| REPORT ATTRIBUTE |

DETAILS |

| Historical Period |

2020-2023 |

| Base Year |

2024 |

| Forecast Period |

2025-2032 |

| Robot Precision Strain Wave Gear Market Size 2024 |

USD 1,461.04 million |

| Robot Precision Strain Wave Gear Market, CAGR |

9.38% |

| Robot Precision Strain Wave Gear Market Size 2032 |

USD 3,148.37 million |

Market Overview

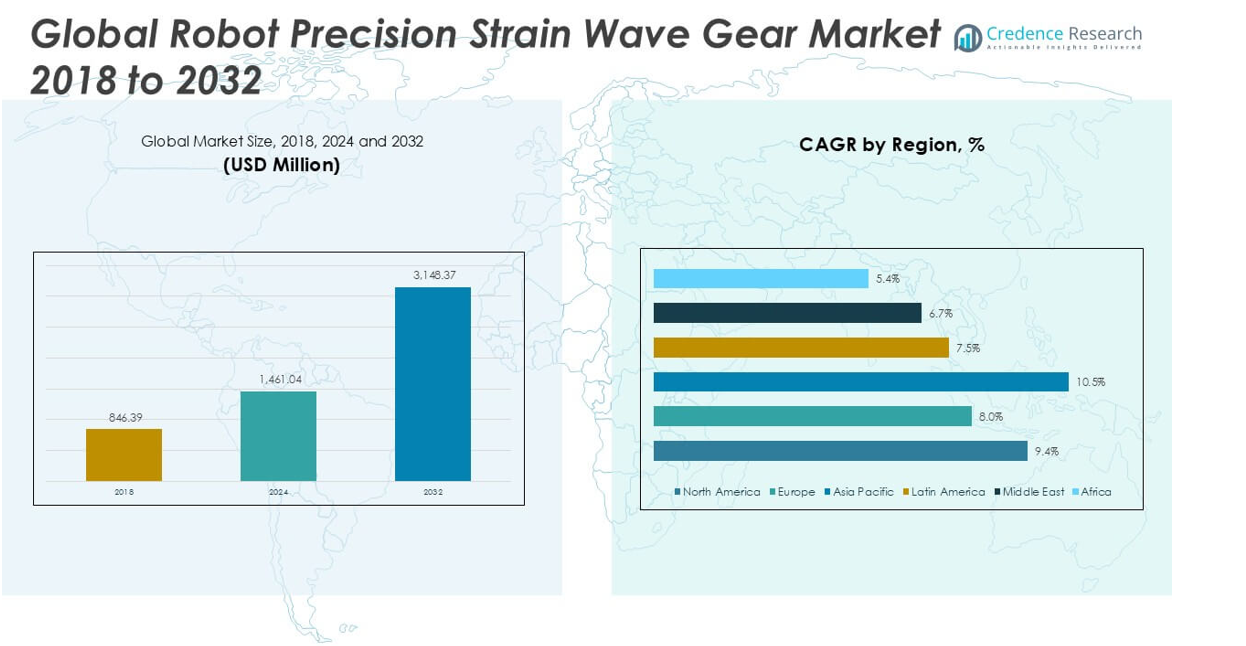

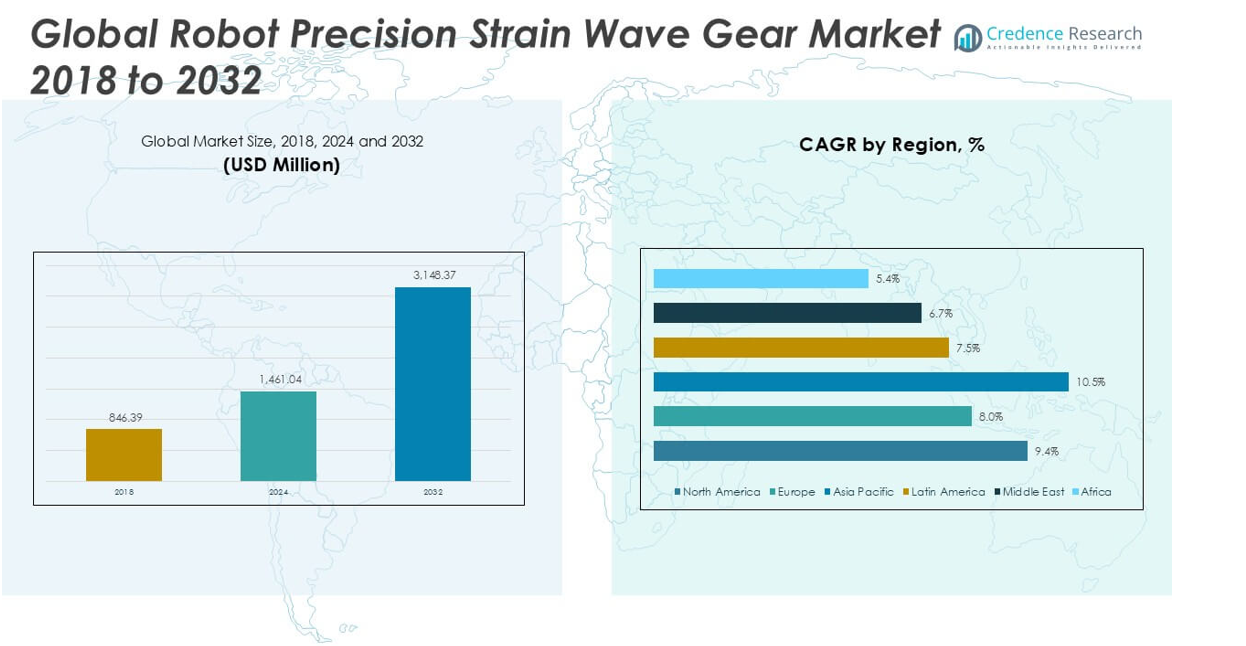

The Robot Precision Strain Wave Gear Market was valued at USD 846.39 million in 2018 and grew to USD 1,461.04 million in 2024. It is anticipated to reach USD 3,148.37 million by 2032, reflecting a compound annual growth rate (CAGR) of 9.38% during the forecast period.

The Robot Precision Strain Wave Gear Market is driven by the growing demand for compact, lightweight, and high-torque transmission systems in robotics and automation. Increased deployment of industrial robots across automotive, electronics, and manufacturing sectors is accelerating market growth. These gears enable precise motion control, making them essential in robotic arms and humanoid robots. Advancements in automation, AI integration, and collaborative robotics are further expanding their adoption. The market benefits from rising investments in smart factories and Industry 4.0 initiatives, where efficiency and precision are critical. Trends indicate a shift toward miniaturized gear systems to meet space constraints in compact robotic platforms. Additionally, technological innovations such as the use of advanced materials and 3D printing in gear production are enhancing durability and performance. Growing focus on energy efficiency and reduced maintenance is also encouraging manufacturers to adopt strain wave gear systems, positioning them as vital components in next-generation robotics.

