Market Overview:

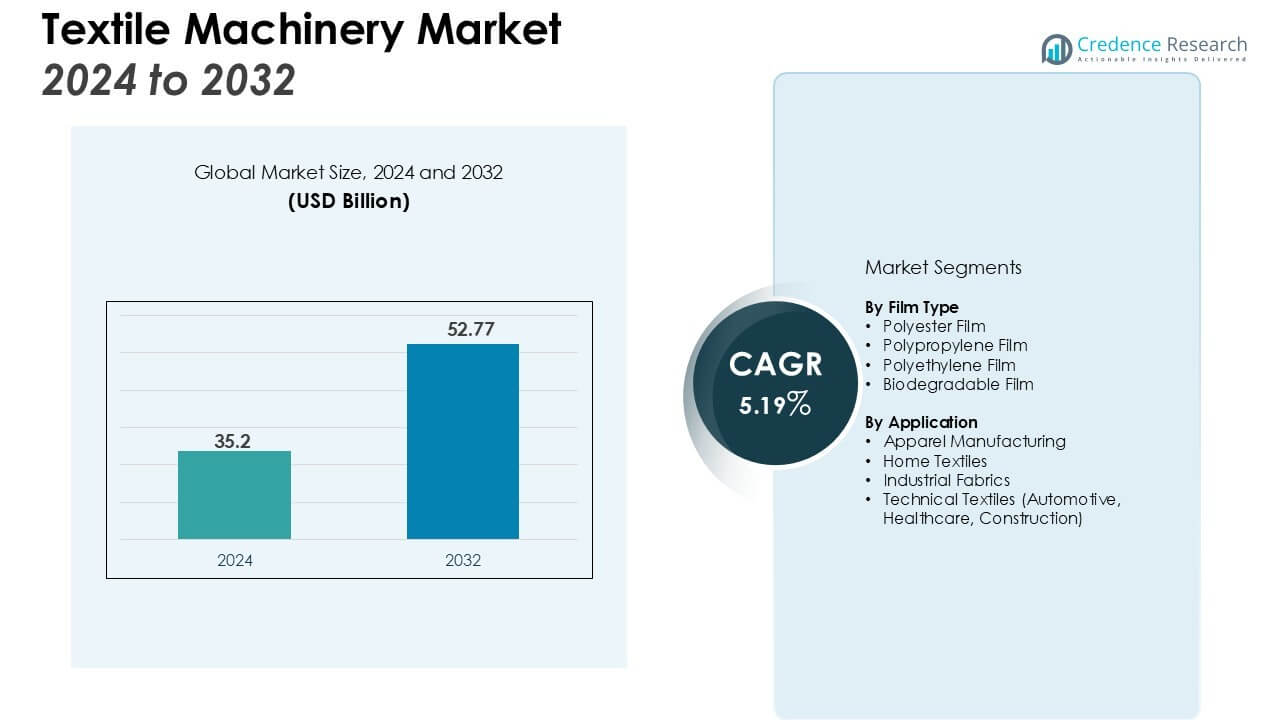

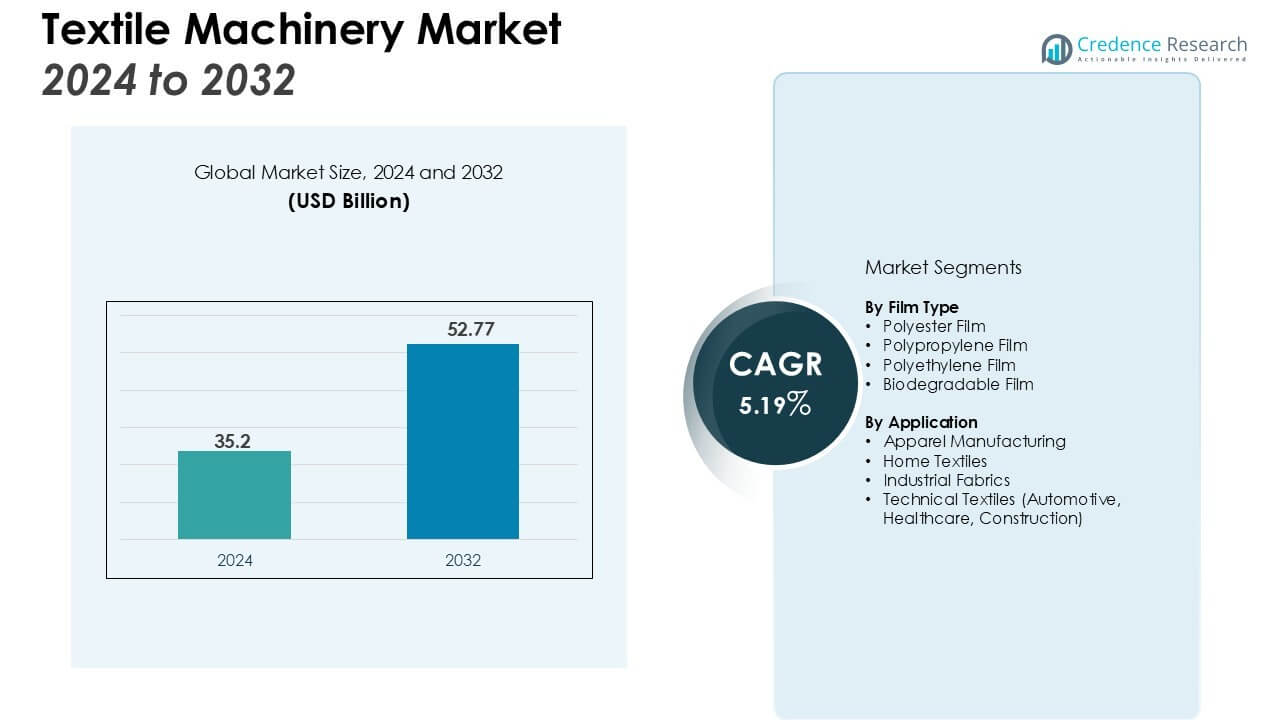

The Textile Machinery Market size was valued at USD 35.2 billion in 2024 and is anticipated to reach USD 52.77 billion by 2032, at a CAGR of 5.19% during the forecast period (2024-2032).

| REPORT ATTRIBUTE |

DETAILS |

| Historical Period |

2020-2023 |

| Base Year |

2024 |

| Forecast Period |

2025-2032 |

| Textile Machinery Market Size 2024 |

USD 35.2 Billion |

| Textile Machinery Market, CAGR |

5.19% |

| Textile Machinery Market Size 2032 |

USD 52.77 Billion |

Key drivers of market growth include the rising demand for high-quality textiles in various applications such as apparel, home textiles, and industrial fabrics. Additionally, the increasing adoption of automation and digitalization in textile manufacturing processes is enhancing productivity and efficiency, making the machinery more cost-effective. Sustainability trends are also driving the market as manufacturers seek environmentally friendly technologies and processes, contributing to the development of eco-efficient machinery. Furthermore, the growing demand for technical textiles in industries like automotive and healthcare is expected to create additional growth opportunities. The emergence of smart textiles, which integrate sensors and electronics, is further bolstering the demand for advanced machinery.

Regionally, Asia-Pacific holds the largest market share, with China and India being the key contributors due to their large-scale textile manufacturing industries. The region is also seeing significant investments in advanced machinery to enhance production capabilities. North America and Europe follow, where technological advancements and high demand for high-performance textile products are supporting market growth.

