Market Overview:

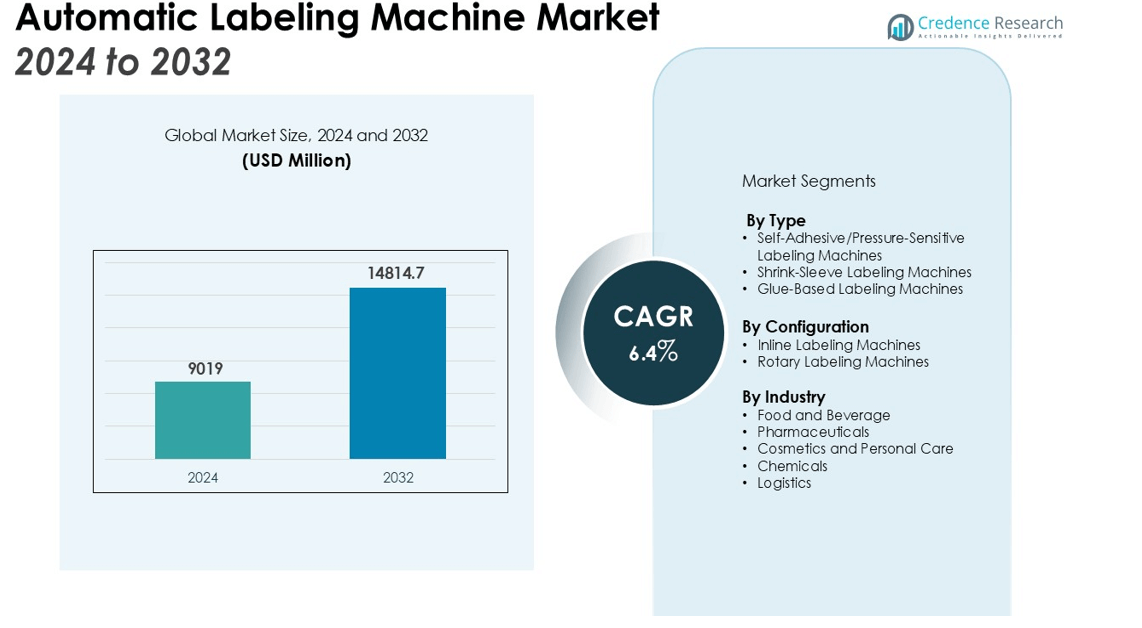

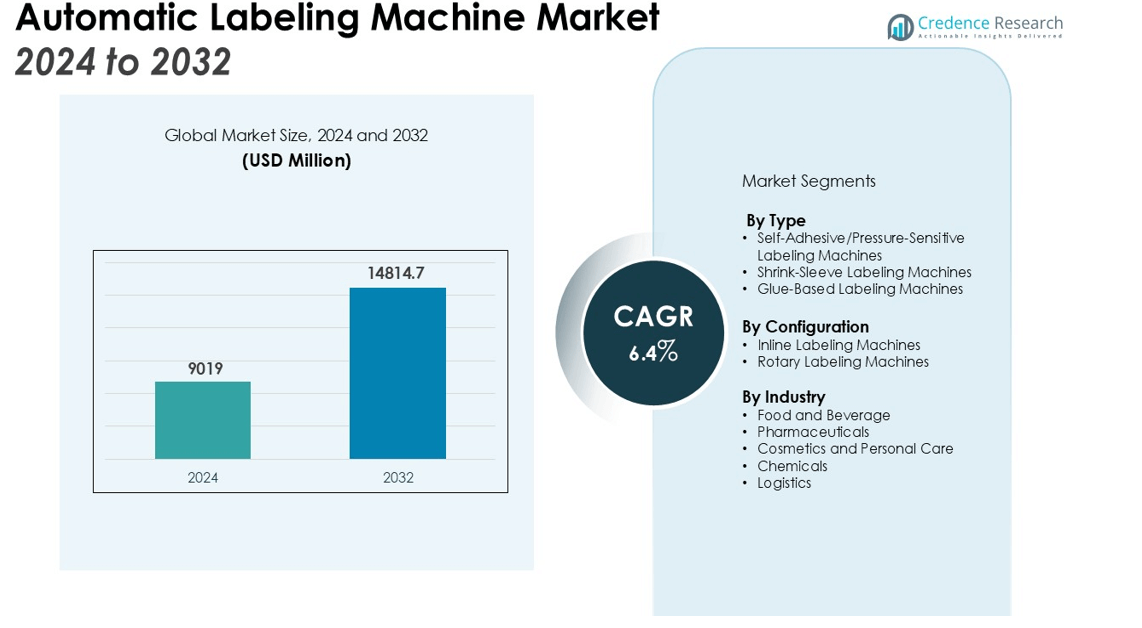

The Automatic Labeling Machine Market size was valued at USD 9019 million in 2024 and is anticipated to reach USD 14814.7 million by 2032, at a CAGR of 6.4% during the forecast period (2024-2032).

