Market Overview:

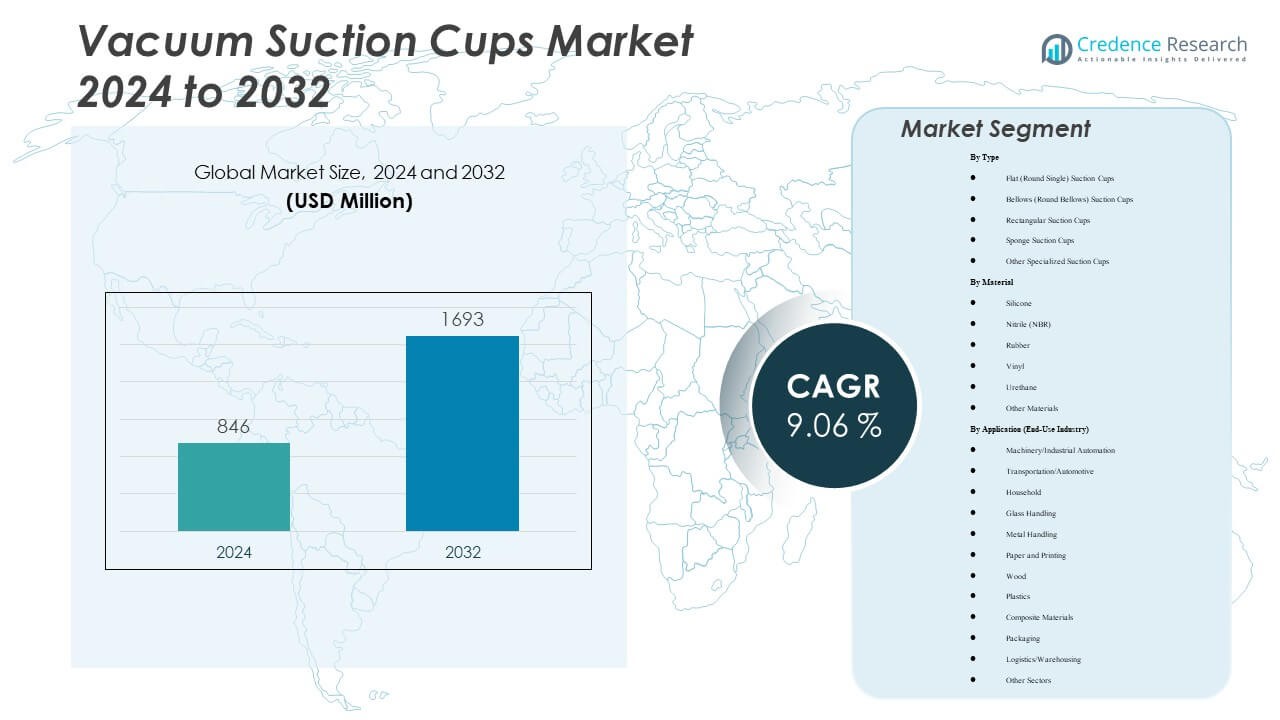

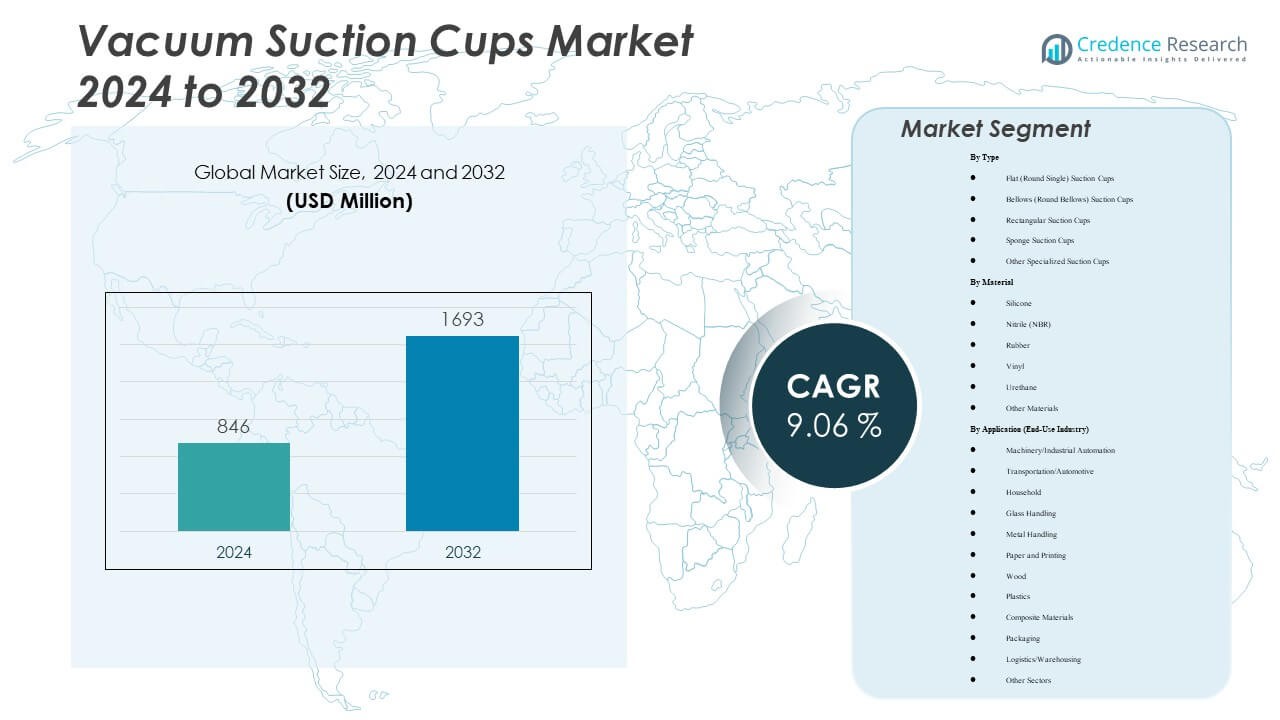

The Vacuum Suction Cups Market is projected to grow from USD 846 million in 2024 to an estimated USD 1693 million by 2032, with a compound annual growth rate (CAGR) of 9.06% from 2024 to 2032.

| REPORT ATTRIBUTE |

DETAILS |

| Historical Period |

2020-2024 |

| Base Year |

2024 |

| Forecast Period |

2025-2032 |

| Vacuum Suction Cups Market Size 2024 |

USD 846 Million |

| Vacuum Suction Cups Market, CAGR |

9.06% |

| Vacuum Suction Cups Market Size 2032 |

USD 1693 Million |

The market is being driven by increasing automation across manufacturing sectors, where vacuum suction cups are essential in robotic pick-and-place operations, material handling, and packaging lines. Industries such as automotive, electronics, and food processing are adopting advanced suction cup systems to improve speed, efficiency, and precision. Furthermore, the growing emphasis on lightweight and durable materials has encouraged manufacturers to develop innovative suction cup designs tailored to diverse surfaces, further expanding application potential.

Regionally, Asia-Pacific leads the Vacuum Suction Cups Market, supported by strong industrial growth and a high concentration of manufacturing facilities in countries like China, Japan, and South Korea. Europe and North America also hold significant shares, driven by demand from automotive and packaging sectors. Meanwhile, emerging economies in Latin America and the Middle East are witnessing rising adoption due to increasing industrial automation and infrastructural development. These regions are attracting investment in manufacturing, which is fostering demand for vacuum handling equipment, positioning them as future growth contributors in the global market.

Access crucial information at unmatched prices!

Request your sample report today & start making informed decisions powered by Credence Research Inc.!

