning

- Automotive Parts Refinishing

- Marine Industry Applications

By Material Type

- Aluminum Oxide Sand

- Silica Sand

- Steel Grit

- Glass Beads

- Baking Soda

By Pressure Type

- High-Pressure Sandblasting Machines

- Low-Pressure Sandblasting Machines

- Vacuum Sandblasting Machines

By Geography

- North America

- Europe

- Germany

- France

- U.K.

- Italy

- Spain

- Rest of Europe

- Asia Pacific

- China

- Japan

- India

- South Korea

- South-east Asia

- Rest of Asia Pacific

- Latin America

- Brazil

- Argentina

- Rest of Latin America

- Middle East & Africa

- GCC Countries

- South Africa

- Rest of the Middle East and Africa

Competitive Landscape

Competitive landscape in the Industrial Sandblasting Machines Market features key players such as Clemco Industries, Airblast, Axxiom Manufacturing, ABShot Tecnics, Applied Concepts, ACE, Trinity Tool, Midwest Finishing Systems, Ningbo Qianfeng Machinery, and Abrasive Blasting Service & Supplies. The market reflects a diverse mix of global manufacturers, regional specialists, and technology-driven innovators offering dry, wet, automated, and portable blasting systems. Leading companies focus on expanding product portfolios, integrating advanced dust-control technologies, and enhancing automation capabilities to meet rising safety and efficiency standards. Strategic investments in R&D support the development of environmentally compliant systems and precision blasting solutions for aerospace, automotive, marine, and heavy fabrication sectors. Partnerships with distributors, expansion into emerging markets, and customized industrial solutions strengthen competitive positioning. As demand grows for high-performance, digitally enabled blasting systems, players increasingly prioritize innovation, operational reliability, and service support to maintain market leadership.

Shape Your Report to Specific Countries or Regions & Enjoy 30% Off!

Key Player Analysis

- ACE

- Trinity Tool

- ABShot Tecnics

- Applied Concepts

- Airblast

- Axxiom Manufacturing

- Clemco Industries

- Midwest Finishing Systems

- Ningbo Qianfeng Machinery

- Abrasive Blasting Service & Supplies

Recent Developments

- In August 2025, BlastOne announced a strategic partnership with investment firms Kaltroco and Five V Capital to accelerate innovation and global growth.

- In June 2025, Medical Manufacturing Technologies (MMT) announced the acquisition of Comco a recognised leader in the micro-precision sandblasting sector

Report Coverage

The research report offers an in-depth analysis based on Type, Application, Material Type, Pressure Type and Geography. It details leading market players, providing an overview of their business, product offerings, investments, revenue streams, and key applications. Additionally, the report includes insights into the competitive environment, SWOT analysis, current market trends, as well as the primary drivers and constraints. Furthermore, it discusses various factors that have driven market expansion in recent years. The report also explores market dynamics, regulatory scenarios, and technological advancements that are shaping the industry. It assesses the impact of external factors and global economic changes on market growth. Lastly, it provides strategic recommendations for new entrants and established companies to navigate the complexities of the market.

Future Outlook

- The Industrial Sandblasting Machines Market will experience steady growth as industries prioritize efficient and consistent surface preparation.

- Adoption of automated sandblasting systems will increase as manufacturers seek higher precision and reduced labor dependency.

- Environmentally compliant, low-dust blasting technologies will gain strong traction due to tightening global safety regulations.

- Digital monitoring, robotics, and smart control features will become standard in advanced blasting equipment.

- Demand from aerospace, automotive, and marine MRO operations will continue to strengthen long-term market expansion.

- Portable sandblasting machines will see rising use in construction, marine repair, and field maintenance projects.

- Eco-friendly abrasive materials will replace silica-based media, encouraging sustainable industrial practices.

- Emerging economies will drive significant demand through expanding manufacturing and infrastructure development.

- Integration of predictive maintenance and energy-efficient components will enhance equipment lifespan and reliability.

- Manufacturers will increasingly focus on customized solutions to meet specific industry requirements and application complexities.