Market Overview:

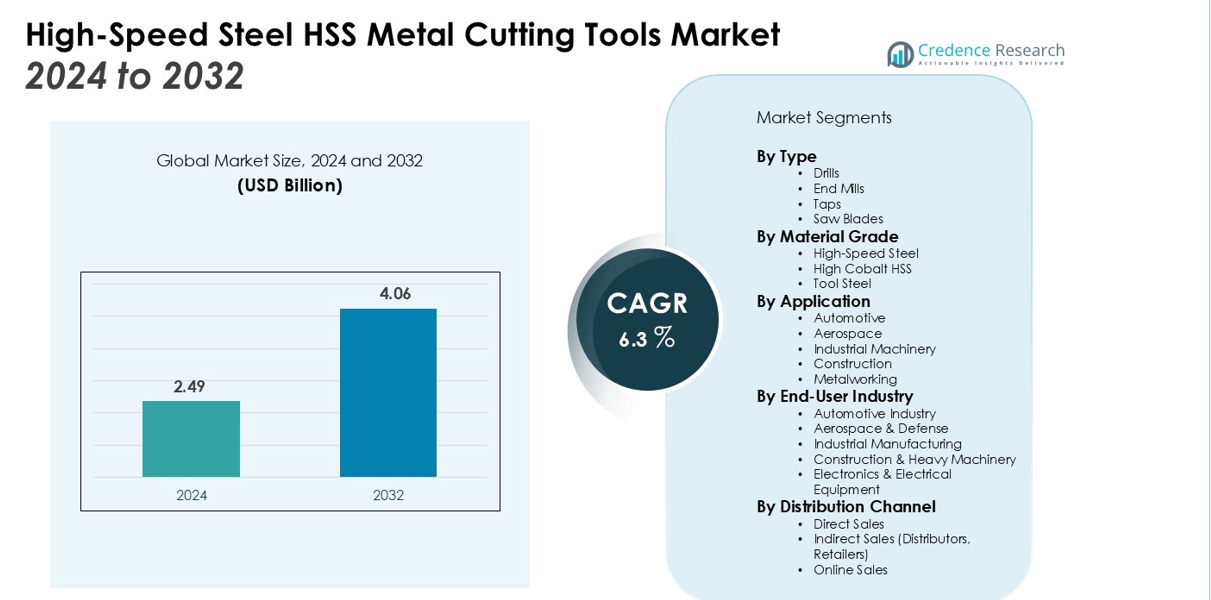

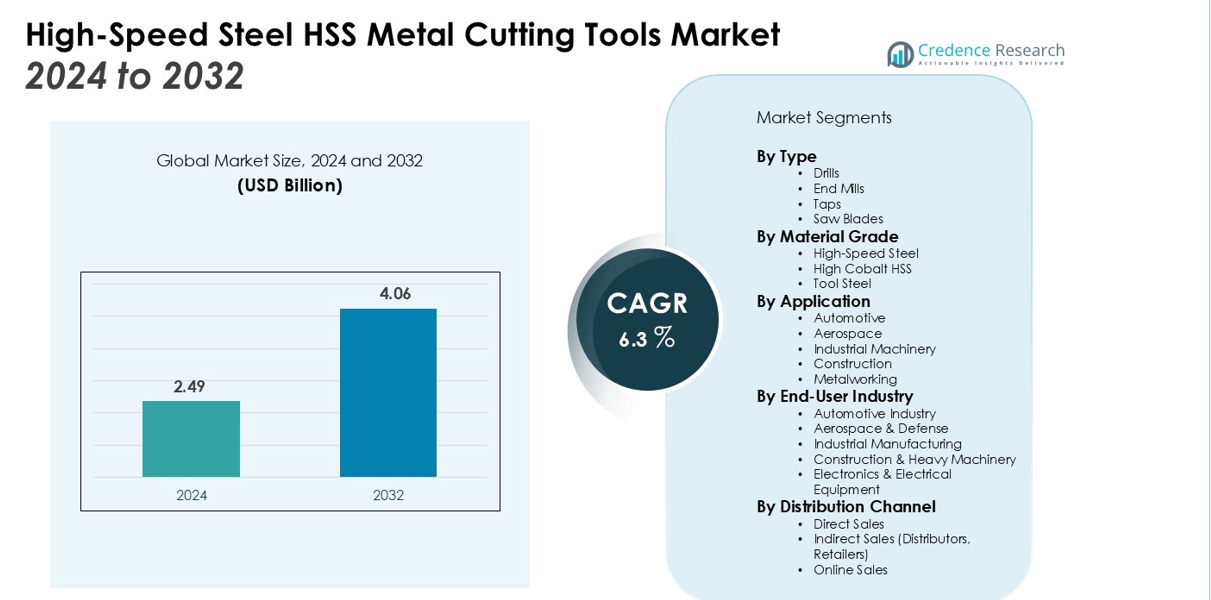

The High-Speed Steel HSS Metal Cutting Tools Market size was valued at USD 2.49 billion in 2024 and is anticipated to reach USD 4.06 billion by 2032, at a CAGR of 6.3% during the forecast period (2024-2032).

| REPORT ATTRIBUTE |

DETAILS |

| Historical Period |

2020-2023 |

| Base Year |

2024 |

| Forecast Period |

2025-2032 |

| High-Speed Steel (HSS) Metal Cutting Tools Market Size 2024 |

USD 2.49 billion |

| High-Speed Steel (HSS) Metal Cutting Tools Market, CAGR |

6.3% |

| High-Speed Steel (HSS) Metal Cutting Tools Market Size 2032 |

USD 4.06 billion |

The key drivers of the HSS metal cutting tools market include the growing demand for high-efficiency machining solutions that ensure better precision and longer tool life. Advancements in HSS technology, such as the development of coatings and the introduction of improved alloys, have enhanced tool performance, further boosting market adoption. Additionally, the rising industrialization in emerging economies and the growing demand for cost-effective, high-quality manufacturing solutions contribute significantly to the market expansion. The increasing focus on sustainability and eco-friendly manufacturing practices also plays a significant role in driving the demand for HSS metal cutting tools, as companies seek solutions that reduce waste and improve energy efficiency.

Regionally, North America holds the largest market share, supported by strong automotive and aerospace industries and a well-established manufacturing base. Europe follows closely, driven by innovations in manufacturing technologies and strict regulations that promote the use of high-performance tools. The Asia Pacific region is expected to witness the highest growth, fueled by the expanding industrial base in countries like China and India, where demand for advanced cutting tools is rapidly increasing. This regional shift is also driven by the increasing adoption of automation and precision engineering in manufacturing processes.

Market Insights:

- The High-Speed Steel (HSS) Metal Cutting Tools Market is valued at USD 49 billion in 2024 and is expected to reach USD 4.06 billion by 2032, driven by demand for high-efficiency machining solutions.

- Advancements in coatings like TiN and TiAlN, and improved alloys, enhance tool durability and performance, expanding market adoption.

- The rapid industrialization in emerging economies, particularly in Asia Pacific, increases the demand for high-performance HSS tools.

- HSS tools offer cost-effective performance with long lifespan, reducing tool replacement frequency and optimizing manufacturing costs.

- The rise of carbide tools, known for superior hardness and wear resistance, challenges the market share of HSS tools in high-performance applications.

- Fluctuations in the cost of key raw materials like tungsten, cobalt, and molybdenum increase production costs and impact market competitiveness.

- North America holds 39% of the market, Europe holds 33%, and Asia Pacific accounts for 38%, driven by industrial growth and technological advancements.

Access crucial information at unmatched prices!

Request your sample report today & start making informed decisions powered by Credence Research Inc.!

Download Sample

Market Drivers:

Increasing Demand for Precision and Efficiency in Manufacturing

The growing demand for high-efficiency machining solutions is one of the key drivers for the High-Speed Steel (HSS) Metal Cutting Tools Market. Industries such as automotive, aerospace, and general manufacturing require tools that ensure high precision, consistent performance, and minimal wear. HSS tools provide these benefits, making them essential for machining processes that demand durability and efficiency. Manufacturers continue to seek solutions that improve operational productivity while maintaining quality standards, fueling the need for advanced cutting tools.

- For instance, precision instrument manufacturer Mitutoyo produces a High Accuracy Check Master for calibrating machine tools that guarantees a block pitch accuracy of 1.2 micrometers (μm) over a 300mm length, ensuring the highest level of machining precision.

Technological Advancements in HSS Tool Performance

Technological innovations in HSS metal cutting tools have significantly enhanced their performance and versatility. The development of specialized coatings, such as TiN (Titanium Nitride) and TiAlN (Titanium Aluminum Nitride), has increased tool life and wear resistance. Improved alloys have also contributed to stronger, more durable tools, enabling better cutting capabilities in challenging applications. These advancements make HSS tools a reliable choice for industries that require high-quality and long-lasting machining tools.

