Market Overview:

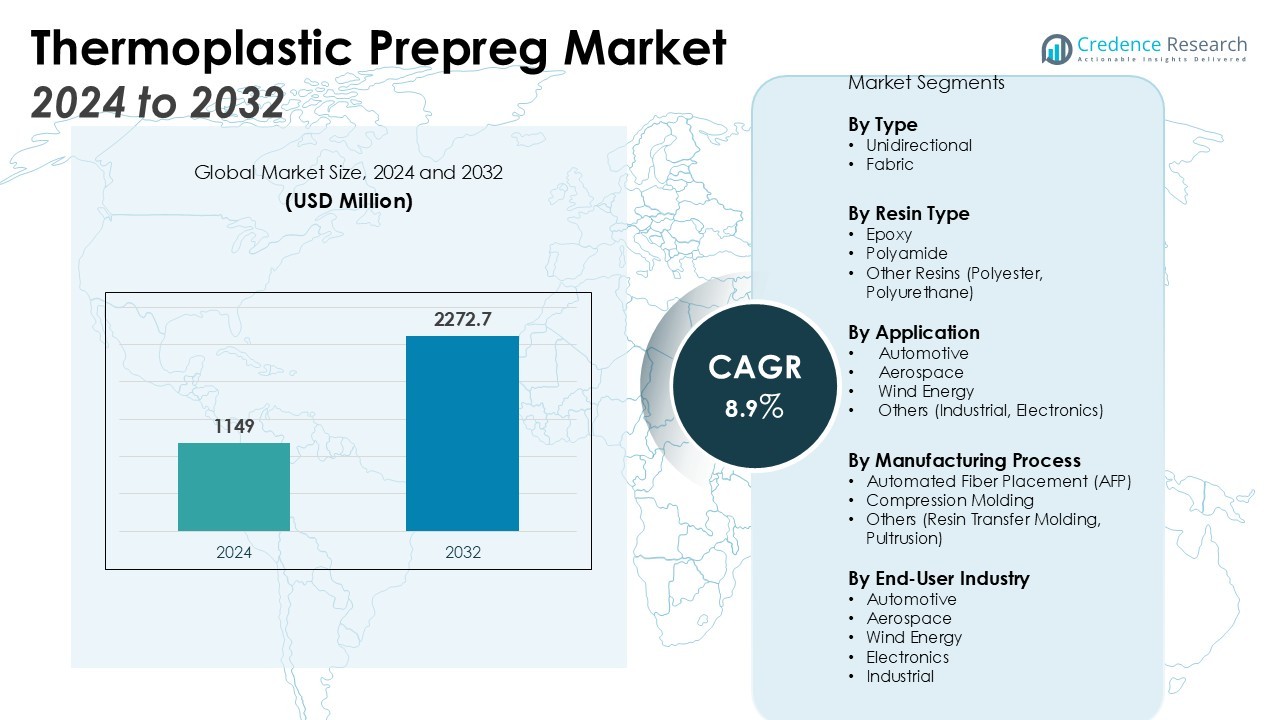

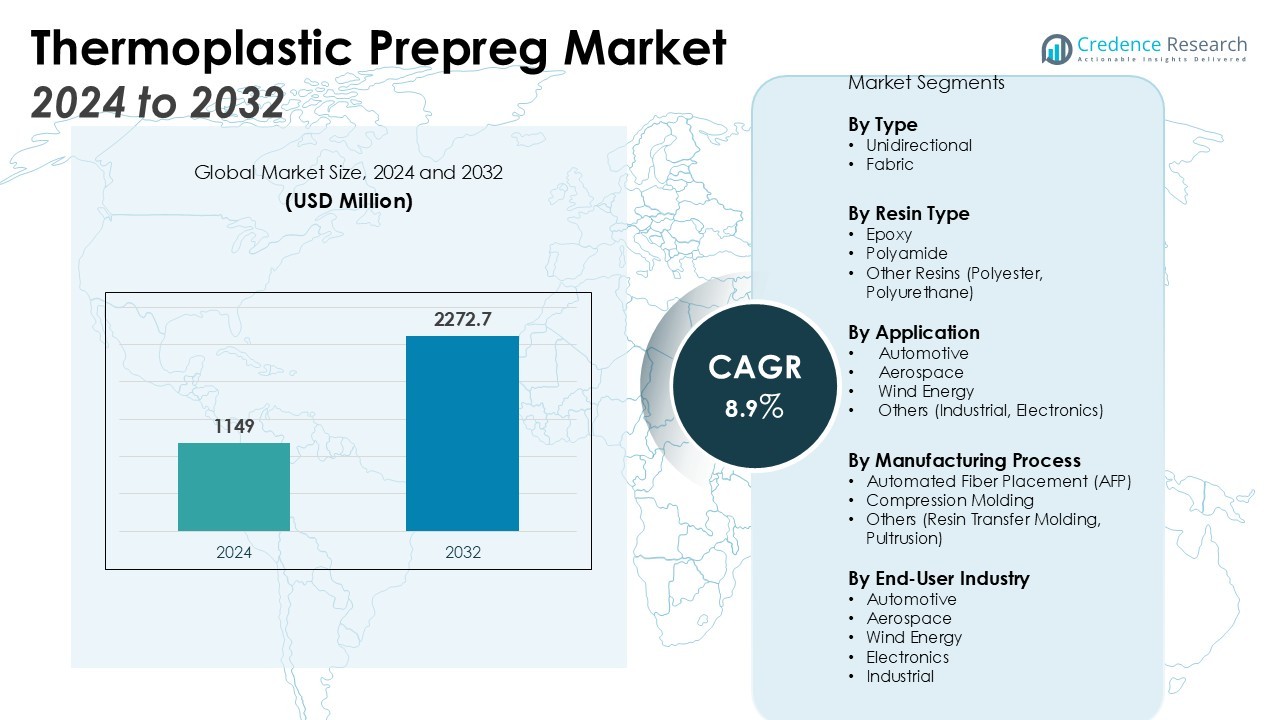

The Thermoplastic Prepreg Market size was valued at USD 1149 million in 2024 and is anticipated to reach USD 2272.7 million by 2032, at a CAGR of 8.9% during the forecast period (2024-2032).

| REPORT ATTRIBUTE |

DETAILS |

| Historical Period |

2020-2024 |

| Base Year |

2024 |

| Forecast Period |

2025-2032 |

| Thermoplastic Prepreg Market Size 2024 |

USD 1149 Million |

| Thermoplastic Prepreg Market, CAGR |

8.9% |

| Thermoplastic Prepreg Market Size 2032 |

USD 2272.7 Million |

Key drivers of market expansion include the rising adoption of thermoplastic prepregs in electric vehicles and fuel-efficient aircraft, owing to their excellent properties for lightweight and durable structures. Additionally, advancements in manufacturing technologies, such as automated fiber placement (AFP) and compression molding, are enhancing production efficiency and scalability, further propelling market growth. The continuous innovation in thermoplastic resin systems is also fueling the market by offering improved performance characteristics for demanding applications.

Regionally, North America holds a significant market share due to its robust aerospace and defense sector, with companies like Airbus driving demand for thermoplastic prepregs in aircraft manufacturing. Europe maintains dominance in the market, recovering at the fastest rate during the forecast period. The Asia-Pacific region is also witnessing strong growth, driven by expanding automotive and manufacturing industries, particularly in countries like China and India. Additionally, increasing investments in renewable energy infrastructure, particularly in wind energy, are boosting the demand for thermoplastic prepregs in the region.

Access crucial information at unmatched prices!

Request your sample report today & start making informed decisions powered by Credence Research Inc.!

Download Sample

Market Insights:

- The thermoplastic prepreg market was valued at USD 1.149 billion in 2024 and is projected to reach USD 2.273 billion by 2032, growing at a CAGR of 8.9% during the forecast period.

- Rising adoption in electric vehicles and fuel-efficient aircraft is driving the demand for thermoplastic prepregs, thanks to their lightweight and durable properties.

- Technological advancements in automated fiber placement (AFP) and compression molding are improving production efficiency and reducing costs, boosting market growth.

- The recyclability of thermoplastic prepregs makes them a more sustainable option, appealing to industries focused on environmental responsibility.

- North America holds 35% of the global thermoplastic prepreg market share, driven by the aerospace and automotive sectors.

- Europe accounts for 30% of the global market share, with strong growth in automotive, aerospace, and renewable energy sectors.

- Asia-Pacific holds 25% of the global thermoplastic prepreg market share, with rapid growth driven by the automotive and manufacturing sectors in China, Japan, and India.

Market Drivers:

Rising Demand for Lightweight and Durable Materials in Automotive and Aerospace Industries

The increasing demand for lightweight and durable materials is a significant driver for the thermoplastic prepreg market. In the automotive sector, manufacturers are focused on enhancing fuel efficiency and reducing emissions by adopting materials that contribute to the reduction of overall vehicle weight. Thermoplastic prepregs offer the necessary strength and lightweight properties, making them ideal for applications in electric vehicles. Similarly, the aerospace industry relies heavily on thermoplastic prepregs for creating high-performance, fuel-efficient aircraft components due to their exceptional strength-to-weight ratio.

- For instance, Arkema’s Rilsan® HT, a high-performance polyamide, can replace metal in engine components, resulting in parts that are up to 6 times lighter than their steel counterparts.

Technological Advancements in Manufacturing Processes

Technological advancements in manufacturing processes are propelling growth in the thermoplastic prepreg market. The development of automated fiber placement (AFP) and compression molding technologies has significantly increased the efficiency and scalability of thermoplastic prepreg production. These innovations reduce labor costs, enhance precision, and improve overall production timelines, allowing manufacturers to meet the rising demand for high-quality, cost-effective thermoplastic prepregs across industries.

- For instance, Toray’s Cetex® TC1100 thermoplastic composites have been used extensively in the industry, with more than 7 million parts currently in flight on aircraft from major manufacturers like Airbus and Boeing.

Expanding Applications in Wind Energy Sector

The wind energy sector is contributing to the growing adoption of thermoplastic prepregs. The need for durable, lightweight materials to construct wind turbine blades has led to the increased use of thermoplastic prepregs. These materials offer superior fatigue resistance, which is critical for the long lifespan of wind turbine components, and they also allow for faster manufacturing processes, reducing the time and cost involved in producing turbine blades.

Environmental Sustainability and Recycling Capabilities

Thermoplastic prepregs are increasingly favored for their environmental benefits, particularly in their ability to be recycled. Unlike traditional thermoset composites, thermoplastic prepregs can be reprocessed and reused, offering a more sustainable option for industries aiming to reduce their carbon footprint. This recyclability feature is crucial as more industries, particularly automotive and aerospace, turn to materials that align with global sustainability goals, further driving demand for thermoplastic prepregs.

Market Trends:

Growing Adoption of Thermoplastic Prepregs in Electric Vehicles

The thermoplastic prepreg market is witnessing significant growth due to its increasing adoption in electric vehicles (EVs). The rising emphasis on reducing vehicle weight to improve energy efficiency and extend battery life has led automakers to explore advanced materials like thermoplastic prepregs. These materials offer a unique combination of strength, durability, and lightweight properties that make them ideal for use in critical components, such as body panels and structural parts. As the EV industry continues to expand, driven by the demand for more sustainable transportation solutions, the use of thermoplastic prepregs is expected to increase, enabling manufacturers to meet performance and environmental standards.

- For instance, Autoneum’s Prime-Light technology for inner dashes and floor insulators can save 2 kilograms of weight in a typical car compared to conventional components.

Advancements in Resin Systems and Product Innovation

Innovation in resin systems is another prominent trend shaping the thermoplastic prepreg market. Manufacturers are continually developing new resin formulations to enhance the performance and processing capabilities of thermoplastic prepregs. These innovations focus on improving properties such as thermal resistance, impact resistance, and mechanical strength. As industries like aerospace, automotive, and wind energy demand increasingly complex materials with higher performance standards, thermoplastic prepregs are evolving to meet these needs. These advancements also support the growing trend of using thermoplastic prepregs in highly demanding applications, further driving market growth and product adoption across various sectors.

- For instance, Nexx Technologies’ innovative NT-350HT resin system demonstrates advanced processing capabilities, enabling a snap cure in as little as four minutes at 350°F.

Market Challenges Analysis:

High Production Costs and Complex Manufacturing Processes

One of the key challenges facing the thermoplastic prepreg market is the high production costs associated with manufacturing these materials. The advanced technology required to produce thermoplastic prepregs, such as automated fiber placement (AFP) and compression molding, increases the overall cost of production. These costs can limit the adoption of thermoplastic prepregs, particularly in industries where cost-sensitive applications dominate. Manufacturers are also challenged by the complexity of these production processes, which demand high precision and expertise, further elevating operational expenses. Overcoming these cost barriers remains essential for expanding the use of thermoplastic prepregs in a broader range of industries.

Limited Availability of Raw Materials and Supply Chain Issues

The thermoplastic prepreg market is also constrained by the limited availability of raw materials, particularly high-quality fibers and resins, which are essential for producing high-performance prepregs. Supply chain issues, including fluctuating material prices and the reliance on a small number of suppliers, further exacerbate this challenge. These supply chain disruptions can cause delays in production timelines and increase material costs, impacting the overall affordability and availability of thermoplastic prepregs. For the market to grow sustainably, addressing these material and supply chain challenges is crucial.

Market Opportunities:

Expansion of Thermoplastic Prepreg Applications in Emerging Industries

The thermoplastic prepreg market presents significant opportunities in emerging industries such as renewable energy and electric vehicles. The growing demand for lightweight, high-strength materials in wind energy applications, particularly for turbine blades, offers a strong growth opportunity. Thermoplastic prepregs’ recyclability and ability to withstand harsh environmental conditions make them an ideal choice for these applications. Similarly, the expanding electric vehicle sector is increasingly adopting thermoplastic prepregs to reduce vehicle weight and improve energy efficiency. As these industries continue to grow, the demand for thermoplastic prepregs is expected to rise, presenting new avenues for market expansion.

Technological Advancements and Sustainable Innovations

Ongoing advancements in resin technologies and sustainable production practices offer further opportunities for growth in the thermoplastic prepreg market. New developments in thermoplastic resin formulations that focus on enhanced durability, higher performance, and recyclability present a key opportunity for companies to differentiate their products. Additionally, the push for sustainability and eco-friendly materials across various industries creates an opportunity to position thermoplastic prepregs as a sustainable alternative to traditional materials. By addressing environmental concerns while maintaining performance standards, the thermoplastic prepreg market can attract new customers and penetrate markets that prioritize sustainability.

Market Segmentation Analysis:

By Type

The thermoplastic prepreg market is segmented into unidirectional and fabric types. Unidirectional thermoplastic prepregs are commonly used in high-performance applications due to their superior strength and durability. Fabric thermoplastic prepregs are gaining popularity in applications that require more flexibility, making them suitable for various structural components in industries like automotive and aerospace. The demand for both types is growing as industries focus on lightweight and strong materials for improved performance.

- For instance, BPREG Composites offers its EcoRein/W, a woven fabric prepreg, in widths of up to 160 cm to suit various manufacturing needs.

By Resin Type

The market is divided into epoxy, polyamide, and other resin types. Epoxy-based thermoplastic prepregs dominate the market, offering excellent bonding properties, heat resistance, and mechanical strength, which make them ideal for high-stress applications. Polyamide-based prepregs are gaining traction in automotive and industrial applications for their enhanced flexibility and ease of processing. Other resins, such as polyester and polyurethane, serve niche applications, particularly where lower performance specifications are required.

- For instance, Toray T800S carbon fiber epoxy prepreg delivers tensile strength of 5,880 MPa with modulus of 294 GPa, enabling Boeing 787 Dreamliner to incorporate 32,000 kilograms of carbon fiber reinforced polymer composites throughout its airframe structure.

By Application

In terms of application, the thermoplastic prepreg market is segmented into automotive, aerospace, wind energy, and others. The automotive segment is experiencing rapid growth, driven by the increasing adoption of electric vehicles and the need for lightweight materials to improve fuel efficiency. Aerospace remains a key sector, with thermoplastic prepregs used in the production of durable and lightweight components for aircraft. The wind energy sector is expanding, with thermoplastic prepregs used in the manufacturing of turbine blades that require high strength and resistance to environmental factors.

Segmentations:

By Type

By Resin Type

- Epoxy

- Polyamide

- Other Resins (Polyester, Polyurethane)

By Application

- Automotive

- Aerospace

- Wind Energy

- Others (Industrial, Electronics)

By Manufacturing Process

- Automated Fiber Placement (AFP)

- Compression Molding

- Others (Resin Transfer Molding, Pultrusion)

By End-User Industry

- Automotive

- Aerospace

- Wind Energy

- Electronics

- Industrial

By Region

- North America

- Europe

- Asia-Pacific

- Latin America

- Middle East & Africa

Regional Analysis:

North America: Stronghold in Aerospace and Automotive Sectors

North America accounted for 35% of the global thermoplastic prepreg market in 2023. The region’s dominance is driven by its robust aerospace and automotive sectors. The United States, in particular, plays a central role, with companies like Boeing and Lockheed Martin contributing to the growing demand for lightweight, durable materials in aircraft production. The increasing focus on electric vehicles (EVs) further enhances the adoption of thermoplastic prepregs due to their lightweight characteristics, which improve energy efficiency. Advanced manufacturing technologies, such as automated fiber placement (AFP) and compression molding, support the widespread application of thermoplastic prepregs across various industries.

Europe: Leading Automotive, Aerospace, and Renewable Energy Industries

Europe holds a 30% share of the global thermoplastic prepreg market, driven by its established automotive, aerospace, and renewable energy sectors. The region’s automotive industry, led by companies like BMW, Volkswagen, and Mercedes-Benz, increasingly uses thermoplastic prepregs to reduce vehicle weight and enhance fuel efficiency. The growing demand for wind energy has also contributed to the market’s growth, with thermoplastic prepregs used in the production of turbine blades. Europe’s aerospace industry, with major players like Airbus, significantly contributes to the demand for high-performance materials, while the region’s commitment to sustainability further accelerates the adoption of thermoplastic prepregs.

Asia-Pacific: Expanding Automotive and Manufacturing Sectors

Asia-Pacific accounted for 25% of the global thermoplastic prepreg market in 2023 and is experiencing rapid growth, particularly in countries like China, Japan, and India. The automotive sector in the region is a major driver of demand for thermoplastic prepregs, as manufacturers seek lightweight materials to enhance fuel efficiency and support the transition to electric vehicles. China’s manufacturing industry also contributes significantly to the demand, especially in the electronics and consumer goods sectors. The region’s low manufacturing costs and increasing investment in advanced technologies make it an attractive hub for thermoplastic prepreg production, further driving market growth.

Shape Your Report to Specific Countries or Regions & Enjoy 30% Off!

Key Player Analysis:

- Polystrand

- Teijin

- Tencate

- Vector Systems

- Cytec

- Lanxess

- Fibrtec

- Porcher Industries Groupe

- Barrday

- Chomarat

Competitive Analysis:

The thermoplastic prepreg market is competitive, with major players such as Toray Industries, Hexcel Corporation, and SGL Carbon leading the industry by focusing on innovative resin formulations and advanced manufacturing technologies. These companies invest significantly in research and development to enhance product performance, recyclability, and cost-effectiveness. Smaller players are emerging with specialized solutions for niche applications, such as wind energy and electronics. Technological advancements in automated fiber placement (AFP) and compression molding are further driving market growth by improving manufacturing efficiency and scalability. With expanding production capacities in North America and Europe, key players aim to meet the growing demand from the automotive and aerospace sectors. The increasing adoption of thermoplastic prepregs in electric vehicles adds to the competitive dynamics, pushing companies to continuously innovate and expand their offerings.

Recent Developments:

- In March 2025, Teijin Carbon launched its new sustainable carbon fiber brand, Tenax Next™, at JEC World 2025, introducing products with a reduced CO₂ footprint and repurposed materials.

- In February 2025, TenCate launched Pivot® Performance Turf, a revolutionary synthetic turf that is recyclable, requires no performance infill, and is engineered to replicate the playability of a natural grass field.

- In March 2025, LANXESS showcased a new non-biocidal additive, Klarix® XIT, at the European Coatings Show, designed to remove biocides from water-based products like adhesives and paints after production.

Market Concentration & Characteristics:

The thermoplastic prepreg market is moderately concentrated, with a few key players such as Toray Industries, Hexcel Corporation, and SGL Carbon dominating the space. These companies hold a significant share of the market, driven by their extensive product portfolios and strong research and development capabilities. The market is characterized by high barriers to entry, primarily due to the advanced manufacturing processes and high costs associated with production. However, the market also features opportunities for smaller companies specializing in niche applications, such as wind energy and automotive sectors. Companies in the market focus on technological innovations, improving manufacturing efficiency, and expanding production capacities to meet the growing demand. As industries like aerospace, automotive, and renewable energy increasingly adopt thermoplastic prepregs, market dynamics continue to evolve, with competition intensifying in high-demand regions like North America and Europe.

Report Coverage:

The research report offers an in-depth analysis based on Type, Resin Type, Application, Manufacturing Process, End-User Industry and Region. It details leading market players, providing an overview of their business, product offerings, investments, revenue streams, and key applications. Additionally, the report includes insights into the competitive environment, SWOT analysis, current market trends, as well as the primary drivers and constraints. Furthermore, it discusses various factors that have driven market expansion in recent years. The report also explores market dynamics, regulatory scenarios, and technological advancements that are shaping the industry. It assesses the impact of external factors and global economic changes on market growth. Lastly, it provides strategic recommendations for new entrants and established companies to navigate the complexities of the market.

Future Outlook:

- The thermoplastic prepreg market is projected to experience robust growth, driven by increasing demand across aerospace, automotive, and renewable energy sectors.

- Technological advancements in manufacturing processes, such as automated fiber placement and compression molding, are enhancing production efficiency and scalability.

- The aerospace industry is expected to remain a significant consumer of thermoplastic prepregs, with companies like Boeing and Airbus exploring lightweight materials for next-generation aircraft.

- The automotive sector’s shift towards electric vehicles is fueling the adoption of thermoplastic prepregs for lightweighting and improved energy efficiency.

- The wind energy sector is expanding, with increasing investments in offshore wind farms driving demand for durable and lightweight materials like thermoplastic prepregs.

- Asia-Pacific is anticipated to be the fastest-growing region, with countries like China and India investing in infrastructure and manufacturing capabilities.

- North America and Europe are expected to maintain significant market shares, supported by strong aerospace and automotive industries.

- Sustainability initiatives and recycling capabilities of thermoplastic prepregs align with global environmental goals, enhancing their appeal.

- The integration of thermoplastic prepregs into mass transit systems, such as trains and buses, is increasing due to their fire safety and weight reduction properties.

- Ongoing research and development efforts are focused on enhancing the properties and processing techniques of thermoplastic prepregs to meet evolving industry demands.