Market Overview

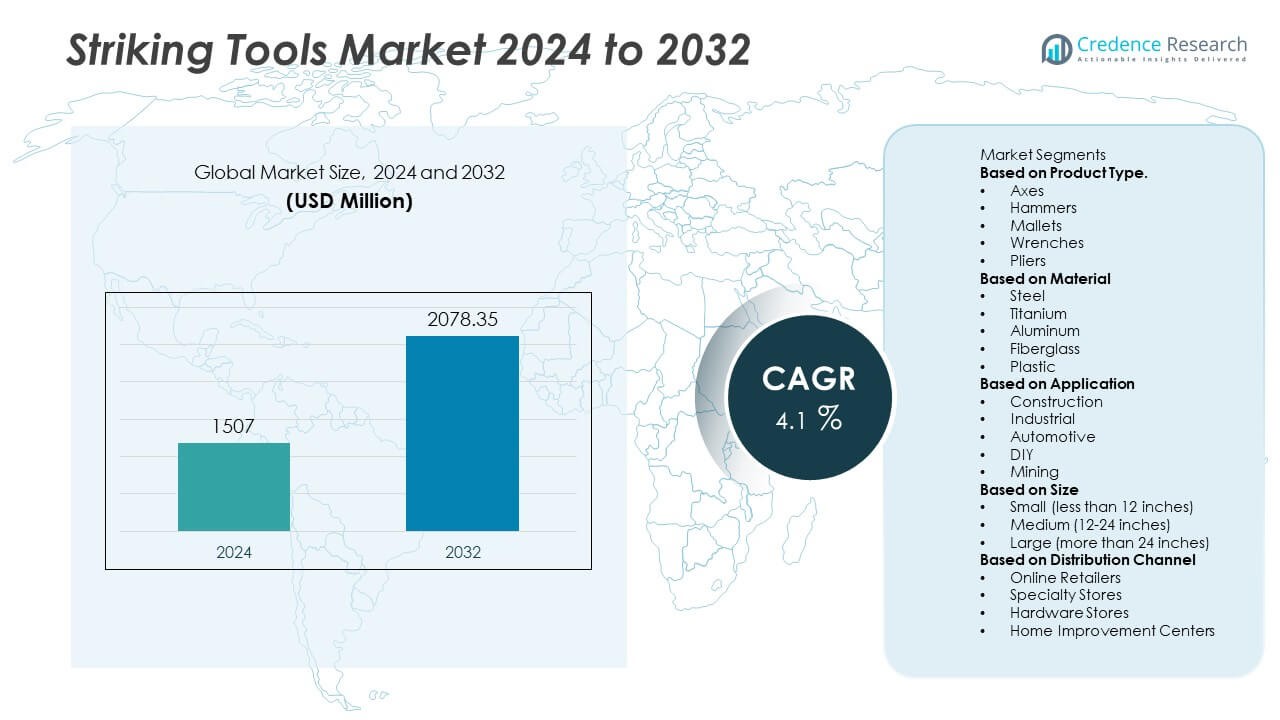

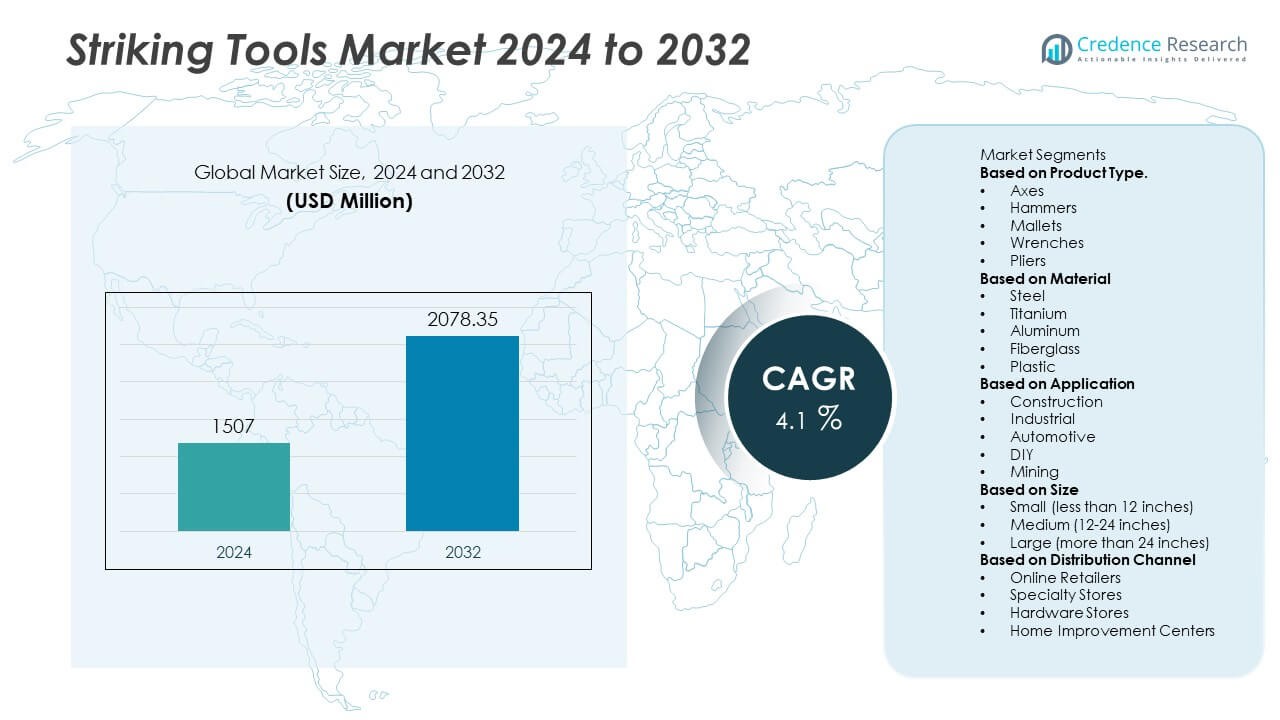

The Striking Tools Market was valued at USD 1,507 million in 2024 and is projected to reach USD 2,078.35 million by 2032, growing at a CAGR of 4.1% during the forecast period.

| REPORT ATTRIBUTE |

DETAILS |

| Historical Period |

2020-2024 |

| Base Year |

2024 |

| Forecast Period |

2025-2032 |

| Striking Tools Market Size 2024 |

USD 1,507 Million |

| Striking Tools Market, CAGR |

4.1% |

| Striking Tools Market Size 2032 |

USD 2,078.35 Million |

The Striking Tools Market is driven by increasing demand from construction, automotive, and industrial sectors requiring durable and efficient hand tools. Manufacturers focus on ergonomic designs and material innovations to enhance safety and performance. Growth in infrastructure development and DIY activities contributes to rising tool adoption.

Geographically, the Striking Tools Market spans North America, Europe, Asia Pacific, Latin America, and the Middle East and Africa, with North America and Asia Pacific holding significant industry presence due to strong construction and industrial activity. The United States, China, and India serve as key demand centers driven by infrastructure development, automotive production, and home improvement trends. Europe sees stable growth supported by strict workplace safety standards and high-quality tool demand in industrial sectors. Leading companies in this market include Stanley Black & Decker, known for its broad hand tool portfolio and global presence, and Techtronic Industries, which emphasizes cordless innovation and brand diversification. Ingersoll Rand focuses on industrial-grade tool reliability, while Apex Tool Group delivers a wide range of striking tools under multiple recognized brands.

Access crucial information at unmatched prices!

Request your sample report today & start making informed decisions powered by Credence Research Inc.!

Download Sample

Market Insights

- The Striking Tools Market was valued at USD 1,507 million in 2024 and is projected to reach USD 2,078.35 million by 2032, expanding at a CAGR of 4.1% during the forecast period.