Download Sample

Market Insights:

- The Vacuum Suction Cups Market is valued at USD 846 million in 2024 and is expected to reach USD 1693 million by 2032, growing at a CAGR of 9.06%.

- Rising industrial automation across sectors such as automotive, packaging, and electronics is a major growth driver.

- Growing demand for smart suction systems with sensors and predictive maintenance features enhances operational efficiency.

- Surface compatibility issues and performance degradation under extreme conditions limit product versatility and lifespan.

- Asia-Pacific leads the market with 41% share, driven by strong manufacturing bases in China, Japan, and South Korea.

- North America holds 27% share, supported by high-tech automation adoption in the U.S. and Canada.

- Europe commands 22% market share, led by Germany, France, and Italy, where stringent quality standards and energy-efficient systems are prioritized.

Market Drivers:

Rising Industrial Automation Across Manufacturing Sectors Boosts Product Demand

The rapid growth of industrial automation continues to fuel demand for vacuum suction cups in various applications. Automation in industries like automotive, packaging, and consumer electronics depends heavily on precision handling, which vacuum suction cups enable. They offer reliable gripping solutions that reduce production downtime and enhance operational efficiency. The need for streamlined operations in high-speed environments supports their adoption. Manufacturers are upgrading machinery with robotic systems that use suction cups for fast and accurate material transfer. The Vacuum Suction Cups Market benefits directly from these advancements. It supports greater throughput and enables production lines to run with minimal human intervention. Adoption across assembly lines and material handling systems further strengthens market growth.

