Market Overview:

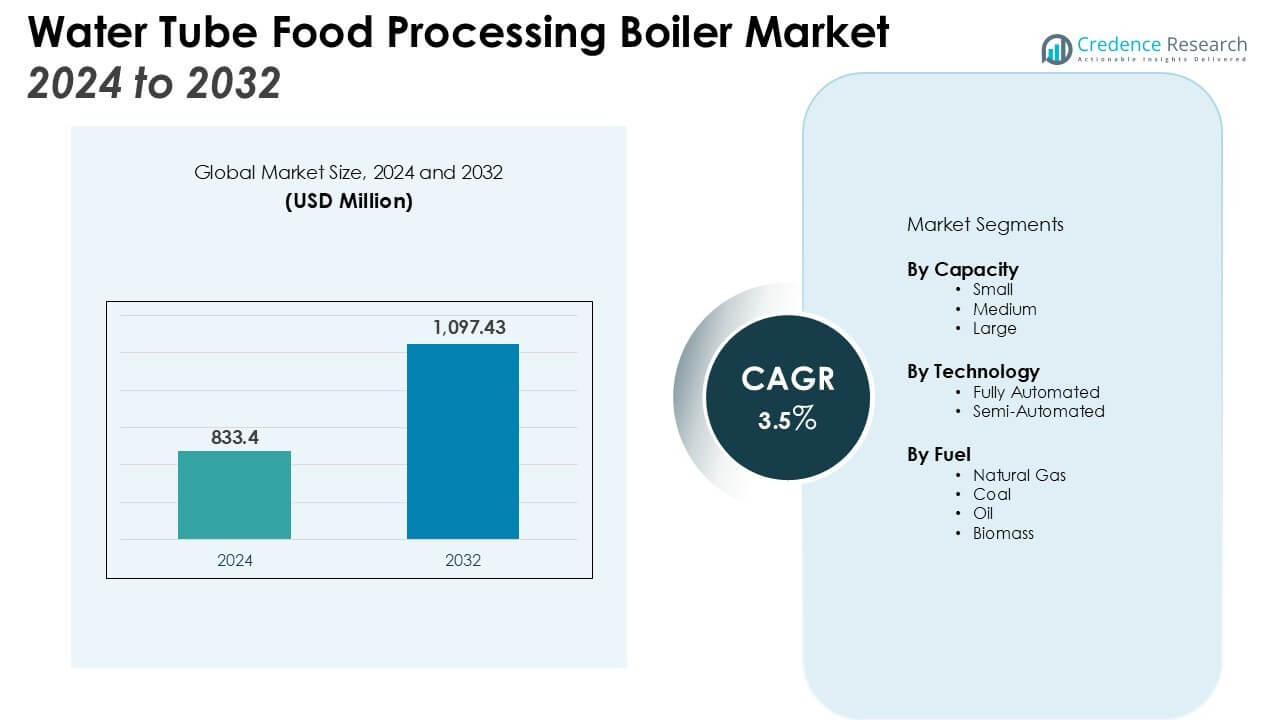

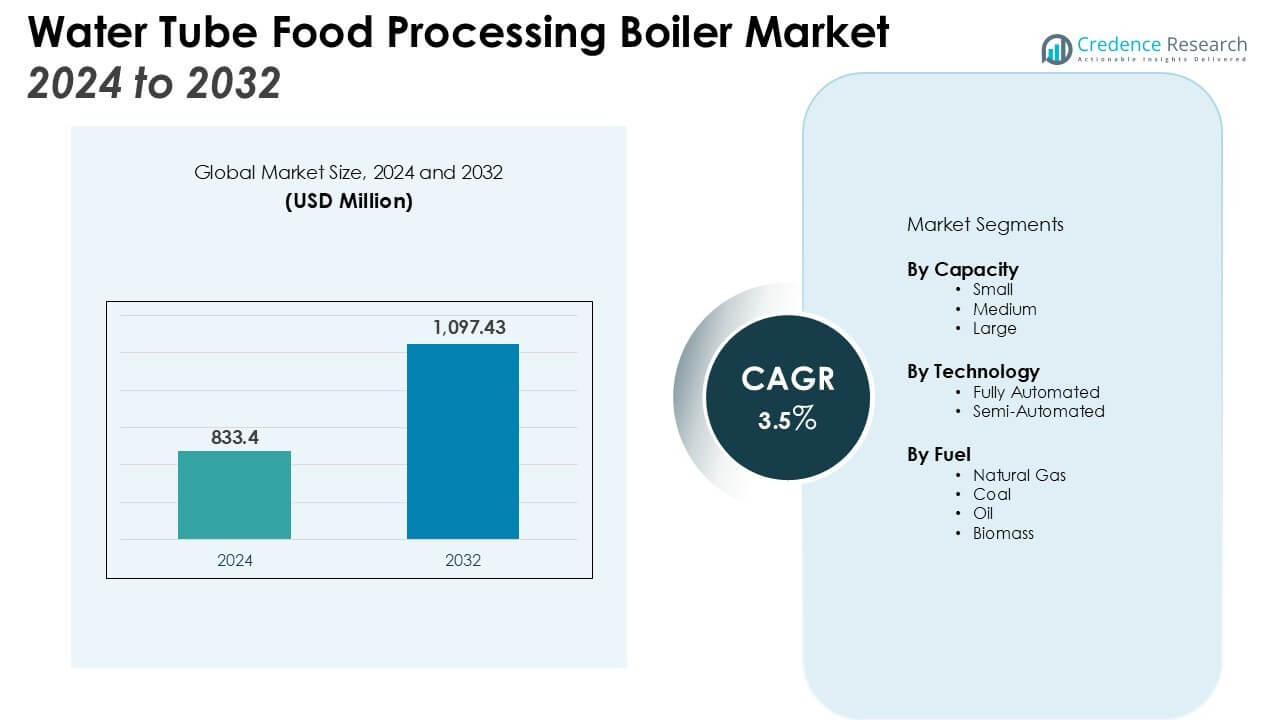

The Water Tube Food Processing Boiler Market size was valued at USD 833.4 million in 2024 and is anticipated to reach USD 1,097.43 million by 2032, at a CAGR of 3.5% during the forecast period (2024-2032).

| REPORT ATTRIBUTE |

DETAILS |

| Historical Period |

2020-2023 |

| Base Year |

2024 |

| Forecast Period |

2025-2032 |

| Water Tube Food Processing Boiler Market Size 2024 |

USD 833.4 Million |

| Water Tube Food Processing Boiler Market, CAGR |

3.5% |

| Water Tube Food Processing Boiler Market Size 2032 |

USD 1,097.43 Million |

The market is experiencing steady growth as manufacturers prioritize energy-efficient steam solutions to improve performance. Rising consumption of processed and packaged foods continues to strengthen demand across food processing facilities. Environmental standards are also encouraging companies to upgrade boiler systems with modern, compliant technologies. The integration of advanced automation and digital monitoring is further enhancing operational efficiency and safety. Growing focus on sustainable production practices is also shaping investment decisions across the industry.

North America shows strong momentum, supported by strict emission standards and ongoing infrastructure improvements. Asia-Pacific is emerging as the fastest-growing region, driven by urbanization, industrial expansion, and significant investment in food-processing infrastructure. Europe maintains stable growth, supported by modernized food processing facilities and strict energy-efficiency regulations. Rising investments in Latin America are also contributing to market expansion through the development of new processing plants.

Access crucial information at unmatched prices!

Request your sample report today & start making informed decisions powered by Credence Research Inc.!

Download Sample

Market Insights:

- The Water Tube Food Processing Boiler Market was valued at USD 833.4 million and is projected to reach USD 1,097.43 million, registering a CAGR of 3.5%.

- Rising demand for energy-efficient steam solutions drives adoption across large-scale food processing facilities.

- Stricter environmental regulations encourage companies to modernize boiler systems with advanced and compliant technologies.

- Integration of automation and digital monitoring improves operational efficiency, predictive maintenance, and plant safety.

- North America holds 28% share, supported by strong emission standards and modernization initiatives.

- Asia-Pacific leads with 39% share, driven by industrial expansion, urbanization, and rising food consumption.

- Europe accounts for 24% share, while Latin America and the Middle East show growing potential with new food processing projects.

