Market Overview:

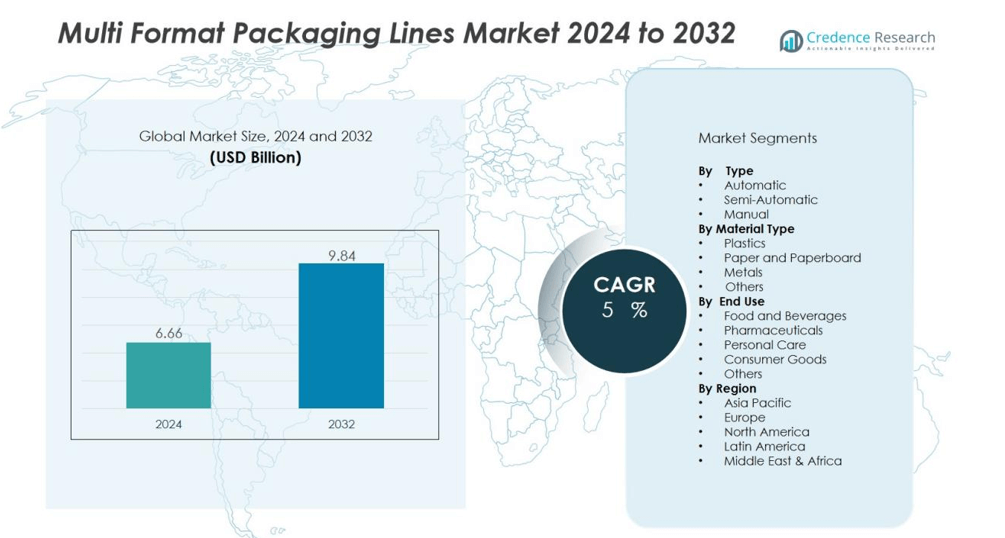

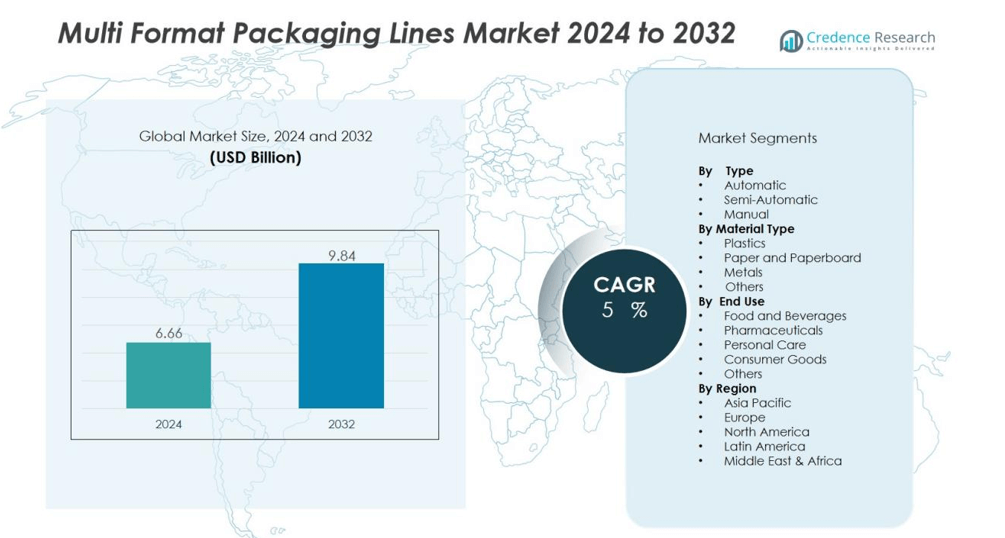

The multi format packaging lines market size was valued at USD 6.66 billion in 2024 and is anticipated to reach USD 9.84 billion by 2032, at a CAGR of 5 % during the forecast period (2024-2032).

| REPORT ATTRIBUTE |

DETAILS |

| Historical Period |

2020-2023 |

| Base Year |

2024 |

| Forecast Period |

2025-2032 |

| Multi Format Packaging Lines Market Size 2024 |

USD 6.66 billion |

| Multi Format Packaging Lines Market, CAGR |

5% |

| Multi Format Packaging Lines Market Size 2032 |

USD 9.84 billion |

Key drivers of this market include the growing emphasis on operational flexibility and faster changeovers to meet diverse consumer preferences. Companies are adopting smart packaging technologies, robotics, and IoT-enabled systems to improve efficiency and reduce downtime. Sustainability initiatives also play a central role, as brands seek packaging solutions that minimize waste and energy consumption while maintaining cost efficiency. The demand for packaging equipment that supports eco-friendly materials further accelerates market adoption.

Regionally, North America and Europe lead the market due to strong adoption of automation and regulatory focus on sustainability. Asia-Pacific is emerging as the fastest-growing region, fueled by rapid industrialization, expanding consumer markets, and investments in modern packaging infrastructure. Latin America and the Middle East & Africa are also witnessing gradual growth, supported by increasing demand for consumer goods and rising packaging industry investments.

Market Insights:

- The multi format packaging lines market was valued at USD 6.66 billion in 2024 and is expected to reach USD 9.84 billion by 2032, at a CAGR of 5%.

- Rising demand for flexibility and faster changeovers is driving adoption across food, beverage, pharmaceutical, and personal care sectors.

- Automation, robotics, and IoT-enabled systems are improving efficiency, reducing downtime, and cutting labor dependency.

- Sustainability initiatives are pushing manufacturers to adopt eco-friendly and recyclable packaging solutions.

- High capital investment and integration complexity remain significant challenges for small and mid-sized enterprises.

- North America holds 32% market share and Europe accounts for 29%, supported by automation and sustainability focus.

- Asia-Pacific holds 27% market share and is the fastest-growing region, fueled by industrialization and e-commerce expansion.

Access crucial information at unmatched prices!

Request your sample report today & start making informed decisions powered by Credence Research Inc.!

Download Sample

Market Drivers:

Rising Demand for Flexibility and Versatility in Packaging Operations:

The multi format packaging lines market is driven by the need for systems that can handle multiple package types without requiring frequent equipment changes. Manufacturers across food, beverage, pharmaceutical, and personal care industries are prioritizing flexibility to meet diverse consumer demands. It supports faster product launches and allows companies to remain competitive in dynamic markets. This versatility reduces operational downtime and optimizes production efficiency.

- For instance, Bosch Packaging Technology’s PME 4061 mandrel wheel package maker enables three-dimensional format changes in only 4 hours with two operators, dramatically cutting changeover time and minimizing downtime while accommodating various bag styles and sizes

Increasing Adoption of Automation and Smart Technologies:

Automation and smart packaging technologies are reshaping the multi format packaging lines market. Robotics, IoT integration, and advanced control systems enable faster changeovers, real-time monitoring, and higher productivity. It reduces reliance on manual processes, cutting labor costs and minimizing errors. Companies are investing heavily in these technologies to streamline production and improve overall equipment effectiveness.

- For instance, a leading Latin American confectionery partnered with Bosch Packaging Technology to retrofit its secondary packaging line with tool-less, automated changeover capabilities, reducing format changeover time from 60 minutes to 10 minutes.

Strong Push Toward Sustainability and Eco-Friendly Packaging:

Sustainability is a key driver influencing purchasing decisions in the multi format packaging lines market. Global regulations and consumer awareness are pushing companies to adopt packaging solutions that minimize waste and support recyclable or biodegradable materials. It aligns production with environmental goals while reducing long-term costs. Sustainable packaging systems also help brands strengthen their market positioning.

Expanding Consumer Markets and Rising Global Industrialization:

The rapid growth of consumer goods demand in emerging economies significantly supports the multi format packaging lines market. Industrialization in Asia-Pacific and Latin America is fueling investments in advanced packaging infrastructure. It allows local manufacturers to meet increasing demand efficiently while competing with global brands. Expanding retail channels and e-commerce growth further accelerate the adoption of flexible packaging systems worldwide.

Market Trends:

Integration of Digitalization and Smart Packaging Technologies:

A major trend in the multi format packaging lines market is the integration of digitalization and smart packaging technologies. Manufacturers are increasingly adopting IoT-enabled systems, robotics, and advanced sensors to improve line efficiency and reduce downtime. It enables predictive maintenance, real-time data analysis, and remote monitoring, which enhance productivity. Smart packaging solutions also support traceability and compliance, particularly in food and pharmaceutical applications. Companies are focusing on digital transformation to meet growing consumer expectations for faster delivery and greater transparency. This shift toward connected systems is expected to set new industry standards for operational excellence.

- For instance, after implementing Tetra Pak’s Predictive Maintenance with Condition Monitoring at a European dairy plant, unplanned downtime was cut by exactly 140 hours in the first year, while waste was reduced by 4,200 packs per month.

Growing Focus on Sustainable and Consumer-Centric Packaging Solutions:

Sustainability and consumer preferences are shaping key trends in the multi format packaging lines market. Brands are demanding equipment capable of handling eco-friendly materials such as recyclable plastics, biodegradable films, and lightweight packaging. It ensures compliance with tightening environmental regulations while reducing carbon footprints. Consumers are also driving the need for innovative formats, including resealable packs, portion-sized packages, and customizable designs. Manufacturers are aligning with these demands by investing in machinery that offers high adaptability without compromising efficiency. This focus on sustainable and consumer-centric solutions is redefining packaging strategies across global industries.

- For instance, in February 2025, Tetra Pak introduced carton packaging in India incorporating 5 percent ISCC Plus certified recycled polymers sourced and produced at its Chakan, Pune facility

Market Challenges Analysis:

High Capital Investment and Integration Complexity:

One of the key challenges in the multi format packaging lines market is the high upfront investment required for advanced machinery. Small and mid-sized enterprises often struggle to allocate resources for such systems, slowing adoption. It also requires specialized expertise for installation and integration with existing production lines. Compatibility issues with legacy equipment further increase costs and operational risks. These barriers limit accessibility, especially in price-sensitive regions, and create slower return on investment for many businesses.

Skilled Workforce Shortage and Maintenance Issues:

Another challenge facing the multi format packaging lines market is the shortage of skilled professionals to operate and maintain advanced systems. Complex automation and digital technologies demand continuous training and technical knowledge. It increases dependency on specialized staff and exposes manufacturers to potential downtime if expertise is unavailable. Maintenance costs also rise due to the sophisticated nature of equipment, creating hurdles for long-term operations. These issues highlight the importance of workforce development and reliable support systems to ensure efficiency.

Market Opportunities:

Expansion in Emerging Markets and Rising Consumer Demand :

The multi format packaging lines market presents strong opportunities in emerging economies where consumer demand for packaged goods continues to rise. Rapid urbanization, growth of middle-class populations, and expansion of retail and e-commerce channels create favorable conditions for adoption. It allows manufacturers to tap into new revenue streams while improving efficiency and meeting varied packaging needs. Governments in these regions are also investing in industrial infrastructure, which further supports market growth. Companies focusing on localized solutions and affordable automation are likely to secure competitive advantages.

Advancements in Sustainable and Customizable Packaging Solutions :

Growing emphasis on sustainability and personalization creates new opportunities for the multi format packaging lines market. Equipment that can handle recyclable and biodegradable materials while delivering innovative designs aligns with consumer and regulatory demands. It enables brands to meet environmental goals while appealing to eco-conscious buyers. Customization options such as portion packaging, resealable designs, and unique formats are gaining traction across food, beverage, and personal care sectors. Manufacturers investing in flexible, future-ready technologies stand to benefit from long-term growth. This opportunity highlights the industry’s shift toward sustainable innovation and consumer-centric strategies.

Market Segmentation Analysis:

By Type:

The multi format packaging lines market by type is segmented into automatic, semi-automatic, and manual systems. Automatic systems dominate due to their efficiency, speed, and reduced human error. It enables faster changeovers and higher throughput, making them suitable for large-scale production. Semi-automatic lines cater to mid-sized businesses that balance cost and flexibility, while manual systems remain relevant in smaller industries. The growing preference for automation is expected to continue shaping this segment.

- For Instance, Sidel’s EvoFilm™ seamless shrink-wrapping machine, a component of their automatic packaging solutions, can achieve speeds of up to 120 cycles per minute for PET bottles in a three-lane configuration, demonstrating a precise high-throughput capability for large bottling plants

By Material Type:

By material type, the market includes plastics, paper and paperboard, metals, and others. Plastics hold a significant share due to durability and adaptability across diverse formats. It offers lightweight benefits and compatibility with both rigid and flexible packaging. Paper and paperboard are gaining momentum due to rising sustainability goals and regulatory pressures. Metals are used in niche applications requiring strength and long shelf life. This segment reflects the industry’s shift toward recyclable and eco-friendly materials.

For instance, Amcor’s AmLite Ultra Re mono-material snack film is produced at a 36 µm thickness, enabling material reduction while remaining fully recyclable

By End Use:

The market by end use spans food and beverages, pharmaceuticals, personal care, consumer goods, and others. Food and beverages account for the largest share due to high demand for flexible and varied packaging formats. It supports efficiency in handling portion packs, multipacks, and resealable options. Pharmaceuticals are adopting advanced systems for compliance, precision, and safety standards. Personal care and consumer goods sectors also contribute, driven by customization and branding needs. These diverse applications ensure steady growth across industries.

Segmentations:

By Type

- Automatic

- Semi-Automatic

- Manual

By Material Type

- Plastics

- Paper and Paperboard

- Metals

- Others

By End Use

- Food and Beverages

- Pharmaceuticals

- Personal Care

- Consumer Goods

- Others

By Region

- North America

- Europe

- UK

- France

- Germany

- Italy

- Spain

- Russia

- Belgium

- Netherlands

- Austria

- Sweden

- Poland

- Denmark

- Switzerland

- Rest of Europe

- Asia Pacific

- China

- Japan

- South Korea

- India

- Australia

- Thailand

- Indonesia

- Vietnam

- Malaysia

- Philippines

- Taiwan

- Rest of Asia Pacific

- Latin America

- Brazil

- Argentina

- Peru

- Chile

- Colombia

- Rest of Latin America

- Middle East

- UAE

- KSA

- Israel

- Turkey

- Iran

- Rest of Middle East

- Africa

- Egypt

- Nigeria

- Algeria

- Morocco

- Rest of Africa

Regional Analysis:

North America and Europe:

North America holds 32% market share in the multi format packaging lines market, while Europe accounts for 29%. The dominance of these regions is driven by strong automation adoption and advanced manufacturing infrastructure. It benefits from stringent regulatory frameworks that emphasize sustainability and packaging efficiency. Food, beverage, and pharmaceutical sectors in these regions demand high flexibility to meet evolving consumer preferences. Investments in digitalization and robotics further strengthen regional competitiveness. Leading manufacturers in these markets continue to focus on innovation and cost optimization.

Asia-Pacific :

Asia-Pacific holds 27% market share in the multi format packaging lines market and is the fastest-growing region. The growth is fueled by rapid industrialization, expansion of consumer markets, and increasing investments in packaging technologies. It benefits from rising demand for packaged food, personal care, and healthcare products. Governments in China, India, and Southeast Asia are supporting industrial expansion with favorable policies and infrastructure projects. Local manufacturers are adopting flexible systems to compete with global players. E-commerce expansion further accelerates demand for multi-format solutions across the region.

Latin America and Middle East & Africa:

Latin America holds 7% market share in the multi format packaging lines market, while the Middle East & Africa account for 5%. Growth in these regions is supported by increasing demand for consumer goods and rising investments in modern packaging infrastructure. It reflects strong potential for long-term adoption despite economic challenges in certain markets. Retail expansion, growing disposable incomes, and the push for sustainable packaging create favorable conditions. Global manufacturers are entering these regions through partnerships and localized solutions. These factors collectively support gradual but steady market expansion.

Shape Your Report to Specific Countries or Regions & Enjoy 30% Off!

Key Player Analysis:

- Barry-Wehmiller Companies

- Coesia Group

- Bosch Packaging Technology (Syntegon)

- Fuji Machinery Co., Ltd.

- IMA Group

- Ishida Co., Ltd.

- Haver & Boecker

- KHS GmbH

- Multivac Group

- Marchesini Group

- ProMach Inc.

Competitive Analysis:

The multi format packaging lines market is highly competitive, driven by technological innovation and the demand for operational efficiency. Key players such as Barry-Wehmiller Companies, Coesia Group, Bosch Packaging Technology (Syntegon), Fuji Machinery Co., Ltd., IMA Group, Ishida Co., Ltd., and Haver & Boecker are focusing on expanding product portfolios and strengthening global reach. It is marked by continuous investment in automation, robotics, and sustainable packaging technologies to meet evolving industry needs. Companies are competing on factors such as speed, flexibility, integration with smart systems, and cost efficiency. Strategic partnerships, acquisitions, and regional expansions are common approaches to enhance competitiveness. The strong emphasis on eco-friendly packaging and smart manufacturing solutions creates opportunities for differentiation. It continues to evolve as established players integrate advanced digital solutions while addressing the growing demand for sustainable and versatile packaging equipment across diverse end-use industries.

Recent Developments:

- In December 2023, Barry-Wehmiller announced the integration of its filling and closing businesses into BW Filling & Closing, enhancing its packaging machinery solutions globally.

- In April 2025, Coesia COMPANY acquired SAM Europe, enhancing Coesia capabilities in machinery for industrial plants and energy-storage system manufacturing.

Report Coverage:

The research report offers an in-depth analysis based on Type, Material Type, End Use and Region . It details leading Market players, providing an overview of their business, product offerings, investments, revenue streams, and key applications. Additionally, the report includes insights into the competitive environment, SWOT analysis, current Market trends, as well as the primary drivers and constraints. Furthermore, it discusses various factors that have driven Market expansion in recent years. The report also explores Market dynamics, regulatory scenarios, and technological advancements that are shaping the industry. It assesses the impact of external factors and global economic changes on Market growth. Lastly, it provides strategic recommendations for new entrants and established companies to navigate the complexities of the Market.

Future Outlook:

- The multi format packaging lines market will witness strong demand for systems offering faster changeovers and high flexibility.

- Automation, robotics, and IoT integration will continue to enhance productivity and reduce downtime.

- Manufacturers will invest in machinery capable of handling recyclable and biodegradable packaging materials.

- Digitalization will drive predictive maintenance, real-time monitoring, and improved production efficiency.

- Food, beverage, and pharmaceutical industries will remain the leading adopters of multi-format systems.

- Asia-Pacific will emerge as the fastest-expanding region due to industrial growth and rising consumer demand.

- North America and Europe will sustain dominance by focusing on sustainability and advanced automation.

- Customization in packaging, such as portion packs and resealable formats, will gain higher adoption.

- Global players will expand into emerging economies through partnerships and localized manufacturing.

- Sustainability initiatives and regulatory support will shape long-term opportunities for innovative packaging solutions.