Market Overview

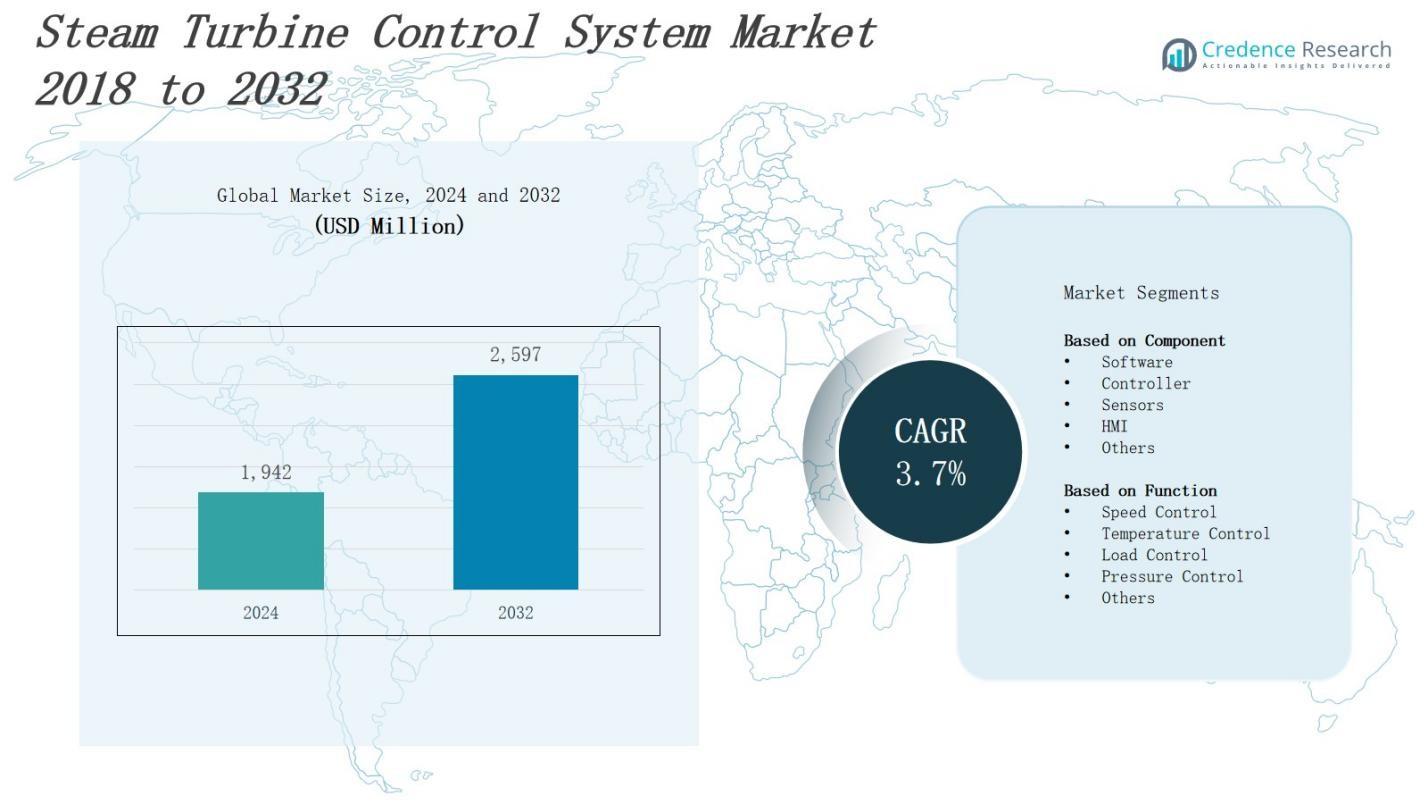

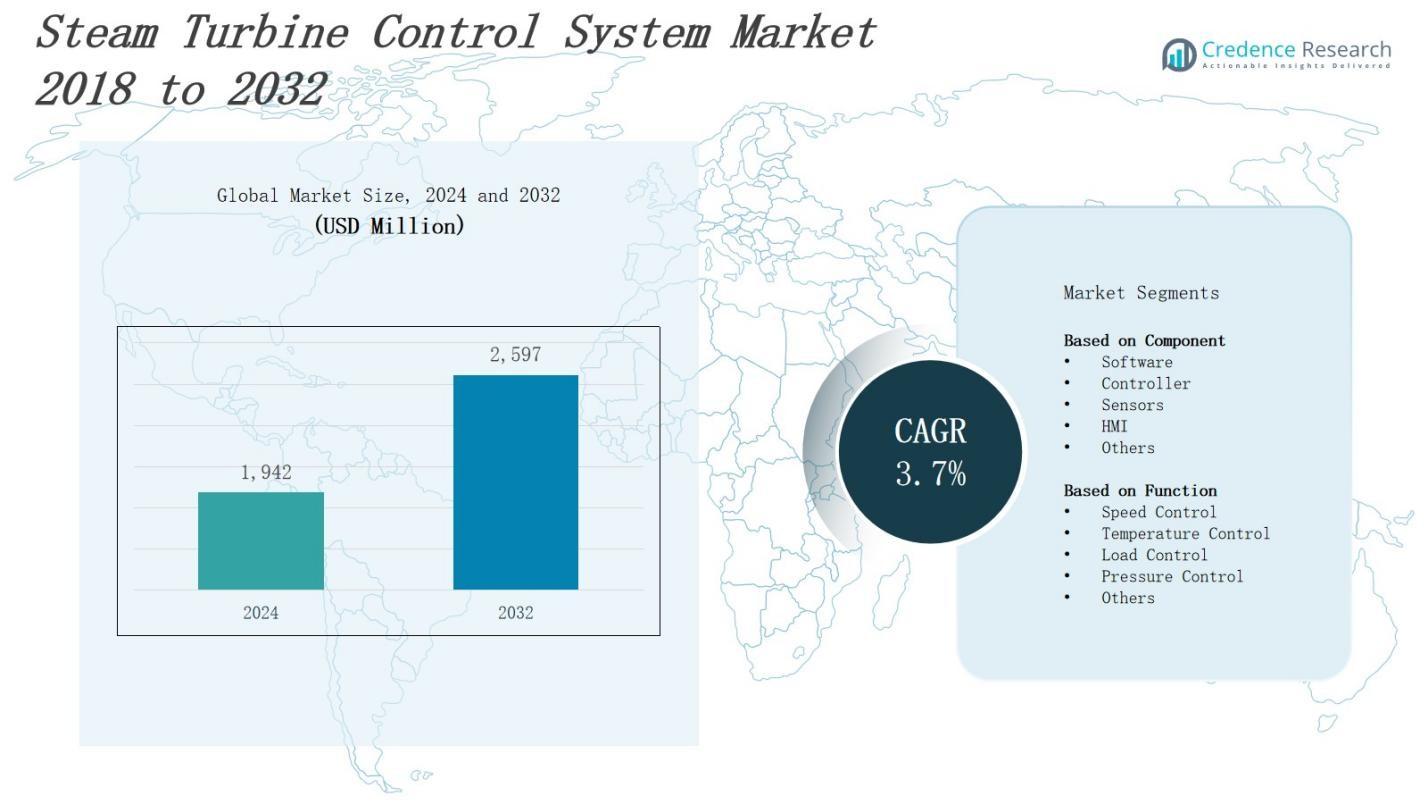

The Steam Turbine Control System Market is projected to grow from USD 1,942 million in 2024 to USD 2,597 million by 2032, registering a compound annual growth rate (CAGR) of 3.7%.

| REPORT ATTRIBUTE |

DETAILS |

| Historical Period |

2020-2024 |

| Base Year |

2024 |

| Forecast Period |

2025-2032 |

| Steam Turbine Control System Market Size 2024 |

USD 1,942 Million |

| Steam Turbine Control System Market, CAGR |

3.7% |

| Steam Turbine Control System Market Size 2032 |

USD 2,597 Million |

The steam turbine control system market advances as industries prioritize enhanced operational efficiency and reliability in power generation. Growing demand for automation and real-time monitoring drives the integration of advanced digital control technologies. Regulatory mandates targeting energy efficiency and emission reduction further accelerate adoption. Additionally, modernization initiatives in aging power plants and expanding renewable energy integration create opportunities for advanced control solutions. Manufacturers focus on improving system precision, fault diagnostics, and predictive maintenance capabilities to reduce downtime and maintenance costs. These trends collectively support steady market growth by addressing the evolving needs of energy producers globally.

The steam turbine control system market spans key regions including North America, Europe, Asia-Pacific, and the Rest of the World, each contributing significantly to global growth. North America leads with advanced infrastructure, followed by Europe’s strong focus on emission reduction and energy transition. Asia-Pacific drives expansion through rapid industrialization and power infrastructure development, while emerging markets in Latin America, the Middle East, and Africa in the Rest of the World offer growth opportunities. Leading players such as Siemens Energy, General Electric, ABB, Schneider Electric, and Honeywell International dominate the competitive landscape globally.

Access crucial information at unmatched prices!

Request your sample report today & start making informed decisions powered by Credence Research Inc.!

Download Sample

Market Insights

- The steam turbine control system market is projected to grow from USD 1,942 million in 2024 to USD 2,597 million by 2032, with a CAGR of 3.7%.

- Growing demand for automation and real-time monitoring drives the integration of advanced digital control technologies, enhancing operational efficiency and reliability in power generation.

- Regulatory mandates focused on energy efficiency and emission reduction accelerate the adoption of sophisticated turbine control solutions.

- Modernization of aging power plants and increasing renewable energy integration create opportunities for advanced control system deployment.

- The market spans North America, Europe, Asia-Pacific, and the Rest of the World, with North America leading due to mature infrastructure and strong digital adoption.

- Asia-Pacific experiences rapid growth from industrialization and infrastructure development, while Europe emphasizes emission reduction and energy transition policies.

- Challenges include high initial investment, complex integration processes, cybersecurity risks, and the need for skilled maintenance personnel, affecting market adoption and reliability.

Market Drivers

Rising Demand for Efficient Power Generation

The steam turbine control system market experiences growth due to the increasing need for efficient and reliable power generation. Industries such as energy, manufacturing, and utilities require precise control to optimize turbine performance and reduce fuel consumption. Enhanced control systems improve operational stability, enabling plants to meet growing electricity demand with minimal wastage. It supports seamless integration with combined cycle and cogeneration power plants, further boosting efficiency. The market benefits from expanding industrialization and electrification, which drive continuous upgrades in power infrastructure. Efficient energy production remains a critical priority for utilities globally.

- For instance, Mitsubishi Power improved its steam turbine control system to enhance operational stability, enabling combined cycle plants to achieve higher efficiency with lower emissions.

Technological Advancements and Digital Integration

Technological innovation fuels market expansion through the incorporation of automation, IoT, and real-time monitoring in steam turbine control systems. These advancements enable precise turbine regulation and fault detection, minimizing downtime and maintenance costs. The integration of predictive analytics enhances decision-making for plant operators, increasing system reliability. Digital control systems replace conventional analog technologies, offering improved scalability and flexibility. Manufacturers invest heavily in developing intelligent control solutions that optimize turbine output and support remote operations. It leads to higher operational efficiency and reduced lifecycle costs.

- For instance, Woodward’s Peak® 150 digital control system provides tight speed regulation for steam turbines with remote input capabilities, improving operational precision.

Regulatory Focus on Energy Efficiency and Emission Reduction

Stringent government regulations targeting energy efficiency and environmental sustainability drive adoption of advanced control systems. The steam turbine control system market responds to regulatory pressures by delivering solutions that help plants reduce greenhouse gas emissions and meet emission limits. Control systems improve fuel utilization, supporting cleaner and more sustainable power generation. Regulatory incentives encourage utilities to upgrade legacy systems to modern, compliant technologies. Meeting environmental standards becomes a priority for power producers aiming to avoid penalties and enhance corporate responsibility. It reinforces the demand for sophisticated turbine controls.

Modernization of Aging Power Infrastructure

Many power plants worldwide face aging infrastructure that requires modernization to maintain reliability and performance. The steam turbine control system market benefits from retrofitting projects aimed at upgrading legacy control equipment with advanced digital systems. Modern controls improve turbine responsiveness, operational safety, and ease of maintenance. Investments in refurbishment extend plant life while increasing output efficiency. Emerging economies, in particular, invest in infrastructure upgrades to meet growing energy demands. It creates consistent opportunities for market players to provide innovative control solutions and services tailored to retrofit needs.

Market Trends

Adoption of Advanced Digital Control Technologies

The steam turbine control system market increasingly embraces advanced digital control technologies that offer enhanced precision and flexibility. Digital systems replace traditional analog controls, providing improved data acquisition, real-time monitoring, and automation capabilities. It enables operators to optimize turbine performance, reduce human error, and execute predictive maintenance effectively. Enhanced communication protocols support seamless integration with plant-wide control networks. Manufacturers continue to innovate with scalable and customizable digital solutions that meet diverse operational requirements. This trend supports improved reliability and operational efficiency.

- For instance, Heinzmann’s CGC-ET digital governor integrates turbine speed control with generator functions such as synchronizing and load sharing, improving operational accuracy and diagnostic capabilities.

Integration of IoT and Remote Monitoring Solutions

Integration of Internet of Things (IoT) technologies and remote monitoring solutions drives significant changes within the steam turbine control system market. It allows continuous data collection from turbines and associated equipment, offering real-time insights into operational status and potential faults. Remote monitoring reduces the need for on-site inspections, lowering operational costs and enhancing safety. Predictive analytics based on IoT data improve maintenance scheduling and asset management. This connectivity supports faster decision-making and enhances overall system responsiveness to dynamic conditions.

- For instance, Yokogawa’s Wireless Steam Trap Monitoring Device uses LoRaWAN technology to wirelessly monitor steam trap conditions in industrial plants, allowing prompt maintenance actions, reducing failures, and improving energy efficiency.

Focus on Cybersecurity in Control Systems

Growing concerns about cybersecurity risks influence trends in the steam turbine control system market. Increased digitalization and network connectivity expose control systems to potential cyber threats, prompting manufacturers to prioritize robust cybersecurity measures. It involves implementing secure communication protocols, intrusion detection systems, and regular security audits to protect critical infrastructure. Operators demand solutions that safeguard data integrity and ensure uninterrupted operations. Strengthening cybersecurity enhances stakeholder confidence and complies with regulatory requirements for critical energy assets.

Expansion of Retrofit and Modernization Projects

Retrofit and modernization projects gain momentum as power plants seek to extend operational life and improve efficiency. The steam turbine control system market experiences growing demand for upgrading legacy controls with state-of-the-art digital systems. It improves turbine responsiveness, operational safety, and reduces maintenance complexity. Emerging economies actively pursue infrastructure modernization to support increasing power generation needs. Market players capitalize on this trend by offering tailored retrofit solutions and comprehensive support services. This approach maximizes existing asset value while improving performance.

Market Challenges Analysis

High Initial Investment and Integration Complexity

The steam turbine control system market faces challenges due to the high upfront costs associated with advanced control technologies. Implementing state-of-the-art digital and automation systems requires substantial capital expenditure, which can deter smaller power producers and industries. It demands skilled personnel for installation and integration with existing plant infrastructure, often leading to prolonged downtime during upgrades. Compatibility issues arise when retrofitting older turbines with modern control solutions, complicating the integration process. These factors increase project timelines and budgets, affecting adoption rates. Market participants must focus on cost-effective solutions and streamlined integration to overcome these barriers.

Cybersecurity Risks and Maintenance Requirements

Increasing reliance on digital and networked control systems exposes the steam turbine control system market to significant cybersecurity threats. Control systems become vulnerable to cyberattacks that can disrupt operations, compromise data integrity, and cause safety hazards. It necessitates continuous investment in cybersecurity measures, including secure protocols and real-time threat monitoring, which adds to operational costs. Furthermore, maintaining complex control systems requires specialized expertise to ensure consistent performance and prevent unexpected failures. The scarcity of skilled workforce in some regions limits efficient maintenance and troubleshooting. Addressing these challenges is crucial for sustaining market growth and system reliability.

Market Opportunities

Growing Demand for Renewable and Hybrid Power Integration

The steam turbine control system market benefits from increasing demand for renewable energy integration and hybrid power plants. It supports the efficient operation of combined cycle and cogeneration plants that combine steam turbines with renewable sources such as solar and biomass. This trend drives the need for flexible and adaptive control systems capable of managing variable power inputs while maintaining optimal turbine performance. Opportunities arise for manufacturers to develop specialized solutions tailored to hybrid configurations. Expanding renewable energy policies worldwide further accelerates investments in advanced control technologies. Market players can leverage this shift toward cleaner energy to enhance product offerings and capture new segments.

Expansion in Emerging Economies and Infrastructure Development

Emerging economies present significant growth opportunities for the steam turbine control system market due to ongoing industrialization and increasing electricity demand. Many countries invest in modernizing power generation infrastructure and upgrading aging plants to meet expanding energy needs. It creates a favorable environment for deploying advanced turbine control systems that improve efficiency and reliability. Government initiatives focused on energy security and sustainability support large-scale projects, driving market penetration. Companies that provide cost-effective retrofit solutions and localized support services can gain competitive advantage. Expanding presence in these high-growth regions remains a strategic priority for industry players.

