| REPORT ATTRIBUTE |

DETAILS |

| Historical Period |

2020-2023 |

| Base Year |

2024 |

| Forecast Period |

2025-2032 |

| U.S. Construction Aggregates Market Size 2024 |

USD 1,17,118.25 Million |

| U.S. Construction Aggregates Market, CAGR |

4.95% |

| U.S. Construction Aggregates Market Size 2032 |

USD 1,72,429.31 Million |

Market Overview

U.S. Construction Aggregates Market size was valued at USD 1,17,118.25 million in 2024 and is anticipated to reach USD 1,72,429.31 million by 2032, at a CAGR of 4.95% during the forecast period (2024-2032).

The U.S. construction aggregates market is driven by robust infrastructure development initiatives, increasing urbanization, and growing demand for residential and commercial construction projects. Government investments in highways, bridges, and public transportation systems under programs like the Infrastructure Investment and Jobs Act are significantly fueling aggregate consumption. Additionally, the surge in demand for renewable energy installations, such as wind and solar farms, further contributes to market expansion. Technological advancements in aggregate production and recycling practices are enhancing operational efficiency and sustainability. The market is also witnessing a shift towards eco-friendly materials and the use of recycled aggregates to meet environmental regulations and reduce carbon footprints. Moreover, the steady rise in private sector investments in real estate and industrial development supports long-term market growth. These trends collectively position construction aggregates as a critical component in the evolving landscape of U.S. infrastructure and construction activities.

The U.S. construction aggregates market is driven by extensive infrastructure development, urbanization, and the growing demand for residential and commercial construction. Key regions such as the Midwest, South, and West are witnessing high demand due to ongoing highway expansion projects, residential developments, and industrial construction. The availability of raw materials, coupled with advanced transportation networks, supports the steady supply of aggregates across these regions. Leading companies dominating the market include CRH plc, Eagle Materials Inc., SRC Group, Tarmac, Sika AG, Boral Limited, CEMEX S.A.B. de C.V., Heidelberg Materials AG, Vulcan Materials Company, Martin Marietta Materials Inc., and Adbri Limited. These players focus on strategic acquisitions, advanced production technologies, and sustainable solutions to strengthen their market presence. Additionally, the rising emphasis on recycled aggregates and eco-friendly construction materials is influencing competitive strategies, ensuring long-term sustainability and market growth in the U.S. construction aggregates sector.

Access crucial information at unmatched prices!

Request your sample report today & start making informed decisions powered by Credence Research Inc.!

Download Sample

Market Insights

- The U.S. Construction Aggregates market was valued at USD 1,17,118.25 million in 2024 and is expected to reach USD 1,72,429.31 million by 2032, growing at a CAGR of 4.95%.

- The market is driven by increasing infrastructure development projects, including roads, bridges, and residential buildings.

- Growing demand for sustainable and recycled aggregates is shaping industry trends, with companies focusing on eco-friendly solutions.

- Major players are expanding their production capacities and investing in advanced mining technologies to enhance efficiency and profitability.

- Fluctuating raw material costs and environmental regulations pose challenges to market growth, impacting production and pricing strategies.

- The Midwest and Southern regions dominate the U.S. market due to extensive construction activities and large-scale infrastructure investments.

- Rising urbanization and government initiatives for smart city projects further boost the demand for construction aggregates across various states.