- For instance, specialty steel producer Böhler developed a powder metallurgy HSS grade, S290PM Microclean, which is engineered to achieve a hardness of 70 HRC, providing extreme thermal stability and wear resistance for demanding cutting operations.

Industrialization and Expanding Manufacturing Base in Emerging Economies

Rapid industrialization in emerging economies, particularly in Asia Pacific, has contributed significantly to the growth of the HSS metal cutting tools market. As countries like China and India continue to expand their manufacturing capabilities, the demand for high-performance cutting tools is increasing. The shift towards automated production processes further boosts the adoption of HSS tools, which are essential for high-precision applications in mass production.

Rising Need for Cost-Effective Manufacturing Solutions

The growing demand for cost-effective manufacturing solutions is also driving market growth. HSS metal cutting tools offer a balance of cost and performance, making them an attractive option for companies looking to optimize their production costs. Their long lifespan and reliability reduce tool replacement frequency, which leads to overall savings in manufacturing processes. This cost-effectiveness is particularly appealing to industries seeking to improve profitability while maintaining high manufacturing standards.

Market Trends:

Shift Toward Advanced Coatings and Alloys in HSS Tools

A significant trend in the High-Speed Steel (HSS) Metal Cutting Tools Market is the increasing use of advanced coatings and improved alloys. Coatings such as Titanium Nitride (TiN), Titanium Aluminum Nitride (TiAlN), and other specialized layers are being applied to enhance wear resistance and extend tool life. These coatings allow HSS tools to perform under extreme conditions, providing better heat resistance and improved surface finish. The shift toward these advanced materials is driven by the demand for higher precision, reduced downtime, and improved cost efficiency in industrial applications. The adoption of new alloys that offer higher strength and better performance is becoming more common, enabling tools to endure longer cutting periods and harder materials, thereby expanding the range of applications for HSS tools.

- For instance, Ionbond’s Optimizer™ Plus, an AlCrN-based coating, allows for wet and dry machining at high speeds, withstanding temperatures up to 1080°C.

Rising Automation and Customization in Manufacturing Processes

Another prominent trend in the High-Speed Steel HSS Metal Cutting Tools Market is the rise in automation and the demand for customized solutions. The ongoing industrial automation and the growing use of computer numerical control (CNC) machines require tools that offer both precision and flexibility. HSS tools are increasingly being tailored to meet the specific needs of automated manufacturing systems, allowing for more efficient mass production. Companies are also seeking customized tools that optimize machining performance in specialized sectors like aerospace, automotive, and medical device manufacturing. This trend reflects a broader move toward more flexible, high-performance solutions that can meet the evolving requirements of modern manufacturing systems.

- For instance, Sumitomo’s high-feed milling system features an innovative insert design with an arc-shaped cutting edge, this allows for a maximum feed rate of 3.5 mm per tooth, enabling stable, high-efficiency machining even with long tool overhangs.

Market Challenges Analysis:

Intense Competition from Carbide and Other Cutting Tools

One of the key challenges facing the High-Speed Steel (HSS) Metal Cutting Tools Market is the increasing competition from carbide and other advanced cutting materials. Carbide tools, known for their superior hardness and resistance to wear, are often preferred for high-performance applications, especially in industries dealing with difficult-to-machine materials. This shift toward carbide tools, which offer better performance and durability in specific applications, is putting pressure on the demand for HSS tools. As carbide becomes more affordable and accessible, HSS tools face difficulty in maintaining their market share in high-end industrial applications that require extreme precision and efficiency.

Rising Raw Material Prices and Cost Pressures

The rising cost of raw materials is another challenge for the High-Speed Steel HSS Metal Cutting Tools Market. The prices of key materials, such as tungsten, cobalt, and molybdenum, which are essential in manufacturing HSS tools, have seen fluctuations in recent years. These price hikes directly impact the production cost of HSS tools, making it difficult for manufacturers to offer competitive pricing while maintaining product quality. Increased raw material costs can lead to higher end-user prices, potentially reducing demand, especially in cost-sensitive markets. Manufacturers must find ways to optimize production processes to mitigate these rising costs and ensure market competitiveness.

Market Opportunities:

Growing Demand for High-Precision and Automated Manufacturing Solutions

The High-Speed Steel (HSS) Metal Cutting Tools Market presents significant opportunities driven by the increasing adoption of automation and high-precision manufacturing techniques. With industries such as automotive, aerospace, and medical devices emphasizing accuracy and efficiency, there is a rising demand for cutting tools that provide superior performance. HSS tools are well-suited for these applications, offering a combination of durability and cost-effectiveness. The continued growth of automated production lines, coupled with the need for tools that can handle complex machining tasks, presents a strong growth opportunity for HSS metal cutting tool manufacturers.

Expansion in Emerging Markets and Industrialization

Emerging markets, particularly in Asia-Pacific, offer substantial growth opportunities for the High-Speed Steel HSS Metal Cutting Tools Market. The rapid industrialization in countries like China and India has resulted in increased manufacturing activities, creating demand for efficient and reliable cutting tools. As these regions expand their manufacturing capabilities, the need for advanced, cost-effective HSS tools that support mass production and high-volume machining is set to rise. Additionally, the growing focus on improving manufacturing processes in these regions provides a favorable environment for HSS tools to penetrate new sectors, including electronics and consumer goods.

Market Segmentation Analysis:

By Type

The High-Speed Steel (HSS) Metal Cutting Tools Market is segmented into various types, including drills, end mills, taps, and saw blades. Drills and end mills dominate the market due to their extensive use in precision machining across industries such as automotive and aerospace. These tools are preferred for their ability to maintain high cutting speeds and durability under extreme conditions. As industries focus on automation and high-efficiency production, the demand for reliable and long-lasting cutting tools continues to grow, boosting the market share of these tool types.

- For instance, Sandvik’s Alpha 360 drilling tool is engineered for high-efficiency production, specifically designed for hole diameters of 48-51mm in face drilling and bolting applications.

By Material Grade

HSS tools are available in different material grades, including high cobalt, high-speed steel, and tool steel. High-speed steel tools, which are typically less expensive, are used in general machining applications. High cobalt-grade HSS tools offer enhanced wear resistance and are preferred for applications involving tough materials. The increasing demand for precision and durability across industries is driving the growth of high-performance material grades, making them a popular choice for demanding applications such as aerospace and automotive manufacturing.

By Application

The High-Speed Steel (HSS) Metal Cutting Tools Market serves a variety of applications, including automotive, aerospace, construction, and industrial machinery. The automotive sector holds the largest market share, driven by the need for high-precision and efficient machining tools. The aerospace industry follows, with stringent quality and performance standards demanding specialized cutting tools. HSS tools’ versatility and durability make them ideal for diverse applications, further expanding their use in these key industries.

- For instance, to meet the precision demands of the aerospace sector, BIG DAISHOWA’s RBX12 Air Power Spindle enables HSS tools to achieve rotational speeds of up to 120,000 RPM for high-speed micro-machining operations.

Segmentations:

- By Type:

- Drills

- End Mills

- Taps

- Saw Blades

- By Material Grade:

- High-Speed Steel

- High Cobalt HSS

- Tool Steel

- By Application:

- Automotive

- Aerospace

- Industrial Machinery

- Construction

- Metalworking

- By End-User Industry:

- Automotive Industry

- Aerospace & Defense

- Industrial Manufacturing

- Construction & Heavy Machinery

- Electronics & Electrical Equipment

- By Distribution Channel:

- Direct Sales

- Indirect Sales (Distributors, Retailers)

- Online Sales

- By Region:

- North America

- Europe

- UK

- France

- Germany

- Italy

- Spain

- Russia

- Rest of Europe

- Asia Pacific

- China

- Japan

- South Korea

- India

- Australia

- Southeast Asia

- Rest of Asia Pacific

- Latin America

- Brazil

- Argentina

- Rest of Latin America

- Middle East

- GCC Countries

- Israel

- Turkey

- Rest of Middle East

- Africa

- South Africa

- Egypt

- Rest of Africa

Regional Analysis:

North America: Advanced Manufacturing and Aerospace Leadership

North America holds 39% of the High-Speed Steel (HSS) Metal Cutting Tools Market. The United States and Canada play significant roles, with industries like aerospace, automotive, and medical devices driving demand for HSS tools. The region’s focus on technological advancements, automation, and strict quality standards further boosts the demand for high-performance cutting tools. Strong manufacturing sectors in both countries create a stable environment for market growth, while increased investments in precision machining and robotics support further market expansion.

Europe: Precision Engineering and Automotive Innovation

Europe accounts for 33% of the High-Speed Steel Metal Cutting Tools Market, with Germany leading the demand due to its automotive and industrial machinery sectors. Countries such as France and Italy also contribute significantly, driven by aerospace and manufacturing industries that prioritize high-precision tools. The region’s focus on precision engineering and the growing transition to electric vehicle production further boosts the demand for HSS tools. Technological innovation and strict regulations in manufacturing continue to support the consistent growth of HSS tools in Europe.

Asia Pacific: Rapid Industrialization and Manufacturing Expansion

Asia Pacific holds 38% of the High-Speed Steel (HSS) Metal Cutting Tools Market, with China, India, and Japan driving significant demand. The region’s rapid industrialization fuels the need for durable, high-performance cutting tools, especially in automotive, aerospace, and construction sectors. India’s growing adoption of automated manufacturing processes plays a vital role in the market’s growth, while expanding industrial bases and technological progress in the region continue to drive demand for HSS tools. The ongoing shift toward advanced manufacturing further strengthens market opportunities.

Shape Your Report to Specific Countries or Regions & Enjoy 30% Off!

Key Player Analysis:

- Erasteel

- BIG Kaiser Precision Tooling

- Emuge

- Dormer Pramet

- TimkenSteel

- GWS Tool Group

- Sandvik Coromant

- Hannibal Carbide Tool

- Kennametal

- Seco Tools

- Niagara Cutter

- RTS Cutting Tools

- Toolmex Industrial Solutions

- Sumitomo Electric Industries

Competitive Analysis:

The High-Speed Steel (HSS) Metal Cutting Tools Market is highly competitive, with major players such as Kennametal Inc., Sandvik AB, Seco Tools, Dormer Pramet, and Mitsubishi Materials leading the market. These companies maintain a strong market position through extensive distribution networks, brand reputation, and continuous product innovation. Smaller, emerging players focus on niche segments and regional markets, offering specialized and cost-effective solutions. Collaborations and partnerships between tool manufacturers and machine tool OEMs are common, driving demand for integrated solutions. Technological advancements, including the development of advanced coatings and improved material grades, are crucial in maintaining competitiveness. Companies invest heavily in research and development to enhance performance, durability, and efficiency, while automation and Industry 4.0 technologies influence market dynamics. Overall, the market remains dynamic, with companies constantly adapting to evolving industry trends and customer demands.

Recent Developments:

- In March 2025, BIG DAISHOWA, the parent company of BIG KAISER, introduced new HSK-EZ15 tooling solutions.

- In March 2025, Sandvik Coromant launched new solutions in metal-cutting machining.

Report Coverage:

The research report offers an in-depth analysis based on Type, Material Grade, Application, End-User Industry, Distribution Channel and Region. It details leading market players, providing an overview of their business, product offerings, investments, revenue streams, and key applications. Additionally, the report includes insights into the competitive environment, SWOT analysis, current market trends, as well as the primary drivers and constraints. Furthermore, it discusses various factors that have driven market expansion in recent years. The report also explores market dynamics, regulatory scenarios, and technological advancements that are shaping the industry. It assesses the impact of external factors and global economic changes on market growth. Lastly, it provides strategic recommendations for new entrants and established companies to navigate the complexities of the market.

Future Outlook:

- The demand for high-efficiency and precision machining will continue to drive the growth of the High-Speed Steel (HSS) Metal Cutting Tools Market.

- Technological advancements, such as the development of specialized coatings and enhanced material grades, will improve tool performance and expand applications.

- The expansion of the automotive and aerospace sectors will further boost the demand for durable and high-performance cutting tools.

- Rising industrial automation and the adoption of Industry 4.0 technologies will increase the need for reliable HSS tools in mass production processes.

- Emerging economies, particularly in Asia Pacific, will see significant growth as manufacturing capabilities expand, creating new opportunities for HSS tool adoption.

- The shift toward sustainability and eco-friendly manufacturing practices will drive demand for energy-efficient and waste-reducing cutting tools.

- Advancements in additive manufacturing and 3D printing will offer new possibilities for HSS tools, creating potential growth avenues.

- Increased focus on reducing production costs while maintaining quality standards will lead to greater use of cost-effective HSS tools in various industries.

- The rise in custom solutions and tailored HSS tools for specific applications will cater to the evolving needs of industries such as medical devices and electronics.

- Competitive pressure from carbide and other advanced materials will push HSS tool manufacturers to innovate continuously and enhance product offerings to maintain market share.