Market Segmentation Analysis:

By Component

The steam turbine control system market divides into several key components including software, controllers, sensors, human-machine interfaces (HMI), and others. Software holds a critical role by enabling automation, data analysis, and system optimization, driving high adoption across industries. Controllers provide precise regulation of turbine operations, ensuring stability and performance. Sensors gather real-time data on temperature, pressure, and speed, supporting accurate control functions. HMIs facilitate user interaction and monitoring, enhancing operational efficiency. Each component contributes uniquely to system reliability and effectiveness, shaping the overall market dynamics.

- For instance, Siemens uses a fast digital processor, like the S7-416 Programmable Logic Controller, as the core of their steam turbine control system, which manages sensor data, executes open and closed loop control, and regulates valve actuators to ensure precise turbine speed, inlet pressure, and load control.

By Function

The steam turbine control system market segments by function into speed control, temperature control, load control, pressure control, and others. Speed control remains a primary function, maintaining turbine rotation within optimal ranges to ensure efficient power output. Temperature control safeguards equipment by managing heat levels, preventing damage and improving lifespan. Load control balances turbine output with demand fluctuations, optimizing energy distribution. Pressure control maintains system stability and safety by regulating steam pressure within required limits. These functions collectively enhance turbine performance and operational safety, reinforcing the market’s critical role in power generation.

- For example, GE’s steam turbines integrate temperature sensors with automated cooling adjustments to maintain optimal internal conditions and extend turbine life. Load control balances turbine output with demand fluctuations, optimizing energy distribution.

Segments:

Based on Component

- Software

- Controller

- Sensors

- HMI

- Others

Based on Function

- Speed Control

- Temperature Control

- Load Control

- Pressure Control

- Others

Based on the Geography:

- North America

- Europe

- Germany

- France

- U.K.

- Italy

- Spain

- Rest of Europe

- Asia Pacific

- China

- Japan

- India

- South Korea

- South-east Asia

- Rest of Asia Pacific

- Latin America

- Brazil

- Argentina

- Rest of Latin America

- Middle East & Africa

- GCC Countries

- South Africa

- Rest of the Middle East and Africa

Regional Analysis

North America

North America leads the steam turbine control system market with a significant market share of 32%. The region benefits from a mature power generation infrastructure and strong adoption of advanced digital control technologies. Utilities and industrial sectors invest heavily in upgrading legacy systems to improve efficiency and meet stringent environmental regulations. It experiences steady demand driven by modernization of aging power plants and integration of renewable energy sources. The presence of key market players and advanced research facilities further supports innovation and market growth. North America’s regulatory framework encourages energy efficiency and emission reduction, reinforcing the demand for sophisticated control systems.

Europe

Europe holds 28% of the steam turbine control system market, supported by established power infrastructure and progressive energy policies. It focuses on reducing carbon emissions through advanced control solutions that optimize fuel usage and turbine performance. The region invests in retrofitting older plants with digital control technologies to extend operational life and comply with environmental standards. It faces growing demand from industries such as manufacturing, chemical, and utilities seeking reliable power generation. European countries emphasize energy transition, encouraging the adoption of hybrid and renewable-integrated power plants, which boosts the market. Strong governmental support accelerates deployment of innovative control systems across the region.

Asia-Pacific

Asia-Pacific captures 30% of the steam turbine control system market due to rapid industrialization and expanding electricity demand. Emerging economies in the region invest in new power generation projects and upgrade existing infrastructure to support economic growth. It witnesses growing adoption of modern turbine control systems that improve efficiency and reduce downtime. Government initiatives promoting sustainable energy and energy security drive the market forward. The region also experiences increasing penetration of combined cycle and cogeneration plants requiring advanced control solutions. Local manufacturers and multinational companies actively expand their presence to meet diverse market needs.

Rest of the World

The Rest of the World region holds 10% market share in the steam turbine control system market, driven by developing countries investing in power infrastructure modernization. It includes regions such as Latin America, the Middle East, and Africa, where increasing electrification efforts stimulate demand. The market benefits from projects aimed at improving grid stability and expanding generation capacity. It faces challenges due to limited skilled workforce and budget constraints but offers growth potential through government support and foreign investments. Suppliers focus on cost-effective and scalable solutions to penetrate these emerging markets.

Shape Your Report to Specific Countries or Regions & Enjoy 30% Off!

Key Player Analysis

- Schneider Electric

- Honeywell International

- ABB

- Rockwell Automation

- Ethos Energy Group

- Siemens Energy

- Emerson Electric

- Petrotech

- Heinzmann

- DEIF

- General Electric

- Sulzer

Competitive Analysis

The steam turbine control system market features a competitive landscape dominated by established global players with extensive technological expertise. Companies like Siemens Energy, General Electric, ABB, and Schneider Electric leverage advanced R&D capabilities to develop innovative control solutions that enhance turbine efficiency, reliability, and safety. It maintains a strong focus on digital transformation, incorporating automation, IoT, and predictive analytics into their offerings. Honeywell International and Rockwell Automation compete by providing integrated control platforms tailored to various industrial applications. Emerging companies such as Ethos Energy Group and Petrotech specialize in niche markets and aftermarket services, expanding their reach through strategic partnerships and customization. The market also sees competition based on product quality, system integration, and after-sales support. Manufacturers invest in expanding their geographic footprint and local service networks to capture growing demand in emerging economies. It emphasizes continuous innovation and customer-centric solutions to sustain market position and respond to evolving industry requirements. Competitive pricing and scalability of control systems remain critical factors influencing buyer decisions across sectors. Overall, the market’s competitive dynamics drive rapid technological advancements and improved operational efficiencies for end users worldwide.

Recent Developments

- On May 9, 2025, Siemens Energy introduced the TURLOOP control system, enhancing steam turbine performance with advanced features like automatic startup and precise load regulation.

- In the second quarter of 2023, GE Vernova acquired Nexus Controls, a company specializing in aftermarket control system upgrades and field services, to strengthen its turbine control offerings.

- In November 2024, GE Vernova acquired Woodward’s heavy-duty gas turbine combustion assets to bolster its domestic supply chain and meet increasing demand for gas turbine.

- In May 2025, Siemens Energy launched the Omnivise T3000, an advanced distributed control system designed for optimizing both conventional and renewable energy infrastructures with enhanced cybersecurity and digital twin simulation capabilities.

Market Concentration & Characteristics

The steam turbine control system market exhibits a moderately concentrated structure dominated by a few key global players such as Siemens Energy, General Electric, ABB, Schneider Electric, and Honeywell International. These companies leverage advanced technological expertise, extensive R&D investments, and broad service networks to maintain competitive advantage. It focuses on delivering high-quality, reliable, and customizable control solutions that meet diverse industry requirements. Market dynamics emphasize innovation in digitalization, automation, and predictive maintenance to enhance turbine performance and operational efficiency. The presence of strong regional players in emerging markets increases competition, particularly through tailored retrofit and service offerings. It faces barriers such as high capital costs and integration complexity, favoring established companies with technical capabilities and financial resources. Overall, the market’s characteristics reflect a blend of technological sophistication, strategic partnerships, and customer-centric approaches that shape competitive positioning and growth potential.

Report Coverage

The research report offers an in-depth analysis based on Component, Function and Geography. It details leading market players, providing an overview of their business, product offerings, investments, revenue streams, and key applications. Additionally, the report includes insights into the competitive environment, SWOT analysis, current market trends, as well as the primary drivers and constraints. Furthermore, it discusses various factors that have driven market expansion in recent years. The report also explores market dynamics, regulatory scenarios, and technological advancements that are shaping the industry. It assesses the impact of external factors and global economic changes on market growth. Lastly, it provides strategic recommendations for new entrants and established companies to navigate the complexities of the market.

Future Outlook

- Digital control technologies will see broader adoption, improving precision and operational efficiency in turbines.

- IoT integration enables real-time monitoring, enhancing fault detection and reducing turbine downtime significantly.

- Retrofitting aging power plants with modern control systems extends operational life and boosts reliability.

- Regulatory demands push energy efficiency, encouraging upgrades to low-emission, compliant turbine control solutions.

- Predictive maintenance tools reduce unexpected failures and optimize maintenance schedules for smoother turbine operations.

- Emerging economies drive growth by investing heavily in modernizing power infrastructure and control technologies.

- Cybersecurity becomes essential to protect turbine controls from increasing cyber threats and operational disruptions.

- Hybrid and renewable plants require adaptable control systems to manage fluctuating power inputs effectively.

- Market leaders expand service networks, offering remote monitoring and faster support to global customers.

- Continuous innovation focuses on enhancing turbine safety, performance, and integration with smart grid systems.