Market Overview

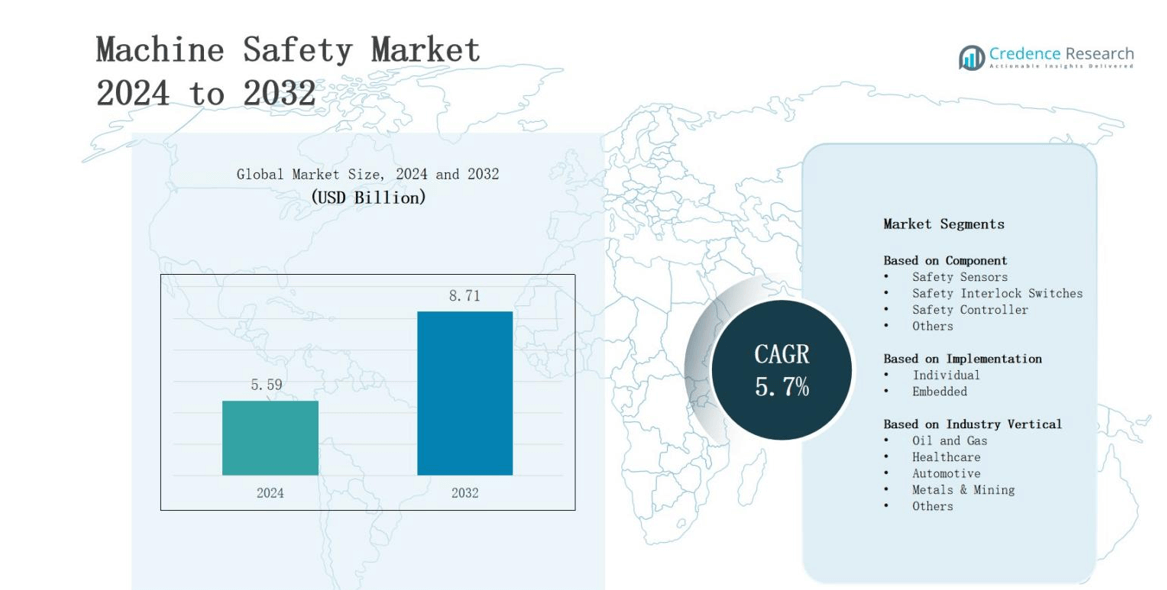

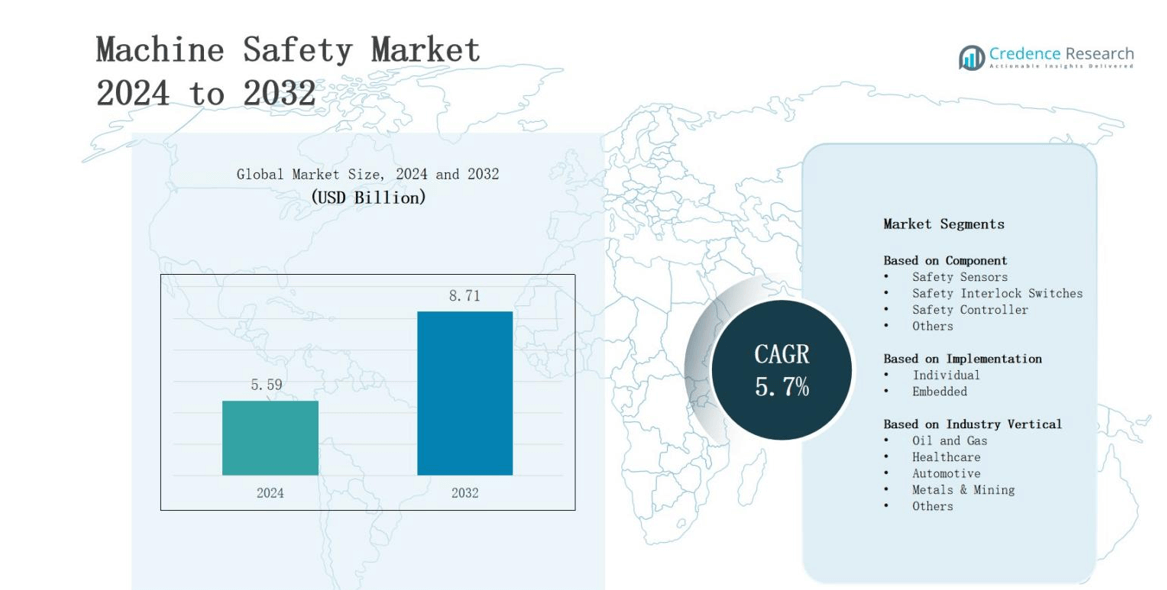

The global machine safety market is projected to grow from USD 5.59 billion in 2024 to USD 8.71 billion by 2032, registering a CAGR of 5.7%.

