Market Overview

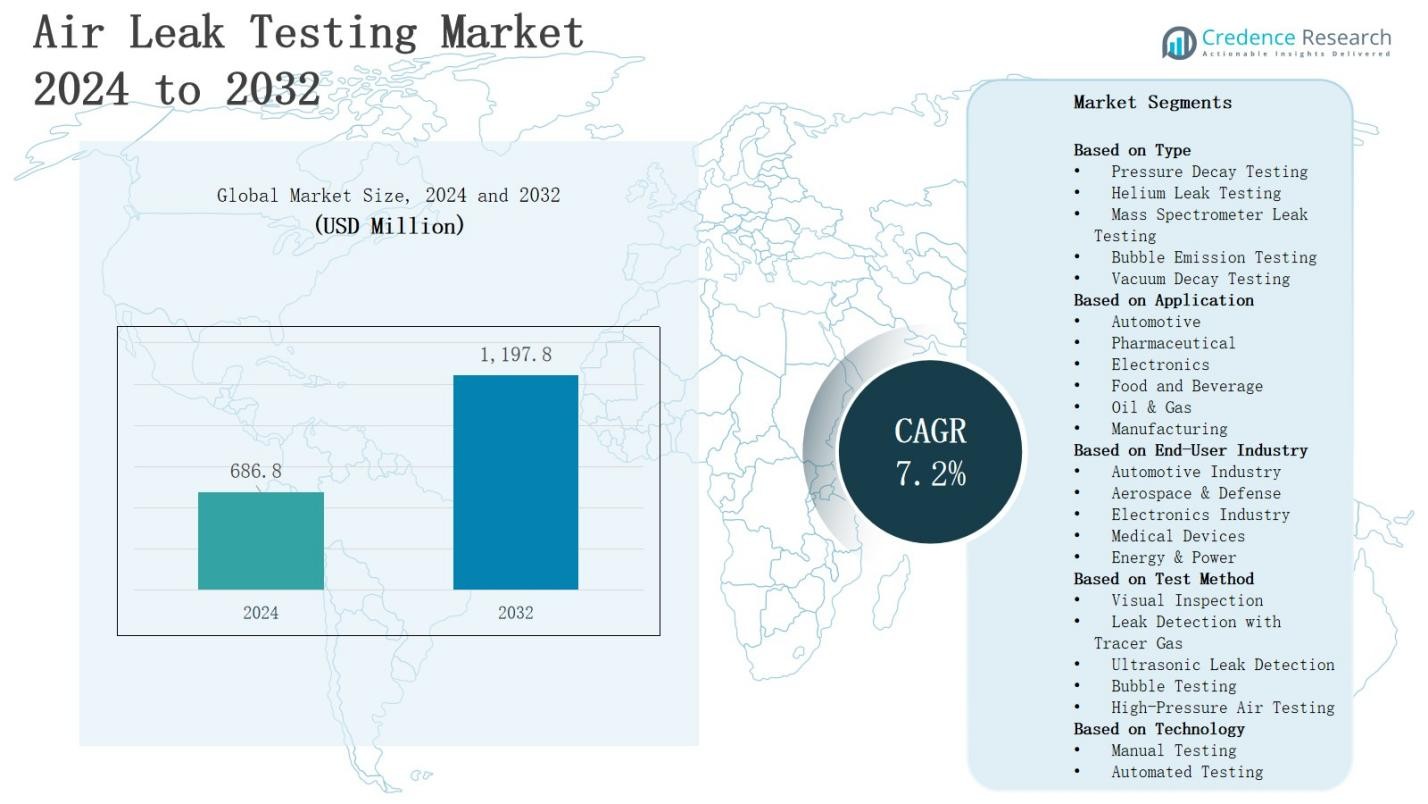

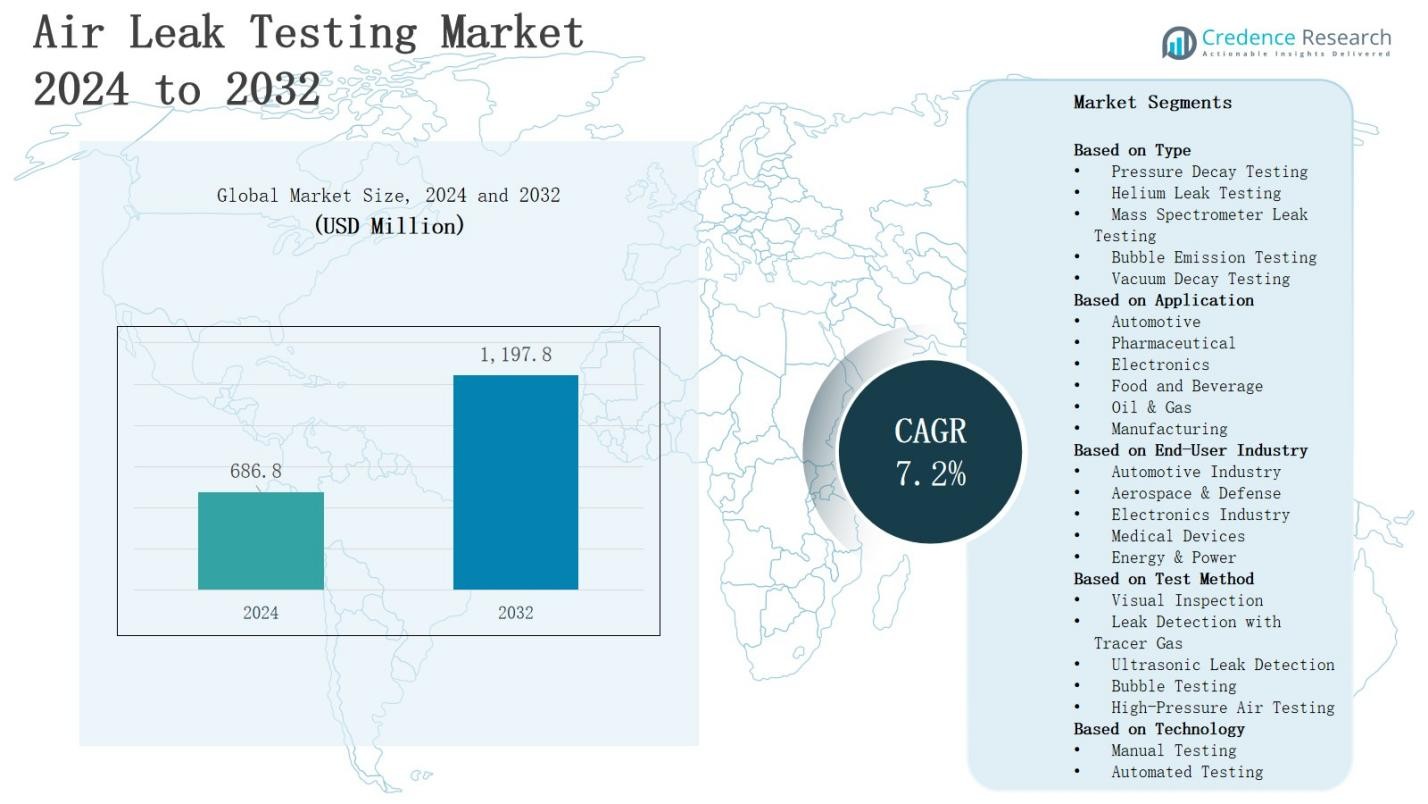

The global air leak testing market is projected to grow from USD 686.8 million in 2024 to USD 1,197.8 million by 2032, registering a CAGR of 7.2% during the forecast period.

| REPORT ATTRIBUTE |

DETAILS |

| Historical Period |

2020-2024 |

| Base Year |

2024 |

| Forecast Period |

2025-2032 |

| Air Leak Testing Market Size 2024 |

USD 686.8 Million |

| Air Leak Testing Market, CAGR |

7.2% |

| Air Leak Testing Market Size 2032 |

USD 1,197.8 Million |

The air leak testing market is driven by rising demand for stringent quality control in automotive, aerospace, and manufacturing industries to ensure product safety and performance. Increasing adoption of automated leak detection systems, supported by advancements in sensor technology and data analytics, enhances testing accuracy and efficiency. Growing regulatory compliance requirements and the need to reduce product recalls further accelerate market growth. Trends include integration of IoT-enabled monitoring for real-time diagnostics, adoption of non-destructive testing methods, and the shift toward environmentally friendly leak detection solutions, enabling manufacturers to meet sustainability goals while maintaining operational excellence.

The air leak testing market spans North America, Europe, Asia-Pacific, and the Rest of the World, each contributing to its global expansion. North America leads with advanced manufacturing and regulatory compliance, while Europe benefits from strong aerospace and automotive sectors. Asia-Pacific grows rapidly through industrialization and EV adoption, and the Rest of the World sees rising demand from oil and gas, energy, and manufacturing. Key players include Cosmo Instruments, Vacuum Instruments, ATEQ Corp, Pfeiffer Vacuum, LACO Technologies, INFICON Holding, Roper Technologies, InterTech Development, CETA TESTSYSTEME, and TASI Group.

Access crucial information at unmatched prices!

Request your sample report today & start making informed decisions powered by Credence Research Inc.!

Download Sample

Market Insights

- The global air leak testing market will grow from USD 686.8 million in 2024 to USD 1,197.8 million by 2032, at a CAGR of 7.2%, driven by demand for stringent quality control in critical industries.

- Advancements in sensor technology, automation, and IoT integration improve testing accuracy, real-time monitoring, and operational efficiency across manufacturing environments.

- Sustainability goals push adoption of eco-friendly and energy-efficient leak detection methods in sectors like HVAC, packaging, and power generation.

- Expanding applications in automotive, aerospace, medical devices, and electronics, along with rising global trade, fuel market growth.

- High equipment, integration, and maintenance costs limit adoption for small and medium-sized manufacturers, especially in emerging markets.

- North America leads with 34% share, followed by Asia-Pacific at 28%, Europe at 27%, and Rest of the World at 11%, each with distinct industry drivers.

- Key players include Cosmo Instruments, Vacuum Instruments, ATEQ Corp, Pfeiffer Vacuum, LACO Technologies, INFICON Holding, Roper Technologies, InterTech Development, CETA TESTSYSTEME, and TASI Group.

Market Drivers

Stringent Quality and Safety Requirements

The air leak testing market is propelled by strict quality assurance demands in industries such as automotive, aerospace, and medical devices. Manufacturers prioritize defect-free products to enhance safety, reliability, and brand reputation. It plays a critical role in detecting leaks that can compromise performance or safety. Regulatory bodies enforce rigorous compliance standards, driving adoption of advanced leak detection systems. Companies invest in precise testing solutions to minimize recalls and warranty claims, ensuring long-term operational credibility.

- For instance, TQC Ltd developed a fully automatic robotic leak test cell for automotive plastic components, integrating air decay leak testing with robotic handling to achieve 100% part inspection and improve production speed and quality.

Technological Advancements in Leak Detection

Rapid innovation in sensor technology, automation, and data analytics strengthens the air leak testing market by improving detection accuracy and efficiency. IoT-enabled systems allow real-time monitoring and data-driven insights for predictive maintenance. Automated solutions reduce human error, increase throughput, and enhance consistency. It supports faster product development cycles by integrating with production lines. Advancements in non-destructive testing methods further expand its application across diverse sectors seeking precision and reliability in leak detection.

- For instance, Facilio’s automated refrigerant leak detection system continuously monitors refrigeration units, sending instant alerts to maintenance teams via mobile notifications to promptly address leaks and prevent escalation.

Growing Emphasis on Sustainability and Energy Efficiency

Environmental concerns and resource conservation objectives push industries to adopt energy-efficient leak detection methods. The air leak testing market addresses these goals by identifying leaks that lead to energy loss or emissions. It helps companies align with sustainability commitments and reduce operational costs. Demand rises in sectors like HVAC, power generation, and packaging. Businesses integrate eco-friendly detection technologies to meet environmental regulations while improving long-term efficiency and resource management.

Expanding Industrial Applications and Global Trade

The widening scope of industrial applications supports steady growth in the air leak testing market. It is essential in sectors handling liquids, gases, and pressurized systems. Rising global trade increases the need for reliable product testing to meet international standards. Industries adopt portable and automated systems for flexibility in diverse production environments. Growing cross-border manufacturing partnerships amplify the demand for standardized, high-precision leak detection solutions that ensure consistent quality across markets.

Market Trends

Integration of IoT and Real-Time Monitoring

The air leak testing market is witnessing a strong shift toward IoT-enabled solutions that allow real-time monitoring, data logging, and predictive analysis. It enables manufacturers to track performance trends, identify faults quickly, and implement proactive maintenance. Wireless connectivity and cloud-based analytics improve accessibility to test results across global operations. This integration reduces downtime and improves productivity while supporting data-driven decision-making. Industries benefit from enhanced visibility and control over quality assurance processes through connected leak detection systems.

- For instance, Tata Consultancy Services (TCS) leverages IoT and cloud analytics to optimize manufacturing processes by integrating real-time data monitoring and predictive maintenance, thereby boosting operational efficiency and quality control across global operations.

Rising Adoption of Non-Destructive Testing Methods

Demand for non-destructive testing (NDT) solutions is increasing in the air leak testing market as manufacturers prioritize preserving product integrity during inspections. It helps identify defects without compromising the usability of components. Advanced techniques, including helium mass spectrometry and ultrasonic testing, are gaining traction for their precision. Sectors like medical devices, automotive, and aerospace use NDT to meet strict standards. The trend reflects a broader industry focus on quality without sacrificing manufacturing efficiency.

- For instance, Applus+ uses bubble leak testing, which involves pressurizing a component and detecting escaping gas bubbles through a liquid solution to locate leaks precisely.

Automation and AI-Driven Leak Detection

The adoption of automation and artificial intelligence is transforming the air leak testing market by streamlining inspection processes and improving accuracy. It minimizes operator dependence and standardizes test procedures across production lines. AI algorithms analyze vast datasets to identify patterns and predict potential defects. Automated systems reduce inspection time, lower costs, and maintain consistent performance. This trend aligns with manufacturers’ goals to optimize throughput and enhance quality assurance in competitive global markets.

Sustainability-Focused Innovations in Leak Detection

The air leak testing market is evolving toward environmentally sustainable practices through the development of eco-friendly detection systems. It supports industries in reducing emissions, conserving resources, and meeting environmental compliance mandates. Energy-efficient equipment, recyclable testing materials, and low-impact detection gases are gaining prominence. Businesses integrate sustainable technologies into production to improve their green credentials. This trend reflects the growing intersection between operational efficiency, regulatory compliance, and corporate environmental responsibility in modern manufacturing environments.

Market Challenges Analysis

High Equipment and Implementation Costs

The air leak testing market faces challenges from the substantial capital investment required for advanced leak detection systems. It can be difficult for small and medium-sized manufacturers to justify the expense, especially in cost-sensitive industries. Complex integration with existing production lines often demands customization and technical expertise, further increasing costs. Maintenance and calibration expenses add to the financial burden. The high initial outlay can delay adoption, particularly in emerging markets where budget constraints limit access to advanced quality assurance tools.

Technical Limitations and Operational Constraints

Operational challenges in the air leak testing market include limitations in detecting extremely small leaks or those in complex geometries. It can lead to false positives or missed defects if testing methods are not precisely matched to application requirements. Environmental factors such as temperature fluctuations, humidity, and vibration can impact test accuracy. Skilled personnel are required to operate and interpret results, creating dependency on specialized expertise. These constraints can slow inspection processes and reduce overall efficiency in high-volume manufacturing environments.

Market Opportunities

Expansion in Emerging Industrial Sectors

The air leak testing market has significant growth potential in emerging sectors such as electric vehicles, renewable energy, and advanced medical devices. It supports manufacturers in meeting stringent safety and efficiency standards for high-performance systems. Growing infrastructure in Asia-Pacific, Latin America, and the Middle East creates opportunities for adoption in manufacturing plants and assembly lines. Rising demand for quality assurance in fluid handling, HVAC, and packaging further expands its application scope. These sectors require precise and reliable leak detection solutions to ensure operational integrity and compliance.

Advancements in Portable and Automated Solutions

Technological innovation offers opportunities for the air leak testing market through the development of portable, compact, and automated systems. It allows manufacturers to perform on-site inspections with greater flexibility and reduced downtime. Integration with AI and cloud-based platforms enables predictive analytics and remote monitoring capabilities. The demand for user-friendly, plug-and-play systems is increasing among small and medium enterprises. Such advancements help industries improve quality control processes while lowering operational costs and reducing dependency on specialized operators.

Market Segmentation Analysis:

By Type

The air leak testing market is segmented into pressure decay testing, helium leak testing, mass spectrometer leak testing, bubble emission testing, and vacuum decay testing. Pressure decay testing remains widely used for its cost-effectiveness and simplicity in detecting leaks in sealed systems. Helium and mass spectrometer methods offer high precision for critical applications in aerospace, medical devices, and electronics. Bubble emission testing serves low-pressure, visual inspection needs, while vacuum decay testing is preferred for sensitive packaging and pharmaceutical products requiring non-destructive evaluation.

- For instance, Cell Instruments’ LSST-01 leak tester employs pressure decay to evaluate the burst pressure and sealing strength of flexible packaging used in food and medical products, ensuring package integrity under stress.

By Application

The air leak testing market serves diverse applications, including automotive, pharmaceutical, electronics, food and beverage, oil and gas, and manufacturing. It plays a vital role in ensuring the safety and reliability of fuel systems, pipelines, and critical components in automotive and oil & gas sectors. Pharmaceutical and food industries rely on it to safeguard product sterility and prevent contamination. Electronics manufacturing benefits from precise leak detection to maintain performance and product longevity.

- For instance, W. v. d. Heyde, a world market leader in leak detection machines, specializes in testing the air tightness of aluminum car wheels. Their customized solutions detect fine pores and leak paths in rims which can cause air loss, ensuring wheel reliability before market release.

By End-User Industry

End-user industries in the air leak testing market include automotive, aerospace & defense, electronics, medical devices, and energy & power. It supports the automotive sector in verifying fuel, brake, and air conditioning system integrity. Aerospace & defense depend on highly sensitive leak detection for safety-critical systems. Electronics and medical devices industries require precise methods to meet strict quality standards. The energy & power sector uses it to maintain operational efficiency and prevent hazardous leaks in pipelines and equipment.

Segments:

Based on Type

- Pressure Decay Testing

- Helium Leak Testing

- Mass Spectrometer Leak Testing

- Bubble Emission Testing

- Vacuum Decay Testing

Based on Application

- Automotive

- Pharmaceutical

- Electronics

- Food and Beverage

- Oil & Gas

- Manufacturing

Based on End-User Industry

- Automotive Industry

- Aerospace & Defense

- Electronics Industry

- Medical Devices

- Energy & Power

Based on Test Method

- Visual Inspection

- Leak Detection with Tracer Gas

- Ultrasonic Leak Detection

- Bubble Testing

- High-Pressure Air Testing

Based on Technology

- Manual Testing

- Automated Testing

Based on the Geography:

- North America

- Europe

- Germany

- France

- U.K.

- Italy

- Spain

- Rest of Europe

- Asia Pacific

- China

- Japan

- India

- South Korea

- South-east Asia

- Rest of Asia Pacific

- Latin America

- Brazil

- Argentina

- Rest of Latin America

- Middle East & Africa

- GCC Countries

- South Africa

- Rest of the Middle East and Africa

Regional Analysis

North America

North America holds 34% of the air leak testing market, driven by advanced manufacturing capabilities and strong adoption of quality assurance technologies. It benefits from high regulatory standards in automotive, aerospace, and medical device industries, ensuring strict compliance with leak detection requirements. Major players in the region invest in automated and IoT-enabled systems to improve efficiency and accuracy. The presence of established automotive production hubs in the United States and Canada fuels demand. It also gains momentum from rising adoption in energy and power sectors to enhance operational safety. Continuous innovation strengthens the region’s competitive position globally.

Europe

Europe accounts for 27% of the air leak testing market, supported by stringent environmental regulations and high-quality manufacturing standards. It serves as a hub for advanced aerospace, pharmaceutical, and automotive industries that require precision leak detection solutions. Strong R&D investment and government emphasis on sustainability accelerate the adoption of energy-efficient testing systems. The region’s focus on reducing emissions in industrial operations boosts demand. It benefits from well-established infrastructure and skilled workforce, fostering innovation and technology integration. The shift toward Industry 4.0 further drives the deployment of automated leak testing solutions.

Asia-Pacific

Asia-Pacific captures 28% of the air leak testing market, driven by rapid industrialization and expanding manufacturing sectors in China, Japan, India, and South Korea. It experiences strong demand from automotive, electronics, and energy sectors seeking advanced quality control solutions. Government initiatives promoting industrial safety and efficiency stimulate market growth. Increasing investment in renewable energy and electric vehicles expands application areas. It gains further momentum from the presence of cost-effective manufacturing facilities. The region’s competitive pricing and high production volumes enhance its global market influence.

Rest of the World

The Rest of the World holds 11% of the air leak testing market, with demand growing in Latin America, the Middle East, and Africa. It benefits from infrastructure development and industrial expansion, particularly in oil and gas, energy, and manufacturing. Adoption rates rise as industries prioritize safety compliance and operational reliability. Growing exports of industrial goods encourage adoption of standardized leak testing solutions. It also sees increasing use in food and beverage industries for packaging integrity. Expanding industrial capabilities position the region for sustained growth in leak detection technologies.

Shape Your Report to Specific Countries or Regions & Enjoy 30% Off!