The geographical analysis of the Robot Precision Strain Wave Gear Market highlights strong growth across North America, Europe, and Asia Pacific, with Asia Pacific leading in industrial robot deployment due to advanced manufacturing hubs in China, Japan, and South Korea. North America remains a major contributor, supported by technological advancements and automation in automotive and aerospace sectors. Europe shows steady growth driven by industrial automation and precision engineering, particularly in Germany and France. Key players in this market include Harmonic Drive Systems, known for its innovative gear solutions across robotics and aerospace; Leaderdrive, a prominent Chinese manufacturer offering cost-effective strain wave gears; and Nidec-Shimpo, which supplies compact, high-performance gear units for industrial applications. Shenzhen Han’s Motion Technology also plays a vital role with its focus on intelligent motion control products. These companies are shaping the market through investments in R&D, partnerships, and product innovation tailored to evolving robotic demands.

Market Insights

- The Robot Precision Strain Wave Gear Market was valued at USD 846.39 million in 2018 and reached USD 1,461.04 million in 2024; it is projected to reach USD 3,148.37 million by 2032, growing at a CAGR of 9.38% during the forecast period.

- Rising demand for high-precision motion control in robotic systems used in automotive, electronics, and manufacturing sectors is driving market expansion.

- Increasing adoption of collaborative robots, miniaturization of gear systems, and integration of AI in robotics are shaping new growth opportunities.

- Key players such as Harmonic Drive Systems, Leaderdrive, and Nidec-Shimpo dominate the market through innovative gear technologies and expanding global footprints.

- High manufacturing costs, complex gear design requirements, and limited load capacity in heavy-duty applications remain key restraints to widespread adoption.

- Asia Pacific leads the market with strong demand from China, Japan, and South Korea, while North America and Europe follow with stable growth in automation and industrial robotics.