- Demand continues to grow due to the expansion of the construction, manufacturing, and automotive sectors across both developed and developing economies.

- Manufacturers are integrating ergonomic designs, vibration-dampening handles, and durable alloy materials to enhance tool performance and user safety.

- Key players such as Stanley Black & Decker, Techtronic Industries, and Apex Tool Group are focusing on expanding product portfolios and strengthening distribution networks.

- High dependency on manual labor in developing countries and fluctuating raw material prices limit the adoption of advanced striking tools.

- North America and Asia Pacific lead the market in demand and production, driven by infrastructure upgrades, DIY activities, and industrial expansion.

- The market remains competitive with companies investing in research, global expansion, and strategic partnerships to strengthen brand positioning.

Market Drivers

Growth in Construction and Infrastructure Projects Accelerates Tool Demand

The rise in global construction activities strongly supports the demand for striking tools. Increasing urbanization and industrial development in emerging economies has led to higher infrastructure investment. Governments continue to prioritize transportation, housing, and energy infrastructure, all of which require manual and power tools for onsite tasks. The Striking Tools Market reflects this momentum through strong uptake across construction supply chains. Professionals rely on tools like hammers, sledges, and mallets for tasks including demolition, framing, and surface preparation. The demand increases with larger workforce participation and strict timelines in project delivery.

- For instance, Ingersoll Rand reported that its pneumatic tools division delivered over 200,000 units to construction projects in Asia-Pacific during 2023, supporting large-scale infrastructure developments.

Expanding DIY Culture and Home Renovation Trends Stimulate Retail Sales

Consumer interest in home improvement and do-it-yourself (DIY) projects continues to expand, especially in North America and Europe. This trend boosts sales of compact and ergonomic striking tools for personal and semi-professional use. Hardware retailers and e-commerce platforms report increased volume in categories such as claw hammers and ball-peen hammers. The Striking Tools Market benefits from this behavior shift, which supports tool purchases outside traditional trade channels. Marketing efforts targeting hobbyists and home users also help sustain interest throughout seasonal campaigns. It helps broaden product reach and diversify application settings.

- For instance, data from the Home Improvement Research Institute highlighted a rise in online sales of manual striking tools coinciding with seasonal home improvement peaks. The Striking Tools Market benefits from this behavior shift, which supports tool purchases outside traditional trade channels. Marketing efforts targeting hobbyists and home users also help sustain interest throughout seasonal campaigns. It helps broaden product reach and diversify application settings.

Industrial Manufacturing and Maintenance Sectors Maintain Steady Consumption

Heavy industries, automotive plants, and mechanical workshops remain steady consumers of striking tools. These settings require tools for maintenance, assembly, forging, and metalworking applications. Tools used in manufacturing environments must meet durability and precision standards, creating demand for forged steel heads and anti-vibration handles. The Striking Tools Market caters to these needs through continuous product innovation and performance enhancement. End-users prefer tools that reduce fatigue and support high-repetition tasks. It contributes to productivity and workplace safety.

Innovation in Material Composition and Ergonomic Design Drives Product Preference

Tool manufacturers invest in advanced materials and ergonomic designs to enhance user comfort and tool longevity. Features such as fiberglass handles, anti-slip grips, and impact-absorbing shafts gain popularity among professionals. The Striking Tools Market shows increased preference for tools with high-strength composites that reduce weight without compromising force. These innovations improve tool control and reduce the risk of injury or user fatigue. It aligns with occupational safety regulations and evolving workforce expectations. Product differentiation based on functionality and comfort supports brand loyalty and market growth.

Market Trends

Product Innovation Focuses on Ergonomics, Durability, and User Safety

Manufacturers continue to innovate striking tools by incorporating user-focused features. Tools with anti-vibration handles, slip-resistant grips, and balanced weight distribution gain preference across user segments. These features enhance control and reduce fatigue during prolonged use. The Striking Tools Market responds by integrating fiberglass and carbon fiber materials to improve shock absorption and reduce tool weight. It supports safer working conditions and aligns with professional safety standards. Leading brands use high-strength steel alloys to increase durability and reduce replacement cycles.

- For instance, Estwing’s E3-16S claw hammer features a patented nylon-vinyl shock reduction grip that reduces impact vibration by 70%, and the single-forged steel head has been tested to withstand over 6,000 Newtons of force without structural failure, according to in-house and third-party durability tests.

Digitalization of Retail Channels Increases Accessibility and Product Awareness

E-commerce platforms and digital catalogs improve product reach and customer education. Consumers compare tool features, read user reviews, and access tutorials before purchasing. It influences buyer preferences and helps them select tools based on specific tasks. The Striking Tools Market benefits from strong online visibility, particularly among DIY enthusiasts and small-scale contractors. Online retailers promote bundles, offer targeted discounts, and highlight ergonomic or multi-use tools to attract buyers. This trend supports a shift in how tools are marketed and sold globally.

- For instance, The Striking Tools Market is experiencing significant growth and transformation due to increased online visibility and shifting consumer behavior. Leading online hardware stores are reporting a rise in average order size, driven by bundled tool sets and targeted promotions. This shift is reshaping how tools are marketed and sold, with a growing emphasis on DIY enthusiasts and small-scale contractors.

Professional Demand Aligns with Sector-Specific Tool Customization

Industrial and construction users seek striking tools tailored for specific tasks and material types. Manufacturers develop specialized hammers and mallets for applications in metalworking, carpentry, masonry, and automotive repair. The Striking Tools Market reflects this demand through expanded product lines and modular features. Tool sets designed for job-specific functions help reduce tool redundancy and improve efficiency on worksites. It drives innovation in tool form factors, head shapes, and handle lengths. Companies that offer customization options maintain stronger relationships with professional buyers.

Sustainability and Lifecycle Considerations Shape Product Development

Environmental concerns influence how tools are manufactured, used, and disposed of. Producers explore recyclable materials and more efficient manufacturing processes to reduce environmental impact. The Striking Tools Market increasingly values long-life tools that minimize waste and require fewer replacements. It supports circular economy initiatives and encourages investment in repairable, high-durability tools. End users become more conscious of product lifespan, sourcing practices, and packaging. This trend pushes manufacturers to offer transparency in material sourcing and production methods.

Market Challenges Analysis

Fluctuating Raw Material Costs Impact Production and Pricing Stability

Manufacturers rely on steel, fiberglass, and composite materials, which face frequent cost volatility. Global supply chain disruptions, geopolitical tensions, and resource scarcity contribute to inconsistent material availability. These fluctuations impact production planning and force frequent pricing adjustments, especially for mid-range and premium tool segments. The Striking Tools Market faces pressure to maintain product quality while absorbing cost fluctuations. It limits the ability of smaller manufacturers to stay competitive against larger firms with stronger supply contracts. Volatile input costs also complicate long-term procurement and inventory strategies across distribution channels.

Low-Cost Counterfeit Tools Undermine Brand Value and Consumer Safety

The market sees a rise in counterfeit products that mimic branded tools but fail to meet performance or safety standards. These imitations enter both online and offline retail channels, eroding consumer trust and diluting brand equity. The Striking Tools Market contends with growing intellectual property violations, particularly in regions with weak enforcement. It increases the burden on legitimate manufacturers to invest in authentication measures and consumer education. End users who purchase counterfeit tools face safety risks, often unaware of inferior materials or construction. This challenge affects overall market reputation and creates barriers to premium product adoption.

Market Opportunities

Growing Infrastructure and Urban Development Projects Create New Demand Channels

Large-scale infrastructure investments across developing economies drive steady demand for professional-grade tools. Governments prioritize road construction, commercial buildings, and transportation projects, increasing the need for durable striking tools in concrete and metalwork. The Striking Tools Market stands to benefit from consistent procurement by contractors and construction firms. It presents growth opportunities for brands offering high-impact tools that meet industrial standards. Expansion of affordable housing and smart city projects also widens the user base. Regional players can gain market share by aligning product offerings with local project needs and workforce requirements.

Rising DIY Culture and E-commerce Penetration Expand Retail Opportunities

The shift in consumer behavior toward home improvement and self-repair drives interest in accessible, ergonomic hand tools. Online platforms simplify product comparison, enhance brand visibility, and increase reach across urban and rural markets. The Striking Tools Market gains momentum from digital sales models that support flexible pricing and fast delivery. It creates opportunities for manufacturers to launch exclusive product lines tailored for DIY users. Product bundling, video demonstrations, and user reviews help build brand engagement in the retail space. E-commerce also allows niche brands to compete with established players through targeted promotions and customer-focused innovation.

Market Segmentation Analysis:

By Product Type:

The Striking Tools Market includes a wide range of tools such as hammers, mallets, sledges, axes, and hatchets. Hammers lead the segment due to their versatility in both professional and household applications. It sees high demand in construction, carpentry, and metalworking tasks. Mallets and sledges cater to heavier applications where force dispersion and surface protection are necessary. Axes and hatchets serve specific use cases in forestry, landscaping, and emergency response sectors. Growth in these sub-categories depends on material strength, handle ergonomics, and shock absorption capacity.

- For instance, Fiskars’ X27 Super Splitting Axe features an optimized blade geometry and FiberComp™ handle tested to withstand over 3,200 pounds (14,230 N) of splitting force, while reducing hand strain through vibration-dampening design, verified under ANSI B107.54 performance testing standards.

By Material:

Materials used in striking tools primarily include wood, fiberglass, and steel. Wood remains preferred in traditional models due to its affordability and ease of grip, though it has lower durability compared to other materials. Fiberglass offers enhanced shock resistance, reduced vibration, and lighter weight, making it suitable for frequent professional use. Steel handles deliver high strength and longevity but may require additional cushioning to reduce hand fatigue. The Striking Tools Market shows a gradual shift toward composite and hybrid materials that blend durability with user comfort. It supports manufacturers aiming to differentiate products through performance and ergonomics.

- For instance, Vaughan’s Dalluge 16 oz. titanium hammer uses an American hickory handle combined with a titanium head, achieving a recoil reduction of 10–20% compared to steel-head models of the same weight, as measured under ASTM F2136 hand-arm vibration tests.

By Application:

Application areas span construction, automotive, household, industrial manufacturing, and mining. Construction dominates the segment due to continuous demand for framing, demolition, and finishing tools. The automotive industry requires precision tools for repair and maintenance tasks, driving specialized tool development. Household usage supports growth in lightweight, user-friendly products suitable for DIY and occasional repairs. Industrial applications demand high-durability tools that withstand repeated impact and exposure to harsh environments. The Striking Tools Market aligns its product development with these end-user requirements to sustain relevance and capture varied customer segments. It enables brands to focus on application-specific designs that improve utility, safety, and tool lifespan.

Segments:

Based on Product Type.

- Axes

- Hammers

- Mallets

- Wrenches

- Pliers

Based on Material

- Steel

- Titanium

- Aluminum

- Fiberglass

- Plastic

Based on Application

- Construction

- Industrial

- Automotive

- DIY

- Mining

Based on Size

- Small (less than 12 inches)

- Medium (12-24 inches)

- Large (more than 24 inches)

Based on Distribution Channel

- Online Retailers

- Specialty Stores

- Hardware Stores

- Home Improvement Centers

Based on the Geography:

- North America

- Europe

- UK

- France

- Germany

- Italy

- Spain

- Russia

- Belgium

- Netherlands

- Austria

- Sweden

- Poland

- Denmark

- Switzerland

- Rest of Europe

- Asia Pacific

- China

- Japan

- South Korea

- India

- Australia

- Thailand

- Indonesia

- Vietnam

- Malaysia

- Philippines

- Taiwan

- Rest of Asia Pacific

- Latin America

- Brazil

- Argentina

- Peru

- Chile

- Colombia

- Rest of Latin America

- Middle East

- UAE

- KSA

- Israel

- Turkey

- Iran

- Rest of Middle East

- Africa

- Egypt

- Nigeria

- Algeria

- Morocco

- Rest of Africa

Regional Analysis

North America

North America holds a market share of approximately 32% in the Striking Tools Market. The region benefits from a strong construction sector, widespread adoption of DIY culture, and demand for high-quality hand tools in both residential and commercial settings. The United States leads in consumption due to consistent infrastructure upgrades and a well-established manufacturing base. Companies in North America invest heavily in R&D to produce ergonomic, lightweight, and shock-resistant tools. Brands such as Stanley Black & Decker and Estwing Manufacturing Co. focus on high-durability tools suited for professional tradespeople. It continues to witness growing demand for multipurpose striking tools that meet safety and OSHA compliance standards across worksites.

Europe

Europe accounts for around 26% of the global Striking Tools Market. Countries such as Germany, France, and the UK contribute significantly due to their large-scale construction, automotive, and industrial manufacturing activities. The region shows a preference for precision-engineered tools that conform to EU safety and performance regulations. It benefits from established distribution networks and high-quality standards that support brand loyalty. European consumers often prioritize ergonomics, environmental sustainability, and material durability. Local manufacturers adopt advanced forging and heat-treatment technologies to ensure product longevity. The market responds well to hybrid tools that combine traditional design with advanced materials such as carbon-fiber-reinforced handles.

Asia Pacific

Asia Pacific represents the largest regional market, holding a share of 34%. China, India, and Japan are key contributors due to rapid urbanization, industrialization, and infrastructure development. It serves both domestic and international demand due to the presence of high-volume manufacturing hubs. Competitive pricing and widespread availability of striking tools help expand usage across mid- and low-income user segments. Local manufacturers offer a wide variety of tools catering to agriculture, mining, and home improvement sectors. The region sees rising adoption of automated manufacturing technologies to improve tool consistency and output capacity. Increasing safety awareness and demand for longer-lasting tools also drive innovation in product design and materials.

Latin America

Latin America captures about 4% of the global Striking Tools Market. Brazil, Mexico, and Argentina drive market activity through ongoing construction, automotive repairs, and energy-related projects. It faces challenges related to inconsistent supply chains and import reliance, but local tool makers gain ground through cost-competitive offerings. Government investments in public infrastructure and affordable housing projects stimulate tool demand. Rising consumer interest in DIY repairs and maintenance activities also contributes to market expansion. Brands targeting this region often focus on durable, low-cost tools with minimal maintenance requirements.

Middle East and Africa

The Middle East and Africa collectively hold a 4% market share. Growth in the Gulf Cooperation Council (GCC) countries stems from large-scale infrastructure and construction developments. Africa sees tool demand rising in mining, agriculture, and residential construction. It experiences supply constraints in remote regions, but international brands enter the market through partnerships with local distributors. Governments in both regions invest in training and upskilling programs, increasing professional use of quality striking tools. Demand remains stable for basic, heavy-duty tools suited to rugged operating conditions.

Shape Your Report to Specific Countries or Regions & Enjoy 30% Off!

Key Player Analysis

- Graco Inc.

- Apex Tool Group

- Nortek Inc.