Market Insights:

Market Insights:

- The textile machinery market is expected to reach USD 52.77 billion by 2032, growing at a CAGR of 5.19%.

- Adoption of automation and IoT-enabled machinery is increasing, improving production efficiency and reducing costs.

- Sustainability trends are driving demand for eco-efficient machinery, including waterless dyeing and energy-saving solutions.

- Technological innovations like digital printing and robotics are enhancing textile machinery, offering greater customization.

- High capital investment and maintenance costs pose challenges, especially for smaller manufacturers adopting advanced technologies.

- Supply chain disruptions, material shortages, and geopolitical tensions are increasing costs and delaying production.

- Asia-Pacific leads the market with a 45% share, while North America and Europe focus on technological advancements and sustainability.

Access crucial information at unmatched prices!

Request your sample report today & start making informed decisions powered by Credence Research Inc.!

Download Sample

Market Drivers:

Rising Demand for High-Quality Textiles Across Industries

The demand for high-quality textiles continues to increase in applications such as apparel, home textiles, and industrial fabrics. Consumers are seeking durable, comfortable, and aesthetically appealing products, pushing manufacturers to adopt advanced textile machinery. The growing emphasis on quality over quantity drives the need for more sophisticated machinery capable of producing premium products. This trend is evident across markets such as fashion, interior design, and automotive, further propelling market growth for textile machinery.

