Market Overview

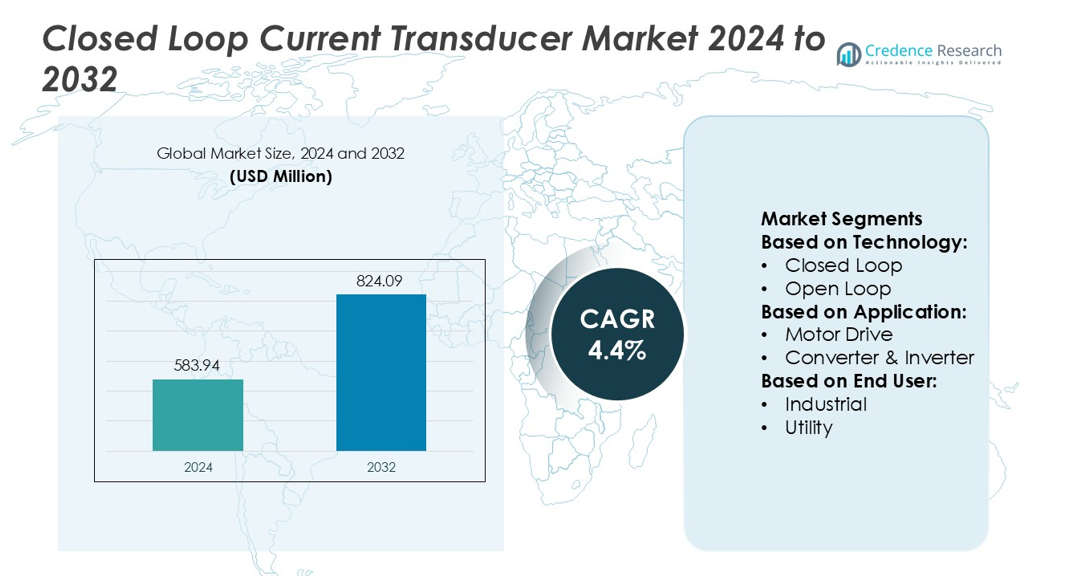

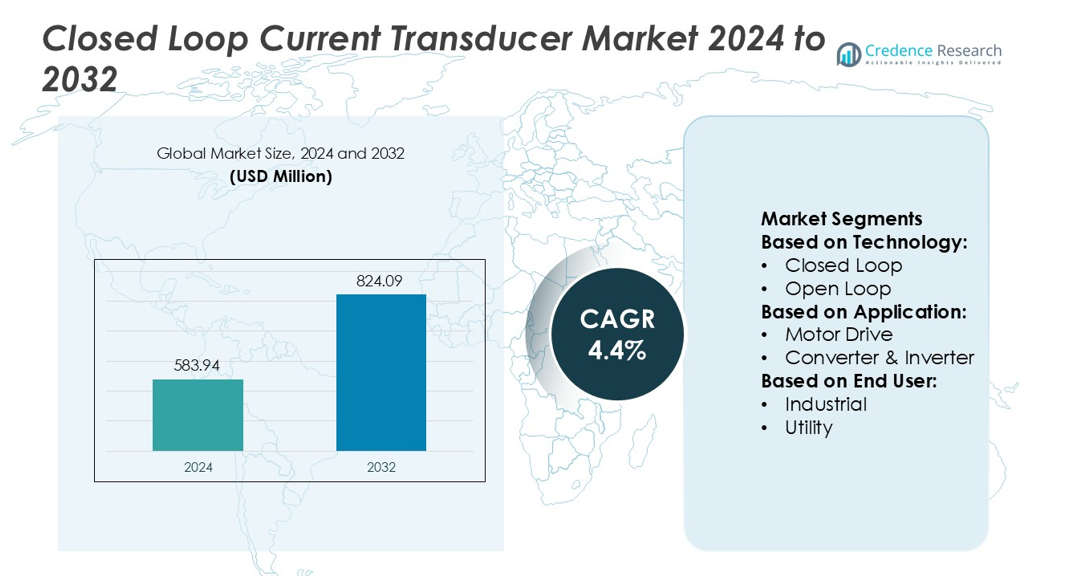

Closed Loop Current Transducer Market size was valued USD 583.94 million in 2024 and is anticipated to reach USD 824.09 million by 2032, at a CAGR of 4.4% during the forecast period.

| REPORT ATTRIBUTE |

DETAILS |

| Historical Period |

2020-2023 |

| Base Year |

2024 |

| Forecast Period |

2025-2032 |

| Closed Loop Current Transducer Market Size 2024 |

USD 583.94 million |

| Closed Loop Current Transducer Market, CAGR |

4.4% |

| Closed Loop Current Transducer Market Size 2032 |

USD 824.09 million |

The Closed Loop Current Transducer Market include ABB, Siemens, Infineon Technologies, LEM, Texas Instruments, Johnson Controls, Phoenix Contact, NK Technologies, Topstek, and Howard Butler. These companies focus on high-accuracy sensing, compact designs, and integrated signal conditioning for electric vehicles, industrial drives, renewable energy systems, and smart grids. Product portfolios continue to expand with digital outputs, wide bandwidth capability, and higher thermal stability to meet modern power electronics requirements. Asia Pacific leads the global market with 35% share, driven by strong electronics manufacturing, rapid industrialization, and fast growth in EV and solar installations.