Market Drivers:

Market Drivers:

Rising Demand for Energy Efficiency in Food Processing

The Water Tube Food Processing Boiler Automation Market benefits from the global shift toward energy-efficient systems. Food processors seek solutions that reduce operational costs while maintaining reliable output. Automated boilers allow precise steam control, minimizing waste and improving plant efficiency. Companies adopt automation to comply with stricter efficiency benchmarks and lower carbon footprints. This shift supports long-term adoption of advanced boiler technologies in large-scale operations.

Growing Emphasis on Food Safety and Quality Standards

Food safety regulations drive automation adoption to maintain consistent heating and sterilization in production lines. Automated water tube boilers provide precise temperature control, ensuring consistent quality. The system reduces risks linked to human error and enhances compliance with international standards. Global food processors invest in these solutions to maintain competitiveness in regulated markets. The Water Tube Food Processing Boiler Automation Market gains momentum from this focus on safety and product reliability.

- For instance, Honeywell’s L4006E Aquastat® Controller, designed for boiler systems, features a factory-set high-limit stop at 250°F to prevent overheating.

Impact of Regulatory Pressure on Emissions Control

Governments impose strict emission regulations on food processing facilities, influencing automation adoption. Automated boilers integrate monitoring tools to reduce pollutants and improve energy use. Companies view compliance not only as a requirement but also as a competitive advantage. It enhances sustainability credentials and strengthens partnerships with environmentally conscious buyers. This regulatory framework continues to be a significant factor shaping demand across the industry.

Integration of Smart Technologies in Food Processing

Digital tools and smart sensors expand capabilities of modern water tube boilers. Automation supports predictive maintenance, remote operation, and real-time performance optimization. It enables processors to reduce downtime and improve overall productivity. Market leaders invest in automation systems to create integrated, connected facilities. The Water Tube Food Processing Boiler Automation Market is set to advance further through innovation in smart and digital technologies.

For instance, a Total Petrochemicals plant deployed Emerson’s Rosemount 648 wireless temperature transmitters to monitor a boiler drum, with the sensors successfully transmitting real-time data to a gateway located 300 meters away.

Market Trends:

Adoption of Advanced Control Systems and Smart Monitoring

The Water Tube Food Processing Boiler Automation Market is witnessing steady growth driven by advanced control integration. Companies implement programmable logic controllers and IoT-enabled monitoring systems to ensure higher efficiency. It supports real-time analysis of steam flow, pressure, and energy use, reducing operational risks. Predictive maintenance powered by data analytics helps extend equipment lifespan and cut downtime. Food processors focus on automation tools that deliver measurable productivity gains and consistent product quality. This trend aligns with broader industry priorities for digital transformation and intelligent factory operations.

- For instance, Miura’s on-demand water tube boilers can produce high-pressure steam from a cold startup in less than 5 minutes.

Shift Toward Sustainable and Flexible Boiler Operations

The market is experiencing a clear trend toward sustainability and adaptability in boiler design. Companies seek automation systems that optimize fuel consumption and reduce emissions in line with environmental targets. It allows greater flexibility in handling different production loads, supporting diverse food processing requirements. Automation also enables seamless integration with renewable energy sources, reflecting a shift to low-carbon operations. Manufacturers prioritize solutions that address both regulatory compliance and long-term cost savings. The Water Tube Food Processing Boiler Automation Market continues to expand under the influence of these sustainability-driven advancements.

- For instance, Frito-Lay installed an innovative 60,000 lb/hr stoker-fired biomass boiler at its Topeka, Kansas, processing facility.

Market Challenges Analysis:

High Capital Costs and Integration Complexity

The Water Tube Food Processing Boiler Automation Market faces significant barriers due to high upfront investment requirements. Many small and medium-sized processors hesitate to adopt automation because of cost concerns. It involves not only the purchase of advanced boilers but also expenses related to installation and training. Integration with existing infrastructure often requires customization, which adds complexity and delays. Limited technical expertise in certain regions also slows adoption rates. These factors create a financial and operational challenge for companies evaluating automation upgrades.

Maintenance Demands and Regulatory Uncertainty

Another challenge relates to ongoing maintenance and compliance with evolving regulatory frameworks. Automated boilers demand regular servicing, calibration, and skilled operators to ensure optimal performance. It increases dependency on specialized service providers, which may not be readily available in every market. Frequent regulatory updates on emissions and safety standards create uncertainty for long-term investments. Companies must adjust systems to remain compliant, leading to operational disruptions. The Water Tube Food Processing Boiler Automation Market must address these hurdles to achieve sustained global growth.