For instance, the Swiss company Rieter’s E 90 comber machine is capable of producing up to 100 kilograms of high-quality combed sliver per hour.

Automation and Digitalization in Textile Manufacturing

The integration of automation and digitalization in textile manufacturing processes is transforming the industry. Advanced textile machinery equipped with automation technologies improves production efficiency, reduces labor costs, and increases output consistency. These advancements enable manufacturers to respond quickly to market demands, reduce lead times, and minimize waste. The growing trend of Industry 4.0, with smart factories and IoT-enabled machinery, is accelerating the adoption of these technologies in textile production.

For instance, Japan’s SHIMA SEIKI’s WHOLEGARMENT® machine can knit an entire garment in a single process, with a production time as short as 30 minutes for one piece.

Sustainability and Eco-Friendly Manufacturing Processes

Sustainability is a key driver in the textile machinery market. Manufacturers are increasingly seeking environmentally friendly solutions that reduce energy consumption, water usage, and emissions. Textile machinery designed for sustainable practices, such as waterless dyeing and energy-efficient machines, is gaining traction. The rising consumer demand for eco-friendly products and stricter environmental regulations across regions further push textile producers to invest in green technologies, driving the growth of textile machinery.

Technological Advancements in Textile Machinery

Ongoing technological innovations are enhancing the capabilities of textile machinery, making it more efficient and versatile. Developments in automation, precision, and the integration of robotics enable textile manufacturers to achieve higher productivity and customization in their products. Moreover, advancements such as digital printing and smart textiles, which combine textiles with electronic components, are opening new growth avenues. These innovations are contributing to the increasing adoption of advanced textile machinery across various industrial sectors.

Market Trends:

Growing Focus on Automation and Smart Manufacturing in Textile Machinery

The textile machinery market is witnessing a strong trend toward automation and smart manufacturing. Manufacturers are increasingly integrating advanced technologies, such as Artificial Intelligence (AI), machine learning, and the Internet of Things (IoT), into textile production processes. These innovations enable real-time monitoring, predictive maintenance, and optimization of machine performance, significantly improving operational efficiency. Textile machinery now features enhanced automation, allowing for faster production cycles, reduced human error, and greater precision in fabric quality. With a focus on flexibility and customization, smart machines also allow manufacturers to quickly adapt to changing consumer demands and product designs. The rising adoption of Industry 4.0 principles in textile production accelerates this shift towards more intelligent and automated machinery.

For instance, German technical textile producer HUESKER utilizes an ABB robot for the handling and palletizing of twine reels, which can weigh up to 17 kilograms, relieving employees of the strenuous task.

Shift Toward Sustainable and Eco-Friendly Textile Machinery Solutions

Sustainability continues to shape the direction of the textile machinery market, with manufacturers focusing on eco-friendly technologies. Increasing environmental concerns and stringent regulations are driving the demand for energy-efficient machines and processes that minimize waste and carbon footprints. Companies are developing textile machinery that uses less water, energy, and chemicals, contributing to cleaner production methods. Innovations like waterless dyeing, recyclable fabrics, and energy-efficient machines are gaining popularity as part of this green revolution. Sustainability is not only a regulatory requirement but also an increasingly important factor in consumer decision-making. As demand for sustainable products rises, textile machinery suppliers are prioritizing the development of eco-efficient solutions to meet market expectations.

For instance, as part of its 2025 sustainability report, Elevate Textiles announced that the company had achieved its best safety performance in more than 10 years, highlighting its commitment to social responsibility goals.

Market Challenges Analysis:

High Initial Investment and Maintenance Costs in Textile Machinery

One of the key challenges in the textile machinery market is the high initial investment and maintenance costs. Advanced textile machinery, especially those incorporating automation and smart technologies, requires significant capital expenditure, making it difficult for smaller manufacturers to adopt these innovations. Furthermore, maintaining these machines can be costly due to the need for specialized parts, regular servicing, and skilled labor. Smaller businesses often struggle to balance these financial burdens, which limits their ability to compete with larger, more established players who can afford to make these investments. As technological advancements continue to evolve, the financial strain on manufacturers may intensify.

Supply Chain Disruptions and Global Trade Uncertainties

Global supply chain disruptions and trade uncertainties present significant challenges for the textile machinery market. Issues such as material shortages, rising shipping costs, and delays in deliveries can lead to production delays and increased costs. The geopolitical tensions and trade restrictions in key manufacturing hubs, such as China and India, further complicate the situation. These disruptions affect the availability and cost of raw materials, essential components, and finished machinery. Manufacturers are under pressure to adapt to these challenges by diversifying their supply chains and improving inventory management practices. These factors may slow the market’s growth and impact profitability in the short term.

Market Opportunities:

Expanding Demand for Technical Textiles Opens New Opportunities for Textile Machinery

The increasing demand for technical textiles presents a significant opportunity for the textile machinery market. Industries such as automotive, healthcare, and construction are adopting advanced textiles for specialized applications, driving the need for highly advanced machinery. Textile machinery that caters to the production of these specialized fabrics, such as non-woven textiles, composites, and functional textiles, has become crucial. The growing focus on smart textiles and fabrics with embedded sensors for applications in wearable technology further expands opportunities for machinery suppliers. Companies that innovate to meet these demands can capitalize on emerging markets and diversify their offerings to include high-performance and industrial-grade textiles.

Sustainability Trends in Textile Machinery Development

Sustainability presents another lucrative opportunity for the textile machinery market. With growing consumer and regulatory pressure for environmentally friendly products, there is an increasing demand for machinery that minimizes energy consumption, waste, and water usage. Eco-efficient solutions, such as machines for waterless dyeing, recyclable fabrics, and energy-saving technologies, are gaining popularity. Manufacturers that invest in developing sustainable machinery can differentiate themselves in the market, addressing both regulatory challenges and consumer preferences. This shift towards greener production methods opens new avenues for growth and positioning as an environmentally responsible market leader.

Market Segmentation Analysis:

By Film Type

The textile machinery market, segmented by film type, includes various specialized films designed for different textile applications. Films such as polyester, polypropylene, and polyethylene are widely used in the production of technical textiles, packaging materials, and high-performance fabrics. Polyester films dominate the segment due to their versatility and superior mechanical properties, making them ideal for durable textile products. The growing demand for eco-friendly solutions is driving innovations in biodegradable films, further diversifying the market. This segment benefits from increased adoption in industries such as automotive and healthcare, where high-strength and lightweight materials are critical.

For instance, Toray Industries has developed an advanced polypropylene film for use in electric vehicle capacitors, manufacturing these films to a thickness of just 3 micrometers, a significant technological achievement for specialized industrial applications.

By Application

In terms of application, the textile machinery market is driven by sectors like apparel, home textiles, industrial fabrics, and technical textiles. Apparel manufacturing remains the largest segment, where machinery is used for spinning, weaving, and knitting. The increasing demand for high-quality, sustainable fabrics is pushing manufacturers to invest in advanced machinery that ensures precision and efficiency. Home textiles, such as bedding and carpets, are also seeing strong growth due to rising consumer demand for comfortable and durable materials. The technical textiles segment, which includes materials for automotive, healthcare, and construction applications, is rapidly expanding. Manufacturers are leveraging advanced machinery to create fabrics that integrate smart technologies and offer enhanced performance characteristics, catering to emerging needs across various industries.

For instance, the BMW Group utilizes its Additive Manufacturing Campus to process up to 12 tonnes of waste powder annually, recycling it into filament and granulate for creating new tools and production aids.

Segmentations:

By Film Type:

- Polyester Film

- Polypropylene Film

- Polyethylene Film

- Biodegradable Film

By Application:

- Apparel Manufacturing

- Home Textiles

- Industrial Fabrics

- Technical Textiles (Automotive, Healthcare, Construction)

By Region:

- North America

- Europe

- Germany

- France

- U.K.

- Italy

- Spain

- Rest of Europe

- Asia Pacific

- China

- Japan

- India

- South Korea

- South-east Asia

- Rest of Asia Pacific

- Latin America

- Brazil

- Argentina

- Rest of Latin America

- Middle East & Africa

- GCC Countries

- South Africa

- Rest of the Middle East and Africa

Regional Analysis:

Asia-Pacific Market Dominance

Asia-Pacific holds the largest share of the global textile machinery market, accounting for 45%. Driven by textile powerhouses like China, India, and Bangladesh, the region continues to lead in machinery investments aimed at increasing production efficiency. The ongoing industrialization, combined with low labor costs and government support, strengthens its position. Adoption of advanced automation and smart technologies further boosts demand. Asia-Pacific’s dominance in textile manufacturing ensures continued growth in the machinery sector, positioning it as the key global market leader.