- Technological advancements in material science and 3D printing are enabling manufacturers to produce lighter, more durable, and high-efficiency gear units.

Access crucial information at unmatched prices!

Request your sample report today & start making informed decisions powered by Credence Research Inc.!

Download Sample

Market Drivers

Rising Demand for High-Precision Robotic Systems Across Industrial Applications

The Robot Precision Strain Wave Gear Market is expanding due to increasing demand for high-precision robotics in automotive, electronics, and manufacturing industries. These sectors require compact and efficient motion control solutions that offer high torque, accuracy, and low backlash. Precision strain wave gears enable smooth and controlled robotic movement, critical for tasks such as welding, assembly, and pick-and-place operations. The shift toward automation in large-scale production lines has amplified the use of such components in robotic arms and actuators. Companies are prioritizing efficiency, and the integration of these gears improves repeatability and operational accuracy. It plays a central role in achieving the mechanical precision necessary for modern industrial robotics.

- For instance, Harmonic Drive Systems’ SHG-25-100-2SH gearhead delivers rated torque up to 274 Nm and maximum momentary torque of 686 Nm, with positional accuracy within ±20 arc-seconds.

Advancement in Collaborative Robots and Miniaturization Trends

The adoption of collaborative robots, or cobots, is pushing demand for lighter and smaller strain wave gears. Cobots operate in human environments and require precise, responsive, and compact transmission systems. The Robot Precision Strain Wave Gear Market benefits from this trend by delivering gear solutions that optimize performance without increasing system weight or size. As industries transition to space-saving automation tools, strain wave gears offer a reliable solution that meets both physical and operational constraints. It supports applications where traditional gearboxes are too bulky or less accurate. Enhanced safety, efficiency, and flexibility in human-robot collaboration further strengthen the gear’s market position.

- For instance, Nidec-Shimpo’s F3C-50S strain wave reducer measures just 50 mm in diameter and supports up to 30 Nm of rated torque, ideal for 6-axis cobots handling payloads up to 7 kg.

Integration of Smart Technologies and Industry 4.0 Frameworks

Smart manufacturing and Industry 4.0 frameworks are fueling the integration of strain wave gears in intelligent robotic systems. These systems demand components that ensure accuracy, responsiveness, and real-time adaptability. The Robot Precision Strain Wave Gear Market aligns well with these requirements, offering low-maintenance, energy-efficient, and durable options. Advanced gear design contributes to higher machine uptime and improved process control in automated environments. It enables seamless coordination between robotic functions and digital control systems. The increasing need for integrated, sensor-driven robotics accelerates the demand for precise and compact gear solutions.

Rising Investments in Medical and Service Robotics

Expanding applications in medical, service, and personal assistance robots are influencing the market positively. These robots require highly precise, silent, and compact transmission systems to perform sensitive and repetitive tasks. The Robot Precision Strain Wave Gear Market is gaining traction in this domain due to its capability to meet strict performance and safety requirements. Medical robotics in surgical and rehabilitation fields rely on these gears for reliable and smooth actuation. It offers long service life and minimal maintenance, aligning with the needs of healthcare environments. Government and private sector investments in non-industrial robotics are further accelerating market penetration.

Market Trends

Shift Toward Lightweight and Compact Gear Designs for Robotic Efficiency

Manufacturers are increasingly focusing on lightweight and compact gear systems to meet the evolving needs of modern robotics. Robotics applications, particularly in mobile platforms and collaborative robots, demand gear mechanisms that do not add bulk or weight. The Robot Precision Strain Wave Gear Market is adapting to this shift by offering miniaturized components with enhanced torque density. These designs allow for streamlined robotic structures without compromising performance or load capacity. It helps reduce energy consumption and increases mechanical efficiency. Compact strain wave gears are also easier to integrate into tight spaces, supporting versatile and adaptive robotic configurations.

- For instance, Leaderdrive’s LSS-20-100-2UH strain wave gear features a 20 mm outer diameter with rated torque output of 15 Nm and weighs only 280 grams, enabling its use in ultra-compact robotic joints.

Growing Use of Advanced Materials and Additive Manufacturing

The incorporation of advanced materials such as high-strength alloys, composites, and engineering plastics is becoming a key trend in gear manufacturing. These materials extend gear lifespan and improve thermal and mechanical properties under continuous operation. The Robot Precision Strain Wave Gear Market is seeing a rise in the use of additive manufacturing techniques, including 3D printing, to create lightweight and complex gear shapes. It enables design flexibility, faster prototyping, and customized solutions tailored for specific robotic applications. Enhanced material durability contributes to lower maintenance requirements and operational reliability. This trend supports the industry’s move toward sustainable and cost-effective production methods.

- For instance, Zhejiang Laifual’s LHT-14A pancake gear has an axial height of 24 mm and outputs rated torque of 8.2 Nm with a 100:1 gear ratio, optimized for service robotics.

Integration of Gear Systems into AI-Driven Robotic Platforms

Strain wave gears are being integrated into robotics platforms powered by artificial intelligence and machine learning. AI-driven systems require precise and responsive motion control to adapt to dynamic environments and variable workloads. The Robot Precision Strain Wave Gear Market is evolving to support these intelligent applications through highly accurate transmission systems. It enables smooth robotic articulation, essential for applications such as autonomous navigation, object manipulation, and real-time adjustments. Improved feedback mechanisms and encoder compatibility are helping bridge mechanical and digital functionalities. This integration aligns with the broader trend of smarter, more autonomous robotic solutions.

Expansion of Consumer Robotics and Personal Assistance Devices

The rapid growth of consumer robotics is influencing the demand for quiet, compact, and efficient strain wave gears. Applications such as home assistance robots, robotic vacuum cleaners, and interactive devices require smooth and precise movement. The Robot Precision Strain Wave Gear Market is responding with solutions designed for reliability and ease of use in domestic settings. It supports quiet operation, minimal maintenance, and long service cycles—factors critical to consumer adoption. Developers are prioritizing ergonomic designs and user-friendly features that integrate seamlessly into daily life. This trend opens new commercial pathways beyond traditional industrial robotics.

Market Challenges Analysis

High Manufacturing Costs and Material Complexity Limit Widespread Adoption

The precision required to manufacture strain wave gears demands advanced equipment, skilled labor, and premium materials, leading to elevated production costs. High-precision tolerances and intricate gear geometries often require multi-stage machining processes and stringent quality checks. The Robot Precision Strain Wave Gear Market faces challenges in scaling production without compromising performance standards. It limits adoption in cost-sensitive industries and startups where affordability is a primary concern. Limited availability of specialized raw materials further inflates procurement costs. These factors collectively hinder broader market penetration, especially in emerging economies and low-budget applications.

Design Limitations and Load Capacity Constraints Affect Broader Utility

Strain wave gears offer high precision and compactness but come with load-bearing and durability limitations in certain high-torque or shock-load applications. Their flexibility-based operating principle can lead to deformation under extreme stress, reducing accuracy and lifespan. The Robot Precision Strain Wave Gear Market must address concerns related to overloading, wear resistance, and dynamic response. It restricts their use in heavy-duty industrial machinery or harsh operating environments. Engineers must often add supplementary mechanisms to enhance load support, increasing system complexity and size. These technical constraints limit their applicability across a wider range of robotic and automation systems.

Market Opportunities

Emerging Demand in Service, Medical, and Personal Robotics Expands Market Reach

The global rise of service and medical robotics presents strong growth potential for strain wave gear applications. Robots used in surgical assistance, rehabilitation, and elderly care require compact, precise, and quiet transmission systems. The Robot Precision Strain Wave Gear Market can tap into this expanding sector by offering customized solutions that meet safety, sterility, and ergonomic requirements. It supports smooth and accurate actuation essential for patient-facing tasks. The growing acceptance of robotics in home and healthcare settings creates new avenues for gear integration. Investment in non-industrial robotic platforms is expected to generate steady long-term demand.

Advancements in Smart Manufacturing and Robotics-as-a-Service (RaaS) Models

The increasing adoption of smart manufacturing and the rise of RaaS platforms provide a favorable environment for gear market expansion. Companies are shifting toward flexible automation systems that require durable, responsive, and compact motion control components. The Robot Precision Strain Wave Gear Market stands to benefit from these models by supplying essential components for scalable and efficient robotic operations. It aligns with modular robotic platforms that prioritize ease of maintenance and long-term performance. Integration with real-time monitoring systems and predictive maintenance tools enhances gear lifecycle management. These trends create sustained opportunities for gear manufacturers across industrial and commercial sectors.

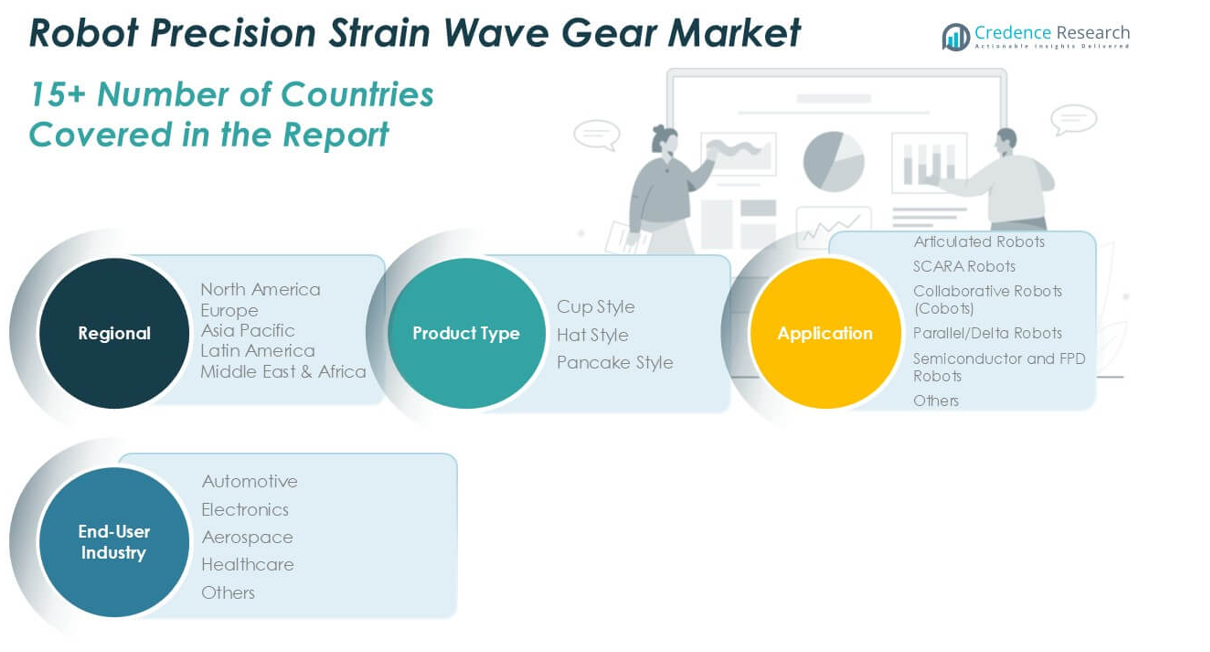

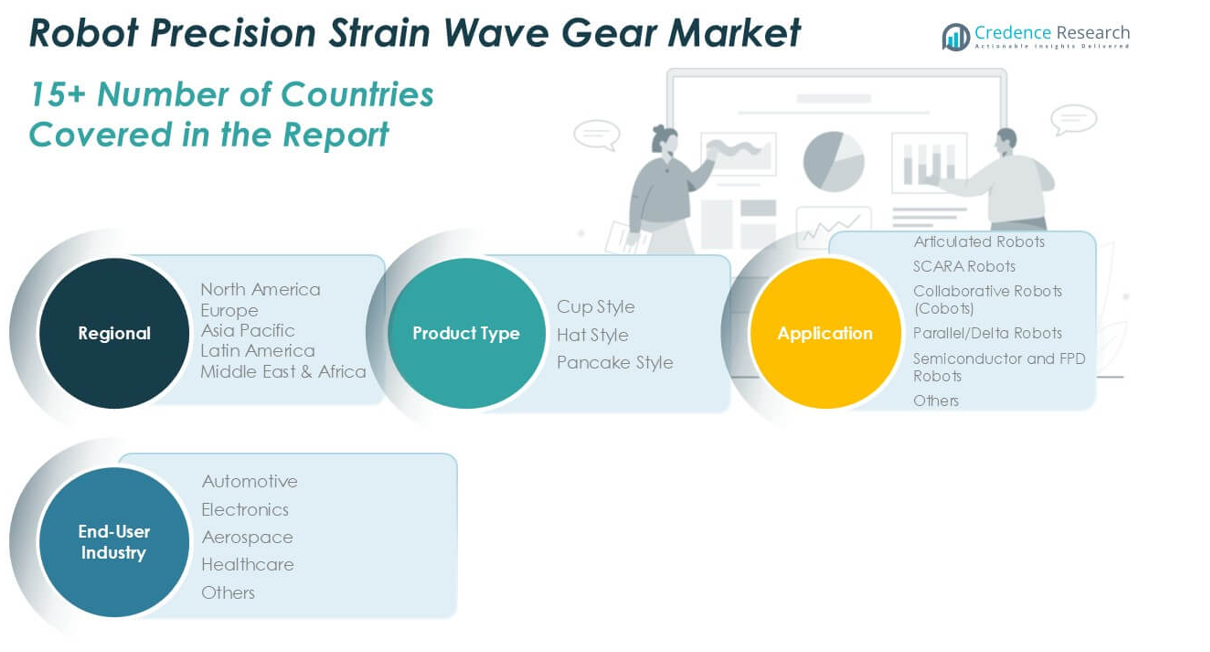

Market Segmentation Analysis:

By Product Type:

Cup style gears dominate the market due to their superior torque capacity, compact structure, and high stiffness. These features make them ideal for high-performance industrial and collaborative robots. Hat style gears hold a moderate share, often used in applications requiring lower axial dimensions while maintaining precision. Pancake style gears are gaining attention in compact robotic platforms where axial space is limited. The Robot Precision Strain Wave Gear Market benefits from growing demand for lightweight and space-saving transmission components across all product types. It supports specialized applications by offering varied formats to match unique dimensional and load requirements.

- For instance, Zhejiang Laifual’s LHT-14A pancake gear has an axial height of 24 mm and outputs rated torque of 8.2 Nm with a 100:1 gear ratio, optimized for service robotics.

By Application:

Articulated robots represent the largest application segment, driven by their widespread use in manufacturing and assembly operations. SCARA robots follow, used extensively in electronics and packaging industries for high-speed and repetitive tasks. Collaborative robots (cobots) are expanding rapidly, supported by their integration into human workspaces and need for precise motion control. Parallel/Delta robots are used in high-speed pick-and-place operations, primarily in food processing and pharmaceuticals. Semiconductor and FPD robots require extremely accurate and vibration-free movement, driving demand for precision strain wave gears. It enables consistent performance across varied robotic configurations, enhancing productivity and accuracy.

- For instance, Beijing CTKM’s harmonic drive series CT-17H is used in semiconductor handling robots and achieves positioning repeatability of ±3 μm and rated torque of 10 Nm in Class 10 cleanroom environments.

By End-User Industry:

The automotive sector leads in end-user adoption due to the high volume of automation and assembly processes. Electronics manufacturing is a fast-growing segment, driven by precision requirements in component placement and inspection tasks. Aerospace applications are increasing due to the need for lightweight, precise, and durable robotic components in maintenance and manufacturing. Healthcare is emerging as a key sector, with robots used in surgery, diagnostics, and rehabilitation requiring highly reliable actuation. The Robot Precision Strain Wave Gear Market supports this diversity with adaptable gear solutions for each industry. It provides high precision, low backlash, and compactness—critical attributes across both traditional and emerging end-user segments.

Segments:

Based on Product Type:

- Cup Style

- Hat Style

- Pancake Style

Based on Application:

- Articulated Robots

- SCARA Robots

- Collaborative Robots (Cobots)

- Parallel/Delta Robots

- Semiconductor and FPD Robots

- Others

Based on End-User Industry:

- Automotive

- Electronics

- Aerospace

- Healthcare

- Others

Based on the Geography:

- North America

- Europe

- UK

- France

- Germany

- Italy

- Spain

- Russia

- Belgium

- Netherlands

- Austria

- Sweden

- Poland

- Denmark

- Switzerland

- Rest of Europe

- Asia Pacific

- China

- Japan

- South Korea

- India

- Australia

- Thailand

- Indonesia

- Vietnam

- Malaysia

- Philippines

- Taiwan

- Rest of Asia Pacific

- Latin America

- Brazil

- Argentina

- Peru

- Chile

- Colombia

- Rest of Latin America

- Middle East

- UAE

- KSA

- Israel

- Turkey

- Iran

- Rest of Middle East

- Africa

- Egypt

- Nigeria

- Algeria

- Morocco

- Rest of Africa

Regional Analysis

North America Robot Precision Strain Wave Gear Market

North America Robot Precision Strain Wave Gear Market grew from USD 361.79 million in 2018 to USD 617.89 million in 2024 and is projected to reach USD 1,335.27 million by 2032, reflecting a compound annual growth rate (CAGR) of 9.4%. North America is holding a 28.2% market share. The U.S. dominates the regional market due to high investments in industrial automation, robotics in automotive manufacturing, and defense applications. Canada and Mexico contribute to market expansion through rising adoption of smart factories and collaborative robots. Strong presence of robotic system integrators and gear manufacturers supports regional growth. It benefits from advanced infrastructure, strong R&D capabilities, and high automation readiness.

Europe Robot Precision Strain Wave Gear Market

Europe Robot Precision Strain Wave Gear Market grew from USD 151.04 million in 2018 to USD 245.78 million in 2024 and is projected to reach USD 479.25 million by 2032, reflecting a CAGR of 8.0%. Europe is holding a 10.4% market share. Germany leads the regional market, followed by France and the UK, driven by strong automation in automotive and aerospace sectors. Growth is supported by EU-led Industry 4.0 initiatives and demand for precision motion systems in manufacturing. High emphasis on energy efficiency and compact robotic systems drives the need for strain wave gears. It finds increasing usage in robotic assembly lines and warehouse automation.

Asia Pacific Robot Precision Strain Wave Gear Market

Asia Pacific Robot Precision Strain Wave Gear Market grew from USD 266.91 million in 2018 to USD 484.30 million in 2024 and is projected to reach USD 1,130.64 million by 2032, reflecting a CAGR of 10.5%. Asia Pacific is holding a 33.6% market share. China, Japan, and South Korea are leading countries in industrial robot deployment, supported by robust electronics and automotive sectors. Government policies in China and Japan promote domestic robotic production and integration of precision gear systems. The region benefits from strong manufacturing bases, competitive costs, and large-scale production facilities. It serves as a central hub for both demand and supply in the gear and robotics ecosystem.

Latin America Robot Precision Strain Wave Gear Market

Latin America Robot Precision Strain Wave Gear Market grew from USD 34.99 million in 2018 to USD 59.54 million in 2024 and is projected to reach USD 111.43 million by 2032, reflecting a CAGR of 7.5%. Latin America is holding a 2.4% market share. Brazil and Mexico lead the region with increasing automation in electronics and automotive industries. Infrastructure modernization and gradual adoption of robotic solutions in industrial applications support market growth. It faces challenges in terms of high costs and limited technical workforce, but government incentives and foreign investments are fostering gradual market development. The region presents long-term potential for gear manufacturers expanding into emerging markets.

Middle East Robot Precision Strain Wave Gear Market

Middle East Robot Precision Strain Wave Gear Market grew from USD 21.35 million in 2018 to USD 33.35 million in 2024 and is projected to reach USD 59.26 million by 2032, reflecting a CAGR of 6.7%. The Middle East is holding a 1.3% market share. The UAE and Saudi Arabia are key contributors, investing in automation technologies within oil & gas, defense, and healthcare sectors. Robotics is being integrated into logistics and infrastructure projects, which fuels demand for compact and efficient gears. It supports modernization efforts across key industrial applications. Economic diversification strategies under initiatives like Saudi Vision 2030 are driving industrial automation and smart technology adoption.

Africa Robot Precision Strain Wave Gear Market

Africa Robot Precision Strain Wave Gear Market grew from USD 10.31 million in 2018 to USD 20.17 million in 2024 and is projected to reach USD 32.51 million by 2032, reflecting a CAGR of 5.4%. Africa is holding a 0.7% market share. South Africa leads the region, followed by Egypt and Nigeria, with a growing presence of manufacturing and mining automation. Limited industrial infrastructure and high cost of advanced robotics slow growth, but targeted government policies are encouraging digital transformation. It finds opportunities in sectors like agriculture, packaging, and healthcare where basic automation gains traction. Foreign investments and regional partnerships are expected to improve future demand.

Shape Your Report to Specific Countries or Regions & Enjoy 30% Off!

Key Player Analysis

- Harmonic Drive Systems

- Leaderdrive

- Zhejiang Laifual

- Shenzhen Han’s Motion Technology

- Nidec-Shimpo

- KOFON

- Beijing CTKM Harmonic Drive

- BENRUN Robot

- BHDI

- Too Eph Transmission Technology

Competitive Analysis

The Robot Precision Strain Wave Gear Market features a competitive landscape driven by innovation, product performance, and strategic global expansion. Leading players include Harmonic Drive Systems, Leaderdrive, Nidec-Shimpo, Shenzhen Han’s Motion Technology, Zhejiang Laifual, KOFON, and Beijing CTKM Harmonic Drive. Harmonic Drive Systems holds a dominant position through its advanced precision gear technology and long-standing presence in robotics and aerospace sectors. Leaderdrive continues to strengthen its footprint in China by offering cost-effective and high-performance alternatives, supported by strong domestic demand. Manufacturers compete by developing customized gear solutions optimized for specific robotic configurations, including articulated arms, SCARA robots, and cobots. Continuous investment in research and development enables firms to improve material durability, reduce backlash, and enhance energy efficiency. Players are also leveraging advanced manufacturing techniques, including additive manufacturing and automated assembly, to improve production scalability and reduce costs. Geographic expansion through strategic alliances, local distribution networks, and international partnerships remains a key approach to accessing high-growth regions like Asia Pacific and North America. In addition to technical superiority, companies prioritize fast lead times and responsive support services to maintain strong client relationships. Competitive success in this market depends on a company’s ability to deliver performance-driven, cost-effective, and application-specific solutions across diverse robotic use cases.

Recent Developments

- In January 2025, KOFON highlighted the integration of advanced strain wave gears in multi-axis robot power units, specifically in the wrist axis of 2-axis robots for routing inspection tasks. Their KSBG-SO Simplicity Box series features a robust crossed roller bearing for improved tilting moment resistance, modularity for easy maintenance, and optimized spiral bevel gear engagement for noise reduction and durability

- In Dec 2024, Nidec-Shimpo Released the Smart-FLEXWAVE, integrating next-generation Nidec FLEXWAVE sensing technology with strain wave gear reduction mechanisms. This product is positioned as the world’s lightest precision strain wave gear, targeting robotics and automation sectors with enhanced performance and integrated sensing for condition monitoring.

Market Concentration & Characteristics

The Robot Precision Strain Wave Gear Market shows moderate to high market concentration, with a few established manufacturers holding significant shares due to their proprietary technologies and long-standing expertise in precision motion control. It is characterized by high entry barriers, including complex engineering requirements, advanced production capabilities, and stringent quality standards. Most companies focus on niche applications, offering tailored gear solutions for specific robotic systems such as articulated robots, cobots, and semiconductor automation. The market emphasizes precision, compactness, and low backlash, making reliability and technical performance key differentiators. It remains innovation-driven, with continuous investments in material science, lightweight design, and digital integration. Customer relationships often span long-term contracts, particularly in industrial and medical robotics, where failure tolerance is minimal. The demand for compact and efficient actuators supports specialization, and most suppliers operate through vertically integrated models to maintain quality control and production efficiency. Regional clusters of production and innovation particularly in Japan, China, and Germany define the competitive dynamics, shaping product availability and pricing across global markets

Report Coverage

The research report offers an in-depth analysis based on Product Type, Application, End-User Industry and Geography. It details leading market players, providing an overview of their business, product offerings, investments, revenue streams, and key applications. Additionally, the report includes insights into the competitive environment, SWOT analysis, current market trends, as well as the primary drivers and constraints. Furthermore, it discusses various factors that have driven market expansion in recent years. The report also explores market dynamics, regulatory scenarios, and technological advancements that are shaping the industry. It assesses the impact of external factors and global economic changes on market growth. Lastly, it provides strategic recommendations for new entrants and established companies to navigate the complexities of the market.

Future Outlook

- The Robot Precision Strain Wave Gear Market will continue to expand through rising adoption of collaborative and service robots.

- Manufacturers will focus on developing gears with higher torque density and reduced backlash to meet precision demands.

- Emerging materials and coatings will enhance gear durability and resistance to wear and temperature variations.

- Integration with smart sensors and condition monitoring systems will improve predictive maintenance capabilities.

- Miniaturization efforts will produce even more compact gear units for space-constrained robotic applications.

- Robotics-as-a-Service (RaaS) deployment will drive demand for modular, plug-and-play gear solutions.

- Adoption of additive manufacturing techniques will enable fast prototyping and custom gear designs.

- Regional growth in Asia Pacific will accelerate due to expansion in electronics and automotive automation.

- Collaborative efforts between gear suppliers and robotics OEMs will yield tailored gear-actuator systems.

- Regulatory trends toward safety and sustainability will pressure companies to innovate in eco-friendly gear designs.