- For instance, ABB’s FlexGripper Vacuum features 10 separate, programmable suction cup zones, enabling flexible picking of up to 5 cases per cycle. This setup supports efficient material handling for products with dimensions up to 1,200×500×300 mm. Integrated sensors monitor each suction zone for product presence, ensuring precision during operation.

Expanding E-commerce and Packaging Industry Drives Demand for Handling Equipment

The surge in e-commerce has created a pressing need for faster and more efficient packaging processes. Vacuum suction cups are widely used in sorting, labeling, and parcel handling, where consistent grip and speed are critical. Fulfillment centers rely on these components to manage a variety of packaging sizes and materials. Their ability to handle delicate and irregularly shaped products gives them an edge in automated systems. The Vacuum Suction Cups Market experiences a rise in demand due to the growing dependence on warehouse automation. It helps logistics companies achieve quicker processing times and reduce labor costs. Packaging lines in food and pharmaceutical sectors also implement suction cups to maintain product safety and speed. This evolving logistics landscape continues to reinforce their essential role.

Focus on Minimizing Downtime Through Predictive Maintenance Supports Growth

Preventing unplanned production halts is a core priority in industrial operations. Vacuum suction cups integrated with sensors and predictive maintenance capabilities enhance reliability. These smart suction cups detect wear, monitor vacuum levels, and alert operators before failure occurs. This advancement lowers repair costs and improves production continuity. The Vacuum Suction Cups Market benefits from this shift toward predictive systems that support Industry 4.0 goals. It enables manufacturers to maintain high uptime and operational efficiency. Smart technology adoption encourages long-term investment in automated handling tools. The rising demand for preventive solutions enhances the importance of advanced suction systems.

- For instance, Schmalz has introduced digital vacuum monitoring tools that continuously record and analyze operational data from suction cup lifters. These predictive maintenance solutions detect abnormal fluctuations such as drops in vacuum level or extended cycle times and can alert operators prior to system failure, enabling maintenance interventions that minimize unplanned downtime.

Surging Adoption in Food, Electronics, and Medical Applications Elevates Market Expansion

Vacuum suction cups find increasing utility in industries where cleanliness, precision, and adaptability are critical. In the food sector, hygienic handling without contamination is essential, and suction cups with FDA-compliant materials meet these standards. Electronics manufacturers need suction systems capable of safely handling fragile components. The Vacuum Suction Cups Market addresses these niche demands with customizable solutions. It allows users to select specific cup shapes, sizes, and materials to suit delicate operations. Medical device manufacturing also benefits from the precision of these systems, especially for sterile and fragile product handling. These diverse industry needs contribute to the market’s growing relevance. The expanding application scope continues to reinforce its value across sectors.

Market Trends

Integration of Smart Technologies to Enable Intelligent Gripping Systems

Manufacturers are increasingly incorporating sensors and IoT capabilities into vacuum suction cups. These smart suction systems provide real-time data on grip strength, vacuum integrity, and surface compatibility. The ability to monitor conditions enables more adaptive and fail-safe operations. Automation systems benefit from the feedback these smart cups offer, allowing them to adjust dynamically. The Vacuum Suction Cups Market sees growing investment in intelligent gripping to meet smart factory requirements. It helps companies meet quality assurance goals through data-driven insights. This trend supports predictive maintenance and reduced waste. Intelligent systems also reduce human intervention and raise operational standards.

Development of Eco-Friendly Materials for Sustainable Operations

Environmental considerations have led to a push for sustainable vacuum suction cups. Manufacturers are exploring recyclable thermoplastics and silicone alternatives to reduce environmental impact. The use of low-energy vacuum pumps also supports green initiatives. The Vacuum Suction Cups Market is experiencing innovation in material science aligned with sustainability goals. It promotes the adoption of non-toxic, biodegradable materials that suit sensitive applications. These trends reflect changing regulatory frameworks and consumer expectations. Companies are responding with products that balance performance and environmental responsibility. Market players gain a competitive edge by offering eco-certified solutions.