North America’s Technological Advancements

North America commands a 25% share of the global textile machinery market. The region’s focus on innovation and technological advancements is propelling growth. The demand for high-performance textiles across automotive, medical, and consumer goods sectors drives manufacturers to adopt the latest machinery technologies. Investment in automation, robotics, and eco-friendly solutions contributes to its market strength. As North America emphasizes high-quality and sustainable textile production, its market share is expected to grow as new technological applications expand.

Europe’s Focus on Sustainability and Innovation

Europe holds a 20% share of the global textile machinery market, with Germany, Italy, and France as key contributors. The region is increasingly focused on developing machinery for sustainable textile production, responding to the demand for eco-efficient solutions. Europe’s commitment to sustainability and innovation in textile production, particularly in technical textiles, fuels market growth. The increasing use of automation and energy-efficient technologies positions Europe as a leader in high-quality, advanced textile machinery. This focus ensures steady market growth in the region.

Shape Your Report to Specific Countries or Regions & Enjoy 30% Off!

Key Player Analysis:

- OC Oerlikon (Switzerland)

- T.E. Private Limited (India)

- Trützschler Group (Germany)

- Murata Machinery (U.S.)

- Rieter (Switzerland)

- Itema Group (Italy)

- SHIMA SEIKI MFG., LTD (Japan)

- Qingdao Jingtian Textile Machinery Co., Ltd (China)

- Savio Macchine Tessili S.p.A (Italy)

- Toyota Industries Corporation (Japan)

Competitive Analysis:

The textile machinery market is highly competitive, with key players such as Laxmi International, Itema, Rieter, Saurer, and Dornier leading the industry. These companies focus on technological innovations, automation, and energy-efficient solutions to maintain a competitive edge. They invest heavily in R&D to improve machinery performance, reduce production costs, and enhance sustainability. The increasing demand for high-quality, customized textiles drives competition among manufacturers to offer versatile and high-performance equipment. Regional players, especially in Asia-Pacific, continue to dominate due to low labor costs and high manufacturing capacities. Key manufacturers are expanding their product offerings by integrating smart technologies like IoT and AI, enhancing machine productivity and flexibility. As demand for sustainable solutions rises, companies are innovating in eco-friendly machinery to align with global environmental regulations, intensifying the competitive landscape in the textile machinery market.

Recent Developments:

- In September 2025, Oerlikon Balzers launched BALINIT OPTURA, a new PVD coating designed for high-performance drilling applications in steel and cast iron.

- In May 2025, Trützschler India opened a new manufacturing facility in Sanand, Gujarat, to produce spinning preparation machinery, card clothing, and nonwoven equipment.

Report Coverage:

The research report offers an in-depth analysis based on Film Type, Application and Region. It details leading market players, providing an overview of their business, product offerings, investments, revenue streams, and key applications. Additionally, the report includes insights into the competitive environment, SWOT analysis, current market trends, as well as the primary drivers and constraints. Furthermore, it discusses various factors that have driven market expansion in recent years. The report also explores market dynamics, regulatory scenarios, and technological advancements that are shaping the industry. It assesses the impact of external factors and global economic changes on market growth. Lastly, it provides strategic recommendations for new entrants and established companies to navigate the complexities of the market.

Future Outlook:

- The demand for high-quality, sustainable textiles will continue to drive innovation in textile machinery.

- Automation and digitalization will play a key role in improving production efficiency and reducing operational costs.

- Smart textiles incorporating IoT and AI technologies will create new opportunities for advanced machinery.

- Manufacturers will increasingly focus on eco-efficient solutions, such as energy-saving machinery and waterless dyeing technologies.

- The growing importance of technical textiles in industries like automotive, healthcare, and construction will stimulate demand for specialized machinery.

- Adoption of Industry 4.0 principles will transform textile production, leading to smarter, more flexible manufacturing processes.

- Regional growth in emerging markets, especially in Asia-Pacific, will contribute to expanding market opportunities.

- Companies will invest in R&D to develop machinery with enhanced customization capabilities, meeting specific consumer needs.

- The shift toward sustainable practices will encourage the development of biodegradable and recyclable films in machinery production.

- The increasing focus on sustainability and regulatory pressures will drive further advancements in green textile machinery technologies.

Market Insights:

Market Insights: