Market Overview

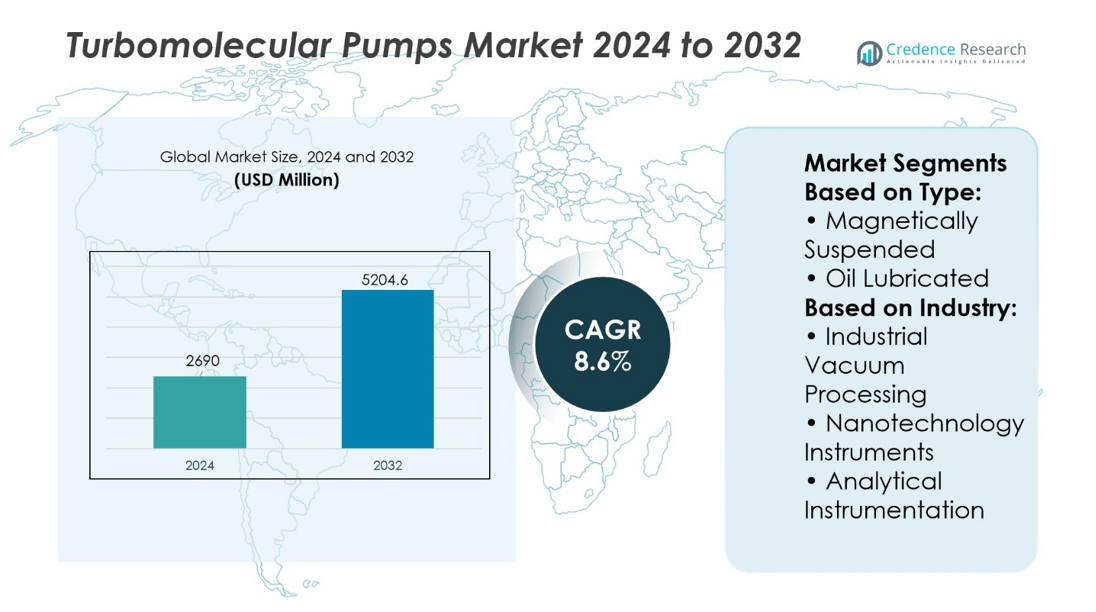

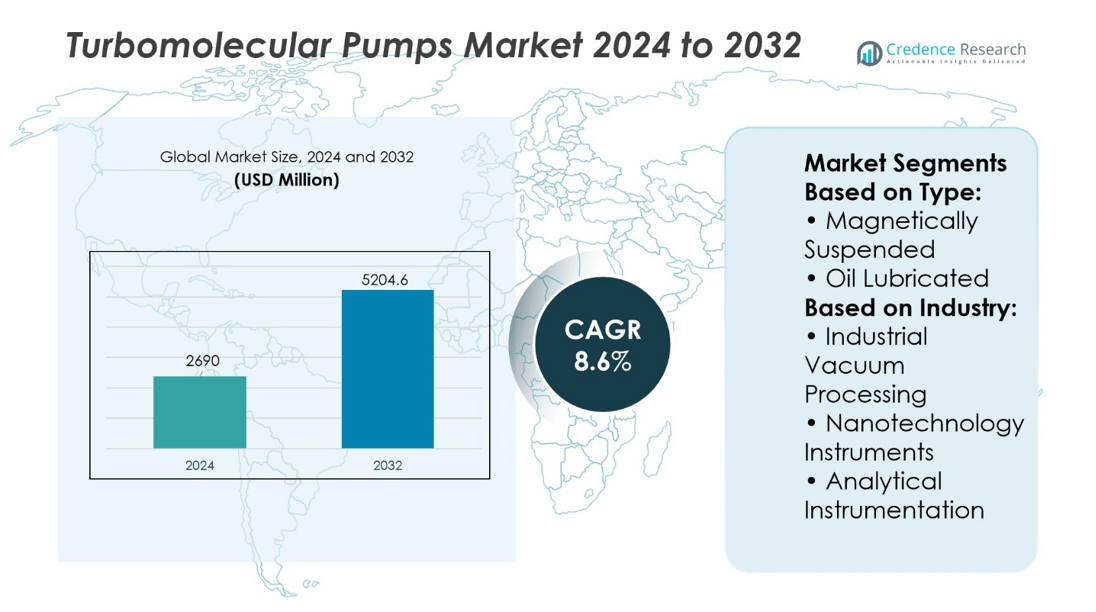

Turbomolecular Pumps Market size was valued at USD 2690 million in 2024 and is anticipated to reach USD 5204.6 million by 2032, at a CAGR of 8.6% during the forecast period.

| REPORT ATTRIBUTE |

DETAILS |

| Historical Period |

2020-2023 |

| Base Year |

2024 |

| Forecast Period |

2025-2032 |

| Turbomolecular Pumps Market Size 2024 |

USD 2690 million |

| Turbomolecular Pumps Market, CAGR |

8.6% |

| Turbomolecular Pumps Market Size 2032 |

USD 5204.6 million |

The Turbomolecular Pumps Market grows with rising demand for ultra-high-vacuum solutions in semiconductor manufacturing, nanotechnology, and advanced analytical instrumentation. It benefits from increasing adoption in aerospace testing, industrial coating, and research laboratories requiring contamination-free environments. Energy-efficient designs, compact form factors, and hybrid pump configurations drive product innovation. Integration of smart monitoring and predictive maintenance enhances operational reliability, aligning with the shift toward Industry 4.0 practices. Expanding applications in renewable energy research and high-precision manufacturing further strengthen market potential, while advancements in rotor design and magnetic bearing technology support performance improvements across diverse industrial and scientific sectors.

The Turbomolecular Pumps Market shows strong presence across Asia-Pacific, North America, and Europe, with Asia-Pacific leading due to extensive semiconductor and electronics manufacturing. North America benefits from advanced aerospace, research, and analytical sectors, while Europe is supported by industrial manufacturing and nanotechnology research. Key players include Shimadzu Corporation, Busch LLC, Pfeiffer Vacuum GmbH, Edwards, KYKY Technology Co. LTD, EBARA Technologies, Inc., Ulvac, Inc., Osaka Vacuum GmbH, Leybold USA Inc, and Agilent, each focusing on innovation, energy efficiency, and application-specific solutions.

Market Insights

- The Turbomolecular Pumps Market size was valued at USD 2690 million in 2024 and is projected to reach USD 5204.6 million by 2032, at a CAGR of 8.6%.

- Rising demand for ultra-high-vacuum solutions in semiconductor manufacturing, nanotechnology, and analytical instrumentation drives growth.

- Energy-efficient designs, compact configurations, and hybrid pump models shape ongoing product innovation.

- Competition remains strong with leading players focusing on advanced rotor designs, magnetic bearings, and predictive maintenance integration.

- High initial investment and sensitivity to operating conditions limit adoption in certain industrial sectors.

- Asia-Pacific leads the market, followed by North America and Europe, supported by sector-specific strengths in manufacturing, aerospace, and research.

- Expanding adoption in renewable energy research, high-precision manufacturing, and industrial coating processes boosts long-term market potential.

Access crucial information at unmatched prices!

Request your sample report today & start making informed decisions powered by Credence Research Inc.!

Download Sample

Market Drivers

Increasing Demand for High-Vacuum Environments in Semiconductor Manufacturing

The Turbomolecular Pumps Market grows with the expanding semiconductor industry, which requires ultra-clean and high-vacuum conditions for wafer fabrication. It enables precise control over contamination levels, critical for producing advanced microchips. Equipment manufacturers integrate these pumps into etching, deposition, and inspection systems to maintain required vacuum levels. Rising production of microprocessors, memory devices, and sensors strengthens the need for consistent, reliable vacuum performance. It supports higher yield rates and improved device quality. Leading suppliers focus on delivering pumps with optimized rotor designs and lower vibration for better integration into sensitive semiconductor processes.

- Edwards Vacuum recently celebrated a major production milestone with the delivery of their 250,000th STP turbomolecular pump, highlighting the widespread use of these pumps in the semiconductor industry.

Advancement in Analytical Instrumentation Across Research and Industrial Sectors

The Turbomolecular Pumps Market benefits from growing use in analytical equipment such as mass spectrometers and electron microscopes. It achieves stable, high-vacuum performance, essential for accurate measurement and imaging. Research laboratories and industrial quality control facilities adopt these pumps to ensure repeatable, high-precision results. The shift toward more complex and miniaturized analytical systems drives demand for compact, high-efficiency pump models. It contributes to faster analysis cycles and enhanced throughput. Manufacturers respond by developing units with reduced maintenance requirements to support continuous operation in demanding environments.

- For instance, Edwards Vacuum has shipped over 320,000 turbomolecular pumps and pumping stations across sectors including analytical instrumentation.

Expansion of Space Exploration and Satellite Development Activities

The Turbomolecular Pumps Market experiences growth from the aerospace sector’s increasing satellite launches and space missions. It provides the vacuum conditions necessary for testing spacecraft components and simulating space environments. Facilities use these pumps in thermal-vacuum chambers to validate performance of satellite subsystems. Growing private and governmental investment in satellite constellations amplifies the requirement for dependable high-vacuum systems. It helps ensure mission reliability and compliance with strict testing protocols. Pump manufacturers design models capable of operating under extended duty cycles to match aerospace application needs.

Rising Adoption in Vacuum Coating Processes for Industrial Applications

The Turbomolecular Pumps Market supports a broad range of vacuum coating applications in optics, automotive, and electronics industries. It enables precise deposition of thin films for lenses, displays, and functional coatings. Production lines use these pumps to maintain uniform vacuum levels, ensuring consistent coating thickness and quality. Increasing demand for energy-efficient coatings, including low-emissivity glass and solar control films, stimulates pump adoption. It plays a role in improving process stability and reducing defect rates. Manufacturers enhance pump durability and performance to meet high-volume industrial production requirements.

Market Trends

Integration of Energy-Efficient Designs to Reduce Operational Costs

The Turbomolecular Pumps Market witnesses a shift toward energy-efficient models that lower power consumption without compromising performance. It addresses the operational cost concerns of end users in semiconductor, research, and industrial sectors. Manufacturers adopt advanced rotor balancing techniques and optimized motor control systems to improve efficiency. Demand grows for pumps with variable speed operation to match vacuum requirements in real time. It reduces heat generation and extends equipment lifespan. Suppliers highlight these features to meet sustainability goals and enhance competitive positioning.

- For instance, Pfeiffer Vacuum has deployed over 180,000 energy-optimized HiPace turbomolecular pumps in semiconductor and analytical installations worldwide.

Miniaturization and Compact Form Factors for Space-Constrained Applications

The Turbomolecular Pumps Market sees increased demand for compact designs suitable for integration into portable and space-limited systems. It responds to the needs of analytical instruments, portable mass spectrometers, and mobile vacuum testing units. Engineers focus on reducing pump weight and footprint while retaining high pumping speeds. Miniaturized pumps enable greater flexibility in system design and transportation. It supports applications in field-based research, environmental monitoring, and mobile laboratories. Manufacturers expand product portfolios with lightweight, high-speed models to address this niche but growing segment.

- For instance, Agilent Technologies has produced over 50,000 TPS-mini integrated turbo pumping units, each combining a 70 L/s turbomolecular pump.

Integration of Smart Monitoring and Predictive Maintenance Capabilities

The Turbomolecular Pumps Market incorporates digital features that enhance operational reliability and maintenance planning. It includes embedded sensors that track vibration, temperature, and rotational speed in real time. Predictive analytics software interprets this data to forecast potential issues before failures occur. Users benefit from reduced unplanned downtime and optimized service intervals. It aligns with the broader industry adoption of Industrial Internet of Things (IIoT) technologies. Manufacturers develop pumps with integrated communication interfaces for seamless data exchange with plant monitoring systems.

Adoption of Hybrid Pump Configurations for Broader Application Coverage

The Turbomolecular Pumps Market experiences a trend toward hybrid designs that combine turbomolecular and backing pump technologies in a single unit. It provides wider operating ranges and eliminates the need for separate roughing systems. Such integration simplifies installation, reduces system complexity, and lowers maintenance requirements. Hybrid pumps serve applications in semiconductor fabrication, surface analysis, and high-vacuum coating. It delivers consistent performance across varying pressure ranges, improving operational flexibility. Manufacturers invest in developing multi-stage hybrid systems to meet diverse industry demands.

Market Challenges Analysis

High Initial Investment and Maintenance Complexity Limiting Broader Adoption

The Turbomolecular Pumps Market faces challenges from the significant upfront costs associated with advanced high-vacuum systems. It demands precision engineering, specialized materials, and stringent manufacturing tolerances, all contributing to higher prices. Smaller laboratories, startups, and cost-sensitive industries often delay adoption due to budget constraints. Maintenance requires skilled technicians familiar with high-speed rotor assemblies and delicate bearing systems, which raises operational expenses. It increases the total cost of ownership and can deter long-term commitments. Manufacturers work to address these concerns by offering modular designs and extended service intervals, yet the challenge remains significant in price-sensitive markets.

Sensitivity to Operating Conditions and Limited Durability in Harsh Environments

The Turbomolecular Pumps Market also contends with performance limitations in environments with high particulate levels, corrosive gases, or frequent power fluctuations. It operates most effectively in clean, controlled conditions, which restricts deployment in certain industrial settings. Exposure to contaminants can degrade rotor balance and bearing life, leading to costly downtime. It requires integration with pre-pumping stages and filtration systems to maintain performance, which adds complexity. Durability issues under harsh operational demands push end users to consider alternative vacuum technologies. Manufacturers invest in protective coatings, magnetic bearings, and advanced sealing systems to mitigate these operational risks, but the constraints remain a barrier in some sectors.

Market Opportunities

Expansion in Emerging Semiconductor and Electronics Manufacturing Hubs

The Turbomolecular Pumps Market has strong growth potential in emerging semiconductor production regions across Asia-Pacific, Eastern Europe, and the Middle East. It benefits from increasing investments in advanced fabrication plants and electronics assembly facilities. Governments and private investors commit significant resources to developing domestic chip production capabilities, creating new demand for high-vacuum systems. The pumps support precise deposition, etching, and inspection processes essential to producing high-performance devices. It also aligns with national strategies to secure semiconductor supply chains and reduce reliance on imports. Manufacturers can capitalize on this trend by establishing localized production and service facilities to meet rising regional demand.

Rising Adoption in Renewable Energy and Advanced Materials Research

The Turbomolecular Pumps Market holds opportunities in research applications related to solar cells, hydrogen fuel systems, and novel material coatings. It enables controlled environments for thin-film deposition, surface modification, and advanced coating technologies. Universities, R&D centers, and clean energy startups expand their infrastructure to support next-generation energy solutions, creating steady demand for reliable vacuum performance. The pumps’ ability to deliver stable, ultra-high-vacuum conditions enhances process quality and repeatability. It positions the technology as a critical enabler for innovation in energy-efficient products and sustainable materials. Manufacturers can strengthen their market position by partnering with research institutions and energy technology developers to integrate customized solutions.

Market Segmentation Analysis:

By Type

The Turbomolecular Pumps Market divides into magnetically suspended and oil lubricated types, each addressing distinct operational requirements. Magnetically suspended pumps operate without physical contact between rotor and bearings, reducing wear and enabling long service life. It supports ultra-clean applications where the absence of lubricants prevents contamination, making them ideal for semiconductor manufacturing and high-purity research. Oil lubricated pumps offer a cost-effective alternative with robust performance in less sensitive environments. They provide reliable vacuum generation for industrial processes where minor contamination risk is acceptable. It ensures versatility across market segments by accommodating both high-specification and cost-conscious users.

- For instance, Leybold’s Turbovac MAG iS maglev series has seen over 10,000 units shipped, highlighting its success in research and industrial settings.

By Industry

The Turbomolecular Pumps Market serves industrial vacuum processing in sectors such as coating, metallurgy, and electronics production. It enables precise control over deposition and treatment processes, ensuring uniform product quality. Manufacturers use these pumps in large-scale coating chambers for glass, optics, and automotive components. It supports consistent vacuum levels critical to adhesion, durability, and functional performance of applied coatings. High pumping speeds and stable operation allow for greater throughput and reduced process times. This segment benefits from ongoing demand for advanced materials and surface treatments in multiple industries.

- For instance, Edwards Vacuum has supplied over 70,000 turbomolecular pumps to vacuum-coating lines in flat-panel display and solar-cell deposition systems.

Segments:

Based on Type:

- Magnetically Suspended

- Oil Lubricated

Based on Industry:

- Industrial Vacuum Processing

- Nanotechnology Instruments

- Analytical Instrumentation

Based on the Geography:

- North America

- Europe

- UK

- France

- Germany

- Italy

- Spain

- Russia

- Belgium

- Netherlands

- Austria

- Sweden

- Poland

- Denmark

- Switzerland

- Rest of Europe

- Asia Pacific

- China

- Japan

- South Korea

- India

- Australia

- Thailand

- Indonesia

- Vietnam

- Malaysia

- Philippines

- Taiwan

- Rest of Asia Pacific

- Latin America

- Brazil

- Argentina

- Peru

- Chile

- Colombia

- Rest of Latin America

- Middle East

- UAE

- KSA

- Israel

- Turkey

- Iran

- Rest of Middle East

- Africa

- Egypt

- Nigeria

- Algeria

- Morocco

- Rest of Africa

Regional Analysis

North America

North America accounts for 28% share of the Turbomolecular Pumps Market, driven by strong demand from the semiconductor, aerospace, and analytical instrumentation sectors. The region benefits from established semiconductor fabrication hubs in the United States, which require advanced high-vacuum solutions for wafer processing and inspection. It also supports extensive aerospace research and satellite development programs that utilize these pumps for thermal-vacuum testing. Growth in biotechnology and life sciences research further boosts adoption in analytical instruments such as mass spectrometers and electron microscopes. Leading manufacturers maintain significant service networks across the region to ensure operational reliability for critical applications. Continuous investment in R&D and manufacturing capacity strengthens North America’s competitive positioning.

Europe

Europe holds 25% share of the Turbomolecular Pumps Market, supported by a strong base of industrial manufacturing, research institutions, and space exploration initiatives. The region is home to major nanotechnology and advanced materials research centers, which rely on ultra-high-vacuum systems for precision experimentation. It also has a mature semiconductor ecosystem in countries like Germany, France, and the Netherlands, where demand for contamination-free processing drives pump usage. European aerospace and defense sectors contribute to consistent procurement for vacuum testing facilities. Manufacturers in the region emphasize sustainable design and energy-efficient pump technologies to align with environmental regulations. Robust collaborations between industry and academia create steady opportunities for innovation in this market.

Asia-Pacific

Asia-Pacific commands the largest share at 35% of the Turbomolecular Pumps Market, fueled by rapid expansion in semiconductor manufacturing, electronics production, and nanotechnology research. Countries such as China, Japan, South Korea, and Taiwan dominate global semiconductor output, necessitating high-volume deployment of turbomolecular pumps. It also benefits from a growing network of research laboratories and universities investing in advanced analytical instrumentation. The presence of large-scale electronics and display panel manufacturing further amplifies demand. Regional governments actively support technology infrastructure development, which encourages adoption across multiple industries. Local manufacturing capabilities and competitive pricing from regional suppliers enhance accessibility for both domestic and international buyers.

Latin America

Latin America represents 7% share of the Turbomolecular Pumps Market, with demand primarily concentrated in industrial vacuum processing and research applications. Brazil and Mexico lead adoption due to their growing automotive, aerospace, and materials processing sectors. It supports industrial coating processes, metallurgy, and quality control laboratories. Expansion of research and development facilities, particularly in academic institutions, creates niche opportunities for analytical instrumentation integration. Limited domestic manufacturing of high-end vacuum systems leads to reliance on imports from North America, Europe, and Asia-Pacific. Strategic partnerships with global suppliers help bridge this gap and ensure technical support for regional end users.

Middle East & Africa

The Middle East & Africa accounts for 5% share of the Turbomolecular Pumps Market, with activity centered in research facilities, energy projects, and specialized industrial processes. Countries in the Gulf Cooperation Council invest in advanced testing infrastructure for aerospace and defense applications. South Africa and Israel show demand from nanotechnology research and high-precision manufacturing. It also finds applications in energy sector laboratories, including those focused on renewable technologies and petrochemical analysis. Limited regional production capacity encourages imports, while international manufacturers often collaborate with local distributors to expand market presence. Growing interest in scientific research and technology innovation underpins steady long-term demand in this region.

Shape Your Report to Specific Countries or Regions & Enjoy 30% Off!

Key Player Analysis

- Shimadzu Corporation

- Busch LLC

- Pfeiffer Vacuum GmbH

- Edwards

- KYKY Technology Co. LTD

- EBARA Technologies, Inc.

- Ulvac, Inc

- Osaka Vacuum GmbH

- Leybold USA Inc

- Agilent

Competitive Analysis

The Turbomolecular Pumps Market features such as Shimadzu Corporation, Busch LLC, Pfeiffer Vacuum GmbH, Edwards, KYKY Technology Co. LTD, EBARA Technologies, Inc., Ulvac, Inc., Osaka Vacuum GmbH, Leybold USA Inc, and Agilent. The Turbomolecular Pumps Market is characterized by intense competition, with manufacturers focusing on technological innovation, product reliability, and application-specific performance. Companies differentiate through advancements in rotor design, magnetic bearing technology, and energy-efficient motor control systems to meet the stringent requirements of industries such as semiconductors, nanotechnology, analytical instrumentation, and industrial vacuum processing. Global players invest in expanding manufacturing capabilities and establishing service networks to ensure quick response times and technical support. Strategic initiatives such as mergers, acquisitions, and collaborative partnerships enable access to new markets and strengthen supply chains. The market also sees a growing emphasis on digital integration, with pumps incorporating real-time monitoring and predictive maintenance to enhance operational uptime. Sustainability, cost efficiency, and long-term service contracts are emerging as critical factors influencing competitive positioning.

Recent Developments

- In February 2024, Shimadzu Corporation and Shimadzu Scientific Instruments (SSI) announced the development of an innovative technique, double isotope-mediated liquid chromatography.

- In January 2024, Agilent and Incyte announced a collaboration to develop Advanced Companion Diagnostics in Hematology and Oncology.

- In February 2023, ULVAC Technologies acquired KYKY Vacuum for an undisclosed amount.

Market Concentration & Characteristics

The Turbomolecular Pumps Market exhibits a moderately concentrated structure, with a limited number of global manufacturers holding a substantial share due to the high technical expertise and capital investment required for production. It is defined by advanced engineering capabilities, stringent quality standards, and strong intellectual property portfolios that create significant entry barriers for new competitors. Leading producers maintain competitive advantage through innovation in rotor dynamics, magnetic bearing systems, and energy-efficient drive technologies. The market serves specialized applications in semiconductor fabrication, nanotechnology, analytical instrumentation, and industrial vacuum processing, where reliability and precision are critical. It operates under a high degree of customer specification, often requiring tailored designs and application-specific performance parameters. Global distribution networks and localized service facilities play an important role in maintaining operational uptime for end users. The competitive landscape is further shaped by long-term supplier relationships, integration of predictive maintenance features, and adherence to evolving environmental and energy-efficiency regulations.

Report Coverage

The research report offers an in-depth analysis based on Type, Industry and Geography. It details leading market players, providing an overview of their business, product offerings, investments, revenue streams, and key applications. Additionally, the report includes insights into the competitive environment, SWOT analysis, current market trends, as well as the primary drivers and constraints. Furthermore, it discusses various factors that have driven market expansion in recent years. The report also explores market dynamics, regulatory scenarios, and technological advancements that are shaping the industry. It assesses the impact of external factors and global economic changes on market growth. Lastly, it provides strategic recommendations for new entrants and established companies to navigate the complexities of the market.

Future Outlook

- Demand will rise with the expansion of semiconductor fabrication facilities in emerging and established markets.

- Adoption will grow in nanotechnology research due to the need for ultra-high-vacuum conditions.

- Manufacturers will focus on compact, high-speed pump designs for space-limited applications.

- Integration of smart monitoring systems will improve predictive maintenance capabilities.

- Energy-efficient models will gain preference to align with sustainability objectives.

- Hybrid pump configurations will see increased use for broader pressure range coverage.

- The aerospace sector will boost demand through satellite and space exploration projects.

- Vacuum coating applications will expand in automotive, optics, and electronics industries.

- Localized production and service centers will strengthen supply chain resilience.

- Collaborations with research institutions will drive product innovation and application diversity.