CHAPTER NO. 1 : INTRODUCTION 30

1.1.1. Report Description 30

Purpose of the Report 30

USP & Key Offerings 30

1.1.2. Key Benefits for Stakeholders 30

1.1.3. Target Audience 31

1.1.4. Report Scope 31

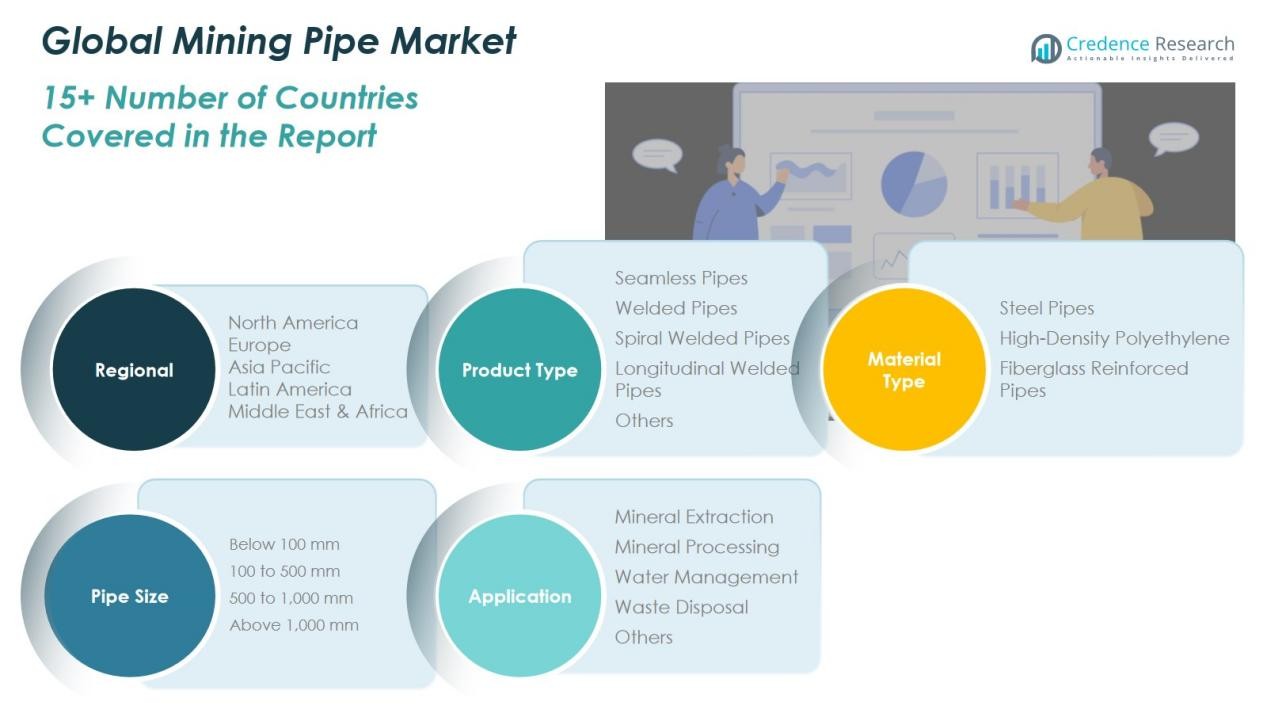

1.1.5. Regional Scope 32

CHAPTER NO. 2 : EXECUTIVE SUMMARY 33

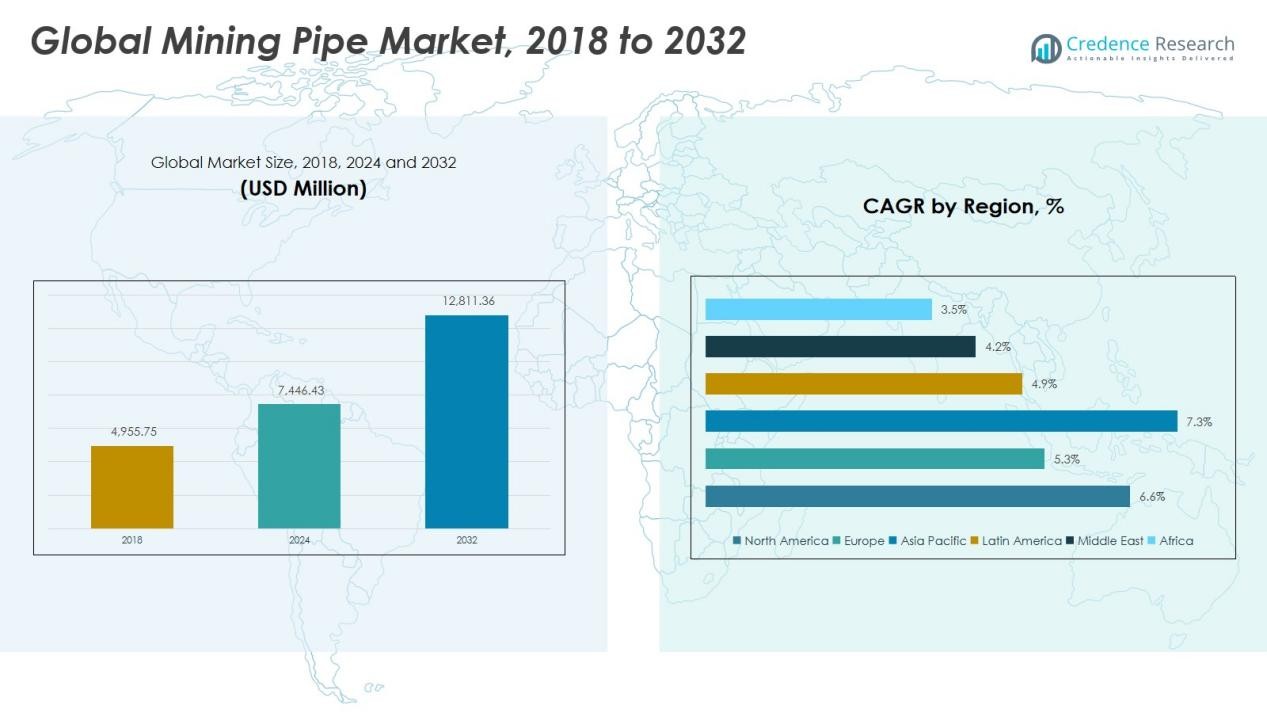

2.1. Mining Pipe Market Snapshot 33

2.1.1. Global Mining Pipe Market, 2018 – 2032 (Thousand Tons) (USD Million) 35

2.2. Insights from Primary Respondents 35

CHAPTER NO. 3 : GEOPOLITICAL CRISIS IMPACT ANALYSIS 36

3.1. Russia-Ukraine and Israel-Palestine War Impacts 36

CHAPTER NO. 4 : MINING PIPE MARKET – INDUSTRY ANALYSIS 37

4.1. Introduction 37

4.2. Market Drivers 38

4.2.1. Rising Mineral Production and Exploration Activities 38

4.2.2. Growing Adoption of Corrosion-Resistant and Lightweight Materials 39

4.3. Market Restraints 40

4.3.1. High Initial Installation and Replacement Costs 40

4.4. Market Opportunities 41

4.4.1. Market Opportunity Analysis 41

4.5. Porter’s Five Forces Analysis 42

4.6. Value Chain Analysis 43

4.7. Buying Criteria 44

CHAPTER NO. 5 : PRICE ANALYSIS 45

5.1. Price Analysis by Region 45

5.1.1. Global Mining Pipe Market Price, By Region, 2018 – 2023 45

5.1.2. Global Product Type Market Price, By Region, 2018 – 2023 45

5.2. Price Analysis by Product Type 46

5.2.1. Global Mining Pipe Market Price, By Product Type, 2018 – 2023 46

5.2.2. Global Product Type Market Price, By Product Type, 2018 – 2023 46

CHAPTER NO. 6 : ANALYSIS COMPETITIVE LANDSCAPE 47

6.1. Company Market Share Analysis – 2023 47

6.1.1. Global Mining Pipe Market: Company Market Share, by Volume, 2023 47

6.1.2. Global Mining Pipe Market: Company Market Share, by Revenue, 2023 48

6.1.3. Global Mining Pipe Market: Top 6 Company Market Share, by Revenue, 2023 48

6.1.4. Global Mining Pipe Market: Top 3 Company Market Share, by Revenue, 2023 49

6.2. Global Mining Pipe Market Company Volume Market Share, 2023 50

6.3. Global Mining Pipe Market Company Revenue Market Share, 2023 51

6.4. Company Assessment Metrics, 2023 52

6.4.1. Stars 52

6.4.2. Emerging Leaders 52

6.4.3. Pervasive Players 52

6.4.4. Participants 52

6.5. Start-ups /SMEs Assessment Metrics, 2023 52

6.5.1. Progressive Companies 52

6.5.2. Responsive Companies 52

6.5.3. Dynamic Companies 52

6.5.4. Starting Blocks 52

6.6. Strategic Developments 53

6.6.1. Acquisitions & Mergers 53

New Product Launch 53

Regional Expansion 53

6.7. Key Players Product Matrix 54

CHAPTER NO. 7 : PESTEL & ADJACENT MARKET ANALYSIS 55

7.1. PESTEL 55

7.1.1. Political Factors 55

7.1.2. Economic Factors 55

7.1.3. Social Factors 55

7.1.4. Technological Factors 55

7.1.5. Environmental Factors 55

7.1.6. Legal Factors 55

7.2. Adjacent Market Analysis 55

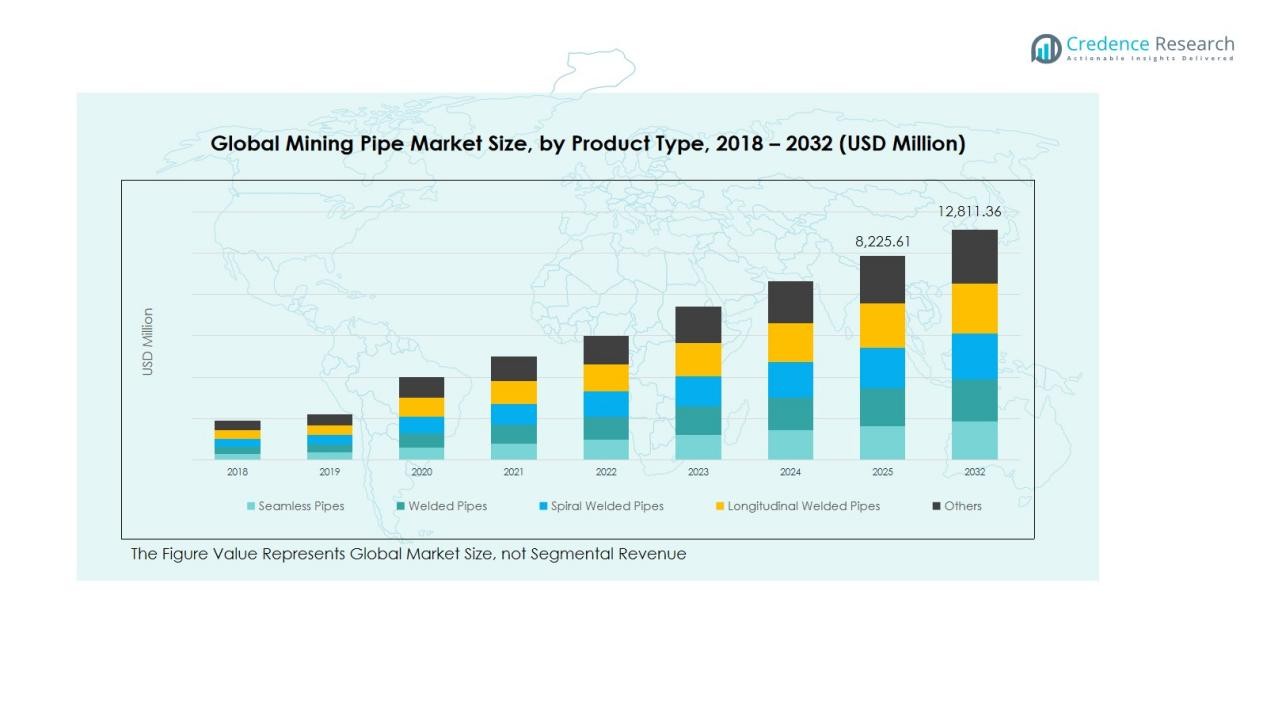

CHAPTER NO. 8 : MINING PIPE MARKET – BY PRODUCT TYPE SEGMENT ANALYSIS 56

8.1. Mining Pipe Market Overview, by Product Type Segment 56

8.1.1. Mining Pipe Market Volume Share, By Product Type, 2023 & 2032 57

8.1.2. Mining Pipe Market Revenue Share, By Product Type, 2023 & 2032 57

8.1.3. Mining Pipe Market Attractiveness Analysis, By Product Type 58

8.1.4. Incremental Revenue Growth Opportunity, by Product Type, 2024 – 2032 58

8.1.5. Mining Pipe Market Revenue, By Product Type, 2018, 2023, 2027 & 2032 59

8.2. Seamless Pipes 60

8.2.1. Global Seamless Pipes Mining Pipe Market Volume & Revenue, By Region, 2018 – 2023 (Thousand Tons) (USD Million) 61

8.2.2. Global Seamless Pipes Mining Pipe Market Volume & Revenue, By Region, 2024 – 2032 (Thousand Tons) (USD Million) 61

8.3. Welded Pipes 63

8.3.1. Global Welded Pipes Mining Pipe Market Volume & Revenue, By Region, 2018 – 2023 (Thousand Tons) (USD Million) 64

8.3.2. Global Welded Pipes Mining Pipe Market Volume & Revenue, By Region, 2024 – 2032 (Thousand Tons) (USD Million) 64

8.4. Spiral Welded Pipes 66

8.5. Global Spiral Welded Pipes Mining Pipe Market Volume & Revenue, By Region, 2018 – 2023 (Thousand Tons) (USD Million) 67

8.6. Global Spiral Welded Pipes Mining Pipe Market Volume & Revenue, By Region, 2024 – 2032 (Thousand Tons) (USD Million) 67

8.7. Longitudinal Welded Pipes 69

8.7.1. Global Longitudinal Welded Pipes Mining Pipe Market Volume & Revenue, By Region, 2018 – 2023 (Thousand Tons) (USD Million) 70

8.7.2. Global Longitudinal Welded Pipes Mining Pipe Market Volume & Revenue, By Region, 2024 – 2032 (Thousand Tons) (USD Million) 70

8.8. Others 72

8.8.1. Global Others Mining Pipe Market Volume & Revenue, By Region, 2018 – 2023 (Thousand Tons) (USD Million) 73

8.8.2. Global Others Mining Pipe Market Volume & Revenue, By Region, 2024 – 2032 (Thousand Tons) (USD Million) 73

CHAPTER NO. 9 : MINING PIPE MARKET – BY MATERIAL TYPE SEGMENT ANALYSIS 74

9.1. Mining Pipe Market Overview, by Material Type Segment 74

9.1.1. Mining Pipe Market Volume Share, By Material Type, 2023 & 2032 75

9.1.2. Mining Pipe Market Revenue Share, By Material Type, 2023 & 2032 75

9.1.3. Mining Pipe Market Attractiveness Analysis, By Material Type 76

9.1.4. Incremental Revenue Growth Opportunity, by Material Type, 2024 – 2032 76

9.1.5. Mining Pipe Market Revenue, By Material Type, 2018, 2023, 2027 & 2032 77

9.2. Steel Pipes 78

9.2.1. Global Steel Pipes Mining Pipe Market Volume & Revenue, By Region, 2018 – 2023 (Thousand Tons) (USD Million) 79

9.2.2. Global Steel Pipes Mining Pipe Market Volume & Revenue, By Region, 2024 – 2032 (Thousand Tons) (USD Million) 79

9.3. High-Density Polyethylene 80

9.3.1. Global High-Density Polyethylene Mining Pipe Market Volume & Revenue, By Region, 2018 – 2023 (Thousand Tons) (USD Million) 81