| REPORT ATTRIBUTE |

DETAILS |

| Historical Period |

2020-2023 |

| Base Year |

2024 |

| Forecast Period |

2025-2032 |

| Machine Safety Market Size 2024 |

USD 5.59 billion |

| Machine Safety Market, CAGR |

5.7% |

| Machine Safety Market Size 2032 |

USD 8.71 billion |

The machine safety market is driven by rising adoption of automation across industries, stringent workplace safety regulations, and increasing demand for advanced safety components to reduce accidents and downtime. Growing awareness of employee safety, coupled with the integration of IoT and Industry 4.0 technologies, further accelerates adoption of safety sensors, controllers, and interlock devices. Manufacturers are investing in innovative solutions to ensure compliance, enhance productivity, and minimize risks. Emerging trends include the shift toward collaborative robotics, predictive maintenance, and AI-enabled safety systems, which collectively shape a more connected and intelligent industrial safety ecosystem.

The machine safety market shows significant growth across North America, Europe, Asia-Pacific, and the Rest of the World, driven by industrial automation, regulatory compliance, and workforce protection initiatives. North America and Europe focus on advanced safety systems and strict standards, while Asia-Pacific leads in adoption due to rapid industrialization, and the Rest of the World presents emerging opportunities. Key players including Siemens AG, Emerson Electric Co., Mitsubishi Electric Corporation, SICK AG, Schneider Electric SE, OMRON Corporation, B&R Automation, Honeywell International, ABB Ltd., Rockwell Automation, and KEYENCE CORPORATION dominate the market with innovative solutions and global reach.

Market Insights

- The machine safety market is projected to grow from USD 5.59 billion in 2024 to USD 8.71 billion by 2032, registering a CAGR of 5.7%, driven by automation adoption and regulatory compliance.

- Safety sensors dominate the component segment with 38% share, supported by real-time monitoring demand, followed by interlock switches at 27%, controllers at 22%, and other components at 13%, enhancing workplace protection.

- Embedded implementation leads with 61% share due to seamless integration with automated machinery, while individual implementation contributes 39%, appealing to SMEs for cost-effective and flexible adoption across industries.

- Automotive holds the largest industry vertical share at 31%, followed by oil and gas at 21%, metals and mining at 18%, healthcare at 15%, and other sectors at 15%, reflecting diversified industrial demand.

- Regionally, Asia-Pacific leads with 31% share, followed by North America at 29%, Europe at 26%, and the Rest of the World at 14%, driven by industrialization, workforce safety initiatives, and adoption of smart technologies.

Access crucial information at unmatched prices!

Request your sample report today & start making informed decisions powered by Credence Research Inc.!

Download Sample

Market Drivers

Rising Adoption of Industrial Automation

The machine safety market experiences strong growth due to widespread adoption of automation in manufacturing and processing industries. Companies aim to increase operational efficiency while ensuring worker safety, which creates demand for safety controllers, sensors, and interlock devices. Automation requires advanced safety protocols to minimize risks associated with high-speed machinery. Governments continue enforcing strict regulations that compel manufacturers to implement certified safety solutions. Automation advances transform operational environments and support rapid safety technology integration.

- For instance, Rockwell Automation’s GuardLink safety system has been deployed in food and beverage plants, using smart safety devices connected over a single cable to minimize wiring and improve diagnostics.

Stringent Workplace Safety Regulations

Governments and industry bodies enforce strict workplace safety standards that drive consistent demand for certified safety systems. Regulations such as ISO and OSHA require industries to comply with robust safety protocols to protect workers. The machine safety market benefits from such frameworks, as organizations must prioritize safety investments. It encourages innovation in protective equipment and monitoring devices. Strong compliance culture ensures workplace incidents remain minimal, while supporting long-term productivity goals. Regulatory enforcement sustains market momentum globally.

- For instance, OSHA’s lockout/tagout standard (29 CFR 1910.147) has driven companies like General Motors and Ford to deploy advanced machine guarding and energy-isolation systems to protect maintenance workers

Growing Focus on Workforce Protection

Worker safety concerns remain a central driver of market expansion, as industrial accidents impose high human and financial costs. The machine safety market addresses these concerns through products that protect workers during machine operation. Employers adopt preventive safety technologies to limit liability and strengthen employee confidence. It ensures improved morale, reduced downtime, and higher efficiency. Expanding industrial sectors in emerging economies amplify the focus on safety, creating broad opportunities for safety solution providers worldwide.

Technological Advancements in Safety Solutions

The market grows steadily with advancements in robotics, IoT, and artificial intelligence that enhance predictive capabilities of safety systems. It enables real-time monitoring and advanced diagnostics, ensuring machines function safely under varying conditions. The machine safety market benefits from integration of smart sensors and cloud-based analytics platforms. Manufacturers introduce innovative solutions that combine automation with enhanced protection. These developments create safer workplaces, optimize productivity, and ensure compliance with international standards. Technology continues shaping next-generation safety frameworks.

Market Trends

Integration of IoT and Smart Safety Systems

The machine safety market is witnessing a rapid shift toward IoT-enabled and connected safety systems that enhance real-time monitoring and predictive analytics. Companies deploy smart sensors and cloud-based platforms to detect anomalies and prevent operational risks. It allows industries to identify issues early and reduce downtime. IoT integration improves visibility, enabling remote supervision of safety protocols. This trend supports compliance, operational efficiency, and proactive safety management across various industrial environments.

- For instance, Axzon provides IoT sensors that deliver real-time temperature and moisture data during automotive manufacturing, helping prevent equipment overheating and failures.

Adoption of Collaborative Robotics and Human-Machine Interaction

The increasing use of collaborative robots in modern factories significantly influences safety practices. The machine safety market adapts by providing solutions that protect workers while allowing closer human-machine collaboration. It focuses on advanced sensors, interlock systems, and adaptive safety controls that maintain safe environments without slowing productivity. Organizations rely on flexible solutions to balance efficiency and protection. This trend reflects the growing acceptance of robotics in manufacturing and process industries worldwide.

- For instance, Omron employs safety area scanners and mats in its collaborative robot setups to create open-area safety guarding, enabling robots to work alongside humans without physical barriers while maintaining safety through advanced sensing technologies.

Shift Toward Predictive Maintenance and Advanced Diagnostics

Industrial operators are prioritizing predictive maintenance to ensure uninterrupted operations and safe machine performance. The machine safety market benefits from diagnostic tools and predictive algorithms that detect potential hazards before they escalate. It reduces unexpected failures and costly downtime while supporting compliance with safety standards. Companies integrate AI-based systems to enhance precision and efficiency in maintenance activities. The trend highlights a growing preference for proactive safety management over traditional reactive approaches.

Emphasis on AI and Data-Driven Safety Solutions

Artificial intelligence plays a crucial role in the development of intelligent machine safety frameworks. The machine safety market leverages AI for risk assessment, automated decision-making, and real-time data interpretation. It helps companies create safer, more adaptive production environments. Data-driven solutions provide actionable insights that strengthen workplace safety strategies. AI integration promotes continuous improvement and supports innovation. This trend defines the evolution of safety solutions toward more dynamic and intelligent ecosystems across industries.

Market Challenges Analysis

High Implementation Costs and Complex Integration

The machine safety market faces challenges related to high initial costs and complex integration processes. Companies often hesitate to invest in advanced safety systems due to budget limitations, particularly in small and medium-sized enterprises. It requires specialized expertise to install and maintain safety devices, which further raises costs. Integration with existing legacy machinery can be difficult, slowing adoption in traditional industries. These financial and technical barriers limit broader market penetration despite rising safety awareness.

Lack of Skilleid Workforce and Awareness Gaps

A shortage of skilled professionals who can manage and operate advanced safety systems continues to challenge market expansion. The machine safety market depends on trained engineers to ensure proper installation, compliance, and maintenance of safety solutions. It also faces awareness gaps among organizations in emerging economies, where safety standards are not strictly enforced. Limited knowledge about the long-term benefits of safety investments often delays adoption. This situation restricts consistent global growth despite technological advancements.

Market Opportunities

Expansion in Emerging Economies and Industrial Growth

The machine safety market holds significant opportunities in emerging economies where industrialization is accelerating rapidly. Manufacturing hubs in Asia-Pacific, Latin America, and Africa are expanding production capacity, which increases demand for advanced safety systems. It allows companies to improve compliance, reduce accidents, and align with global safety standards. Rising foreign investments and supportive government initiatives further encourage the adoption of modern safety solutions. The expansion of industrial sectors creates strong opportunities for safety technology providers worldwide.

Advancements in Digital Technologies and Smart Manufacturing

Growing adoption of digital technologies creates new opportunities for innovative safety solutions. The machine safety market benefits from developments in artificial intelligence, cloud platforms, and advanced robotics that enhance monitoring and predictive maintenance. It enables industries to integrate safety within smart manufacturing frameworks for higher efficiency. Demand for data-driven, adaptive safety systems is rising across sectors such as automotive, pharmaceuticals, and food processing. This digital transformation strengthens the long-term growth outlook for advanced safety solutions.

Market Segmentation Analysis:

By Component

In the machine safety market, safety sensors dominate the component segment with a share of around 38%, supported by rising demand for real-time monitoring and accident prevention across manufacturing facilities. These sensors enhance detection accuracy and support compliance with global safety standards. Safety interlock switches account for nearly 27%, as industries adopt them to ensure safe access during machine operation. Safety controllers represent about 22%, driven by automation growth, while other components hold the remaining 13%.

- For instance, Rockwell Automation’s Guardmaster interlock switches are widely deployed in food and beverage plants to prevent operators from accessing hazardous zones until equipment has stopped.

By Implementation

Embedded implementation leads this segment with a share of 61%, driven by its seamless integration with automated machinery and ability to improve reliability. It enables manufacturers to reduce system complexity while enhancing safety functionality. Individual implementation contributes nearly 39%, appealing to small and medium enterprises seeking flexibility and cost-effective adoption. The machine safety market benefits from the preference for embedded solutions in modern industrial setups where operational efficiency is critical.

- For instance, Siemens integrates embedded safety controllers in its SIMATIC S7-1500 series, allowing built-in fail-safe automation that reduces wiring needs and streamlines machine safety compliance.

By Industry Vertical

The automotive sector holds the largest share at about 31%, fueled by automation in assembly lines and strict safety compliance requirements. Oil and gas follows with around 21%, where safety systems mitigate high-risk operational environments. Metals and mining contributes nearly 18%, supported by rising adoption of advanced machinery protection systems. Healthcare accounts for close to 15%, focusing on precision safety in medical equipment. Other industries collectively represent about 15%, reflecting diversified demand across sectors.

Segments:

Based on Component

- Safety Sensors

- Safety Interlock Switches

- Safety Controller

- Others

Based on Implementation

Based on Industry Vertical

- Oil and Gas

- Healthcare

- Automotive

- Metals & Mining

- Others

Based on the Geography:

- North America

- Europe

- Germany

- France

- U.K.

- Italy

- Spain

- Rest of Europe

- Asia Pacific

- China

- Japan

- India

- South Korea

- South-east Asia

- Rest of Asia Pacific

- Latin America

- Brazil

- Argentina

- Rest of Latin America

- Middle East & Africa

- GCC Countries

- South Africa

- Rest of the Middle East and Africa

Regional Analysis

North America

North America holds a 29% share of the machine safety market, driven by advanced industrial automation and stringent regulatory standards. It benefits from high adoption of IoT-enabled safety systems and smart manufacturing solutions. Leading industries, including automotive, aerospace, and food processing, emphasize compliance and workforce protection. It supports development of innovative safety devices and advanced sensors. Strong government policies and investment in research and development sustain market growth. Companies continue upgrading legacy systems to meet modern safety requirements, boosting overall demand.

Europe

Europe captures 26% of the market, fueled by strict workplace safety regulations and widespread industrial automation. It encourages adoption of advanced safety controllers, interlock switches, and sensors. It focuses on reducing operational hazards and protecting employees across automotive, metals, and pharmaceutical sectors. Emerging trends include collaborative robotics and predictive maintenance integration in production facilities. Investment in AI-driven and connected safety solutions enhances compliance. Regional manufacturers prioritize innovation to maintain competitive advantage and meet international standards.

Asia-Pacific

Asia-Pacific holds the largest share at 31%, led by rapid industrialization and expansion of manufacturing hubs in China, India, and Southeast Asia. It experiences rising adoption of automated machinery, creating strong demand for safety sensors and controllers. Governments enforce safety regulations and promote industrial growth, supporting the machine safety market. It benefits from increasing foreign investment in manufacturing infrastructure. Focus on workforce protection and compliance drives the deployment of advanced solutions. Growing automotive, electronics, and food processing sectors accelerate market penetration.

Rest of the World

The Rest of the World accounts for 14% of the market, with emerging economies investing in industrial safety solutions to modernize production environments. It includes regions in Latin America, the Middle East, and Africa where infrastructure development and industrial expansion create demand for safety devices. The machine safety market benefits from government incentives and international safety standards adoption. It faces challenges due to limited skilled workforce and awareness gaps. Growing industrial sectors present opportunities for technology adoption and enhanced workplace protection.

Shape Your Report to Specific Countries or Regions & Enjoy 30% Off!

Key Player Analysis

- ABB Ltd.

- Honeywell International, Inc.

- OMRON Corporation

- Siemens AG

- Emerson Electric Co.

- Rockwell Automation

- KEYENCE CORPORATION

- Mitsubishi Electric Corporation

- Schneider Electric SE

- SICK AG

- B&R Automation

Competitive Analysis

The machine safety market remains highly competitive, with leading players focusing on innovation, strategic partnerships, and expansion to maintain market leadership. Companies such as Siemens AG, Emerson Electric Co., Mitsubishi Electric Corporation, SICK AG, Schneider Electric SE, OMRON Corporation, B&R Automation, Honeywell International, ABB Ltd., Rockwell Automation, and KEYENCE CORPORATION continually develop advanced safety solutions, including sensors, controllers, and interlock devices. It emphasizes integration with automation systems, IoT platforms, and predictive maintenance tools to meet evolving industrial requirements. Market players invest in research and development to enhance product reliability, compliance with global safety standards, and operational efficiency. Companies compete on technology, product quality, and geographic reach, targeting sectors like automotive, metals and mining, oil and gas, and healthcare. It also explores emerging markets to capture growth opportunities in industrializing regions. Continuous innovation, coupled with strong distribution networks, positions these key players to sustain competitiveness while addressing increasing demand for safer, more efficient industrial operations worldwide.

Recent Developments

- In January 2025, Mitsubishi Electric Corporation launched MELSEC iQR safety local IO modules RX40NC6S-TS and RY48PT20S-TS. The modules are meant to supplement the lineup, improve efficiency, and lower safety costs in industrial automation.

- In December 2023, Balluff announced the CIP Safety I/O module for making safety-rated I/O devices more integrated. The module has the ability to support configurations with 12 single-channel safe inputs, 6 dual-channel safe inputs, and either 4 single-channel or 2 dual-channel safe outputs, and it is IP67 rated.

- In 2025, Honeywell acquired the Li-ion Tamer business from Nexceris, enhancing off-gas detection solutions for lithium-ion batteries.

- In March 2025, Siemens acquired Altair Engineering Inc., a provider of industrial simulation and AI software, to strengthen its AI-powered industrial software portfolio.

Market Concentration & Characteristics

The machine safety market exhibits a moderately consolidated structure, dominated by leading global players such as Siemens AG, Emerson Electric Co., Mitsubishi Electric Corporation, SICK AG, Schneider Electric SE, OMRON Corporation, B&R Automation, Honeywell International, ABB Ltd., Rockwell Automation, and KEYENCE CORPORATION. It demonstrates high technological intensity, with companies investing heavily in research and development to introduce innovative safety sensors, controllers, and interlock devices. Market competition focuses on product quality, compliance with international safety standards, and integration with automation and IoT platforms. It serves diverse industries including automotive, oil and gas, metals and mining, and healthcare, with varying adoption levels across regions. Emerging economies present growth opportunities, while advanced regions emphasize upgrades of legacy systems. The market’s characteristics reflect strong regulatory influence, technological evolution, and the need for reliable, efficient, and adaptive safety solutions, encouraging continuous innovation and strategic partnerships among key players.

Report Coverage

The research report offers an in-depth analysis based on Component, Implementation, Industry Verticals and Geography. It details leading market players, providing an overview of their business, product offerings, investments, revenue streams, and key applications. Additionally, the report includes insights into the competitive environment, SWOT analysis, current market trends, as well as the primary drivers and constraints. Furthermore, it discusses various factors that have driven market expansion in recent years. The report also explores market dynamics, regulatory scenarios, and technological advancements that are shaping the industry. It assesses the impact of external factors and global economic changes on market growth. Lastly, it provides strategic recommendations for new entrants and established companies to navigate the complexities of the market.

Future Outlook

- Automation adoption across industries will continue to drive demand for advanced safety solutions.

- IoT integration will enhance real-time monitoring and predictive maintenance capabilities.

- Collaborative robotics will increase the need for adaptive safety systems in human-machine environments.

- AI-enabled safety devices will improve operational efficiency and risk management.

- Emerging economies will present significant growth opportunities for machine safety solutions

- Upgrades of legacy machinery will stimulate demand for modern safety components.

- Compliance with global safety regulations will remain a key priority for manufacturers.

- Industry-specific customization of safety devices will gain importance.

- Technological innovation will focus on smarter, connected, and scalable safety systems.

- Workforce protection and accident prevention will remain central drivers of market adoption.