| REPORT ATTRIBUTE |

DETAILS |

| Historical Period |

2020-2023 |

| Base Year |

2024 |

| Forecast Period |

2025-2032 |

| Automatic Labeling Machine Market Size 2024 |

USD 9019 million |

| Automatic Labeling Machine Market, CAGR |

6.4% |

| Automatic Labeling Machine Market Size 2032 |

USD 14814.7 million |

Market expansion is driven by increasing demand for high-speed, precise, and regulation-compliant labeling solutions in food and beverage, pharmaceutical, and cosmetics industries. Automation enhances throughput, reduces human error, and ensures product consistency, making it a key investment priority. In pharmaceuticals, stringent serialization and traceability regulations have accelerated adoption, while advancements such as AI-powered vision systems, predictive maintenance, and RFID-enabled sensors have further improved operational efficiency. Rising industrial automation initiatives and sustainability-focused labeling practices are also contributing to growth, with manufacturers increasingly adopting energy-efficient machines to reduce operational costs.

Asia-Pacific holds the largest share, supported by robust manufacturing bases and government-led automation incentives. North America remains a significant market, benefiting from advanced manufacturing infrastructure and high adoption of automated systems. The Middle East and Africa are expected to record notable growth in the coming years, fueled by expanding industrial sectors and modernizing production facilities.

Market Insights:

- The Automatic Labeling Machine Market is valued at USD 9,019 million in 2024 and is projected to reach USD 14,814.7 million by 2032, registering a CAGR of 6.4% during the forecast period.

- Rising demand for high-speed and precise labeling in food and beverage, pharmaceutical, and cosmetics industries is a major growth driver, ensuring compliance and operational efficiency.

- Technological advancements, including AI-powered vision systems, predictive maintenance, and RFID integration, are enhancing accuracy, reducing downtime, and extending machine lifespan.

- Regulatory compliance and traceability requirements, especially in pharmaceuticals, are accelerating adoption, with automated systems minimizing errors and avoiding costly recalls.

- Sustainability-focused designs, featuring energy-efficient models and compatibility with eco-friendly materials, are aligning with corporate and consumer environmental priorities.

- Asia-Pacific leads with a 41% market share due to robust manufacturing bases, automation incentives, and growing demand from export-oriented industries.

- North America and Europe hold 27% and 22% shares respectively, supported by advanced automation infrastructure, strict regulatory frameworks, and strong innovation in sustainable labeling solutions.

Access crucial information at unmatched prices!

Request your sample report today & start making informed decisions powered by Credence Research Inc.!

Download Sample

Market Drivers:

Rising Demand for High-Speed and Precision Labeling Across Industries

The Automatic Labeling Machine Market is witnessing growth driven by the need for faster, more accurate labeling in industries such as food and beverage, pharmaceuticals, and cosmetics. It enables manufacturers to meet stringent production timelines while maintaining label consistency and quality. High-speed systems reduce operational bottlenecks and enhance throughput, directly impacting profitability. Businesses are prioritizing such machines to comply with industry standards and improve customer satisfaction through accurate product information.

- For instance, CDA’s Lea automatic labeling machine uses a pacing system for fast and efficient labeling, processing up to 2000 bottles per hour.

Stringent Regulatory Compliance and Traceability Requirements

Global regulations on product labeling, particularly in pharmaceuticals and packaged goods, are fostering the adoption of advanced labeling technologies. The Automatic Labeling Machine Market benefits from its ability to support serialization, barcoding, and traceability features essential for safety and regulatory adherence. It ensures accurate placement of compliant labels, reducing the risk of penalties and recalls. The growing focus on supply chain transparency has further reinforced the integration of automated labeling solutions in manufacturing facilities.

Technological Advancements in Automation and Machine Vision

Integration of AI-driven vision systems, predictive maintenance, and RFID technology is enhancing the efficiency and reliability of automatic labeling machines. It allows real-time error detection, minimal downtime, and superior label placement accuracy. These advancements not only optimize productivity but also extend equipment lifespan. Manufacturers are investing in technology upgrades to gain a competitive edge and meet evolving customer requirements.

- For instance, Keyence’s VS Series AI-powered vision system is capable of learning and performing inspections with as few as 2 training images, enabling rapid deployment on labeling lines.

Shift Toward Sustainable and Cost-Efficient Labeling Solutions

Environmental concerns and cost optimization are influencing equipment purchasing decisions. The Automatic Labeling Machine Market is responding with energy-efficient models and eco-friendly labeling materials to reduce carbon footprint. It supports sustainable practices while maintaining operational performance. This trend aligns with corporate sustainability goals and growing consumer preference for environmentally responsible brands.

Market Trends:

Integration of Smart Technologies to Enhance Labeling Efficiency

The Automatic Labeling Machine Market is experiencing a notable shift toward smart and connected solutions that improve operational performance. It is incorporating AI-powered vision inspection, IoT connectivity, and advanced sensors to enable real-time monitoring and quality control. These technologies help manufacturers identify errors instantly, optimize label placement, and minimize waste. The adoption of predictive maintenance capabilities is reducing unplanned downtime and extending machine lifespan. Growing demand for customization in packaging is driving the development of machines with flexible settings to accommodate varied label sizes and formats. This trend is fostering a competitive environment where manufacturers prioritize innovation to meet evolving production requirements.

- For instance, Quadrel Labeling Systems has developed a custom small diameter wrap system that can achieve labeling speeds of up to 200 products per minute with high accuracy.

Growing Focus on Sustainability and Energy-Efficient Labeling Solutions

Sustainability is emerging as a critical trend, influencing product design and operational choices within the Automatic Labeling Machine Market. It is driving manufacturers to develop machines that consume less energy, support recyclable label materials, and integrate eco-friendly adhesives. Companies are adopting modular designs that allow easy upgrades, extending the equipment’s usable life and reducing environmental impact. Rising awareness among consumers regarding sustainable packaging is pushing brands to adopt green labeling practices. Industry players are also investing in research to align product offerings with environmental regulations without compromising speed or precision. This shift is not only meeting regulatory demands but also strengthening brand reputation in competitive markets.

- For instance, Weber Marking Systems provides fully electric labeling machines powered by low-energy motors of less than 0.75 kW, a design that significantly lowers energy use by eliminating the need for compressed air systems.

Market Challenges Analysis:

High Initial Investment and Maintenance Costs

The Automatic Labeling Machine Market faces challenges due to the substantial upfront costs associated with advanced equipment and technology integration. It requires significant capital expenditure, which can be a barrier for small and medium-sized enterprises. Ongoing maintenance, calibration, and skilled operator requirements add to operational expenses. The need for regular software updates and component replacements further increases the total cost of ownership. These financial constraints can slow adoption rates, particularly in cost-sensitive markets where manual or semi-automatic alternatives remain viable.

Operational Downtime and Compatibility Issues

Frequent production line changes and diverse packaging formats can create compatibility challenges for automatic labeling machines. It demands complex adjustments, which may lead to downtime and reduced productivity. Integration with existing production systems and synchronization with other automated processes can be technically demanding. Limited operator expertise in handling advanced features often results in underutilization of machine capabilities. Technical breakdowns or errors can disrupt supply chains, leading to delays and customer dissatisfaction. This operational complexity underscores the need for continuous training and robust technical support to ensure optimal performance.

Market Opportunities:

Rising Adoption in Emerging Markets and Diverse Industries

The Automatic Labeling Machine Market is poised to benefit from expanding industrialization and manufacturing activities in emerging economies. It offers significant growth potential in sectors such as pharmaceuticals, food and beverage, cosmetics, and logistics where labeling compliance and speed are critical. Increasing consumer demand for packaged goods and export-oriented production is driving investment in automated labeling solutions. Government incentives for automation adoption in manufacturing are further encouraging market penetration. Growing e-commerce activities are also creating demand for efficient labeling systems to handle high-volume, fast-turnaround operations.

Advancements in Customization and Sustainable Labeling Solutions

Innovations that allow greater customization and adaptability present strong opportunities for the Automatic Labeling Machine Market. It is witnessing the development of modular machines capable of handling multiple label types, shapes, and materials without extensive downtime. The shift toward eco-friendly packaging is encouraging the use of recyclable and biodegradable label materials, creating a need for compatible machines. Integration of AI, IoT, and advanced vision systems enables smarter, more energy-efficient operations. These advancements not only meet evolving regulatory and consumer demands but also open avenues for premium, value-added services in competitive industries.

Market Segmentation Analysis:

By Type

The Automatic Labeling Machine Market is segmented into self-adhesive/pressure-sensitive, shrink-sleeve, and glue-based labeling machines. It serves diverse packaging needs by offering precise application across varying product shapes and materials. Self-adhesive machines dominate due to ease of integration and versatility, while shrink-sleeve systems are gaining traction in industries requiring full-body, tamper-evident labeling. Glue-based machines maintain demand in high-volume production for beverages and consumer goods.

- For instance, in the shrink-sleeve category, N.K. Industries’ machines can label between 50 and 300 bottles per minute.

By Configuration

The market includes inline and rotary configurations, each catering to specific production requirements. Inline machines offer flexibility for moderate-speed operations and are widely used in small to mid-scale facilities. Rotary machines excel in high-speed environments, delivering consistent accuracy in continuous production lines. It enables manufacturers to optimize throughput while ensuring label placement precision, particularly in industries with high-volume output.

- For instance, Markotec’s Inline Top Labeler can be equipped with a servo motor that allows it to reach a labeling speed of 50 meters per minute, applying labels to as many as 400 bottles per minute.

By Industry

Key industry segments include food and beverage, pharmaceuticals, cosmetics and personal care, and others such as chemicals and logistics. The food and beverage sector leads adoption due to regulatory labeling standards and high production rates. Pharmaceuticals rely heavily on these machines for serialization and traceability compliance. Cosmetics and personal care brands use them to support premium packaging designs and brand differentiation. It ensures that labeling processes meet industry-specific requirements while supporting efficiency and compliance.

Segmentations:

By Type

- Self-Adhesive/Pressure-Sensitive Labeling Machines

- Shrink-Sleeve Labeling Machines

- Glue-Based Labeling Machines

By Configuration

- Inline Labeling Machines

- Rotary Labeling Machines

By Industry

- Food and Beverage

- Pharmaceuticals

- Cosmetics and Personal Care

- Chemicals

- Logistics

By Region

- North America

- Europe

- UK

- France

- Germany

- Italy

- Spain

- Russia

- Belgium

- Netherlands

- Austria

- Sweden

- Poland

- Denmark

- Switzerland

- Rest of Europe

- Asia Pacific

- China

- Japan

- South Korea

- India

- Australia

- Thailand

- Indonesia

- Vietnam

- Malaysia

- Philippines

- Taiwan

- Rest of Asia Pacific

- Latin America

- Brazil

- Argentina

- Peru

- Chile

- Colombia

- Rest of Latin America

- Middle East

- UAE

- KSA

- Israel

- Turkey

- Iran

- Rest of Middle East

- Africa

- Egypt

- Nigeria

- Algeria

- Morocco

- Rest of Africa

Regional Analysis:

Asia-Pacific’s Dominance Driven by Expanding Manufacturing Base

The Asia-Pacific region holds a market share of 41% in the Automatic Labeling Machine Market, supported by a strong manufacturing base in countries such as China, Japan, India, and South Korea. It benefits from growing demand in food and beverage, pharmaceuticals, and personal care sectors, driven by rising population and urbanization. Government-led initiatives to promote industrial automation are accelerating adoption rates across diverse industries. Expanding export activities require efficient, high-speed labeling systems to meet international quality and compliance standards. The presence of cost-effective production facilities and a competitive supplier landscape further strengthens the region’s market leadership.

North America’s Growth Anchored in Advanced Automation Infrastructure

North America accounts for 27% of the Automatic Labeling Machine Market, fueled by its well-established industrial automation infrastructure and high adoption of innovative packaging technologies. It is experiencing increased demand from pharmaceuticals, healthcare, and consumer goods sectors, where accuracy and compliance are critical. Companies are investing in AI-integrated and IoT-enabled labeling systems to enhance productivity and traceability. The presence of leading automation technology providers ensures steady innovation and market competitiveness. A strong focus on sustainable packaging is also influencing machine design and operational strategies in the region.

Europe’s Steady Expansion Supported by Regulatory Compliance

Europe represents 22% of the Automatic Labeling Machine Market, driven by stringent labeling and traceability regulations across industries. It benefits from advanced manufacturing practices and high-quality engineering capabilities in countries such as Germany, Italy, and France. The food and beverage sector, in particular, is a major consumer of automated labeling solutions due to strict EU packaging guidelines. Increasing adoption of eco-friendly labeling materials is prompting manufacturers to develop compatible machine technologies. A mature industrial base combined with consistent regulatory enforcement sustains steady growth in this region.

Shape Your Report to Specific Countries or Regions & Enjoy 30% Off!

Key Player Analysis:

- Krones AG (Bavaria, Germany)

- Sidel (Tetra Lavel International S.A.) (Emilia-Romagna, Italy)

- Sacmi Imola S. C. (Emilia-Romagna, Italy)

- Herma (Baden-Württemberg, Germany)

- Fuji Seal International Inc. (Kansai, Japan)

- Marchesini Group S. P. A. (Emilia-Romagna, Italy)

- A. Industria Macchine Automatiche S. P. A. (Emilia-Romagna, Italy)

- KHS GmbH (Salzgitter AG Consolidation Group) (North Rhine-Westphalia, Germany)

- Barry – Wehmiller Companies (Missouri, U.S.)

- ProMach (Ohio, U.S.)

- Novexx Solutions GmbH (Bavaria, Germany)

- Accutek Packaging (California, U.S.)

- Wuxi Sici Auto Co., Ltd. (Jiangsu, China)

- Worldpack Automation Systems (Maharashtra, India)

- Weber Marking Systems GmbH (Rhineland-Palatinate, Germany)

Competitive Analysis:

The Automatic Labeling Machine Market is characterized by strong competition among global and regional players focusing on innovation, technology integration, and product customization. Leading companies are investing in AI-enabled vision systems, IoT connectivity, and energy-efficient designs to enhance performance and meet diverse industry needs. It is driven by demand for high-speed, precise labeling solutions in sectors such as food and beverage, pharmaceuticals, and cosmetics. Major players emphasize strategic partnerships, acquisitions, and expansion into emerging markets to strengthen their global presence. Competitive differentiation is achieved through reliability, flexibility, and the ability to handle varied label formats with minimal downtime. Continuous R&D efforts and customer-focused solutions are enabling manufacturers to maintain market relevance while addressing evolving regulatory, sustainability, and operational efficiency requirements. This competitive environment is fostering rapid technological advancements and raising industry standards.

Recent Developments:

- In August 2025, Herma announced it would introduce a new top and bottom labeling solution at the Fachpack 2025 event.

- In June Barry, Wehmiller Companies announced that a machine learning project by its BW Converting division was selected for the new Microsoft AI Co-Innovation Lab in Milwaukee.

Market Concentration & Characteristics:

The Automatic Labeling Machine Market exhibits moderate to high concentration, with a mix of established global manufacturers and specialized regional players competing for market share. It is defined by strong technological integration, with advancements in AI, IoT, and machine vision shaping product innovation. Leading companies leverage economies of scale, robust distribution networks, and brand reputation to maintain competitive advantage. The market is characterized by high entry barriers due to significant capital investment, regulatory compliance requirements, and the need for advanced engineering capabilities. Demand is sustained by diverse end-use industries, driving continuous adaptation to varying label formats, materials, and production speeds. Sustainability, energy efficiency, and operational flexibility remain key product characteristics influencing purchasing decisions.

Report Coverage:

The research report offers an in-depth analysis based on Type, Configuration, Industry and Region. It details leading market players, providing an overview of their business, product offerings, investments, revenue streams, and key applications. Additionally, the report includes insights into the competitive environment, SWOT analysis, current market trends, as well as the primary drivers and constraints. Furthermore, it discusses various factors that have driven market expansion in recent years. The report also explores market dynamics, regulatory scenarios, and technological advancements that are shaping the industry. It assesses the impact of external factors and global economic changes on market growth. Lastly, it provides strategic recommendations for new entrants and established companies to navigate the complexities of the market.

Future Outlook:

- Demand for advanced automatic labeling machines will grow with increasing automation in manufacturing across food, beverage, pharmaceutical, and cosmetics sectors.

- AI-driven vision inspection and predictive maintenance capabilities will gain wider adoption to improve accuracy and reduce downtime.

- Integration of IoT-enabled monitoring will enhance real-time performance tracking and predictive service scheduling.

- Flexible machines capable of handling multiple label types, shapes, and materials will see higher market penetration.

- Sustainability-focused designs using recyclable materials and energy-efficient systems will become standard offerings.

- Expansion into emerging economies will present significant opportunities due to industrial growth and government automation initiatives.

- Pharmaceutical and healthcare industries will remain key drivers, supported by stringent serialization and traceability mandates.

- E-commerce and logistics sectors will adopt high-speed labeling systems to meet rapid order fulfillment demands.

- Competitive strategies will focus on mergers, acquisitions, and partnerships to expand product portfolios and geographic reach.

- Continuous R&D investments will lead to innovations in high-speed, low-maintenance, and modular labeling systems tailored to diverse industry needs.