Market Overview

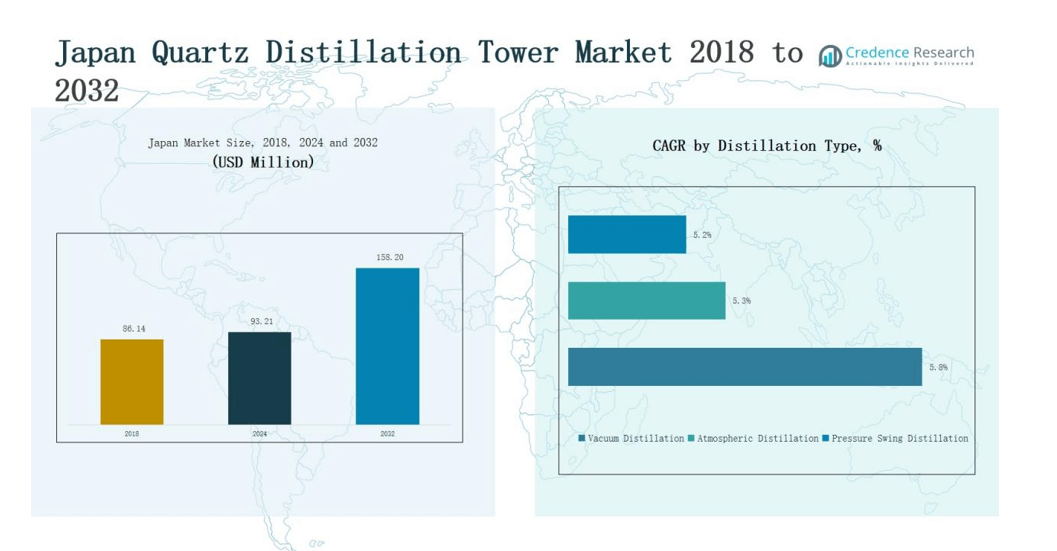

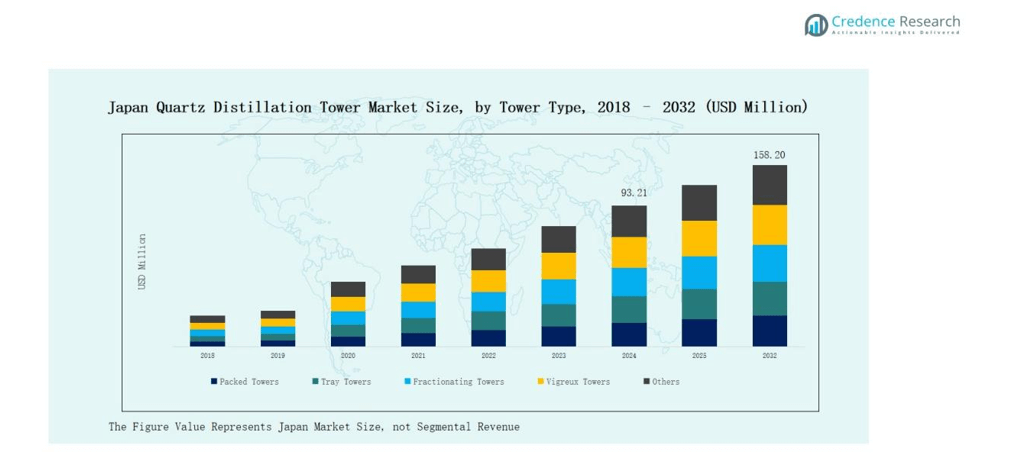

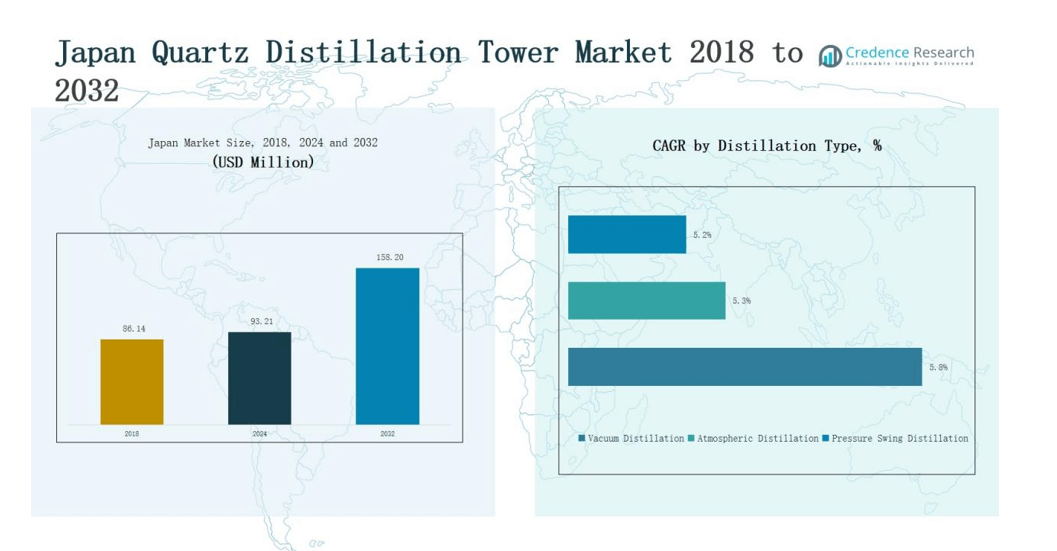

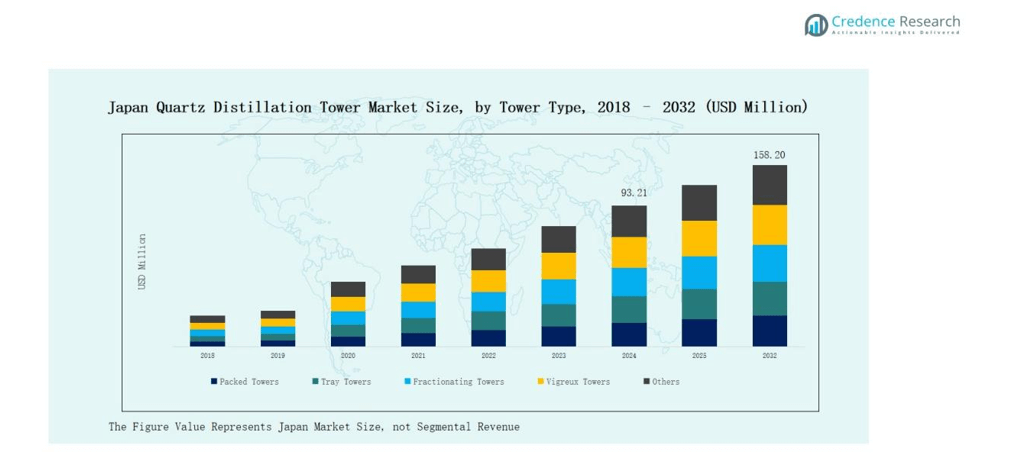

The Japan Quartz Distillation Tower Market was valued at USD 86.14 million in 2018, increased to USD 93.21 million in 2024, and is projected to reach USD 158.20 million by 2032, growing at a CAGR of 6.84% during the forecast period.

| REPORT ATTRIBUTE |

DETAILS |

| Historical Period |

2020-2023 |

| Base Year |

2024 |

| Forecast Period |

2025-2032 |

| Japan Quartz Distillation Tower Market Size 2024 |

USD 93.21 million |

| Japan Quartz Distillation Tower Market, CAGR |

6.84% |

| Japan Quartz Distillation Tower Market Size 2032 |

USD 158.20 million |

The Japan Quartz Distillation Tower Market features strong competition among key manufacturers such as Shin-Etsu Quartz Products Co., Ltd., Tosoh Quartz Corporation, Ohara Corporation, Nitto Boseki Co., Ltd., Nippon Electric Glass Co., Ltd., Kobayashi-Special Glass Co., Ltd., Eikoh Co., Ltd., and ATock Co., Ltd. These companies focus on precision engineering, advanced material purity, and automation to meet the stringent needs of semiconductor, pharmaceutical, and chemical industries. Continuous investments in R&D and process innovation strengthen their market positions. The Kanto region leads the market, holding 39% of the total share in 2024, supported by its robust semiconductor manufacturing base, advanced research infrastructure, and strong industrial concentration.

Market Insights

- The Japan Quartz Distillation Tower Market was valued at USD 86.14 million in 2018, rose to USD 93.21 million in 2024, and is projected to reach USD 158.20 million by 2032, growing at a CAGR of 6.84%.

- The Packed Towers segment led with 41.6% share in 2024, driven by high efficiency, low pressure drop, and strong adoption in semiconductor and pharmaceutical applications.

- The Vacuum Distillation segment dominated the distillation type category with a 52.8% share, supported by demand for heat-sensitive material separation and energy-efficient processes.

- The Stainless Steel segment accounted for 48.3% of the market in 2024, driven by superior corrosion resistance, strength, and suitability for high-temperature distillation operations.

- The Kanto region led with 39% of the total share in 2024, supported by its strong semiconductor manufacturing base, advanced R&D ecosystem, and diversified high-tech industrial structure.

Access crucial information at unmatched prices!

Request your sample report today & start making informed decisions powered by Credence Research Inc.!

Download Sample

Market Segment Insights

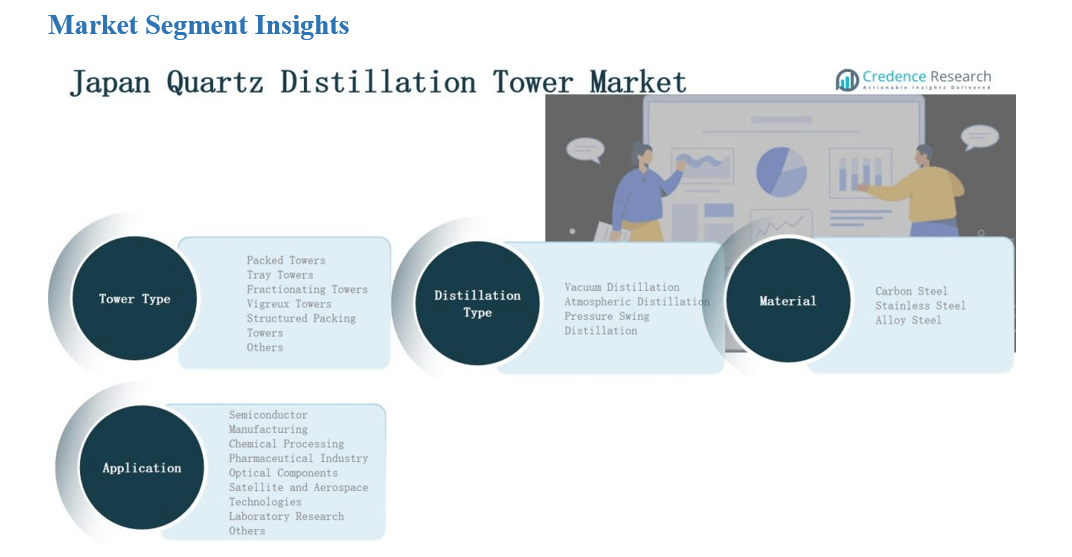

By Tower Type

The Packed Towers segment dominated the Japan Quartz Distillation Tower Market in 2024, accounting for 41.6% of total revenue. Their high efficiency, low pressure drop, and superior mass transfer performance make them ideal for semiconductor and pharmaceutical distillation processes. Growing adoption in high-purity chemical applications and advancements in structured packing design are strengthening their dominance. Rising demand for compact, corrosion-resistant, and energy-efficient designs further boosts adoption across precision industries in Japan.

By Distillation Type

The Vacuum Distillation segment led the market with a 52.8% share in 2024. It is preferred for separating heat-sensitive or high-boiling-point materials in semiconductor and chemical processing. Japan’s strong presence in microelectronics and high-purity chemical production drives its growth. The ability to operate under reduced pressure lowers thermal decomposition risks and energy consumption, making it a favored technology in advanced material refining and ultra-clean distillation processes.

- For instance, Merck KGaA enhanced its semiconductor materials refining line in Darmstadt using advanced vacuum distillation units to achieve ultra-high-purity organosilanes.

By Material

The Stainless Steel segment held the largest market share of 48.3% in 2024. Its excellent corrosion resistance, strength, and thermal stability make it a primary material for tower construction in chemical and semiconductor applications. Continuous improvements in fabrication quality and surface finishing enhance purity and efficiency in distillation operations. The segment benefits from the expanding use of stainless-steel alloys in high-temperature and vacuum distillation systems across Japan’s advanced manufacturing sectors.

- For instance, Pfeiffer Vacuum expanded its stainless steel vacuum components portfolio for chemical vapor deposition (CVD) tools to enhance purity and thermal resistance.

Key Growth Drivers

Expanding Semiconductor Manufacturing Base

Japan’s growing semiconductor sector significantly drives the Quartz Distillation Tower Market. High-purity quartz systems are essential for producing ultra-clean process chemicals used in wafer fabrication. Major players are expanding production capacity to meet advanced chip manufacturing standards. Rising investments in cleanroom technologies and precision material purification further support demand. The focus on energy-efficient and contamination-free distillation systems strengthens market growth across Japan’s electronics and microfabrication industries.

- For instance, Sibelco supplies IOTA high purity quartz sands used in fused quartz crucibles and tubing critical for semiconductor wafer processing, reflecting the demand for materials that withstand high temperatures and chemical purity requirements.

Rising Adoption in Chemical and Pharmaceutical Processing

Quartz distillation towers are increasingly used in Japan’s chemical and pharmaceutical industries for producing high-purity solvents and reagents. The material’s chemical inertness and temperature resistance ensure consistent performance under harsh process conditions. Pharmaceutical companies emphasize contamination control and product consistency, making quartz-based systems a preferred choice. Government incentives supporting pharmaceutical innovation and process modernization continue to enhance market demand across laboratory, pilot, and production-scale applications.

- For instance, Axiva’s quartz double distillation units produce pyrogen-free, ultra-pure water critical for bio-technological research, offering capacities up to 65 liters per hour with long-life spiral heaters.

Advancements in High-Purity Material Technologies

Continuous R&D in high-purity quartz production boosts the efficiency and lifespan of distillation towers. Manufacturers in Japan focus on improving quartz clarity, surface smoothness, and structural uniformity to minimize impurities during distillation. Integration of digital process controls and precision manufacturing enhances tower performance. These innovations align with Japan’s strong industrial focus on sustainability, precision engineering, and clean manufacturing, driving steady adoption across semiconductor, chemical, and optical applications.

Key Trends & Opportunities

Integration of Automation and Smart Monitoring

Automation and IoT-based monitoring are becoming central to Japan’s distillation tower systems. Smart sensors and digital interfaces enable real-time performance tracking, pressure control, and fault detection. This trend supports predictive maintenance and reduces operational downtime. Companies are adopting automated control modules to enhance process accuracy and energy efficiency, particularly in semiconductor and chemical plants, where precision and reliability are critical for maintaining consistent product quality.

- For instance, Fassa Bortolo S.p.A. in Italy began pilot production of compact mixed-material towers designed for flexible scaling and export to microelectronics processing plants.

Growing Focus on Sustainable and Energy-Efficient Designs

Sustainability is a major opportunity for Japan’s quartz distillation tower manufacturers. The shift toward low-energy, corrosion-resistant designs aligns with Japan’s carbon-neutral goals. Companies are developing lightweight structures and advanced thermal insulation to reduce energy usage. Demand is also increasing for recyclable materials and modular tower designs that support easy maintenance and lower environmental impact, driving innovation in eco-efficient distillation technologies across high-tech and industrial sectors.

- For instance, Bacardi’s Bombay Sapphire distillery uses heat exchange systems to reuse heat energy, significantly boosting operational efficiency and sustainability.

Key Challenges

High Production and Installation Costs

Quartz distillation towers involve complex manufacturing and precision engineering, resulting in high capital investment. The cost of high-purity quartz materials and specialized fabrication processes limits adoption among small and medium-scale manufacturers. Installation and maintenance expenses also add to total ownership costs. These financial barriers restrict market penetration, particularly in non-semiconductor industries, slowing wider commercialization despite growing industrial interest in advanced distillation technologies.

Supply Chain Dependence on Raw Quartz Imports

Japan’s limited domestic supply of high-grade quartz affects market stability. Dependence on imports from regions like China and the U.S. exposes manufacturers to raw material price fluctuations and trade disruptions. Variability in quartz quality also impacts production consistency. This supply chain vulnerability increases production lead times and costs, pushing companies to explore alternative sourcing strategies and invest in domestic quartz refinement capabilities to ensure long-term material security.

Technical Complexity in System Customization

Quartz distillation towers require precise customization to meet varied industrial specifications. Designing towers for different pressure, temperature, and purity requirements involves complex engineering and lengthy development cycles. Any error in fabrication can compromise performance or durability. Limited availability of skilled engineers and technicians further challenges the optimization process. These technical constraints delay product deployment and increase operational risk, especially for high-precision applications like semiconductor and pharmaceutical manufacturing.

Regional Analysis

Kanto

The Japan Quartz Distillation Tower Market in the Kanto region held the largest share of 39% in 2024. It benefits from a strong semiconductor manufacturing ecosystem centered around Tokyo and Kanagawa. Major technology firms and research institutes drive demand for high-purity distillation systems. The presence of advanced infrastructure and high investment in R&D supports process innovation and system optimization. Kanto’s industrial diversity, spanning electronics, pharmaceuticals, and optical materials, enhances adoption across multiple applications. Continuous expansion of high-tech facilities strengthens its leadership in production and innovation.

Kansai

The Kansai region accounted for 26% of the total market share in 2024. Osaka, Kyoto, and Hyogo serve as key industrial hubs with a growing focus on chemical and precision equipment manufacturing. The region’s strong base of optical and material processing industries supports adoption of quartz-based distillation systems. Demand from pharmaceutical and fine chemical sectors continues to expand with advancements in purification and separation technologies. Kansai’s established logistics and engineering networks improve distribution efficiency and after-sales service, supporting stable growth across key end-user segments.

Chubu

The Chubu region represented 18% of the total share in 2024, driven by strong industrial infrastructure in Aichi, Shizuoka, and Nagano. It supports the production of electronic components, glass materials, and advanced ceramics that rely on high-purity distillation. Regional manufacturers emphasize automation and process precision, improving yield and operational stability. The presence of technology-oriented universities and R&D centers fosters collaboration for advanced material applications. Continuous investments in cleanroom expansion and process standardization enhance the region’s competitiveness.

Kyushu

The Kyushu region captured 10% of the market in 2024, supported by growing semiconductor fabrication and specialty chemical production. It benefits from government-backed technology parks and regional industrial policies promoting advanced materials manufacturing. Increasing foreign investment in chip foundries strengthens the demand for high-efficiency quartz distillation systems. The region’s industrial clusters in Fukuoka and Kumamoto contribute to rising production capacity. Continuous infrastructure development and workforce specialization ensure a stable long-term growth trajectory for the region.

Other Regions (Hokkaido, Tohoku, Chugoku, Shikoku)

These regions collectively accounted for 7% of the market in 2024. Growth is supported by expanding research facilities and the gradual development of specialty chemical and academic laboratories. Local universities are integrating high-purity distillation units for advanced material studies. These regions also act as secondary supply hubs for supporting national manufacturing networks. Government programs promoting regional innovation and material science research are expected to strengthen their role in future industry expansion.

Market Segmentations:

By Tower Type

- Packed Towers

- Tray Towers

- Fractionating Towers

- Vigreux Towers

- Structured Packing Towers

- Others

By Distillation Type

- Vacuum Distillation

- Atmospheric Distillation

- Pressure Swing Distillation

By Material

- Carbon Steel

- Stainless Steel

- Alloy Steel

By Application

- Semiconductor Manufacturing

- Chemical Processing

- Pharmaceutical Industry

- Optical Components

- Satellite and Aerospace Technologies

- Laboratory Research

- Others

By Region

- Kanto

- Kansai

- Chubu

- Kyushu

- Others

Competitive Landscape

The Japan Quartz Distillation Tower Market is characterized by the presence of leading domestic and international manufacturers focusing on precision engineering, material purity, and automation. Key players such as Shin-Etsu Quartz Products Co., Ltd., Tosoh Quartz Corporation, Ohara Corporation, Nitto Boseki Co., Ltd., and Nippon Electric Glass Co., Ltd. dominate through advanced fabrication capabilities and a strong commitment to R&D. These companies emphasize product customization for semiconductor, chemical, and pharmaceutical applications, ensuring superior corrosion resistance and high thermal stability. Strategic partnerships, automation integration, and process innovation strengthen their competitive positioning. Smaller firms like Kobayashi-Special Glass Co., Ltd., Eikoh Co., Ltd., and ATock Co., Ltd. contribute to niche applications through tailored solutions and localized distribution. The market’s competitive intensity remains high, driven by continuous technological upgrades, sustainability initiatives, and the push toward ultra-pure, energy-efficient distillation systems suited for Japan’s evolving high-tech industries.

Shape Your Report to Specific Countries or Regions & Enjoy 30% Off!

Key Players

- Shin-Etsu Quartz Products Co., Ltd.

- Tosoh Quartz Corporation

- Himeji Rika

- Ohara Corporation

- Nitto Boseki Co., Ltd.

- Nippon Electric Glass Co., Ltd.

- Kobayashi-Special Glass Co., Ltd.

- Eikoh Co., Ltd.

- ATock Co., Ltd.

Recent Developments

- In April 2025, Tosoh Quartz, Inc. received Intel’s EPIC Supplier Award for its contributions to high-purity quartz solutions used in advanced semiconductor manufacturing.

- In June 2025, Rigaku Corporation expanded its semiconductor equipment production capacity in Japan, supporting growing demand for precision quartz components in distillation and processing systems.

- In 2025, Tosoh Quartz also advanced its CPSQ® clean process technology to enhance synthetic quartz quality and production efficiency for high-precision applications.

Report Coverage

The research report offers an in-depth analysis based on Tower Type, Distillation Type, Material, Application and Region. It details leading market players, providing an overview of their business, product offerings, investments, revenue streams, and key applications. Additionally, the report includes insights into the competitive environment, SWOT analysis, current market trends, as well as the primary drivers and constraints. Furthermore, it discusses various factors that have driven market expansion in recent years. The report also explores market dynamics, regulatory scenarios, and technological advancements that are shaping the industry. It assesses the impact of external factors and global economic changes on market growth. Lastly, it provides strategic recommendations for new entrants and established companies to navigate the complexities of the market.

Future Outlook

- Demand for high-purity quartz towers will grow with Japan’s expanding semiconductor production.

- Integration of automation and smart control systems will enhance process precision and efficiency.

- Manufacturers will increase investment in R&D to improve purity and corrosion resistance.

- Local production of quartz materials will strengthen supply chain resilience and reduce import dependency.

- Adoption of sustainable and energy-efficient distillation designs will gain industry-wide focus.

- Collaboration between universities and manufacturers will accelerate technological innovation.

- The pharmaceutical and specialty chemical sectors will create new growth opportunities for tower applications.

- Compact and modular tower designs will gain traction for cleanroom and laboratory installations.

- Competition among domestic players will intensify with increasing export potential to Asian markets.

- Government incentives supporting high-tech manufacturing will continue to drive market expansion.