Market Insights

- Closed Loop Current Transducer Market size was valued at USD 583.94 million in 2024 and is anticipated to reach USD 824.09 million by 2032, growing at a CAGR of 4.4% during the forecast period.

- The market grows due to rising use of electric vehicles, renewable energy systems, and motor drives that require precise current monitoring for safety and efficiency.

- Digital output transducers, wide bandwidth capability, and thermally stable designs are becoming key trends as power electronics demand higher accuracy and faster response time.

- Competition remains strong among ABB, Siemens, Infineon Technologies, LEM, Texas Instruments, Johnson Controls, Phoenix Contact, NK Technologies, Topstek, and Howard Butler, with companies expanding portfolios to serve EV charging, inverters, and industrial automation.

- Asia Pacific leads the global market with 35% share, followed by North America and Europe, while the industrial segment remains dominant due to heavy adoption in automation, smart grids, and power control applications.

Access crucial information at unmatched prices!

Request your sample report today & start making informed decisions powered by Credence Research Inc.!

Download Sample

Market Segmentation Analysis:

By Technology

The Closed Loop technology segment leads the Closed Loop Current Transducer Market with the largest share, supported by high accuracy, low offset drift, and better linearity for sensitive power control systems. Industries prefer closed loop sensors in applications where precise current measurement and real-time monitoring are critical, such as motor drives, renewable power converters, and process automation. Their strong performance in detecting bidirectional currents and compatibility with digital control units reinforces adoption in advanced power electronics. The open-loop segment grows steadily due to compact design and lower cost, finding use in low-power general-purpose devices.

- For instance, Phoenix Contact’s PACT RCP sensor system, which uses flexible Rogowski coils, enables precise current feedback in industrial drives and photovoltaic inverters with a measuring range of up to 4,000 A AC.

By Application

The Motor Drive segment dominates the market, holding the highest share due to the growing use of current transducers in industrial motors, robotics, HVAC systems, and servo mechanisms. Manufacturers use these devices to improve torque control, speed accuracy, and system safety in both AC and DC motor environments. The Converter and Inverter segment expands as renewable power installations and electric vehicle infrastructure increase, requiring stable current feedback. Battery management, UPS, and SMPS systems also adopt transducers to improve load protection and extend equipment life.

- For instance, Johnson Controls’ CTD-C1G00-1 transducer supports selectable current ranges of 30 A, 60 A or 120 A, delivers a 4–20 mA analog output and offers an isolation voltage of 600 VAC rms.

By End User

Industrial users represent the dominant share, driven by large-scale automation, robotics, and power electronics upgrades across manufacturing plants. Companies deploy closed loop transducers to maintain equipment reliability, prevent overload, and support predictive maintenance. The utility segment benefits from grid modernization, renewable power generation, and smart substations that require real-time monitoring of high-voltage currents. Automotive demand rises with electric vehicles, on-board chargers, and powertrain control systems. Other end users, including telecom and data centers, adopt transducers for uninterrupted power operations.

Key Growth Drivers

Rising Demand for Precision in Power Electronics

Industries increasingly adopt high-efficiency power electronics for automation, EV charging, robotics, and renewable energy. Closed loop current transducers offer high accuracy, fast response times, and low offset drift, which help improve control in motor drives, converters, and power inverters. Their ability to monitor bidirectional currents and provide stable feedback supports safety, overload protection, and predictive maintenance. As businesses focus on energy optimization and system reliability, demand for precision current sensing continues to accelerate across industrial and utility segments.

- For instance, Topstek’s TQL series of closed-loop current transducers offers models such as the TQL50A (nominal 50 A) and TQL100A (nominal 100 A). The TQL50A specifically supports a linear measurement range of up to ±150 A (or 3x its nominal current).

Expansion of Electric Vehicles and Battery Systems

Electric vehicles, hybrid systems, and advanced battery packs require accurate current monitoring to prevent overheating, voltage imbalance, and power loss. Closed loop transducers ensure stable signal output even under shifting loads and high-frequency switching. Automakers integrate these sensors into battery management systems, onboard chargers, DC-DC converters, and traction motors. Growth in EV charging stations and fast-charging infrastructure further boosts adoption. As global governments promote cleaner transportation, closed loop current transducers gain stronger market penetration in automotive and energy storage applications.

- For instance, Howard Butler (Hobut) manufactures a wide variety of current sensors and transducers designed for industrial and panel instrumentation applications, including models supporting nominal primary currents around 100 A.

Growth of Renewable Energy and Smart Grids

Solar inverters, wind turbines, and grid-tied converters rely on current transducers for real-time current measurement during power conversion. Closed loop designs support improved efficiency, fault detection, and system protection in high-voltage utility networks. Smart grids require continuous data feedback for load balancing and automated substation operations, increasing sensor deployment in transformers, distribution lines, and inverter systems. Ongoing investments in grid modernization, distributed renewable generation, and microgrids strengthen long-term demand for high-accuracy transducers.

Key Trends & Opportunities

Rising Adoption of Digital and IoT-Enabled Transducers

Smart factories and smart grids require sensors that can transmit real-time data to cloud or control platforms. Manufacturers now offer closed loop current transducers with digital interfaces, self-diagnostics, and remote monitoring capabilities. IoT-enabled sensors improve failure prediction and maintenance scheduling, reducing downtime for utilities and industrial users. As Industry 4.0 expands, digital and software-integrated transducers create opportunities for automation providers, power management companies, and embedded electronics manufacturers.

- For instance, Siemens’ SICAM T 7KG966 digital transducer is available in variants that support a 10/100 Mbit/s Ethernet interface over RJ45 and comply with the Modbus TCP protocol.

Miniaturization and Compact Transducer Designs

Compact, lightweight current transducers gain popularity in EVs, handheld devices, medical power supplies, telecom systems, and compact motor drives. Manufacturers focus on smaller footprints without compromising accuracy or thermal stability. This trend supports wider application in power modules, robotics, and portable renewable systems. As device integration increases, miniaturization opens new opportunities in consumer electronics and advanced mobility systems.

- For instance, TI INA236 is a 16-bit digital current/voltage/power monitor that supports a bus-voltage common-mode range from -0.3 V to +48 V, and reports current with a maximum gain error of 0.1 % and an offset of 5 µV.

Key Challenges

High Cost of Advanced Closed Loop Designs

Closed loop transducers cost more than open-loop alternatives due to specialized magnetic components, control circuitry, and calibration needs. Small and medium manufacturers may choose cheaper options, limiting adoption in low-power or cost-sensitive applications. Price pressure becomes a barrier in emerging markets, where power electronics buyers prioritize affordability. Companies must balance precision with cost-efficiency to expand penetration across wider industries.

Complex Installation and Calibration Issues

Closed loop transducers require proper alignment, shielding, and calibration to maintain accuracy in high-frequency switching environments. Incorrect installation can cause offset drift, thermal issues, or signal distortion. End users often need trained technicians and specialized testing tools, raising the operational burden for utilities and factories. As power systems grow more advanced, manufacturers must simplify calibration processes and offer plug-and-play designs to remove deployment barriers.

Regional Analysis

North America

North America holds 33% share in the Closed Loop Current Transducer Market. Growth is driven by strong demand for energy-efficient control systems, electric vehicles, and industrial automation. The United States leads due to extensive adoption of smart grids, renewable power installations, and advanced motor control technologies across manufacturing. Major companies supply transducers for robotics, EV charging infrastructure, and battery management systems. Canada supports market expansion through clean-energy policies and incentives for solar and wind power. Steady capital spending in data centers and semiconductor fabrication also boosts installation of precise current measurement devices. These factors sustain regional dominance.

Europe

Europe accounts for 29% market share, supported by strict energy-efficiency regulations and rapid industrial electrification. Germany, France, and the UK lead the adoption of closed loop transducers in electric mobility, automation, and power electronics. Renewable power projects, grid stability programs, and electric vehicle charging networks fuel rising demand for precise monitoring and protection devices. Automotive OEMs deploy these transducers in inverters, battery management, and regenerative braking systems. Industrial users focus on reducing power losses and improving system safety, driving replacement of legacy current sensors with closed loop designs that offer better accuracy and thermal stability.

Asia Pacific

Asia Pacific remains the leading and fastest-growing region with 35% share, supported by large-scale industrialization, electronics production, and renewable power installation. China, Japan, and South Korea integrate closed loop transducers into EV platforms, power modules, motor drives, and solar inverters. India accelerates adoption through distribution grid upgrades and new manufacturing facilities. Regional OEMs benefit from low-cost production, high export volumes, and increasing demand for smart control equipment. Semiconductor and battery manufacturing plants also boost sales, as they require highly accurate current monitoring for process control, protection, and system efficiency.

Latin America

Latin America holds 2% share in the Closed Loop Current Transducer Market. Growth improves as Brazil and Mexico expand EV charging networks, industrial drives, and renewable power projects. Utilities adopt closed loop transducers for power quality monitoring and fault detection to reduce grid losses. Manufacturing plants and mining sites use accurate current sensing to safeguard equipment and optimize energy use. Although adoption is still emerging, increasing automation investment and government support for clean electricity drive demand. Local distributors partner with global suppliers to address cost constraints and improve access to advanced sensing technologies.

Middle East & Africa

Middle East & Africa account for 1% market share, with demand concentrated in oil & gas, utilities, and construction industries. Gulf countries invest in solar and grid modernization projects, deploying closed loop transducers for inverter protection, current measurement, and system reliability. South Africa supports growth through industrial automation and renewable power additions. Adoption increases as regional facilities upgrade legacy sensors to high-accuracy closed loop designs for safety and efficiency. Although the market is small, rising infrastructure development and energy diversification programs create opportunities for future expansion across utilities and industrial sectors.

Shape Your Report to Specific Countries or Regions & Enjoy 30% Off!

Market Segmentations:

By Technology:

By Application:

- Motor Drive

- Converter & Inverter

By End User:

By Geography

- North America

- Europe

- Germany

- France

- U.K.

- Italy

- Spain

- Rest of Europe

- Asia Pacific

- China

- Japan

- India

- South Korea

- South-east Asia

- Rest of Asia Pacific

- Latin America

- Brazil

- Argentina

- Rest of Latin America

- Middle East & Africa

- GCC Countries

- South Africa

- Rest of the Middle East and Africa

Competitive Landscape

The Closed Loop Current Transducer Market players such as Phoenix Contact, Johnson Controls, Topstek, Howard Butler, Siemens, LEM, Texas Instruments, NK Technologies, ABB, and Infineon Technologies. The Closed Loop Current Transducer Market remains highly competitive, shaped by continuous product innovation and rising demand for precise current monitoring across industrial and energy applications. Manufacturers focus on compact architectures, better temperature stability, and fast response times to support high-frequency drives, power inverters, and battery systems. Product differentiation is driven by accuracy, noise immunity, and reliability under harsh environments. Many companies expand portfolios with digital output transducers and built-in signal conditioning to reduce installation and calibration costs for end users. Competitors also strengthen regional presence through distributor networks, localized manufacturing, and customization for electric vehicles, solar inverters, and data centers. Strategic partnerships with automation providers and power electronics manufacturers help secure long-term supply contracts. As industrial control systems modernize and renewable installations rise, competition intensifies, pushing suppliers toward smarter, more energy-efficient designs. Ongoing R&D investment remains essential to meet global efficiency standards and capture share in high-growth applications.

Key Player Analysis

Recent Developments

- In October 2025, Infineon expanded its XENSIV magnetic current sensor family with TLE4971/TLI4971 in a 300‑mil package, claiming 0.7% total error over temperature/lifetime; accuracy and isolation characteristics suit closed‑loop current measurement in automotive/industrial inverters and converters.

- In October 2024, Siemens Smart Infrastructure launched the SIMOCODE M‑CP motor management series for MCCs, integrating protection, control, and monitoring with Ethernet connectivity.

- In June 2024, Yokogawa introduced its CT1000S current sensor. Its a AC/DC split core current sensors. The new product is modeled to be used in wide wavelength and high current application industries including renewable energy, automotive, railway infrastructure and ship building.

Report Coverage

The research report offers an in-depth analysis based on Technology, Application, End-User and Geography. It details leading market players, providing an overview of their business, product offerings, investments, revenue streams, and key applications. Additionally, the report includes insights into the competitive environment, SWOT analysis, current market trends, as well as the primary drivers and constraints. Furthermore, it discusses various factors that have driven market expansion in recent years. The report also explores market dynamics, regulatory scenarios, and technological advancements that are shaping the industry. It assesses the impact of external factors and global economic changes on market growth. Lastly, it provides strategic recommendations for new entrants and established companies to navigate the complexities of the market.

Future Outlook

- Demand will rise due to expanding electric vehicle production and charging infrastructure.

- Renewable power plants will integrate more transducers for inverter protection and grid stability.

- Automation in factories and process industries will increase adoption of high-accuracy current sensors.

- Smart grids will require real-time current monitoring, boosting installation in substations and switchgear.

- Compact, PCB-mounted transducers will gain traction in battery systems and power modules.

- Digital output transducers will replace analog units to improve data reporting and system diagnostics.

- Wider temperature-resilient designs will support harsh-environment industries, including oil and gas.

- Semiconductor advancements will reduce noise, improve response time, and enhance accuracy.

- Local manufacturing and cost-optimized models will expand sales in emerging markets.

- Partnerships with inverter, motor drive, and EV manufacturers will create long-term supply opportunities.