Market Opportunities:

Expansion of Automation in Emerging Food Processing Hubs

The Water Tube Food Processing Boiler Automation Market holds strong opportunities in emerging economies with growing food sectors. Rapid urbanization and increasing consumer demand for packaged products create new requirements for efficient steam systems. It enables processors in these regions to adopt advanced automation for higher output and better quality. Governments support industrial modernization through incentives and infrastructure development, further driving adoption. Rising investment in food safety standards also pushes facilities to upgrade to automated boilers. These factors open pathways for market penetration and long-term revenue growth.

Integration of Digital and Sustainable Technologies

Opportunities also arise from the integration of digital platforms and sustainable boiler designs. Smart sensors, remote monitoring, and predictive analytics enhance system efficiency and reduce downtime. It allows processors to streamline operations while meeting stricter sustainability goals. Companies offering automation solutions that integrate renewable energy inputs gain a competitive edge. Growing corporate commitments to reduce carbon footprints create strong demand for eco-friendly automated systems. The Water Tube Food Processing Boiler Automation Market stands to benefit from these innovation-driven advancements across global operations.

Market Segmentation Analysis:

By Capacity

The Water Tube Food Processing Boiler Automation Market is segmented by small, medium, and large capacity units. Small and medium boilers serve bakeries, dairies, and regional plants that require steady steam output. Large capacity units dominate demand in multinational facilities handling high-volume food production. It allows processors to achieve scale, efficiency, and compliance with strict industry standards. Demand for medium capacity units is expanding due to the growth of mid-sized processing operations.

- For instance, the J.R. Simplot food processing facility utilizes large-capacity units, including two natural-gas-fired water-tube boilers each rated to produce 70,000 pounds of steam per hour.

By Technology

Technological segmentation highlights fully automated and semi-automated systems. Fully automated boilers lead adoption due to precise monitoring, lower downtime, and high consistency. Semi-automated systems remain relevant in smaller facilities where cost efficiency is a priority. It reflects varied adoption patterns based on operational scale and investment capacity. Growing interest in predictive maintenance tools is strengthening the preference for fully automated technologies.

- For instance, STEBATEC AG’s automation of a boiler control system for a steam plant with a capacity of 10 tonnes/h enabled it to extend the mandatory testing interval from every 72 hours to every 6 months.

By Fuel

Fuel segmentation includes natural gas, coal, oil, and biomass options. Natural gas-based boilers hold a leading position due to cleaner emissions and strong supply infrastructure. Biomass is gaining attention as processors align operations with sustainability targets. Oil and coal continue in use where cost and availability favor their application. It demonstrates a gradual transition toward cleaner and more sustainable fuel choices within the industry.

Segmentations:

- By Capacity

- By Technology

- Fully Automated

- Semi-Automated

- By Fuel

- Natural Gas

- Coal

- Oil

- Biomass

- By Region

- North America

- Europe

- UK

- France

- Germany

- Italy

- Spain

- Russia

- Belgium

- Netherlands

- Austria

- Sweden

- Poland

- Denmark

- Switzerland

- Rest of Europe

- Asia Pacific

- China

- Japan

- South Korea

- India

- Australia

- Thailand

- Indonesia

- Vietnam

- Malaysia

- Philippines

- Taiwan

- Rest of Asia Pacific

- Latin America

- Brazil

- Argentina

- Peru

- Chile

- Colombia

- Rest of Latin America

- Middle East

- UAE

- KSA

- Israel

- Turkey

- Iran

- Rest of Middle East

- Africa

- Egypt

- Nigeria

- Algeria

- Morocco

- Rest of Africa

Regional Analysis:

Strong Demand in North America Supported by Regulations

North America accounted for 28% share of the Water Tube Food Processing Boiler Automation Market. The region is driven by stringent emission standards and high energy-efficiency requirements. Food processors prioritize advanced boiler automation to meet compliance goals and optimize production. It benefits from government-backed initiatives promoting sustainable industrial operations. Investments in modernizing food manufacturing facilities further support adoption across the United States and Canada. The presence of leading technology providers strengthens the regional market position.

Rapid Growth in Asia-Pacific with Expanding Food Processing Sector

Asia-Pacific held 39% share of the Water Tube Food Processing Boiler Automation Market. The market in countries like China, India, and Southeast Asian nations benefits from urbanization and population growth. It is supported by significant investments in food infrastructure and adoption of international safety standards. Rising focus on automation helps processors enhance efficiency and reduce costs in highly competitive markets. Government policies encouraging modernization further accelerate the adoption of automated water tube boilers.

Steady Expansion in Europe and Emerging Opportunities Elsewhere

Europe captured 24% share of the Water Tube Food Processing Boiler Automation Market. Companies adopt automation to meet sustainability targets and ensure compliance with evolving emission norms. It creates a stable growth environment for suppliers offering innovative and eco-friendly solutions. Latin America and the Middle East present emerging opportunities, supported by new food manufacturing projects. Rising investments in automation in these regions indicate strong potential for future market expansion.

Shape Your Report to Specific Countries or Regions & Enjoy 30% Off!

Key Player Analysis:

- Alfa Laval

- Babcock and Wilcox

- Babcock Wanson

- Bosch Thermotechnology

- Clayton Industries

- Cleaver-Brooks

- Forbes Marshall

- Fulton

- Hoval

- Hurst Boiler

- Johnston Boiler

- Miura America

- Par Techno-Heat

- Rentech Boilers

Competitive Analysis:

The Water Tube Food Processing Boiler Automation Market features strong competition among global and regional players. Companies focus on developing advanced automation systems that enhance energy efficiency and meet strict emission standards. It is shaped by innovation in digital monitoring, predictive maintenance, and integration with sustainable fuel technologies. Leading players prioritize partnerships, acquisitions, and investments in R&D to strengthen their portfolios. Regional companies compete by offering cost-effective solutions tailored to local requirements, while global firms leverage advanced technologies and broad distribution networks. The competitive landscape reflects a balance between innovation-driven strategies and price-sensitive offerings. Growing demand for efficient, compliant, and scalable boiler automation solutions ensures continuous rivalry across all market segments.

Recent Developments:

- In June 2025, Alfa Laval launched its next-generation, AI-based condition monitoring solution, Clariot™, for hygienic process equipment.

- In July 2025, Clayton Industries formed a strategic partnership with Saltes to provide on-demand steam by using innovative molten salt thermal storage technology.

- In July 2025, Forbes Marshall entered into a long-term strategic partnership with Treon, a company based in Finland, to deploy advanced IoT monitoring infrastructure in India, the Middle East, and Southeast Asia.

Report Coverage:

The research report offers an in-depth analysis based on Capacity, Technology, Fuel and Region. It details leading market players, providing an overview of their business, product offerings, investments, revenue streams, and key applications. Additionally, the report includes insights into the competitive environment, SWOT analysis, current market trends, as well as the primary drivers and constraints. Furthermore, it discusses various factors that have driven market expansion in recent years. The report also explores market dynamics, regulatory scenarios, and technological advancements that are shaping the industry. It assesses the impact of external factors and global economic changes on market growth. Lastly, it provides strategic recommendations for new entrants and established companies to navigate the complexities of the market.

Future Outlook:

- The Water Tube Food Processing Boiler Automation Market will witness steady adoption driven by energy-efficiency needs.

- It will gain momentum through stricter environmental standards that require advanced emission control solutions.

- Growing consumer demand for packaged and processed foods will sustain long-term investments in automated systems.

- Automation will expand further with the integration of smart monitoring and predictive maintenance tools.

- It will benefit from rising modernization of food processing facilities in both developed and emerging economies.

- Manufacturers will focus on offering flexible capacity ranges to meet varied operational requirements.

- Adoption of sustainable fuel options such as biomass will accelerate in line with green production targets.

- It will be shaped by digital transformation, enabling real-time data use to optimize performance.

- Regional growth opportunities will emerge from industrial expansion in Asia-Pacific and infrastructure upgrades in Latin America.

- The market will evolve with strong competition, driving continuous innovation in advanced boiler automation solutions.

Market Drivers:

Market Drivers: