Market Overview:

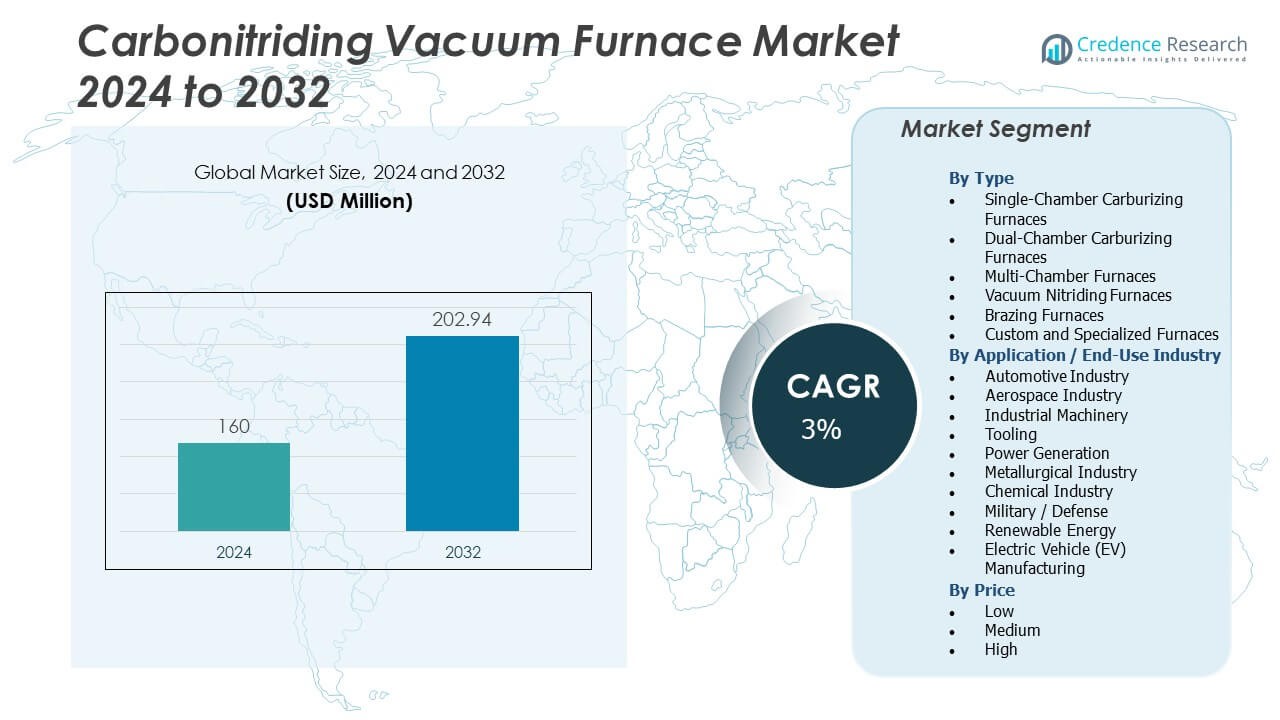

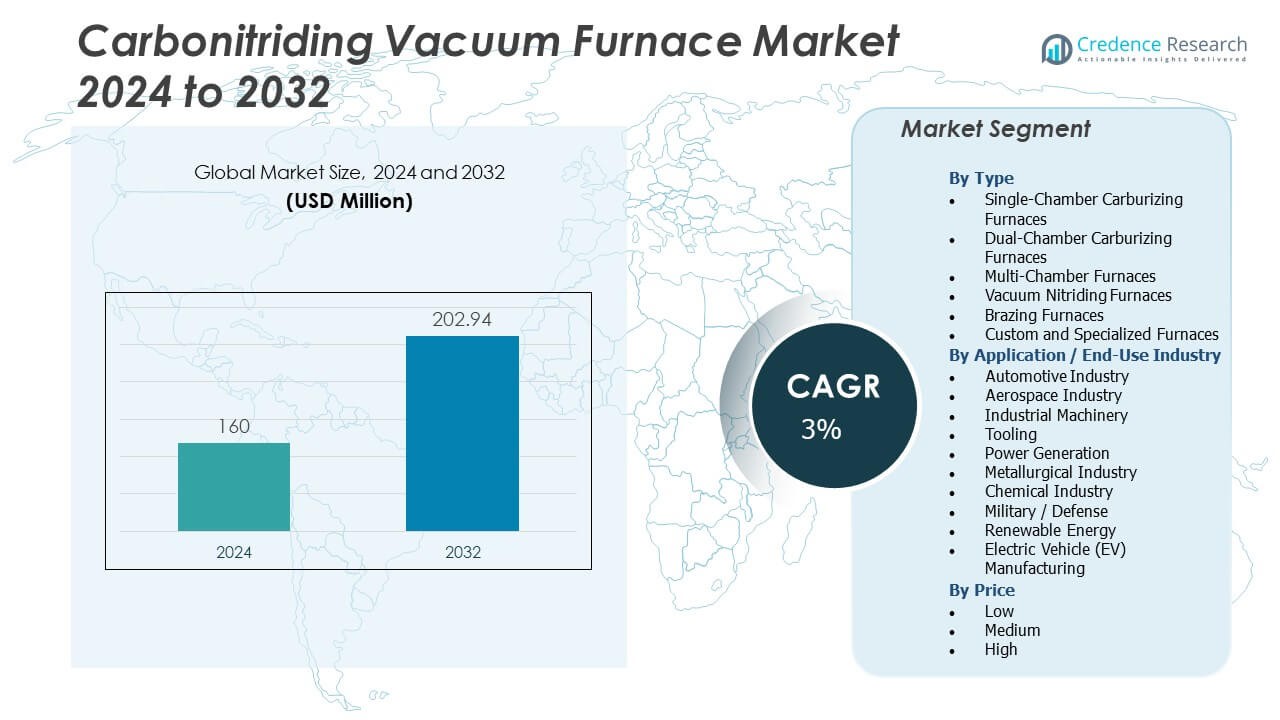

The Carbonitriding Vacuum Furnace Market is projected to grow from USD 160 million in 2024 to an estimated USD 202.94 million by 2032, with a compound annual growth rate (CAGR) of 3% from 2024 to 2032.

| REPORT ATTRIBUTE |

DETAILS |

| Historical Period |

2020-2023 |

| Base Year |

2024 |

| Forecast Period |

2025-2032 |

| Carbonitriding Vacuum Furnace Market Size 2024 |

USD 160 Million |

| Carbonitriding Vacuum Furnace Market, CAGR |

3% |

| Carbonitriding Vacuum Furnace Market Size 2032 |

USD 202.94 Million |

Market momentum is driven by industrial demand for efficient metal heat treatment, especially in automotive, aerospace, and electronics sectors. Manufacturers seek advanced furnaces to enhance product durability, surface hardness, and corrosion resistance. Companies increasingly focus on automated solutions and process accuracy to optimize workflows and reduce operational costs. Growth is further fueled by stricter quality standards and regulatory pressures on energy usage and environmental emissions, making carbonitriding vacuum furnaces highly attractive for next-generation manufacturing.

Asia Pacific leads the market, propelled by rapid industrialization, large-scale manufacturing, and government support for advanced technology deployment. China, Japan, and South Korea show robust adoption due to strong automotive and electronics industries. North America and Europe remain significant players, with established manufacturing infrastructure and ongoing investment in technological innovation. Latin America and the Middle East emerge gradually as regional industries expand, supported by infrastructure development and growing awareness of advanced thermal processing benefits.

Access crucial information at unmatched prices!

Request your sample report today & start making informed decisions powered by Credence Research Inc.!

Download Sample

Market Insights:

- The Carbonitriding Vacuum Furnace Market is projected to grow from USD 160 million in 2024 to approximately USD 202.94 million by 2032, at a CAGR of 3%.

- Growth in the market is primarily driven by increasing demand in automotive, aerospace, and electronics industries requiring enhanced surface hardness and wear resistance.

- Automation advancements and process accuracy improvements boost adoption by optimizing workflows and reducing operational costs.

- Energy efficiency and stringent environmental regulations push manufacturers toward eco-friendly furnace designs.

- Asia Pacific leads the market due to rapid industrialization, strong manufacturing infrastructure, and robust government support for technology upgrades.

- North America sustains its importance with established aerospace, automotive, and defense sectors investing in high-quality, energy-efficient heat treatment technologies.

- Europe and emerging regions such as Latin America and the Middle East show gradual but steady growth attributable to infrastructure development and increasing awareness of advanced thermal processing benefits.

Market Drivers

Advanced Process Efficiency and Quality Assurance

Innovative improvements in process control are driving the adoption of carbonitriding vacuum furnaces across global manufacturing industries. Automotive, aerospace, and heavy engineering companies rely on these furnaces to achieve consistent metallurgical properties and enhance critical component longevity. Stringent quality standards and reliability requirements have made advanced thermal solutions a priority for component suppliers. The carbonitriding vacuum furnace market benefits from precise heat management that reduces waste, increases uniformity, and enables the creation of specialty alloys. High energy efficiency further encourages procurement, as operational savings appeal to budget-conscious buyers. Companies value the ability to customize solutions for specific production lines, improving product quality and throughput. Regulatory mandates targeting emissions and energy use directly influence new purchase decisions. Modern furnace designs reduce oxidation and enable compliance with global environmental standards.