Report Scope

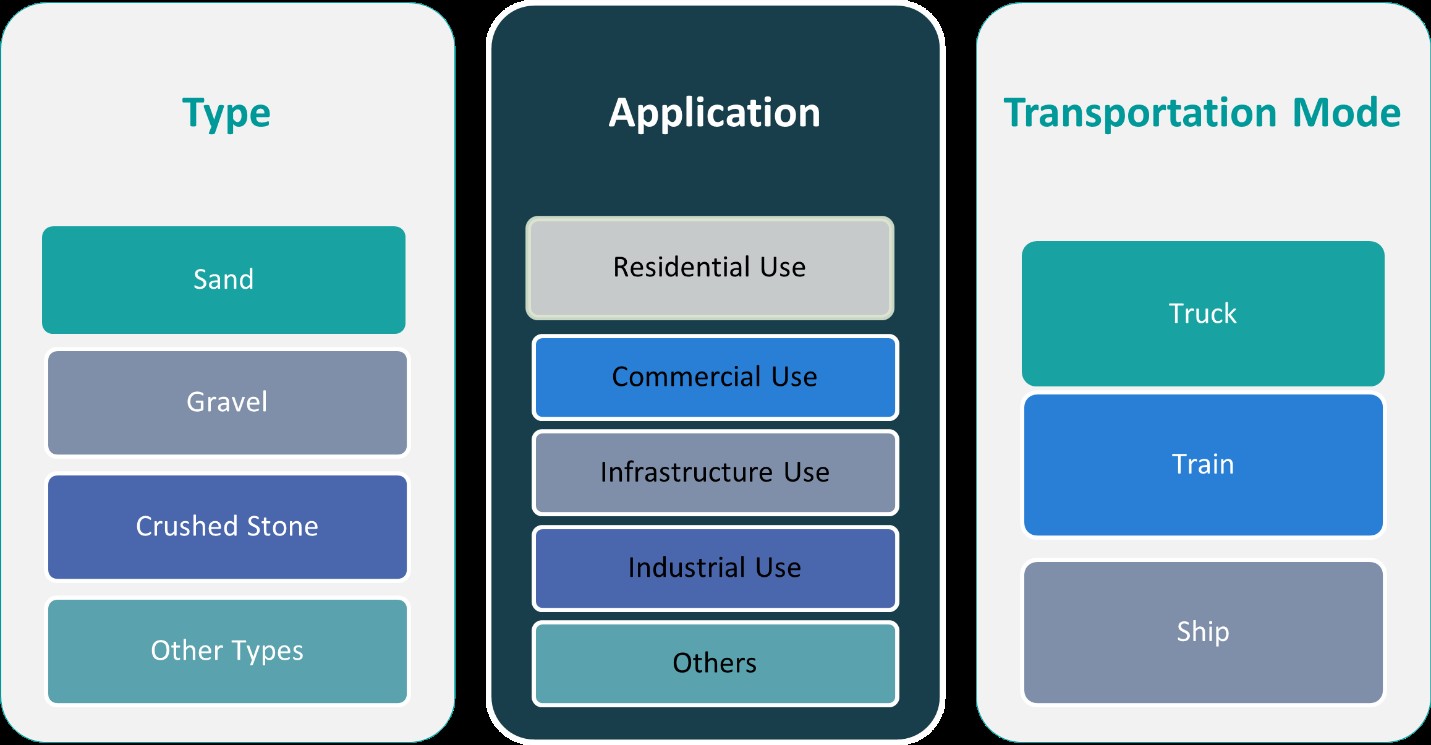

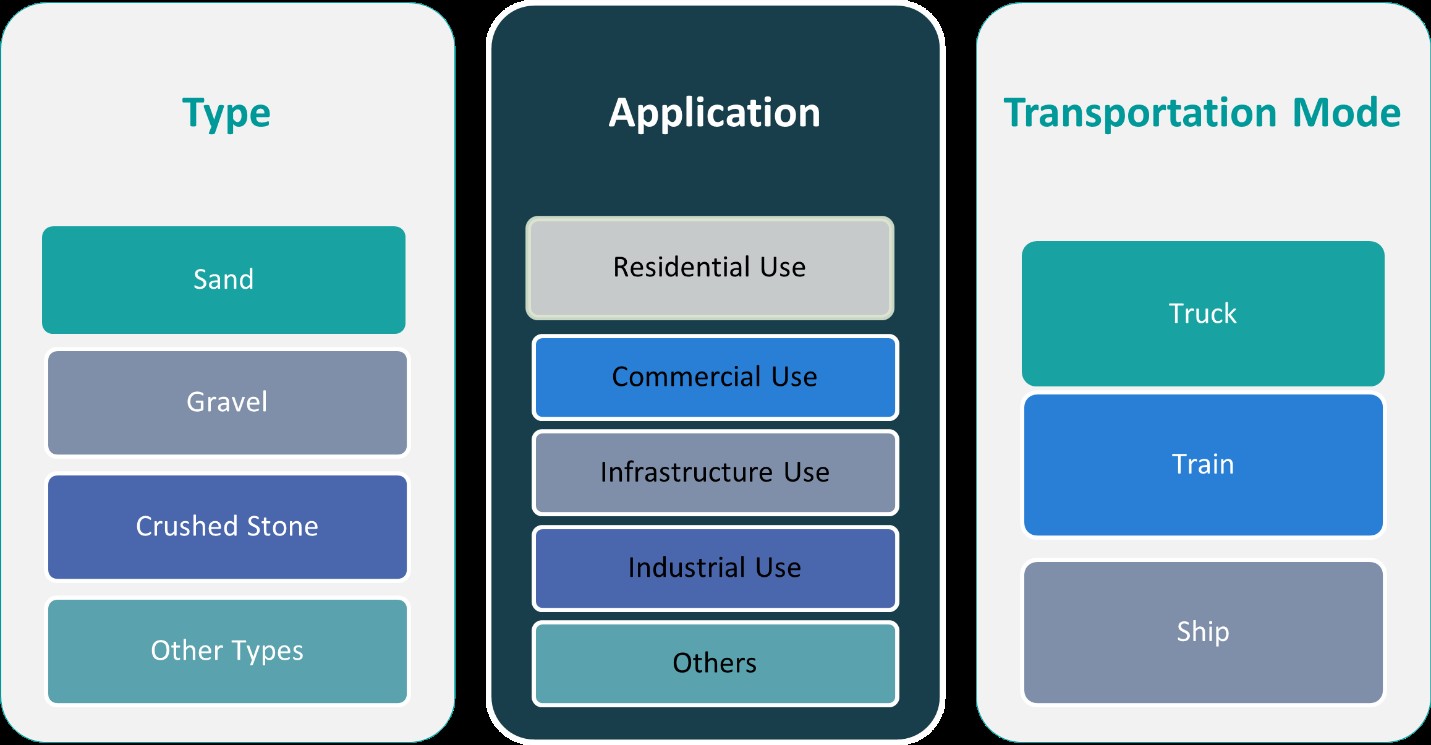

This report segments the U.S. Construction Aggregates Market as follows:

Market Drivers

Expanding Infrastructure Development Initiatives

One of the primary drivers of the U.S. construction aggregates market is the surge in infrastructure development across the country. Government-led initiatives, particularly under the Infrastructure Investment and Jobs Act (IIJA), have unlocked significant funding for the development and rehabilitation of transportation networks, including highways, bridges, railways, and airports. These large-scale projects heavily rely on construction aggregates such as crushed stone, sand, and gravel. As federal and state governments prioritize public infrastructure upgrades to boost economic growth and ensure long-term resilience, the demand for aggregates is expected to remain consistently high. The long project timelines and ongoing maintenance needs ensure sustained market momentum for years to come.

Growth in Residential and Commercial Construction

The steady growth in residential housing and commercial real estate development also plays a crucial role in driving the U.S. construction aggregates market. For instance, the U.S. Department of Housing and Urban Development (HUD) has introduced affordable housing programs to address urban population growth, while cities like Austin, Texas, are experiencing a boom in mixed-use developments. In addition, the post-pandemic rebound in the real estate sector and increased mortgage activity have further accelerated construction starts. Aggregates serve as essential base materials in the construction of foundations, roads, and other structural components, making them indispensable to the construction value chain. This sustained growth in building activity directly translates into increased aggregate consumption.

Rising Focus on Sustainability and Recycled Aggregates

Environmental sustainability and resource efficiency are becoming increasingly important in the construction sector, and this shift is significantly influencing the aggregates market. For instance, the U.S. Green Building Council promotes the use of recycled materials through LEED certifications, encouraging construction companies to adopt eco-friendly aggregates. These alternatives reduce the reliance on virgin raw materials while supporting circular economy goals. Construction firms are investing in on-site crushing and recycling technologies to minimize waste and lower transportation costs. This trend is not only enhancing the environmental profile of projects but also improving profit margins by reducing material acquisition costs. The growing emphasis on sustainable construction is expected to propel innovation and diversify the product offerings within the aggregates sector.

Advancements in Aggregate Production and Logistics

Technological improvements in quarrying, processing, and transportation of construction aggregates are further propelling market growth. Automation, remote monitoring, and advanced crushing and screening technologies are enabling producers to optimize output, reduce operational costs, and ensure consistent product quality. Additionally, improvements in supply chain logistics—such as efficient rail and barge transport—are helping overcome regional supply constraints and ensuring timely delivery to construction sites. These innovations are especially crucial as demand rises across diverse geographies, including urban centers and rural development zones. The ability to scale operations efficiently and reliably positions aggregate producers for long-term competitiveness and supports the evolving needs of the U.S. construction sector.

Market Trends

Growing Demand for Sustainable and Recycled Aggregates

The U.S. construction aggregates market is experiencing a shift toward sustainability, driven by increasing environmental regulations and a growing emphasis on reducing carbon footprints. For instance, the Federal Highway Administration has been actively promoting the use of recycled concrete aggregates in road construction projects, encouraging eco-friendly practices. Similarly, state-level initiatives, such as California’s CalRecycle program, incentivize the adoption of recycled aggregates derived from construction and demolition waste. Companies are investing in advanced processing technologies, such as AI-driven sorting systems, to enhance the quality and efficiency of recycled aggregates, further fueling their adoption across residential, commercial, and infrastructure projects.

Infrastructure Development Driving Aggregate Consumption

The ongoing expansion and modernization of infrastructure projects across the U.S. continue to propel the demand for construction aggregates. For instance, the Bipartisan Infrastructure Law (BIL) has allocated substantial funding for projects like highway expansions and bridge repairs, as highlighted by the U.S. Department of Transportation. Large-scale urban development projects and highway expansions are particularly contributing to increased aggregate consumption. Moreover, the rise of public-private partnerships in infrastructure construction has further accelerated market growth, as private investments complement government funding to ensure steady demand for raw materials.

Rising Adoption of Advanced Quarrying and Processing Technologies

Technological advancements in quarrying and aggregate processing are improving efficiency, reducing waste, and enhancing product quality. Automated crushing and screening equipment, coupled with digital monitoring solutions, enable producers to optimize operations while minimizing environmental impact. Furthermore, artificial intelligence and machine learning applications in predictive maintenance are reducing downtime and operational costs. The adoption of sustainable mining techniques, such as water recycling in washing plants and dust suppression systems, is also gaining prominence, helping manufacturers meet regulatory standards while maintaining high production capacities.

Regional Disparities and Supply Chain Challenges

The U.S. construction aggregates market faces regional disparities in demand, with high-growth urban areas such as Texas, California, and Florida driving consumption, while some rural regions experience slower growth. Supply chain constraints, including rising transportation costs and logistics challenges, have also impacted market dynamics. Aggregates, being high-volume and low-cost materials, are heavily dependent on efficient local sourcing, making transportation a key concern. Companies are increasingly investing in strategically located production facilities and distribution networks to mitigate cost pressures and ensure a steady supply to high-demand regions. Additionally, fluctuations in raw material prices and labor shortages continue to pose challenges for industry players, necessitating adaptive strategies to maintain profitability and operational efficiency.

Market Challenges Analysis

Rising Regulatory and Environmental Constraints

The U.S. construction aggregates market faces significant challenges due to stringent environmental regulations and zoning restrictions. For instance, the U.S. Environmental Protection Agency (EPA) enforces strict guidelines on emissions control and water resource management, requiring companies to conduct comprehensive environmental impact assessments before obtaining mining permits. Similarly, state-level regulations, such as California’s Sustainable Groundwater Management Act, impose additional restrictions on quarry developments to protect natural habitats. Additionally, local community opposition, as seen in recent mining project delays in Texas, highlights the growing emphasis on sustainability and carbon footprint reduction. These regulatory constraints have increased compliance costs, prompting companies to invest in advanced dust suppression systems and water recycling technologies to meet environmental standards.

Supply Chain Disruptions and Rising Costs

Supply chain disruptions pose another critical challenge for the U.S. construction aggregates market, affecting material availability and pricing. Fluctuations in fuel prices directly impact transportation costs, as aggregates are heavy materials requiring extensive logistics operations. Additionally, labor shortages within the trucking and construction industries contribute to delays in material delivery, further straining project timelines. The reliance on rail and maritime transport for regional distribution also presents bottlenecks, particularly in areas experiencing infrastructure constraints. Global economic conditions, including trade restrictions and inflationary pressures, have further exacerbated cost volatility for raw materials, equipment, and fuel. The rising costs of energy and labor have forced many aggregate producers to adjust pricing strategies, which, in turn, affects the overall cost structure of construction projects. Moreover, unpredictable weather patterns, including hurricanes and extreme temperatures, disrupt mining and transportation operations, leading to temporary shortages. Addressing these supply chain inefficiencies requires substantial investment in infrastructure modernization and workforce development, ensuring a more resilient and cost-effective supply network for the industry.

Market Opportunities

The U.S. construction aggregates market is poised for significant growth, driven by increasing infrastructure development and urbanization. Government initiatives such as the Infrastructure Investment and Jobs Act (IIJA) have allocated substantial funding for roadways, bridges, and public transportation systems, creating a steady demand for aggregates like crushed stone, sand, and gravel. Additionally, the surge in residential and commercial construction activities, particularly in metropolitan regions, has further amplified the need for high-quality aggregates. The growing emphasis on sustainable and recycled materials presents a lucrative opportunity for manufacturers to invest in eco-friendly alternatives, such as recycled concrete aggregates, which align with environmental regulations and reduce raw material dependency. Advancements in technology, including automation in aggregate processing and enhanced logistics management, are also improving supply chain efficiency, enabling suppliers to meet rising demands with greater precision.

Furthermore, the increasing adoption of high-performance aggregates in specialized applications, such as high-strength concrete and asphalt, is expanding the market scope. The rise in public-private partnerships (PPPs) for infrastructure projects is unlocking new investment opportunities, fostering long-term growth in the sector. Moreover, the expansion of smart city initiatives and sustainable urban development plans is fueling demand for durable and weather-resistant construction materials. With the shift toward digitization in the construction industry, data-driven forecasting and predictive analytics are enabling suppliers to optimize production and distribution, ensuring cost-effective and timely supply of aggregates. As economic recovery accelerates, coupled with favorable government policies and technological advancements, the U.S. construction aggregates market is well-positioned for sustained growth, offering substantial opportunities for stakeholders across the value chain.

Market Segmentation Analysis:

By Type:

The U.S. construction aggregates market is categorized into sand, gravel, crushed stone, and other types, each serving distinct construction needs. Sand is widely used in concrete production, road base, and masonry applications due to its fine texture and binding properties. With the growing emphasis on sustainable construction, demand for manufactured sand as an alternative to natural sand is increasing. Gravel, known for its durability and permeability, is extensively used in road construction, drainage systems, and landscaping projects. The rising investments in highway expansion and flood control measures are boosting the adoption of gravel-based aggregates. Crushed stone, the largest segment, is a key material for road base, railway ballast, and heavy construction due to its high strength and stability. Infrastructure modernization projects, including bridge rehabilitation and airport expansions, are driving its consumption. Other types of aggregates, such as slag and recycled concrete, are gaining traction as eco-friendly alternatives, supporting the industry’s shift toward sustainable and cost-effective construction materials.

By Application:

By application, the market is segmented into residential, commercial, infrastructure, and industrial use, each presenting unique growth prospects. The residential segment is experiencing robust demand for aggregates due to increasing housing developments and urban expansion. Rising investments in affordable housing and multi-family residential projects further contribute to this growth. Commercial applications, including office buildings, retail centers, and hospitality structures, are driving aggregate consumption, supported by economic recovery and business expansion initiatives. Infrastructure remains the dominant application segment, fueled by government-backed projects for roads, bridges, and public utilities. The ongoing emphasis on resilient infrastructure and smart city developments is expected to further elevate aggregate demand. In the industrial sector, aggregates play a crucial role in manufacturing facilities, power plants, and large-scale construction projects. As the U.S. continues to prioritize industrial growth and energy infrastructure, the demand for construction aggregates in this segment is anticipated to witness steady expansion, reinforcing the market’s long-term growth potential.

Segments:

Based on Type:

- Sand

- Gravel

- Crushed Stone

- Other Types

Based on Application:

- Residential Use

- Commercial Use

- Infrastructure Use

- Industrial Use

Based on End- User:

Based on the Geography:

- Western United States

- Midwestern United States

- Southern United States

- Northeastern United States

Regional Analysis

Southern United States

The Southern United States holds the largest market share, accounting for approximately 38% of total construction aggregate consumption. The region’s dominance is attributed to rapid population growth, urban expansion, and high levels of infrastructure development, particularly in states such as Texas and Florida. Major highway projects, increased residential construction, and commercial real estate expansion are driving aggregate demand. Additionally, the region’s extensive coastline and vulnerability to hurricanes have necessitated large-scale infrastructure resilience projects, further boosting the market. The availability of abundant natural resources, including limestone and gravel, ensures a steady supply of aggregates, making the Southern region a key player in the industry.

Midwestern United States

The Midwestern United States follows, holding a market share of approximately 25%, driven primarily by transportation infrastructure and industrial construction. The region is home to extensive road networks and aging infrastructure that require continuous maintenance and upgrades, spurring demand for crushed stone and sand. States such as Illinois, Ohio, and Michigan are seeing increased aggregate consumption due to federal funding for bridge rehabilitation and railway expansion. Additionally, the presence of a strong manufacturing sector contributes to industrial construction, further fueling market growth. The Midwest also benefits from significant limestone deposits, particularly in states like Indiana and Missouri, which support the production of high-quality construction aggregates. Furthermore, sustainability initiatives promoting recycled aggregates are gaining traction, presenting new opportunities for market expansion in the region.

Western United States

The Western United States accounts for approximately 22% of the market share, with aggregate demand primarily driven by large-scale infrastructure and commercial construction projects. States such as California, Washington, and Arizona are experiencing increased urbanization, necessitating investments in transportation networks, high-rise buildings, and smart city developments. The region’s unique geological conditions and frequent seismic activity have led to strict construction regulations, increasing the demand for high-strength aggregates in earthquake-resistant structures. Additionally, water conservation efforts in arid states have led to a rising preference for permeable aggregates in landscaping and drainage applications. The presence of vast mountainous terrains provides ample resources for crushed stone production, supporting the region’s long-term supply.

Northeastern United States

The Northeastern United States holds the smallest share, at approximately 15%, but remains a crucial market due to its dense urban centers and aging infrastructure. States such as New York, Pennsylvania, and Massachusetts are investing heavily in infrastructure modernization, including roadways, tunnels, and bridges, which drives demand for construction aggregates. The region’s reliance on imported aggregates due to limited natural resources has led to increased use of recycled materials and alternative aggregates. Additionally, stringent environmental regulations have accelerated the adoption of sustainable construction practices, positioning the Northeast as a key hub for innovative aggregate solutions. Despite its smaller market share, steady investments in public transportation and commercial real estate redevelopment ensure continued aggregate demand in the region.

Key Player Analysis

- CRH plc

- Eagle Materials Inc.

- SRC Group

- Tarmac

- Sika AG

- Boral Limited

- CEMEX S.A.B. de C.V.

- Heidelberg Materials AG

- Vulcan Materials Company

- Martin Marietta Materials Inc.

- Adbri Limited

Competitive Analysis

The U.S. Construction Aggregates market is highly competitive, with key players focusing on expanding production capacities, technological advancements, and strategic acquisitions to strengthen their market presence. Leading companies such as Vulcan Materials Company, Martin Marietta Materials, Heidelberg Materials, CRH Americas, and Cemex S.A.B. de C.V. dominate the market, leveraging their extensive distribution networks and large-scale production facilities. These companies are continuously investing in advanced mining and processing technologies to enhance efficiency and meet the growing demand for high-quality aggregates. Market leaders are also focusing on sustainable solutions, including recycled aggregates and low-carbon footprint materials, to align with environmental regulations and customer preferences. Additionally, strategic mergers and acquisitions are common, allowing companies to strengthen their regional presence and optimize supply chain operations. However, intense competition, fluctuating raw material costs, and regulatory challenges pose barriers to market expansion. Despite these challenges, established players maintain a strong foothold through diversified product offerings, extensive logistics capabilities, and long-term contracts with construction and infrastructure companies. The Midwest and Southern regions remain key revenue contributors due to ongoing urbanization and infrastructure investments, positioning these leading players at the forefront of industry growth in the U.S. market.

Recent Developments

- In September 2024, Holcim started the Holcim Sustainable Construction Academy. This is a free online training program that teaches about eco-friendly building methods. It helps people who work in construction learn new skills. The program offers both online classes and face-to-face training.

- In October 2024, CRH Ventures launched the Sustainable Building Materials accelerator to scale up creative climate and build technology firms that specialize in CO2-mineralized materials and sustainable binder solutions.

- In July 2024, Heidelberg Materials launched a recycling plant in Katowice, Poland, using a patented ReConcrete process to recycle demolition concrete and replace virgin material.

- In July 2024, Cemex USA formed a joint venture with Couch Aggregates and Premier Holdings for the production and distribution of aggregates in the Mid-South region. Cemex USA already had a strategic partnership with Couch Aggregates. The company stated that this vertical integration, combined with Premier Holdings’ Gulf Coast marine terminals, would accelerate its regional growth.

- In April 2024, Rogers Group joined The Road Forward initiative to advance sustainable asphalt production and paving practices.

- In January 2024, Heidelberg Materials launched Evo Build, its new global brand for low-carbon and circular products. This initiative aims to provide sustainable solutions for the construction industry, focusing on reducing carbon emissions and promoting circular economy principles.

Market Concentration & Characteristics

The U.S. Construction Aggregates market exhibits a moderate to high level of market concentration, with a few dominant players holding a significant share. Companies such as Vulcan Materials Company, Martin Marietta Materials, Heidelberg Materials, CRH Americas, and Cemex S.A.B. de C.V. maintain a competitive edge through extensive production facilities, advanced mining technologies, and strategic mergers. The market is characterized by capital-intensive operations, high transportation costs, and regulatory compliance requirements, which create entry barriers for new participants. Demand is driven by large-scale infrastructure projects, urban development, and commercial construction, with regional variations in consumption patterns. Established players focus on sustainability initiatives, including recycled aggregates and carbon-neutral solutions, to align with evolving environmental regulations. Additionally, long-term contracts with government and private construction firms ensure steady revenue streams. Despite competition and cost fluctuations, leading firms leverage economies of scale, efficient logistics, and technological advancements to sustain growth in the dynamic U.S. market.

Shape Your Report to Specific Countries or Regions & Enjoy 30% Off!

Report Coverage

The research report offers an in-depth analysis based on Type, Application, Transportation Mode and Geography. It details leading market players, providing an overview of their business, product offerings, investments, revenue streams, and key applications. Additionally, the report includes insights into the competitive environment, SWOT analysis, current market trends, as well as the primary drivers and constraints. Furthermore, it discusses various factors that have driven market expansion in recent years. The report also explores market dynamics, regulatory scenarios, and technological advancements that are shaping the industry. It assesses the impact of external factors and global economic changes on market growth. Lastly, it provides strategic recommendations for new entrants and established companies to navigate the complexities of the market.

Future Outlook

- The U.S. Construction Aggregates market will continue to grow due to increasing infrastructure investments and urban development projects.

- Sustainable and recycled aggregates will gain traction as environmental regulations become more stringent.

- Advancements in mining and processing technologies will enhance efficiency and reduce production costs.

- Market consolidation will intensify as major players pursue mergers and acquisitions to expand their regional presence.

- Government initiatives for smart cities and transportation projects will drive long-term demand for construction aggregates.

- Rising raw material and transportation costs may impact pricing strategies and profit margins for manufacturers.

- Digitalization and automation in aggregate production will improve operational efficiency and supply chain management.

- The Southern and Midwest regions will continue to dominate due to large-scale infrastructure activities.

- Demand for high-performance aggregates in specialized construction projects will increase in the coming years.

- Strategic partnerships between key players and construction firms will ensure a steady supply of aggregates across various sectors.