- For instance, Piab’s MX suction cup family employs DURAFLEX® material, which demonstrated an extended operational life by lasting over 750,000 cycles in testing, reducing the frequency of replacements and contributing to less industrial waste.

Modular and Customizable Designs Address Industry-Specific Demands

Demand is rising for vacuum suction cups that can adapt to various surface types and geometries. Industries require tailored suction solutions for different payloads, materials, and operational speeds. Modular suction cup assemblies allow for faster changeovers and greater flexibility. The Vacuum Suction Cups Market is evolving to provide high customization with interchangeable parts. It allows operators to fine-tune gripping systems based on dynamic needs. This trend enables cost savings by reducing the need for multiple toolsets. Customization improves accuracy and lowers damage risk, especially in high-precision sectors. The growing preference for modularity aligns with lean manufacturing practices.

- For instance, Piab’s piGRIP® system offers a fully modular suction cup that lets users customize lips, bellows, supports, and fittings, matching each component to unique operational requirements. With features like foam lips available in sizes up to 120mm for irregular surfaces and a selection of bellows for effective level compensation, these solutions allow for high customization and rapid changeovers without replacing the entire unit.

Rise in Collaborative Robots Expands Application Scope in Light Industries

The growth of collaborative robots (cobots) in manufacturing has opened new avenues for vacuum suction cups. Cobots often work alongside humans in light-duty tasks that require safe and soft gripping. Vacuum cups with soft-touch materials support these applications by offering non-invasive handling. The Vacuum Suction Cups Market benefits from the rise in cobot deployments across industries like consumer goods and pharmaceuticals. It supports ergonomic designs that minimize physical strain and injury risk. Manufacturers develop lightweight and compact suction systems suited to cobot arms. This trend reflects the shift toward flexible and human-safe automation in production lines.

Market Challenges Analysis

Material and Surface Compatibility Limitations Constrain Application Versatility

One of the key challenges in the Vacuum Suction Cups Market lies in the limited compatibility of suction cups with certain surface types. Porous, rough, or oily surfaces often prevent the formation of a stable vacuum seal. This restricts the use of suction cups in some industrial scenarios, requiring alternative gripping methods. It affects adoption rates in sectors handling irregular or textured products. Manufacturers must invest in R&D to develop specialized cup materials that improve adhesion on difficult surfaces. The cost of producing such specialized solutions may raise operational expenses. It also limits scalability for businesses with diverse product ranges. Addressing this challenge is essential to improve product reliability across industries.

Performance Degradation Under Harsh Environmental Conditions

Exposure to extreme temperatures, chemical agents, or continuous use can degrade suction cup performance. Rubber and silicone-based cups may wear out quickly or lose elasticity in such settings. The Vacuum Suction Cups Market faces hurdles in delivering long-term durability in harsh conditions. It creates a need for advanced materials that withstand exposure without compromising suction quality. Frequent replacements raise maintenance costs and lead to operational inefficiencies. Industries like foundries or chemical processing require high-performance materials that resist deformation. Suppliers must overcome this barrier through innovation in cup design and coating technologies. Failure to do so can hinder adoption in critical high-temperature or corrosive environments.

Market Opportunities

Expansion of Smart Manufacturing and Industrial Robotics Creates High Potential

The shift toward smart manufacturing presents a significant growth opportunity for the Vacuum Suction Cups Market. Factories are increasingly equipped with automated systems and robots that depend on vacuum-based gripping solutions. It aligns with the goals of Industry 4.0, where machines operate with minimal supervision. Companies seek suction systems that integrate seamlessly with robotic arms, vision systems, and digital controls. Manufacturers offering plug-and-play solutions with built-in diagnostics will attract strong demand. High customization capabilities open doors to tailored applications across niche industries. This evolving environment encourages investments in technologically advanced gripping tools. Growth in smart factories globally creates a long-term opportunity for suction cup suppliers.

Emerging Economies Offer Growth Scope Through Infrastructure and Logistics Development

Rapid industrialization in emerging markets such as Southeast Asia, Latin America, and Africa opens new avenues for the Vacuum Suction Cups Market. Governments are investing heavily in manufacturing infrastructure, smart warehouses, and logistics automation. These developments require efficient handling systems, where suction cups play a vital role. It supports safe and precise operations in various sectors, from automotive to food processing. Local demand for cost-effective automation solutions is rising. Manufacturers who establish regional production and distribution networks can benefit from this expanding customer base. The potential for first-mover advantage is high in underserved regions. These conditions make emerging markets critical for future expansion.

Market Segmentation Analysis:

The Vacuum Suction Cups Market is segmented by type, material, and end-use industry, each contributing distinctly to overall growth.

By types, flat suction cups hold a major share due to their versatility in smooth surface handling, while bellows suction cups offer flexibility for curved or uneven surfaces. Rectangular suction cups are widely used in panel lifting, and sponge suction cups find use in delicate product handling. Specialized variants address unique industrial needs, enhancing customization.

By material, silicone leads due to its temperature resistance and compliance with hygiene standards, making it suitable for food and medical applications. Nitrile (NBR) and rubber offer durability for industrial use, while vinyl and urethane support specific environments that require resistance to oils or abrasion. Other materials address niche operational demands based on chemical and thermal resistance.

- For instance, Festo’s ESG series suction cups are manufactured using FDA-compliant VMQ silicone, with a documented operating temperature range from –30°C to +200°C, making them suitable for high-temperature and food-grade automation environments.

By application, machinery and industrial automation represent the largest segment, followed by automotive and packaging industries. It supports material handling in glass, metal, and plastics processing. Logistics and warehousing sectors also drive demand for high-speed and reliable suction solutions. The Vacuum Suction Cups Market continues to diversify across sectors, meeting performance and safety standards in a wide range of industrial tasks.

- For instance, ABB’s FlexGripper Vacuum tool integrates 10 programmable suction cup zones and is designed to handle up to 5 products per cycle, each with dimensions reaching 1,200×500×300 mm, enabling efficient robotic material handling in automotive and electronics assembly operations.

Segmentation:

By Type

- Flat (Round Single) Suction Cups

- Bellows (Round Bellows) Suction Cups

- Rectangular Suction Cups

- Sponge Suction Cups

- Other Specialized Suction Cups

By Material

- Silicone

- Nitrile (NBR)

- Rubber

- Vinyl

- Urethane

- Other Materials

By Application (End-Use Industry)

- Machinery/Industrial Automation

- Transportation/Automotive

- Household

- Glass Handling

- Metal Handling

- Paper and Printing

- Wood

- Plastics

- Composite Materials

- Packaging

- Logistics/Warehousing

- Other Sectors

By Region

- North America

- Europe

- Germany

- France

- U.K.

- Italy

- Spain

- Rest of Europe

- Asia Pacific

- China

- Japan

- India

- South Korea

- South-east Asia

- Rest of Asia Pacific

- Latin America

- Brazil

- Argentina

- Rest of Latin America

- Middle East & Africa

- GCC Countries

- South Africa

- Rest of the Middle East and Africa

Regional Analysis:

Asia-Pacific dominates the Vacuum Suction Cups Market with a market share of 41%, driven by the region’s strong manufacturing base and rapid industrial automation. Countries such as China, Japan, South Korea, and India have seen significant investments in automotive, electronics, and packaging sectors. These industries rely heavily on vacuum suction technology for precise material handling, boosting product demand. The presence of major OEMs and regional automation solution providers enhances market accessibility. Rising labor costs in developed Asian economies further accelerate the shift to automation. The market continues to benefit from government initiatives promoting smart manufacturing across the region.

North America holds the second-largest share at 27%, supported by advanced industrial automation, robotics integration, and a well-established logistics network. The United States leads the region in adopting vacuum-based gripping systems across automotive and consumer goods sectors. Demand for high-precision components in electronics and pharmaceutical industries contributes to steady growth. The Vacuum Suction Cups Market benefits from the U.S. focus on lean manufacturing and predictive maintenance. Canadian industries are also investing in warehouse and packaging automation to enhance operational efficiency. The regional market remains strong due to ongoing technological innovation and high demand for customized automation tools.

Europe accounts for a 22% share, led by Germany, France, and Italy, where automation is deeply integrated into industrial operations. The region’s strong presence in automotive manufacturing, along with its high quality and safety standards, drives demand for durable and hygienic suction systems. European industries favor energy-efficient and sustainable vacuum components aligned with regulatory frameworks. The Vacuum Suction Cups Market in Europe is further supported by initiatives to digitize production facilities. The presence of well-established automation equipment manufacturers ensures consistent supply and product innovation. Eastern European countries show rising demand, reflecting ongoing industrial modernization and foreign direct investments.

Shape Your Report to Specific Countries or Regions & Enjoy 30% Off!

Key Player Analysis:

- SMC Corporation

- Schmalz

- Piab

- ANVER

- DESTACO (Dover)

- Aventics GmbH

- VMECA

- Vi-Cas Manufacturing

- William B. Rudow, Inc.

- AIRBEST PNEUMATICS (Changxing)

- Coval

- Festo

- VUOTOTECNICA

- Yonsha Co., Limited

- GGR Group

- Morali GmbH

- SAPELEM

- Sommer-Technik

- FIPA GmbH

- Myotoku Ltd.

Competitive Analysis:

The Vacuum Suction Cups Market features a mix of global leaders and specialized regional manufacturers competing on technology, material innovation, and customization. Companies like SMC Corporation, Schmalz, Piab, and Festo dominate the high-end automation segment, offering advanced products integrated with smart sensors and IoT capabilities. Emerging players such as AIRBEST PNEUMATICS and VMECA compete on cost efficiency and regional supply chains. The market encourages continuous product innovation to meet diverse industry requirements, including automotive, packaging, and electronics. It remains competitive with frequent product enhancements, strategic partnerships, and expansions into emerging markets. Brand reputation, quality consistency, and responsive customer support play a central role in maintaining market position.

Recent Developments:

- In June 2025, Schmalz extended its technology partnership with Oxipital AI to drive higher performance in robotic automation for picking applications. The collaboration leverages Schmalz’s wide range of vacuum components including suction cups and the vision capabilities of Oxipital AI, aiming to provide more flexible and efficient automated systems.

- In June 2025, DESTACO launched the eRDH Series Electric Parallel Gripper, an advanced solution for automated handling which features teachable sensors, speed and force controls, and selectable grip configurations. With plug-and-play configuration and robust safety features, this gripper enhances the performance and integration with vacuum and robotic systems, targeting industries such as automotive and packaging.

- In April 2025, VMECA released its new SB series vacuum cups—part of their Magic Cup product line—tailored for handling thin films, plastics, and papers. These cups feature an innovative structure that provides support inside the cup lip and are available in different softness grades, including FDA-compliant food-grade versions. The new design is optimized for gentle yet reliable lifting of sensitive packaging materials.

- In Nov 2024, Piab introduced the piGRIP® FLC, a flexible level compensator interface designed to expand the versatility of existing Piab suction cups. The piGRIP® FLC enables secure handling of parts with varying heights and off-angle positions, making it easier for suction cups to adapt to different application needs while maintaining a secure connection and promoting sustainability

Market Concentration & Characteristics:

The Vacuum Suction Cups Market shows moderate concentration with a strong presence of multinational corporations and niche local players. It operates in a technology-driven environment where innovation and adaptability define competitiveness. Standard and customized product offerings co-exist, serving both high-volume industries and precision applications. It supports automation growth with scalable solutions adaptable to various surfaces and operational conditions. Product reliability, material quality, and integration compatibility remain key purchase criteria. The market exhibits steady demand across sectors, with rising interest in eco-friendly and smart suction systems. Pricing strategies vary by application complexity and customer customization needs.

Report Coverage:

The research report offers an in-depth analysis based on type, material, and end-use industry. It details leading market players, providing an overview of their business, product offerings, investments, revenue streams, and key applications. Additionally, the report includes insights into the competitive environment, SWOT analysis, current market trends, as well as the primary drivers and constraints. Furthermore, it discusses various factors that have driven market expansion in recent years. The report also explores market dynamics, regulatory scenarios, and technological advancements that are shaping the industry. It assesses the impact of external factors and global economic changes on market growth. Lastly, it provides strategic recommendations for new entrants and established companies to navigate the complexities of the market.

Future Outlook:

- The market will witness increased demand due to growing adoption of robotic automation in manufacturing and logistics.

- Smart suction systems integrated with sensors and IoT will become a standard feature across industrial applications.

- Customized suction cup designs will gain traction to address specific needs in automotive, electronics, and food sectors.

- Adoption of eco-friendly materials will expand in response to sustainability goals and regulatory compliance.

- Emerging markets will offer growth opportunities due to industrialization and infrastructure development initiatives.

- E-commerce and warehouse automation will drive significant demand for efficient material handling solutions.

- Advancements in lightweight and high-strength materials will enhance product performance and durability.

- Collaborative robots in small- and mid-sized enterprises will increase reliance on compact, safe suction technologies.

- Demand for hygienic and FDA-compliant suction systems will grow in food processing and medical device manufacturing.

- Manufacturers will focus on predictive maintenance features to improve uptime and reduce operational disruptions.