Market Overview:

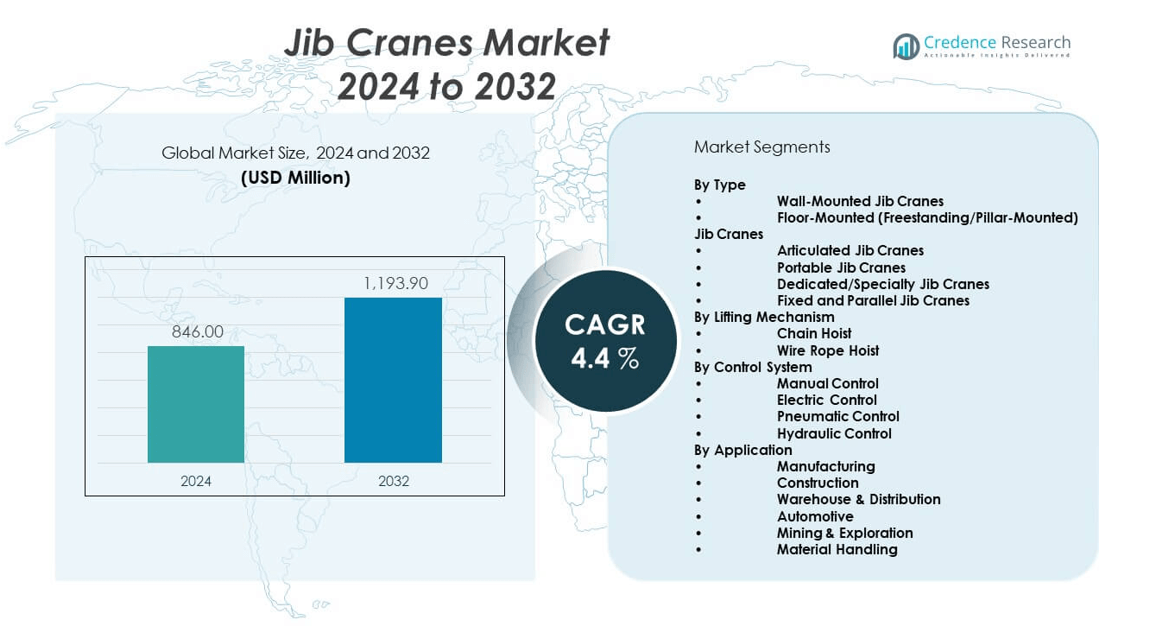

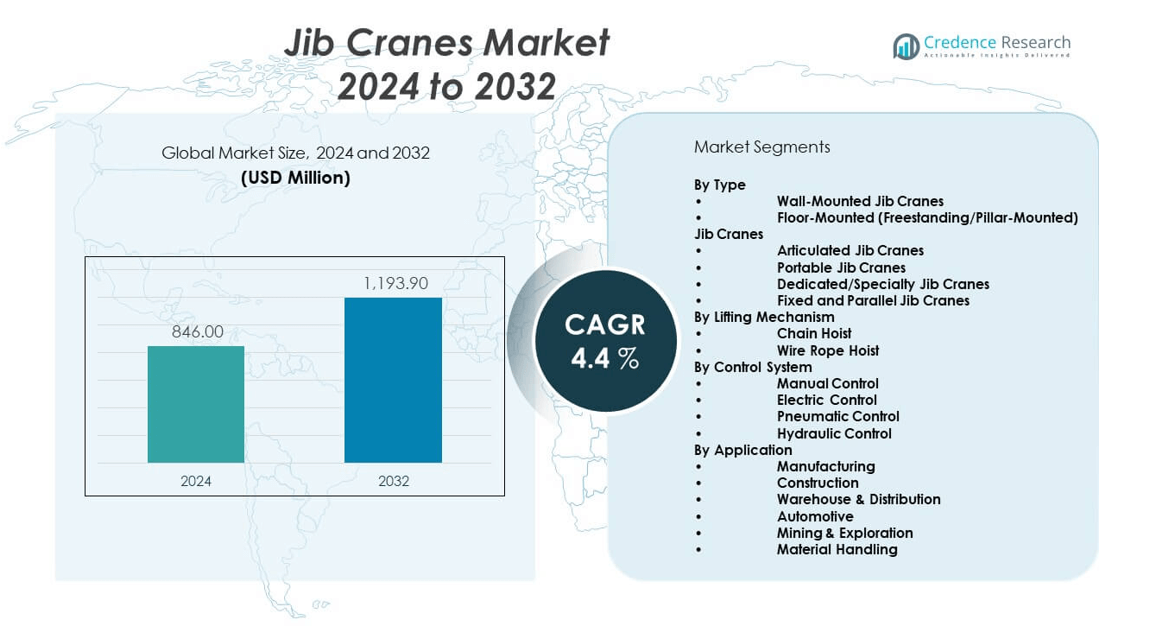

The Jib cranes market is projected to grow from USD 846 million in 2024 to an estimated USD 1,193.9 million by 2032, with a compound annual growth rate (CAGR) of 4.4% from 2024 to 2032.

| REPORT ATTRIBUTE |

DETAILS |

| Historical Period |

2020-2023 |

| Base Year |

2024 |

| Forecast Period |

2025-2032 |

| Jib Cranes Market Size 2024 |

USD 846 million |

| Jib Cranes Market, CAGR |

4.4% |

| Jib Cranes Market Size 2032 |

USD 1,193.9 million |

The market is driven by the increasing demand for flexible material handling equipment across manufacturing, construction, and logistics sectors. Industries prioritize jib cranes for their compact design, rotational flexibility, and ability to improve productivity in confined spaces. Growing automation, rising labor costs, and a focus on workplace safety further accelerate adoption. Small and medium-sized enterprises increasingly integrate jib cranes due to their cost-effectiveness and operational efficiency. Moreover, expanding industrial infrastructure and refurbishment of aging facilities worldwide contribute to sustained market growth.

Regionally, North America and Europe lead the jib cranes market due to their mature industrial bases, technological advancements, and high labor costs encouraging automation. The Asia-Pacific region is emerging as a significant growth area, driven by rapid industrialization, infrastructure development, and expanding manufacturing hubs in China, India, and Southeast Asia. Countries in Latin America and the Middle East are gradually gaining traction, supported by construction activity, investments in oil and gas, and logistics modernization. The regional dynamics reflect a shift toward global industrial decentralization and localized production.

Market Insights:

- The jib cranes market was valued at USD 846 million in 2024 and is projected to reach USD 1,193.9 million by 2032, growing at a CAGR of 4.4% during the forecast period.

- Rising demand for space-efficient material handling in manufacturing, logistics, and construction sectors is driving consistent adoption of jib cranes globally.

- Growth is supported by increasing automation, stringent workplace safety norms, and a shift toward flexible and modular lifting solutions.

- High initial investment costs and limited awareness among small enterprises pose key restraints, particularly in emerging markets.

- North America leads the jib cranes market with a 31.5% share, driven by industrial modernization and strong adoption of electric and smart control cranes.

- Asia-Pacific is the fastest-growing region due to rapid industrial expansion, infrastructure development, and increasing SME participation.

- Europe maintains steady demand backed by regulatory compliance, automation trends, and continued investment in industrial infrastructure.

Access crucial information at unmatched prices!

Request your sample report today & start making informed decisions powered by Credence Research Inc.!

Download Sample

Market Drivers:

Rising Demand for Flexible Lifting Solutions in Manufacturing Facilities:

The Jib cranes market benefits from strong demand across manufacturing environments that require efficient material movement within confined spaces. It offers compact design and rotational movement, making it suitable for precision tasks at workstations. Industries such as automotive, electronics, and metal fabrication utilize jib cranes to streamline processes. Increasing pressure to improve throughput and reduce manual handling incidents fuels this adoption. Companies seek equipment that minimizes worker fatigue and enhances workflow. The market aligns well with lean manufacturing and just-in-time operations. Jib cranes support customization, enabling integration with specific workstation layouts. The rise in global factory automation further reinforces their relevance.

- For instance, Konecranes offers pillar-mounted and wall-mounted jib cranes with lifting capacities up to 2,000 kg, providing manual to motorized slewing with rotation adjustments every two degrees, which supports precise and ergonomic handling at workstations in automotive and electronics assembly lines.

Increasing Investments in Infrastructure and Construction Projects:

Global infrastructure development drives sustained demand for jib cranes in construction and civil engineering sectors. It supports operations such as material positioning, equipment handling, and concrete formwork setup. Urbanization in developing economies and aging infrastructure upgrades in developed countries expand the scope of applications. Governments and private players allocate budgets for industrial parks, railways, ports, and smart city projects. The Jib cranes market leverages this momentum through portable and wall-mounted variants for temporary and permanent sites. Its role becomes vital in small-to-medium construction zones that require agile lifting tools. Crane rental services also adopt jib cranes to offer flexibility to contractors.

- For example, companies like Gorbel have developed portable jib cranes optimized for quick setup and repositioning, which are ideal for small-to-medium construction sites needing flexible lifting tools and crane rental services.

Focus on Enhancing Workplace Safety and Operational Efficiency:

Workplace safety remains a central concern for manufacturers and construction firms, leading to increased use of ergonomic lifting equipment. Jib cranes reduce dependency on manual labor, lowering the risk of musculoskeletal injuries. It supports repetitive lifting without fatigue and handles heavy or awkward loads with stability. Safety compliance regulations across regions, including OSHA and ISO standards, encourage the installation of such systems. Jib cranes offer controlled movement, improving precision and reducing accidents. Integration with smart sensors and overload protection features supports proactive safety measures. It serves as a safer alternative to forklifts in tight or high-traffic areas. Safety-led procurement strategies continue to benefit the market.

Growth of Small and Medium Enterprises (SMEs) in Emerging Economies:

The expansion of SMEs in Asia-Pacific, Latin America, and Eastern Europe boosts demand for cost-effective material handling solutions. The Jib cranes market caters well to SMEs due to its relatively low cost, ease of installation, and minimal space requirements. These businesses often lack capacity for large gantry or overhead cranes and seek flexible alternatives. Jib cranes help improve production efficiency without significant capital expenditure. Government incentives and industrial policy reforms in developing economies encourage SMEs to invest in scalable infrastructure. The availability of localized crane manufacturing also makes it accessible to smaller firms. It helps such businesses transition toward semi-automated operations and better workforce productivity.

Market Trends:

Integration of Smart Technologies for Real-Time Monitoring and Control:

Digital transformation trends reshape how jib cranes operate and deliver value. Manufacturers now embed IoT sensors and condition-monitoring systems into crane structures. These enable remote tracking of usage, load cycles, and maintenance needs. Predictive maintenance helps avoid unplanned downtime and reduces long-term operational costs. The Jib cranes market benefits from integration with industrial IoT platforms for centralized control. Cloud-based dashboards allow real-time diagnostics and performance visualization. This smart connectivity appeals to users investing in Industry 4.0 frameworks. Digital retrofitting of older jib cranes also creates a new aftermarket opportunity for OEMs.

- For example, Konecranes integrates advanced sensors that monitor multiple metrics such as rope angle, working hours, and component wear, transmitting data securely to cloud platforms for machine learning analysis. This technology helps reduce sway during lifts and prevents mechanical wear, enhancing operational safety and equipment longevity.

Shift Toward Modular and Custom-Built Crane Configurations:

End-users increasingly seek modular jib cranes that adapt to dynamic shop floor layouts. Manufacturers respond by offering customizable boom lengths, rotation angles, mounting options, and load capacities. This modularity enhances operational flexibility in varied work environments. The Jib cranes market evolves to support specialized applications such as clean rooms, explosive environments, or marine docks. Engineering-to-order (ETO) practices gain traction, enabling better alignment with client-specific needs. Modular systems simplify installation, transport, and upgrades. Such flexibility supports industries with frequent retooling or layout adjustments. It also enables phased capital investments.

Rising Preference for Portable and Wall-Mounted Variants in Urban Facilities:

Urban industrial operations often face space constraints, prompting demand for space-efficient crane solutions. Wall-mounted and portable jib cranes meet these needs with minimal structural intrusion. Logistics hubs, retail warehouses, and service centers deploy these systems to optimize vertical handling. The Jib cranes market expands its footprint in such sectors, offering compact designs without sacrificing capacity. Portability ensures ease of relocation across job sites. Maintenance departments in high-rise buildings and manufacturing plants also utilize these for maintenance tasks. Compact jib cranes help eliminate the need for large forklifts in confined spaces.

Increased Adoption of Environmentally Friendly and Energy-Efficient Designs:

Sustainability goals influence procurement decisions in material handling. Manufacturers now prioritize lighter structures, recyclable materials, and energy-efficient components. Electric chain hoists integrated with jib cranes reduce energy consumption compared to older hydraulic models. The Jib cranes market incorporates sustainability through optimized structural designs that reduce material usage. Lightweight aluminum models replace heavy steel in some applications. Recyclability of metals used in crane fabrication supports environmental targets. Companies also implement energy regeneration features and use environment-safe lubricants. Sustainable practices improve brand reputation and meet regulatory expectations.

Market Challenges Analysis:

High Initial Capital Investment and Limited Awareness Among Small Enterprises:

Despite long-term cost savings, the initial investment for installing jib cranes remains a barrier for many small businesses. It includes expenses for the crane system, foundation reinforcement, and integration with existing workflows. SMEs in emerging markets often lack awareness of the benefits and financing options available. The Jib cranes market faces challenges convincing cost-sensitive customers of its ROI. Perceptions of complexity and long lead times deter adoption. Distribution and dealer networks may also be underdeveloped in remote areas, limiting market penetration. The industry must focus on education campaigns, lease options, and entry-level models to address these hurdles.

Technical Limitations and Incompatibility with Heavy-Duty or Large-Area Applications:

Jib cranes are ideal for localized lifting but have limited utility in large or heavy-load operations. Their load-bearing capacity and rotation range are constrained by design. Industries requiring movement across broader distances or heavier payloads opt for gantry or bridge cranes instead. The Jib cranes market often loses opportunities in these segments due to functional constraints. Customization can help, but it increases complexity and cost. Misalignment between user expectations and actual capability leads to dissatisfaction. Ensuring proper application-specific consultation becomes critical for OEMs and resellers to avoid mismatch.

Market Opportunities:

Growth of E-Commerce Warehouses and Urban Logistics Hubs Expands Deployment:

The boom in e-commerce and last-mile delivery infrastructure creates fresh demand for material handling in compact, urban spaces. Jib cranes offer an efficient solution for loading, unloading, and organizing goods in these tight environments. The Jib cranes market stands to gain as warehousing becomes more vertical and space optimization becomes essential. Companies prioritize fast, safe, and precise handling near dispatch points.

Rise in Equipment Rental Models and SME Financing Support Bolsters Adoption:

Crane rental and lease-to-own models grow rapidly, making jib cranes more accessible to short-term projects and small enterprises. Financial institutions and government-backed credit lines support SMEs to modernize their operations. The Jib cranes market can leverage this by offering service-based models and flexible payment plans. Scalable systems appeal to startups seeking low-risk automation tools.

Market Segmentation Analysis:

By Type

The Jib cranes market includes several types catering to different industrial needs. Floor-mounted (freestanding/pillar-mounted) jib cranes account for the highest demand due to their load capacity and stability. Wall-mounted cranes support operations in facilities with limited floor space. Articulated jib cranes offer enhanced mobility for complex lifting angles, while portable variants provide flexibility across job sites. Dedicated and fixed parallel jib cranes address specific workflows in manufacturing and assembly environments.

- For example, Floor-mounted (pillar-mounted) jib cranes dominate due to their high load capacity and stability, with companies like Konecranes providing models supporting smooth slewing and lifting up to 2 tonnes with precise load handling controls.

By Capacity

Jib cranes in the 1 Ton – 5 Tons and 5–10 Tons categories dominate due to widespread use in general industrial and logistics operations. Below 1 Ton cranes are suitable for light-duty applications, including repair and inspection. Cranes in the 10–50 Tons range serve sectors like steel and heavy engineering, while those above 50 Tons support niche segments such as shipyards and power plants.

- For instance, Konecranes’ product line includes cranes designed for lifting up to 50 tons, serving heavy engineering and steel sectors, reflecting technological advancements in load sensors and variable frequency drives for safe, wear-minimized operations.

By Lifting Mechanism

Chain hoists remain prevalent for their cost efficiency and lower maintenance in moderate load operations. Wire rope hoists are favored in applications requiring smoother handling and higher load-bearing strength, such as in construction or mining.

By Control System

Manual control is typically used in simple, infrequent lifting tasks. Electric control dominates due to its ease of use and compatibility with smart technologies. Pneumatic and hydraulic systems serve specialized applications that demand high precision or operation in hazardous environments.

By Application

Jib cranes are widely adopted in manufacturing, warehouse logistics, and construction. Automotive, mining, and material handling applications also rely on them for operational efficiency, safety, and precision.

Segmentation:

By Type

- Wall-Mounted Jib Cranes

- Floor-Mounted (Freestanding/Pillar-Mounted) Jib Cranes

- Articulated Jib Cranes

- Portable Jib Cranes

- Dedicated/Specialty Jib Cranes

- Fixed and Parallel Jib Cranes

By Lifting Mechanism

- Chain Hoist

- Wire Rope Hoist

By Control System

- Manual Control

- Electric Control

- Pneumatic Control

- Hydraulic Control

By Application

- Manufacturing

- Construction

- Warehouse & Distribution

- Automotive

- Mining & Exploration

- Material Handling

By Geography

- North America

- Europe

- Germany

- France

- U.K.

- Italy

- Spain

- Rest of Europe

- Asia Pacific

- China

- Japan

- India

- South Korea

- South-east Asia

- Rest of Asia Pacific

- Latin America

- Brazil

- Argentina

- Rest of Latin America

- Middle East & Africa

- GCC Countries

- South Africa

- Rest of the Middle East and Africa

Regional Analysis:

North America: Mature Market Driven by Industrial Automation

North America holds a significant share of the Jib cranes market, accounting for approximately 31.5%, or USD 266.5 million in 2024. The region benefits from a well-established industrial base, high labor costs, and a strong push toward automation, especially in the United States and Canada. Demand remains strong in manufacturing, automotive, and warehousing sectors, where jib cranes enhance workflow efficiency and safety. Electric control systems and smart hoist integrations are widely adopted to support Industry 4.0 initiatives. Infrastructure modernization and facility upgrades in logistics continue to drive replacement demand. The presence of key manufacturers and distributors ensures steady supply chain support across industries.

Asia-Pacific: Fastest Growing Region Led by Manufacturing Expansion

Asia-Pacific represents the fastest growing and second-largest regional market, holding around 28.5%, or USD 241.1 million in 2024. The region’s growth is led by China, India, Japan, and Southeast Asia, where industrialization and capital investment in manufacturing and construction are rising steadily. Governments in the region support SME development and infrastructure expansion, which promotes adoption of cost-effective and scalable lifting solutions like jib cranes. Local manufacturers offer competitive pricing and customization, enabling broader market penetration. Construction, warehousing, and materials handling segments contribute heavily to regional demand. It offers strong potential for electric and portable jib crane adoption across growing logistics hubs.

Europe, Latin America, and Middle East & Africa: Steady Demand with Varied Industrial Focus

Europe accounts for about 21.5% of the Jib cranes market, representing USD 181.9 million in 2024. Demand is supported by strong industrial engineering, automotive production, and stringent workplace safety regulations. Germany, France, and Italy are major markets, driven by automation and modernization initiatives. Latin America holds an estimated 10% share, or USD 84.6 million, driven by construction activity and mining operations in Brazil, Mexico, and Chile. The Middle East & Africa contributes approximately 8.5%, or USD 71.9 million, with demand arising from oil & gas infrastructure, port logistics, and utility-scale construction projects. Each of these regions exhibits stable growth but varies in end-user composition and procurement priorities.

Shape Your Report to Specific Countries or Regions & Enjoy 30% Off!

Key Player Analysis:

- Spanco

- Gorbel

- Konecranes

- Ingersoll Rand

- Bushman Equipment

- ABUS Crane Systems

- Demag

- Harrington Hoists

- Knight Global

- American Crane

- Columbus McKinnon Corporation

- Terex Donati

Competitive Analysis:

The Jib cranes market features a moderately consolidated landscape with a mix of global players and specialized regional manufacturers. Companies such as Konecranes, Gorbel, Spanco, and Columbus McKinnon lead with diverse product portfolios, strong distribution networks, and advanced engineering capabilities. These players focus on customization, automation integration, and aftersales support to strengthen customer retention. Mid-sized firms target niche applications through cost-effective and application-specific solutions. Market participants compete on reliability, load capacity, operational flexibility, and price-performance ratio. Technological innovation and adherence to safety standards remain key differentiators. Strategic partnerships and geographic expansion continue to define competitive positioning.

Recent Developments:

- In April 2025, Konecranes acquired Polipastos y Instalaciones MEG S.L. (PIMEG), a Spanish company specializing in crane sales, service, and maintenance based in Sabadell, Catalonia. This acquisition strengthens Konecranes’ presence in the Spanish market and expands its crane service capabilities.

- In early 2024, Konecranes delivered two 25-ton self-powered portal jib cranes to the U.S. Navy base in Bangor, Washington, with two additional cranes scheduled for delivery to the Bremerton naval base by June 2025. These cranes replace aging equipment, improving safety and operational capacity for the Navy, and were manufactured in Waukesha, Wisconsin.

- Additionally, in December 2024, Konecranes received its fifth portal jib crane order from the U.S. Navy, this time for delivery to the Norfolk Naval Shipyard in Virginia. Alongside this, Konecranes secured orders for 68 standard duty cranes for an aerospace customer in the Asia-Pacific region and multiple X-series crane orders in Europe for manufacturing and automotive industry customers, highlighting a strong market demand across sectors.

Market Concentration & Characteristics:

The Jib cranes market is moderately concentrated, with a few major players holding significant global share and several regional manufacturers addressing localized demand. It is characterized by steady growth, recurring demand from core industries, and moderate entry barriers due to engineering requirements and safety compliance standards. Product customization, integration with digital systems, and aftersales service play a crucial role in brand differentiation. Buyers prioritize performance, reliability, and total cost of ownership when selecting vendors.

Report Coverage:

The research report offers an in-depth analysis based on type, capacity, lifting mechanism, control system, application, and geography. It details leading market players, providing an overview of their business, product offerings, investments, revenue streams, and key applications. Additionally, the report includes insights into the competitive environment, SWOT analysis, current market trends, as well as the primary drivers and constraints. Furthermore, it discusses various factors that have driven market expansion in recent years. The report also explores market dynamics, regulatory scenarios, and technological advancements that are shaping the industry. It assesses the impact of external factors and global economic changes on market growth. Lastly, it provides strategic recommendations for new entrants and established companies to navigate the complexities of the market.

Future Outlook:

- Demand will grow across logistics and warehousing due to space-optimized material handling.

- SMEs will increasingly adopt low-capacity jib cranes for affordable automation.

- Product innovations will focus on compact designs and smart control integration.

- Asia-Pacific will continue leading growth due to industrial expansion and infrastructure development.

- Manufacturers will expand rental and leasing offerings to meet flexible demand.

- Digital monitoring and predictive maintenance features will drive product upgrades.

- Sustainability concerns will influence material choices and energy-efficient designs.

- Multi-axis articulated jib cranes will gain traction in specialized manufacturing.

- Strategic acquisitions will help global players enter untapped regional markets.

- Safety regulations will push for standard-compliant, ergonomically designed cranes.