Key Player Analysis

- Cosmo Instruments

- Vacuum Instruments

- ATEQ Corp

- Pfeiffer Vacuum

- LACO Technologies

- INFICON Holdin

- Roper Technologies

- InterTech Development

- CETA TESTSYSTEME

- TASI Group

Competitive Analysis

The air leak testing market is characterized by strong competition among global and regional players focusing on technological innovation, product reliability, and application-specific solutions. Key companies such as Cosmo Instruments, Vacuum Instruments, ATEQ Corp, Pfeiffer Vacuum, LACO Technologies, INFICON Holding, Roper Technologies, InterTech Development, CETA TESTSYSTEME, and TASI Group compete by expanding product portfolios and integrating IoT, automation, and data analytics into their systems. It benefits from advancements in non-destructive testing methods, enabling higher precision in diverse industries including automotive, aerospace, medical devices, and energy. Players invest in R&D to develop portable, energy-efficient, and user-friendly systems that meet stringent regulatory and environmental requirements. Strategic partnerships, acquisitions, and regional expansions strengthen their market presence and customer reach. The growing demand for high-accuracy leak detection across industrial applications drives companies to differentiate through performance, service capabilities, and cost-efficiency while ensuring compliance with international quality standards.

Recent Developments

- In May 2025, INFICON introduced the Ecotec 4000, a next-generation multi-gas sniffer leak detector, at the Control exhibition in Stuttgart. The system delivers high sensitivity, can detect up to four refrigerant gases simultaneously, and features enhanced gas flow rates for accessing tight production areas.

- In May 2025, ATEQ Corp launched its Early Decision Tool, designed to streamline leak detection workflows and improve efficiency in manufacturing operations.

- In May 2025, INFICON launched the Ecotec 4000 at the Control exhibition in Stuttgart. This next-generation multi-gas sniffer leak detector can identify up to four refrigerant gases simultaneously, offers high gas flow rates for hard-to-reach areas, and supports robotic integration.

- In February 2025, Marposs presented its advanced air and helium leak testing systems at ACREX INDIA 2025, focusing on HVAC-R and consumer appliance sectors with high-precision mass spectrometer technology.

Market Concentration & Characteristics

The air leak testing market exhibits moderate to high concentration, with a mix of global leaders and specialized regional players competing on technology, precision, and application expertise. It is driven by stringent quality control requirements in automotive, aerospace, medical devices, and industrial manufacturing. Leading companies focus on advanced sensor integration, IoT-enabled monitoring, and automated systems to enhance accuracy and efficiency. The market favors suppliers capable of offering customized solutions, fast turnaround, and compliance with international standards. Barriers to entry include high equipment costs, technical expertise requirements, and established customer relationships of existing players. Demand growth is supported by the shift toward non-destructive testing, energy-efficient solutions, and sustainability-focused manufacturing. Industry consolidation through partnerships, acquisitions, and global expansions is common, enabling suppliers to strengthen portfolios and market reach. Strong after-sales service, training support, and reliability in high-volume production environments remain critical factors in securing long-term customer retention and competitive advantage.

Report Coverage

The research report offers an in-depth analysis based on Type, Application, End-User Industry, Test Method, Technology and Geography. It details leading market players, providing an overview of their business, product offerings, investments, revenue streams, and key applications. Additionally, the report includes insights into the competitive environment, SWOT analysis, current market trends, as well as the primary drivers and constraints. Furthermore, it discusses various factors that have driven market expansion in recent years. The report also explores market dynamics, regulatory scenarios, and technological advancements that are shaping the industry. It assesses the impact of external factors and global economic changes on market growth. Lastly, it provides strategic recommendations for new entrants and established companies to navigate the complexities of the market.

Future Outlook

- Demand for automated leak detection systems will increase across high-volume manufacturing sectors.

- Adoption of IoT-enabled and AI-driven solutions will enhance real-time monitoring and predictive maintenance.

- Non-destructive testing methods will gain wider use in industries requiring high product integrity.

- Sustainability-focused leak detection technologies will see greater integration into production processes.

- Portable and user-friendly testing equipment will experience rising adoption among small and medium enterprises.

- Growth in electric vehicles and renewable energy sectors will expand application opportunities.

- Regional manufacturing expansion will drive demand for standardized quality control solutions.

- Regulatory compliance will continue to shape innovation and system capabilities.

- Industry partnerships and acquisitions will strengthen global reach and technological expertise.

- Skilled workforce training will remain essential for maximizing testing accuracy and operational efficiency.