9.3.2. Global High-Density Polyethylene Mining Pipe Market Volume & Revenue, By Region, 2024 – 2032 (Thousand Tons) (USD Million) 81

9.4. Fiberglass Reinforced Pipes 83

9.5. Global Fiberglass Reinforced Pipes Mining Pipe Market Volume & Revenue, By Region, 2018 – 2023 (Thousand Tons) (USD Million) 84

9.6. Global Fiberglass Reinforced Pipes Mining Pipe Market Volume & Revenue, By Region, 2024 – 2032 (Thousand Tons) (USD Million) 84

CHAPTER NO. 10 : MINING PIPE MARKET – BY PIPE SIZE SEGMENT ANALYSIS 86

10.1. Mining Pipe Market Overview, by Pipe Size Segment 86

10.1.1. Mining Pipe Market Volume Share, By Pipe Size, 2023 & 2032 87

10.1.2. Mining Pipe Market Revenue Share, By Pipe Size, 2023 & 2032 87

10.1.3. Mining Pipe Market Attractiveness Analysis, By Pipe Size 88

10.1.4. Incremental Revenue Growth Opportunity, by Pipe Size, 2024 – 2032 88

10.1.5. Mining Pipe Market Revenue, By Pipe Size, 2018, 2023, 2027 & 2032 89

10.2. Below 100 mm 90

10.2.1. Global Below 100 mm Mining Pipe Market Volume & Revenue, By Region, 2018 – 2023 (Thousand Tons) (USD Million) 91

10.2.2. Global Below 100 mm Mining Pipe Market Volume & Revenue, By Region, 2024 – 2032 (Thousand Tons) (USD Million) 91

10.3. 100 to 500 mm 93

10.3.1. Global 100 to 500 mm Mining Pipe Market Volume & Revenue, By Region, 2018 – 2023 (Thousand Tons) (USD Million) 94

10.3.2. Global 100 to 500 mm Mining Pipe Market Volume & Revenue, By Region, 2024 – 2032 (Thousand Tons) (USD Million) 94

10.4. 500 to 1,000 mm 96

10.5. Global 500 to 1,000 mm Mining Pipe Market Volume & Revenue, By Region, 2018 – 2023 (Thousand Tons) (USD Million) 97

10.6. Global 500 to 1,000 mm Mining Pipe Market Volume & Revenue, By Region, 2024 – 2032 (Thousand Tons) (USD Million) 97

10.7. Above 1,000 mm 99

10.7.1. Global Above 1,000 mm Mining Pipe Market Volume & Revenue, By Region, 2018 – 2023 (Thousand Tons) (USD Million) 100

10.7.2. Global Above 1,000 mm Mining Pipe Market Volume & Revenue, By Region, 2024 – 2032 (Thousand Tons) (USD Million) 100

CHAPTER NO. 11 : MINING PIPE MARKET – BY APPLICATION SEGMENT ANALYSIS 102

11.1. Mining Pipe Market Overview, by Application Segment 102

11.1.1. Mining Pipe Market Volume Share, By Application, 2023 & 2032 103

11.1.2. Mining Pipe Market Revenue Share, By Application, 2023 & 2032 103

11.1.3. Mining Pipe Market Attractiveness Analysis, By Application 104

11.1.4. Incremental Revenue Growth Opportunity, by Application, 2024 – 2032 104

11.1.5. Mining Pipe Market Revenue, By Application, 2018, 2023, 2027 & 2032 105

11.2. Mineral Extraction 106

11.2.1. Global Mineral Extraction Mining Pipe Market Volume & Revenue, By Region, 2018 – 2023 (Thousand Tons) (USD Million) 107

11.2.2. Global Mineral Extraction Mining Pipe Market Volume & Revenue, By Region, 2024 – 2032 (Thousand Tons) (USD Million) 107

11.3. Mineral Processing 109

11.3.1. Global Mineral Processing Mining Pipe Market Volume & Revenue, By Region, 2018 – 2023 (Thousand Tons) (USD Million) 110

11.3.2. Global Mineral Processing Mining Pipe Market Volume & Revenue, By Region, 2024 – 2032 (Thousand Tons) (USD Million) 110

11.4. Water Management 112

11.5. Global Water Management Mining Pipe Market Volume & Revenue, By Region, 2018 – 2023 (Thousand Tons) (USD Million) 113

11.6. Global Water Management Mining Pipe Market Volume & Revenue, By Region, 2024 – 2032 (Thousand Tons) (USD Million) 113

11.7. Waste Disposal 115

11.7.1. Global Waste Disposal Mining Pipe Market Volume & Revenue, By Region, 2018 – 2023 (Thousand Tons) (USD Million) 116

11.7.2. Global Waste Disposal Mining Pipe Market Volume & Revenue, By Region, 2024 – 2032 (Thousand Tons) (USD Million) 116