- Fortive Corporation

- Ingersoll Rand

- Techtronic Industries

- Altra Industrial Motion

- Emerson Electric

- Stanley Black Decker

- Eaton Corporation

Competitive Analysis

The Striking Tools Market features a competitive landscape dominated by leading players including Stanley Black & Decker, Techtronic Industries, Apex Tool Group, Emerson Electric, Fortive Corporation, Eaton Corporation, Ingersoll Rand, Graco Inc., Nortek Inc., and Altra Industrial Motion. These companies compete through product innovation, brand strength, and global distribution capabilities. Stanley Black & Decker maintains strong market visibility with an extensive tool portfolio and global retail reach. Techtronic Industries continues to invest in R&D to improve ergonomics and tool performance, targeting both professional and consumer segments. Apex Tool Group focuses on durable hand tools with targeted applications in industrial settings, while Emerson Electric and Eaton Corporation leverage their engineering expertise to produce reliable, heavy-duty tools. Ingersoll Rand emphasizes industrial-grade performance for professional applications. Companies are also adopting strategies such as mergers, acquisitions, and digital marketing to enhance competitiveness. Innovation in material composition, vibration control, and safety features further differentiates product offerings in this highly consolidated and performance-driven market.

Recent Developments

- In July 2025, Graco Inc. finalized the acquisition of Color Service, an Italian company specializing in automated dosing systems for powders and liquids. This acquisition is not directly related to striking tools, but it is expected to enhance Graco’s product offerings in industrial sectors like coatings and material handling by adding advanced automation solutions.

- In September 2024, Graco introduced the Stellair ACE and Stellair air spray guns, the first industrial spray guns to receive Ergonomics Performance Certification. These guns are designed to reduce fatigue and boost productivity for industrial painters through ergonomic advancements such as significantly reduced weight and minimized muscle effort.

- In July 2024, Graco Inc. introduced the Xtreme Torque (XT) Airless Sprayer Line, including the Ultra XT and Mark XT models. These sprayers are designed with a brushless motor that provides up to 15 times more torque than traditional motors, enabling quieter operation (up to 10 times quieter) and offering selectable performance modes.

Market Concentration & Characteristics

The Striking Tools Market displays a moderately fragmented structure, with a blend of established global manufacturers and numerous regional players competing across segments. It caters to a wide range of end users, including construction, automotive, industrial, and household sectors, which demand tools with high durability, precision, and ergonomic design. The market reflects a high degree of product standardization for basic tools like hammers and sledges, while premium offerings integrate anti-vibration technology, improved grip, and composite materials. It sees consistent demand from industrial maintenance and infrastructure projects, contributing to stable revenue streams. Global players focus on innovation and brand strength, while local manufacturers often rely on pricing and distribution networks. It features steady replacement cycles due to wear-and-tear, driving recurring sales. Regulatory compliance related to tool safety and workplace efficiency influences product development. The market benefits from e-commerce platforms, expanding visibility for both premium and budget segments. Demand fluctuates with construction activity and industrial output.

Report Coverage

The research report offers an in-depth analysis based on Product Type, Material, Application, Size, Distribution Channel and Geography. It details leading market players, providing an overview of their business, product offerings, investments, revenue streams, and key applications. Additionally, the report includes insights into the competitive environment, SWOT analysis, current market trends, as well as the primary drivers and constraints. Furthermore, it discusses various factors that have driven market expansion in recent years. The report also explores market dynamics, regulatory scenarios, and technological advancements that are shaping the industry. It assesses the impact of external factors and global economic changes on market growth. Lastly, it provides strategic recommendations for new entrants and established companies to navigate the complexities of the market.

Future Outlook

- The demand for ergonomic striking tools will grow as users prioritize comfort and safety in industrial and DIY applications.

- Growth in global construction and infrastructure projects will continue to drive tool consumption across developing and developed economies.

- Manufacturers will invest in composite materials and anti-vibration technologies to improve durability and performance.

- E-commerce platforms will expand market reach, especially for small and medium-sized tool brands targeting professional users.

- The industrial sector will adopt more specialized striking tools tailored to application-specific needs in energy, mining, and automotive.

- Rising awareness of workplace safety will encourage companies to upgrade to certified, precision-engineered tools.

- The Asia Pacific region will remain the largest contributor due to its growing manufacturing output and infrastructure development.

- Environmental regulations will influence design innovations using recyclable and sustainable raw materials.

- Strategic mergers and acquisitions will reshape competition as larger companies seek product line expansion and regional dominance.

- Digital integration in distribution and inventory systems will streamline supply chains and improve availability in key markets.