11.8. Others 118

11.8.1. Global Others Mining Pipe Market Volume & Revenue, By Region, 2018 – 2023 (Thousand Tons) (USD Million) 119

11.8.2. Global Others Mining Pipe Market Volume & Revenue, By Region, 2024 – 2032 (Thousand Tons) (USD Million) 119

CHAPTER NO. 12 : MINING PIPE MARKET – REGIONAL ANALYSIS 120

12.1. Mining Pipe Market Overview, by Regional Segments 120

12.2. Region 121

12.2.1. Global Mining Pipe Market Volume Share, By Region, 2023 & 2032 121

12.2.2. Global Mining Pipe Market Revenue Share, By Region, 2023 & 2032 121

12.2.3. Mining Pipe Market Attractiveness Analysis, By Region 122

12.2.4. Incremental Revenue Growth Opportunity, by Region, 2024 – 2032 122

12.2.5. Mining Pipe Market Revenue, By Region, 2018, 2023, 2027 & 2032 123

12.2.6. Global Mining Pipe Market Volume & Revenue, By Region, 2018 – 2023 (Thousand Tons) (USD Million) 124

12.2.7. Global Mining Pipe Market Volume & Revenue, By Region, 2024 – 2032 (Thousand Tons) (USD Million) 124

12.3. Product Type 125

12.3.1. Global Mining Pipe Market Volume & Revenue, By Product Type, 2018 – 2023 (Thousand Tons) (USD Million) 125

12.4. Global Mining Pipe Market Volume & Revenue, By Product Type, 2024 – 2032 (Thousand Tons) (USD Million) 125

12.5. Material Type 126

12.5.1. Global Mining Pipe Market Volume & Revenue, By Material Type, 2018 – 2023 (Thousand Tons) (USD Million) 126

12.5.2. Global Mining Pipe Market Volume & Revenue, By Material Type, 2024 – 2032 (Thousand Tons) (USD Million) 126

12.6. Pipe Size 127

12.6.1. Global Mining Pipe Market Volume & Revenue, By Pipe Size, 2018 – 2023 (Thousand Tons) (USD Million) 127

12.6.2. Global Mining Pipe Market Volume & Revenue, By Pipe Size, 2024 – 2032 (Thousand Tons) (USD Million) 127

12.7. Application 128

12.7.1. Global Mining Pipe Market Volume & Revenue, By Application, 2018 – 2023 (Thousand Tons) (USD Million) 128

12.7.2. Global Mining Pipe Market Volume & Revenue, By Application, 2024 – 2032 (Thousand Tons) (USD Million) 128

CHAPTER NO. 13 : MINING PIPE MARKET – NORTH AMERICA 129

13.1. North America 129

13.1.1. Key Highlights 129

13.1.2. North America Mining Pipe Market Volume, By Country, 2018 – 2032 (Thousand Tons) 130

13.1.3. North America Mining Pipe Market Revenue, By Country, 2018 – 2023 (USD Million) 131

13.1.4. North America Mining Pipe Market Volume, By Product Type, 2018 – 2023 (Thousand Tons) 132

13.1.5. North America Mining Pipe Market Revenue, By Product Type, 2018 – 2023 (USD Million) 133

13.1.6. North America Mining Pipe Market Volume, By Material Type, 2018 – 2023 (Thousand Tons) 134

13.1.7. North America Mining Pipe Market Revenue, By Material Type, 2018 – 2023 (USD Million) 135

13.1.8. North America Mining Pipe Market Volume, By Pipe Size, 2018 – 2023 (Thousand Tons) 136

13.1.9. North America Mining Pipe Market Revenue, By Pipe Size, 2018 – 2023 (USD Million) 137

13.1.10. North America Mining Pipe Market Volume, By Application, 2018 – 2023 (Thousand Tons) 138

13.1.11. North America Mining Pipe Market Revenue, By Application, 2018 – 2023 (USD Million) 139

13.2. U.S. 140

13.3. Canada 140

13.4. Mexico 140

CHAPTER NO. 14 : MINING PIPE MARKET – EUROPE 141

14.1. Europe 141

14.1.1. Key Highlights 141

14.1.2. Europe Mining Pipe Market Volume, By Country, 2018 – 2032 (Thousand Tons) 142

14.1.3. Europe Mining Pipe Market Revenue, By Country, 2018 – 2023 (USD Million) 143

14.1.4. Europe Mining Pipe Market Volume, By Product Type, 2018 – 2023 (Thousand Tons) 144

14.1.5. Europe Mining Pipe Market Revenue, By Product Type, 2018 – 2023 (USD Million) 145

14.1.6. Europe Mining Pipe Market Volume, By Material Type, 2018 – 2023 (Thousand Tons) 146

14.1.7. Europe Mining Pipe Market Revenue, By Material Type, 2018 – 2023 (USD Million) 147

14.1.8. Europe Mining Pipe Market Volume, By Pipe Size, 2018 – 2023 (Thousand Tons) 148

14.1.9. Europe Mining Pipe Market Revenue, By Pipe Size, 2018 – 2023 (USD Million) 149

14.1.10. Europe Mining Pipe Market Volume, By Application, 2018 – 2023 (Thousand Tons) 150

14.1.11. Europe Mining Pipe Market Revenue, By Application, 2018 – 2023 (USD Million) 151

14.2. UK 152

14.3. France 152

14.4. Germany 152

14.5. Italy 152

14.6. Spain 152

14.7. Russia 152

14.8. Belgium 152

14.9. Netherland 152

14.10. Austria 152

14.11. Sweden 152

14.12. Poland 152

14.13. Denmark 152

14.14. Switzerland 152

14.15. Rest of Europe 152

CHAPTER NO. 15 : MINING PIPE MARKET – ASIA PACIFIC 153

15.1. Asia Pacific 153

15.1.1. Key Highlights 153

15.1.2. Asia Pacific Mining Pipe Market Volume, By Country, 2018 – 2032 (Thousand Tons) 154

15.1.3. Asia Pacific Mining Pipe Market Revenue, By Country, 2018 – 2023 (USD Million) 155

15.1.4. Asia Pacific Mining Pipe Market Volume, By Product Type, 2018 – 2023 (Thousand Tons) 156

15.1.5. Asia Pacific Mining Pipe Market Revenue, By Product Type, 2018 – 2023 (USD Million) 157

15.1.6. Asia Pacific Mining Pipe Market Volume, By Material Type, 2018 – 2023 (Thousand Tons) 158

15.1.7. Asia Pacific Mining Pipe Market Revenue, By Material Type, 2018 – 2023 (USD Million) 159

15.1.8. Asia Pacific Mining Pipe Market Volume, By Pipe Size, 2018 – 2023 (Thousand Tons) 160

15.1.9. Asia Pacific Mining Pipe Market Revenue, By Pipe Size, 2018 – 2023 (USD Million) 161

15.1.10. Asia Pacific Mining Pipe Market Volume, By Application, 2018 – 2023 (Thousand Tons) 162

15.1.11. Asia Pacific Mining Pipe Market Revenue, By Application, 2018 – 2023 (USD Million) 163

15.2. China 164

15.3. Japan 164

15.4. South Korea 164

15.5. India 164

15.6. Australia 164

15.7. Thailand 164

15.8. Indonesia 164

15.9. Vietnam 164

15.10. Malaysia 164

15.11. Philippines 164

15.12. Taiwan 164

15.13. Rest of Asia Pacific 164

CHAPTER NO. 16 : MINING PIPE MARKET – LATIN AMERICA 165

16.1. Latin America 165

16.1.1. Key Highlights 165

16.1.2. Latin America Mining Pipe Market Volume, By Country, 2018 – 2032 (Thousand Tons) 166

16.1.3. Latin America Mining Pipe Market Revenue, By Country, 2018 – 2023 (USD Million) 167

16.1.4. Latin America Mining Pipe Market Volume, By Product Type, 2018 – 2023 (Thousand Tons) 168

16.1.5. Latin America Mining Pipe Market Revenue, By Product Type, 2018 – 2023 (USD Million) 169

16.1.6. Latin America Mining Pipe Market Volume, By Material Type, 2018 – 2023 (Thousand Tons) 170

16.1.7. Latin America Mining Pipe Market Revenue, By Material Type, 2018 – 2023 (USD Million) 171

16.1.8. Latin America Mining Pipe Market Volume, By Pipe Size, 2018 – 2023 (Thousand Tons) 172

16.1.9. Latin America Mining Pipe Market Revenue, By Pipe Size, 2018 – 2023 (USD Million) 173

16.1.10. Latin America Mining Pipe Market Volume, By Application, 2018 – 2023 (Thousand Tons) 174

16.1.11. Latin America Mining Pipe Market Revenue, By Application, 2018 – 2023 (USD Million) 175

16.2. Brazil 176

16.3. Argentina 176

16.4. Peru 176

16.5. Chile 176

16.6. Colombia 176

16.7. Rest of Latin America 176

CHAPTER NO. 17 : MINING PIPE MARKET – MIDDLE EAST 177

17.1. Middle East 177

17.1.1. Key Highlights 177

17.1.2. Middle East Mining Pipe Market Volume, By Country, 2018 – 2032 (Thousand Tons) 178

17.1.3. Middle East Mining Pipe Market Revenue, By Country, 2018 – 2023 (USD Million) 179

17.1.4. Middle East Mining Pipe Market Volume, By Product Type, 2018 – 2023 (Thousand Tons) 180

17.1.5. Middle East Mining Pipe Market Revenue, By Product Type, 2018 – 2023 (USD Million) 181

17.1.6. Middle East Mining Pipe Market Volume, By Material Type, 2018 – 2023 (Thousand Tons) 182

17.1.7. Middle East Mining Pipe Market Revenue, By Material Type, 2018 – 2023 (USD Million) 183

17.1.8. Middle East Mining Pipe Market Volume, By Pipe Size, 2018 – 2023 (Thousand Tons) 184

17.1.9. Middle East Mining Pipe Market Revenue, By Pipe Size, 2018 – 2023 (USD Million) 185

17.1.10. Middle East Mining Pipe Market Volume, By Application, 2018 – 2023 (Thousand Tons) 186

17.1.11. Middle East Mining Pipe Market Revenue, By Application, 2018 – 2023 (USD Million) 187

17.2. UAE 188

17.3. KSA 188

17.4. Israel 188

17.5. Turkey 188

17.6. Iran 188

17.7. Rest of Middle East 188

CHAPTER NO. 18 : MINING PIPE MARKET – AFRICA 189

18.1. Africa 189

18.1.1. Key Highlights 189

18.1.2. Africa Mining Pipe Market Volume, By Country, 2018 – 2032 (Thousand Tons) 190

18.1.3. Africa Mining Pipe Market Revenue, By Country, 2018 – 2023 (USD Million) 191

18.1.4. Africa Mining Pipe Market Volume, By Product Type, 2018 – 2023 (Thousand Tons) 192

18.1.5. Africa Mining Pipe Market Revenue, By Product Type, 2018 – 2023 (USD Million) 193

18.1.6. Africa Mining Pipe Market Volume, By Material Type, 2018 – 2023 (Thousand Tons) 194

18.1.7. Africa Mining Pipe Market Revenue, By Material Type, 2018 – 2023 (USD Million) 195

18.1.8. Africa Mining Pipe Market Volume, By Pipe Size, 2018 – 2023 (Thousand Tons) 196

18.1.9. Africa Mining Pipe Market Revenue, By Pipe Size, 2018 – 2023 (USD Million) 197

18.1.10. Africa Mining Pipe Market Volume, By Application, 2018 – 2023 (Thousand Tons) 198

18.1.11. Africa Mining Pipe Market Revenue, By Application, 2018 – 2023 (USD Million) 199

18.2. Egypt 200

18.3. Nigeria 200

18.4. Algeria 200

18.5. Morocco 200

18.6. Rest of Africa 200

CHAPTER NO. 19 : COMPANY PROFILES 201

19.1. Vallourec S.A. 201

19.1.1. Company Overview 201

19.1.2. Product Portfolio 201

19.1.3. Swot Analysis 201

19.1.4. Business Strategy 201

19.1.5. Financial Overview 202

19.2. Metalurgica Gerdau S.A. 203

19.3. Georg Fischer Ltd. 203

19.4. China National Petroleum Corporation (CNPC) 203

19.5. PSL Limited 203

19.6. Jindal Saw Ltd. 203

19.7. Welspun Corp Limited 203

19.8. Company 8 203

19.9. Company 9 203

19.10. Company 10 203

19.11. Company 11 203

19.12. Company 12 203

19.13. Company 13 203

19.14. Company 14 203

List of Figures

FIG NO. 1. Global Mining Pipe Market Volume & Revenue, 2018 – 2032 (Thousand Tons) (USD Million) 35

FIG NO. 2. Porter’s Five Forces Analysis for Global Mining Pipe Market 42

FIG NO. 3. Value Chain Analysis for Global Mining Pipe Market 43

FIG NO. 4. Global Mining Pipe Market Price, By Region, 2018 – 2023 45

FIG NO. 5. Global Mining Pipe Market Price, By Product Type, 2018 – 2023 46

FIG NO. 6. Company Share Analysis, 2023 47

FIG NO. 7. Company Share Analysis, 2023 48

FIG NO. 8. Company Share Analysis, 2023 48

FIG NO. 9. Company Share Analysis, 2023 49

FIG NO. 10. Mining Pipe Market – Company Volume Market Share, 2023 50

FIG NO. 11. Mining Pipe Market – Company Revenue Market Share, 2023 51

FIG NO. 12. Mining Pipe Market Volume Share, By Product Type, 2023 & 2032 57

FIG NO. 13. Mining Pipe Market Revenue Share, By Product Type, 2023 & 2032 57

FIG NO. 14. Market Attractiveness Analysis, By Product Type 58

FIG NO. 15. Incremental Revenue Growth Opportunity by Product Type, 2024 – 2032 58

FIG NO. 16. Mining Pipe Market Revenue, By Product Type, 2018, 2023, 2027 & 2032 59

FIG NO. 17. Global Mining Pipe Market for Seamless Pipes, Volume & Revenue (Thousand Tons) (USD Million) 2018 – 2032 60

FIG NO. 18. Global Mining Pipe Market for Welded Pipes, Volume & Revenue (Thousand Tons) (USD Million) 2018 – 2032 63

FIG NO. 19. Global Mining Pipe Market for Spiral Welded Pipes, Volume & Revenue (Thousand Tons) (USD Million) 2018 – 2032 66

FIG NO. 20. Global Mining Pipe Market for Longitudinal Welded Pipes, Volume & Revenue (Thousand Tons) (USD Million) 2018 – 2032 69

FIG NO. 21. Global Mining Pipe Market for Others, Volume & Revenue (Thousand Tons) (USD Million) 2018 – 2032 72

FIG NO. 22. Mining Pipe Market Volume Share, By Material Type, 2023 & 2032 75

FIG NO. 23. Mining Pipe Market Revenue Share, By Material Type, 2023 & 2032 75

FIG NO. 24. Market Attractiveness Analysis, By Material Type 76

FIG NO. 25. Incremental Revenue Growth Opportunity by Material Type, 2024 – 2032 76

FIG NO. 26. Mining Pipe Market Revenue, By Material Type, 2018, 2023, 2027 & 2032 77

FIG NO. 27. Global Mining Pipe Market for Steel Pipes, Volume & Revenue (Thousand Tons) (USD Million) 2018 – 2032 78

FIG NO. 28. Global Mining Pipe Market for High-Density Polyethylene, Volume & Revenue (Thousand Tons) (USD Million) 2018 – 2032 80

FIG NO. 29. Global Mining Pipe Market for Fiberglass Reinforced Pipes, Volume & Revenue (Thousand Tons) (USD Million) 2018 – 2032 83

FIG NO. 30. Mining Pipe Market Volume Share, By Pipe Size, 2023 & 2032 87

FIG NO. 31. Mining Pipe Market Revenue Share, By Pipe Size, 2023 & 2032 87

FIG NO. 32. Market Attractiveness Analysis, By Pipe Size 88

FIG NO. 33. Incremental Revenue Growth Opportunity by Pipe Size, 2024 – 2032 88

FIG NO. 34. Mining Pipe Market Revenue, By Pipe Size, 2018, 2023, 2027 & 2032 89

FIG NO. 35. Global Mining Pipe Market for Below 100 mm, Volume & Revenue (Thousand Tons) (USD Million) 2018 – 2032 90

FIG NO. 36. Global Mining Pipe Market for 100 to 500 mm, Volume & Revenue (Thousand Tons) (USD Million) 2018 – 2032 93

FIG NO. 37. Global Mining Pipe Market for 500 to 1,000 mm, Volume & Revenue (Thousand Tons) (USD Million) 2018 – 2032 96

FIG NO. 38. Global Mining Pipe Market for Above 1,000 mm, Volume & Revenue (Thousand Tons) (USD Million) 2018 – 2032 99

FIG NO. 39. Mining Pipe Market Volume Share, By Application, 2023 & 2032 103

FIG NO. 40. Mining Pipe Market Revenue Share, By Application, 2023 & 2032 103

FIG NO. 41. Market Attractiveness Analysis, By Application 104

FIG NO. 42. Incremental Revenue Growth Opportunity by Application, 2024 – 2032 104

FIG NO. 43. Mining Pipe Market Revenue, By Application, 2018, 2023, 2027 & 2032 105

FIG NO. 44. Global Mining Pipe Market for Mineral Extraction, Volume & Revenue (Thousand Tons) (USD Million) 2018 – 2032 106

FIG NO. 45. Global Mining Pipe Market for Mineral Processing, Volume & Revenue (Thousand Tons) (USD Million) 2018 – 2032 109

FIG NO. 46. Global Mining Pipe Market for Water Management, Volume & Revenue (Thousand Tons) (USD Million) 2018 – 2032 112

FIG NO. 47. Global Mining Pipe Market for Waste Disposal, Volume & Revenue (Thousand Tons) (USD Million) 2018 – 2032 115

FIG NO. 48. Global Mining Pipe Market for Others, Volume & Revenue (Thousand Tons) (USD Million) 2018 – 2032 118

FIG NO. 49. Global Mining Pipe Market Volume Share, By Region, 2023 & 2032 121

FIG NO. 50. Global Mining Pipe Market Revenue Share, By Region, 2023 & 2032 121

FIG NO. 51. Market Attractiveness Analysis, By Region 122

FIG NO. 52. Incremental Revenue Growth Opportunity by Region, 2024 – 2032 122

FIG NO. 53. Mining Pipe Market Revenue, By Region, 2018, 2023, 2027 & 2032 123

FIG NO. 54. North America Mining Pipe Market Volume & Revenue, 2018 – 2032 (Thousand Tons) (USD Million) 129

FIG NO. 55. Europe Mining Pipe Market Volume & Revenue, 2018 – 2032 (Thousand Tons) (USD Million) 141

FIG NO. 56. Asia Pacific Mining Pipe Market Volume & Revenue, 2018 – 2032 (Thousand Tons) (USD Million) 153

FIG NO. 57. Latin America Mining Pipe Market Volume & Revenue, 2018 – 2032 (Thousand Tons) (USD Million) 165

FIG NO. 58. Middle East Mining Pipe Market Volume & Revenue, 2018 – 2032 (Thousand Tons) (USD Million) 177

FIG NO. 59. Africa Mining Pipe Market Volume & Revenue, 2018 – 2032 (Thousand Tons) (USD Million) 189

List of Tables

TABLE NO. 1. : Global Mining Pipe Market: Snapshot 33

TABLE NO. 2. : Drivers for the Mining Pipe Market: Impact Analysis 38

TABLE NO. 3. : Restraints for the Mining Pipe Market: Impact Analysis 40

TABLE NO. 4. : Global Mining Pipe Market Volume & Revenue, By Region, 2018 – 2023 45

TABLE NO. 5. : Global Mining Pipe Market Volume & Revenue, By Product Type, 2018 – 2023 46

TABLE NO. 6. : Global Seamless Pipes Mining Pipe Market Volume & Revenue, By Region, 2018 – 2023 (Thousand Tons) (USD Million) 61

TABLE NO. 7. : Global Seamless Pipes Mining Pipe Market Volume & Revenue, By Region, 2024 – 2032 (Thousand Tons) (USD Million) 61

TABLE NO. 8. : Global Welded Pipes Mining Pipe Market Volume & Revenue, By Region, 2018 – 2023 (Thousand Tons) (USD Million) 64

TABLE NO. 9. : Global Welded Pipes Mining Pipe Market Volume & Revenue, By Region, 2024 – 2032 (Thousand Tons) (USD Million) 64

TABLE NO. 10. : Global Spiral Welded Pipes Mining Pipe Market Volume & Revenue, By Region, 2018 – 2023 (Thousand Tons) (USD Million) 67

TABLE NO. 11. : Global Spiral Welded Pipes Mining Pipe Market Volume & Revenue, By Region, 2024 – 2032 (Thousand Tons) (USD Million) 67

TABLE NO. 12. : Global Longitudinal Welded Pipes Mining Pipe Market Volume & Revenue, By Region, 2018 – 2023 (Thousand Tons) (USD Million) 70

TABLE NO. 13. : Global Longitudinal Welded Pipes Mining Pipe Market Volume & Revenue, By Region, 2024 – 2032 (Thousand Tons) (USD Million) 70

TABLE NO. 14. : Global Others Mining Pipe Market Volume & Revenue, By Region, 2018 – 2023 (Thousand Tons) (USD Million) 73

TABLE NO. 15. : Global Others Mining Pipe Market Volume & Revenue, By Region, 2024 – 2032 (Thousand Tons) (USD Million) 73

TABLE NO. 16. : Global Steel Pipes Mining Pipe Market Volume & Revenue, By Region, 2018 – 2023 (Thousand Tons) (USD Million) 79

TABLE NO. 17. : Global Steel Pipes Mining Pipe Market Volume & Revenue, By Region, 2024 – 2032 (Thousand Tons) (USD Million) 79

TABLE NO. 18. : Global High-Density Polyethylene Mining Pipe Market Volume & Revenue, By Region, 2018 – 2023 (Thousand Tons) (USD Million) 81

TABLE NO. 19. : Global High-Density Polyethylene Mining Pipe Market Volume & Revenue, By Region, 2024 – 2032 (Thousand Tons) (USD Million) 81

TABLE NO. 20. : Global Fiberglass Reinforced Pipes Mining Pipe Market Volume & Revenue, By Region, 2018 – 2023 (Thousand Tons) (USD Million) 84

TABLE NO. 21. : Global Fiberglass Reinforced Pipes Mining Pipe Market Volume & Revenue, By Region, 2024 – 2032 (Thousand Tons) (USD Million) 84

TABLE NO. 22. : Global Below 100 mm Mining Pipe Market Volume & Revenue, By Region, 2018 – 2023 (Thousand Tons) (USD Million) 91

TABLE NO. 23. : Global Below 100 mm Mining Pipe Market Volume & Revenue, By Region, 2024 – 2032 (Thousand Tons) (USD Million) 91

TABLE NO. 24. : Global 100 to 500 mm Mining Pipe Market Volume & Revenue, By Region, 2018 – 2023 (Thousand Tons) (USD Million) 94

TABLE NO. 25. : Global 100 to 500 mm Mining Pipe Market Volume & Revenue, By Region, 2024 – 2032 (Thousand Tons) (USD Million) 94

TABLE NO. 26. : Global 500 to 1,000 mm Mining Pipe Market Volume & Revenue, By Region, 2018 – 2023 (Thousand Tons) (USD Million) 97

TABLE NO. 27. : Global 500 to 1,000 mm Mining Pipe Market Volume & Revenue, By Region, 2024 – 2032 (Thousand Tons) (USD Million) 97

TABLE NO. 28. : Global Above 1,000 mm Mining Pipe Market Volume & Revenue, By Region, 2018 – 2023 (Thousand Tons) (USD Million) 100

TABLE NO. 29. : Global Above 1,000 mm Mining Pipe Market Volume & Revenue, By Region, 2024 – 2032 (Thousand Tons) (USD Million) 100

TABLE NO. 30. : Global Mineral Extraction Mining Pipe Market Volume & Revenue, By Region, 2018 – 2023 (Thousand Tons) (USD Million) 107

TABLE NO. 31. : Global Mineral Extraction Mining Pipe Market Volume & Revenue, By Region, 2024 – 2032 (Thousand Tons) (USD Million) 107

TABLE NO. 32. : Global Mineral Processing Mining Pipe Market Volume & Revenue, By Region, 2018 – 2023 (Thousand Tons) (USD Million) 110

TABLE NO. 33. : Global Mineral Processing Mining Pipe Market Volume & Revenue, By Region, 2024 – 2032 (Thousand Tons) (USD Million) 110

TABLE NO. 34. : Global Water Management Mining Pipe Market Volume & Revenue, By Region, 2018 – 2023 (Thousand Tons) (USD Million) 113

TABLE NO. 35. : Global Water Management Mining Pipe Market Volume & Revenue, By Region, 2024 – 2032 (Thousand Tons) (USD Million) 113

TABLE NO. 36. : Global Waste Disposal Mining Pipe Market Volume & Revenue, By Region, 2018 – 2023 (Thousand Tons) (USD Million) 116

TABLE NO. 37. : Global Waste Disposal Mining Pipe Market Volume & Revenue, By Region, 2024 – 2032 (Thousand Tons) (USD Million) 116

TABLE NO. 38. : Global Others Mining Pipe Market Volume & Revenue, By Region, 2018 – 2023 (Thousand Tons) (USD Million) 119

TABLE NO. 39. : Global Others Mining Pipe Market Volume & Revenue, By Region, 2024 – 2032 (Thousand Tons) (USD Million) 119

TABLE NO. 40. : Global Mining Pipe Market Volume & Revenue, By Region, 2018 – 2023 (Thousand Tons) (USD Million) 124

TABLE NO. 41. : Global Mining Pipe Market Volume & Revenue, By Region, 2024 – 2032 (Thousand Tons) (USD Million) 124

TABLE NO. 42. : Global Mining Pipe Market Volume & Revenue, By Product Type, 2018 – 2023 (Thousand Tons) (USD Million) 125

TABLE NO. 43. : Global Mining Pipe Market Volume & Revenue, By Product Type, 2024 – 2032 (Thousand Tons) (USD Million) 125

TABLE NO. 44. : Global Mining Pipe Market Volume & Revenue, By Material Type, 2018 – 2023 (Thousand Tons) (USD Million) 126

TABLE NO. 45. : Global Mining Pipe Market Volume & Revenue, By Material Type, 2024 – 2032 (Thousand Tons) (USD Million) 126

TABLE NO. 46. : Global Mining Pipe Market Volume & Revenue, By Pipe Size, 2018 – 2023 (Thousand Tons) (USD Million) 127

TABLE NO. 47. : Global Mining Pipe Market Volume & Revenue, By Pipe Size, 2024 – 2032 (Thousand Tons) (USD Million) 127

TABLE NO. 48. : Global Mining Pipe Market Volume & Revenue, By Application, 2018 – 2023 (Thousand Tons) (USD Million) 128

TABLE NO. 49. : Global Mining Pipe Market Volume & Revenue, By Application, 2024 – 2032 (Thousand Tons) (USD Million) 128

TABLE NO. 50. : North America Mining Pipe Market Volume, By Country, 2018 – 2023 (Thousand Tons) 130

TABLE NO. 51. : North America Mining Pipe Market Volume, By Country, 2024 – 2032 (Thousand Tons) 130

TABLE NO. 52. : North America Mining Pipe Market Revenue, By Country, 2018 – 2023 (USD Million) 131

TABLE NO. 53. : North America Mining Pipe Market Revenue, By Country, 2024 – 2032 (USD Million) 131

TABLE NO. 54. : North America Mining Pipe Market Volume, By Product Type, 2018 – 2023 (Thousand Tons) 132

TABLE NO. 55. : North America Mining Pipe Market Volume, By Product Type, 2024 – 2032 (Thousand Tons) 132

TABLE NO. 56. : North America Mining Pipe Market Revenue, By Product Type, 2018 – 2023 (USD Million) 133

TABLE NO. 57. : North America Mining Pipe Market Revenue, By Product Type, 2024 – 2032 (USD Million) 133

TABLE NO. 58. : North America Mining Pipe Market Volume, By Material Type, 2018 – 2023 (Thousand Tons) 134

TABLE NO. 59. : North America Mining Pipe Market Volume, By Material Type, 2024 – 2032 (Thousand Tons) 134

TABLE NO. 60. : North America Mining Pipe Market Revenue, By Material Type, 2018 – 2023 (USD Million) 135

TABLE NO. 61. : North America Mining Pipe Market Revenue, By Material Type, 2024 – 2032 (USD Million) 135

TABLE NO. 62. : North America Mining Pipe Market Volume, By Pipe Size, 2018 – 2023 (Thousand Tons) 136

TABLE NO. 63. : North America Mining Pipe Market Volume, By Pipe Size, 2024 – 2032 (Thousand Tons) 136

TABLE NO. 64. : North America Mining Pipe Market Revenue, By Pipe Size, 2018 – 2023 (USD Million) 137

TABLE NO. 65. : North America Mining Pipe Market Revenue, By Pipe Size, 2024 – 2032 (USD Million) 137

TABLE NO. 66. : North America Mining Pipe Market Volume, By Application, 2018 – 2023 (Thousand Tons) 138

TABLE NO. 67. : North America Mining Pipe Market Volume, By Application, 2024 – 2032 (Thousand Tons) 138

TABLE NO. 68. : North America Mining Pipe Market Revenue, By Application, 2018 – 2023 (USD Million) 139

TABLE NO. 69. : North America Mining Pipe Market Revenue, By Application, 2024 – 2032 (USD Million) 139

TABLE NO. 70. : Europe Mining Pipe Market Volume, By Country, 2018 – 2023 (Thousand Tons) 142

TABLE NO. 71. : Europe Mining Pipe Market Volume, By Country, 2024 – 2032 (Thousand Tons) 142

TABLE NO. 72. : Europe Mining Pipe Market Revenue, By Country, 2018 – 2023 (USD Million) 143

TABLE NO. 73. : Europe Mining Pipe Market Revenue, By Country, 2024 – 2032 (USD Million) 143

TABLE NO. 74. : Europe Mining Pipe Market Volume, By Product Type, 2018 – 2023 (Thousand Tons) 144

TABLE NO. 75. : Europe Mining Pipe Market Volume, By Product Type, 2024 – 2032 (Thousand Tons) 144

TABLE NO. 76. : Europe Mining Pipe Market Revenue, By Product Type, 2018 – 2023 (USD Million) 145

TABLE NO. 77. : Europe Mining Pipe Market Revenue, By Product Type, 2024 – 2032 (USD Million) 145

TABLE NO. 78. : Europe Mining Pipe Market Volume, By Material Type, 2018 – 2023 (Thousand Tons) 146

TABLE NO. 79. : Europe Mining Pipe Market Volume, By Material Type, 2024 – 2032 (Thousand Tons) 146

TABLE NO. 80. : Europe Mining Pipe Market Revenue, By Material Type, 2018 – 2023 (USD Million) 147

TABLE NO. 81. : Europe Mining Pipe Market Revenue, By Material Type, 2024 – 2032 (USD Million) 147

TABLE NO. 82. : Europe Mining Pipe Market Volume, By Pipe Size, 2018 – 2023 (Thousand Tons) 148

TABLE NO. 83. : Europe Mining Pipe Market Volume, By Pipe Size, 2024 – 2032 (Thousand Tons) 148

TABLE NO. 84. : Europe Mining Pipe Market Revenue, By Pipe Size, 2018 – 2023 (USD Million) 149

TABLE NO. 85. : Europe Mining Pipe Market Revenue, By Pipe Size, 2024 – 2032 (USD Million) 149

TABLE NO. 86. : Europe Mining Pipe Market Volume, By Application, 2018 – 2023 (Thousand Tons) 150

TABLE NO. 87. : Europe Mining Pipe Market Volume, By Application, 2024 – 2032 (Thousand Tons) 150

TABLE NO. 88. : Europe Mining Pipe Market Revenue, By Application, 2018 – 2023 (USD Million) 151

TABLE NO. 89. : Europe Mining Pipe Market Revenue, By Application, 2024 – 2032 (USD Million) 151

TABLE NO. 90. : Asia Pacific Mining Pipe Market Volume, By Country, 2018 – 2023 (Thousand Tons) 154

TABLE NO. 91. : Asia Pacific Mining Pipe Market Volume, By Country, 2024 – 2032 (Thousand Tons) 154

TABLE NO. 92. : Asia Pacific Mining Pipe Market Revenue, By Country, 2018 – 2023 (USD Million) 155

TABLE NO. 93. : Asia Pacific Mining Pipe Market Revenue, By Country, 2024 – 2032 (USD Million) 155

TABLE NO. 94. : Asia Pacific Mining Pipe Market Volume, By Product Type, 2018 – 2023 (Thousand Tons) 156

TABLE NO. 95. : Asia Pacific Mining Pipe Market Volume, By Product Type, 2024 – 2032 (Thousand Tons) 156

TABLE NO. 96. : Asia Pacific Mining Pipe Market Revenue, By Product Type, 2018 – 2023 (USD Million) 157

TABLE NO. 97. : Asia Pacific Mining Pipe Market Revenue, By Product Type, 2024 – 2032 (USD Million) 157

TABLE NO. 98. : Asia Pacific Mining Pipe Market Volume, By Material Type, 2018 – 2023 (Thousand Tons) 158

TABLE NO. 99. : Asia Pacific Mining Pipe Market Volume, By Material Type, 2024 – 2032 (Thousand Tons) 158

TABLE NO. 100. : Asia Pacific Mining Pipe Market Revenue, By Material Type, 2018 – 2023 (USD Million) 159

TABLE NO. 101. : Asia Pacific Mining Pipe Market Revenue, By Material Type, 2024 – 2032 (USD Million) 159

TABLE NO. 102. : Asia Pacific Mining Pipe Market Volume, By Pipe Size, 2018 – 2023 (Thousand Tons) 160

TABLE NO. 103. : Asia Pacific Mining Pipe Market Volume, By Pipe Size, 2024 – 2032 (Thousand Tons) 160

TABLE NO. 104. : Asia Pacific Mining Pipe Market Revenue, By Pipe Size, 2018 – 2023 (USD Million) 161

TABLE NO. 105. : Asia Pacific Mining Pipe Market Revenue, By Pipe Size, 2024 – 2032 (USD Million) 161

TABLE NO. 106. : Asia Pacific Mining Pipe Market Volume, By Application, 2018 – 2023 (Thousand Tons) 162

TABLE NO. 107. : Asia Pacific Mining Pipe Market Volume, By Application, 2024 – 2032 (Thousand Tons) 162

TABLE NO. 108. : Asia Pacific Mining Pipe Market Revenue, By Application, 2018 – 2023 (USD Million) 163

TABLE NO. 109. : Asia Pacific Mining Pipe Market Revenue, By Application, 2024 – 2032 (USD Million) 163

TABLE NO. 110. : Latin America Mining Pipe Market Volume, By Country, 2018 – 2023 (Thousand Tons) 166

TABLE NO. 111. : Latin America Mining Pipe Market Volume, By Country, 2024 – 2032 (Thousand Tons) 166

TABLE NO. 112. : Latin America Mining Pipe Market Revenue, By Country, 2018 – 2023 (USD Million) 167

TABLE NO. 113. : Latin America Mining Pipe Market Revenue, By Country, 2024 – 2032 (USD Million) 167

TABLE NO. 114. : Latin America Mining Pipe Market Volume, By Product Type, 2018 – 2023 (Thousand Tons) 168

TABLE NO. 115. : Latin America Mining Pipe Market Volume, By Product Type, 2024 – 2032 (Thousand Tons) 168

TABLE NO. 116. : Latin America Mining Pipe Market Revenue, By Product Type, 2018 – 2023 (USD Million) 169

TABLE NO. 117. : Latin America Mining Pipe Market Revenue, By Product Type, 2024 – 2032 (USD Million) 169

TABLE NO. 118. : Latin America Mining Pipe Market Volume, By Material Type, 2018 – 2023 (Thousand Tons) 170

TABLE NO. 119. : Latin America Mining Pipe Market Volume, By Material Type, 2024 – 2032 (Thousand Tons) 170

TABLE NO. 120. : Latin America Mining Pipe Market Revenue, By Material Type, 2018 – 2023 (USD Million) 171

TABLE NO. 121. : Latin America Mining Pipe Market Revenue, By Material Type, 2024 – 2032 (USD Million) 171

TABLE NO. 122. : Latin America Mining Pipe Market Volume, By Pipe Size, 2018 – 2023 (Thousand Tons) 172

TABLE NO. 123. : Latin America Mining Pipe Market Volume, By Pipe Size, 2024 – 2032 (Thousand Tons) 172

TABLE NO. 124. : Latin America Mining Pipe Market Revenue, By Pipe Size, 2018 – 2023 (USD Million) 173

TABLE NO. 125. : Latin America Mining Pipe Market Revenue, By Pipe Size, 2024 – 2032 (USD Million) 173

TABLE NO. 126. : Latin America Mining Pipe Market Volume, By Application, 2018 – 2023 (Thousand Tons) 174

TABLE NO. 127. : Latin America Mining Pipe Market Volume, By Application, 2024 – 2032 (Thousand Tons) 174

TABLE NO. 128. : Latin America Mining Pipe Market Revenue, By Application, 2018 – 2023 (USD Million) 175

TABLE NO. 129. : Latin America Mining Pipe Market Revenue, By Application, 2024 – 2032 (USD Million) 175

TABLE NO. 130. : Middle East Mining Pipe Market Volume, By Country, 2018 – 2023 (Thousand Tons) 178

TABLE NO. 131. : Middle East Mining Pipe Market Volume, By Country, 2024 – 2032 (Thousand Tons) 178

TABLE NO. 132. : Middle East Mining Pipe Market Revenue, By Country, 2018 – 2023 (USD Million) 179

TABLE NO. 133. : Middle East Mining Pipe Market Revenue, By Country, 2024 – 2032 (USD Million) 179

TABLE NO. 134. : Middle East Mining Pipe Market Volume, By Product Type, 2018 – 2023 (Thousand Tons) 180

TABLE NO. 135. : Middle East Mining Pipe Market Volume, By Product Type, 2024 – 2032 (Thousand Tons) 180

TABLE NO. 136. : Middle East Mining Pipe Market Revenue, By Product Type, 2018 – 2023 (USD Million) 181

TABLE NO. 137. : Middle East Mining Pipe Market Revenue, By Product Type, 2024 – 2032 (USD Million) 181

TABLE NO. 138. : Middle East Mining Pipe Market Volume, By Material Type, 2018 – 2023 (Thousand Tons) 182

TABLE NO. 139. : Middle East Mining Pipe Market Volume, By Material Type, 2024 – 2032 (Thousand Tons) 182

TABLE NO. 140. : Middle East Mining Pipe Market Revenue, By Material Type, 2018 – 2023 (USD Million) 183

TABLE NO. 141. : Middle East Mining Pipe Market Revenue, By Material Type, 2024 – 2032 (USD Million) 183

TABLE NO. 142. : Middle East Mining Pipe Market Volume, By Pipe Size, 2018 – 2023 (Thousand Tons) 184

TABLE NO. 143. : Middle East Mining Pipe Market Volume, By Pipe Size, 2024 – 2032 (Thousand Tons) 184

TABLE NO. 144. : Middle East Mining Pipe Market Revenue, By Pipe Size, 2018 – 2023 (USD Million) 185

TABLE NO. 145. : Middle East Mining Pipe Market Revenue, By Pipe Size, 2024 – 2032 (USD Million) 185

TABLE NO. 146. : Middle East Mining Pipe Market Volume, By Application, 2018 – 2023 (Thousand Tons) 186

TABLE NO. 147. : Middle East Mining Pipe Market Volume, By Application, 2024 – 2032 (Thousand Tons) 186

TABLE NO. 148. : Middle East Mining Pipe Market Revenue, By Application, 2018 – 2023 (USD Million) 187

TABLE NO. 149. : Middle East Mining Pipe Market Revenue, By Application, 2024 – 2032 (USD Million) 187

TABLE NO. 150. : Africa Mining Pipe Market Volume, By Country, 2018 – 2023 (Thousand Tons) 190

TABLE NO. 151. : Africa Mining Pipe Market Volume, By Country, 2024 – 2032 (Thousand Tons) 190

TABLE NO. 152. : Africa Mining Pipe Market Revenue, By Country, 2018 – 2023 (USD Million) 191

TABLE NO. 153. : Africa Mining Pipe Market Revenue, By Country, 2024 – 2032 (USD Million) 191

TABLE NO. 154. : Africa Mining Pipe Market Volume, By Product Type, 2018 – 2023 (Thousand Tons) 192

TABLE NO. 155. : Africa Mining Pipe Market Volume, By Product Type, 2024 – 2032 (Thousand Tons) 192

TABLE NO. 156. : Africa Mining Pipe Market Revenue, By Product Type, 2018 – 2023 (USD Million) 193

TABLE NO. 157. : Africa Mining Pipe Market Revenue, By Product Type, 2024 – 2032 (USD Million) 193

TABLE NO. 158. : Africa Mining Pipe Market Volume, By Material Type, 2018 – 2023 (Thousand Tons) 194

TABLE NO. 159. : Africa Mining Pipe Market Volume, By Material Type, 2024 – 2032 (Thousand Tons) 194

TABLE NO. 160. : Africa Mining Pipe Market Revenue, By Material Type, 2018 – 2023 (USD Million) 195

TABLE NO. 161. : Africa Mining Pipe Market Revenue, By Material Type, 2024 – 2032 (USD Million) 195

TABLE NO. 162. : Africa Mining Pipe Market Volume, By Pipe Size, 2018 – 2023 (Thousand Tons) 196

TABLE NO. 163. : Africa Mining Pipe Market Volume, By Pipe Size, 2024 – 2032 (Thousand Tons) 196

TABLE NO. 164. : Africa Mining Pipe Market Revenue, By Pipe Size, 2018 – 2023 (USD Million) 197

TABLE NO. 165. : Africa Mining Pipe Market Revenue, By Pipe Size, 2024 – 2032 (USD Million) 197

TABLE NO. 166. : Africa Mining Pipe Market Volume, By Application, 2018 – 2023 (Thousand Tons) 198

TABLE NO. 167. : Africa Mining Pipe Market Volume, By Application, 2024 – 2032 (Thousand Tons) 198

TABLE NO. 168. : Africa Mining Pipe Market Revenue, By Application, 2018 – 2023 (USD Million) 199

TABLE NO. 169. : Africa Mining Pipe Market Revenue, By Application, 2024 – 2032 (USD Million) 199