Technological Innovations Fueling Advanced Automation and Predictive Maintenance Needs

Technological evolution remains a key driver in optimizing furnace operation and reliability for industrial users. Manufacturers now demand IoT-enabled systems for real-time monitoring, automatic fault detection, and data-driven maintenance scheduling. These features minimize downtime and improve productivity, supporting uninterrupted manufacturing cycles. State-of-the-art automation manages complex temperature profiles and cooling rates to ensure parts meet demanding specifications. Integration with Enterprise Resource Planning (ERP) accelerates inventory management and overall efficiency. The carbonitriding vacuum furnace market is appealing for buyers seeking total cost of ownership reduction through predictive analytics and remote troubleshooting capabilities. Investment in advanced sensors and process optimization software is increasing, further differentiating market leaders. Companies expect scalable solutions to accommodate production growth without costly overhauls. Automated safety systems protect operators and create safer working environments, aligning with evolving occupational health regulations. Companies deploying such systems improve their market position and attract new customers seeking reliability and value.

Environmental Compliance and Sustainable Manufacturing Practices Reshaping Market Demand

Governments in major industrial regions are enforcing stricter environmental regulations, modifying how manufacturers procure and operate thermal equipment. Carbonitriding vacuum furnaces offer eco-friendly alternatives to traditional heat treatments, emitting fewer pollutants and enabling more sustainable production processes. Energy-efficient models consume less power, helping companies meet strict energy-saving targets. Sustainability goals have stimulated demand for vacuum furnaces incorporating waste heat recovery technology and low-emission gas systems. These solutions serve both internal corporate objectives and external market pressures from environmentally conscious customer bases. Lifecycle analysis and greenhouse gas reporting are increasingly required in supplier contracts, reinforcing furnace designs that achieve cleaner processes. Early adopters of innovative green technologies have gained competitive advantages in regulated sectors such as aerospace and automotive.

- For instance, ECM Technologies documents its ECO vacuum carburizing furnace achieving up to 40% lower energy consumption compared to conventional furnaces, as stated in their product literature and validated by multiple client installations, targeting both European and Asian automotive suppliers.

Strategic Investments and Expanding Applications Enhance Market Momentum Globally

Major industrial clusters worldwide are investing in carbonitriding vacuum furnace technology to advance production capabilities and expand into new markets. Growing demand from electric vehicle and renewable energy component manufacturers is particularly strong, reflecting the need for durable, high-performance parts. Established sectors such as heavy machinery and railway continue to upgrade legacy equipment with smarter, more efficient systems. Flexible furnace designs supporting multiple alloy types provide significant market appeal. Strategic acquisitions and partnerships are facilitating faster implementation and scaling of new operational models. The carbonitriding vacuum furnace market is leveraging increased capital allocation to research and development, expanding product portfolios and application scope. Regional manufacturers are strengthening supply chains with local sourcing and efficient distribution channels, driving higher adoption rates. This momentum is expected to sustain growth trajectories across established and emerging economies.

- For instance, in 2024, Tenova LOI Thermprocess participated in the publicly reported EU LIFE H2Reuse project to deploy industrial hydrogen-ready furnace units for bright annealing and heat treatment in Germany, supporting expansion of decarbonized steel processes and demonstrating longer operational lifespans over legacy systems.

Market Trends

Emergence of Digital Manufacturing and Data-Driven Production Strategies

The carbonitriding vacuum furnace market is embracing digital manufacturing tools, progressing toward fully connected production facilities. Industrial users expect integrated software and hardware platforms that streamline processes and enable precise quality control. Data-driven insights generated during heat treatment cycles support continuous improvement initiatives, resulting in consistent part characteristics and documented process compliance. Enhanced traceability solutions register parts through unique thermal cycles, providing evidence for regulatory audits and customer certifications. Market demand rises for digital twin technology that simulates furnace operations, optimizing throughput and energy use before physical implementation. The fusion of advanced robotics and control systems delivers flexible automation suited for evolving manufacturing landscapes. Companies investing in digital transformation bolster their competitive standing, meet customer expectations, and position themselves as leaders in Industry 4.0 innovation.

Customization Trends Tailoring Equipment to Industry-Specific Needs

Customization in the carbonitriding vacuum furnace market enables clients to tailor equipment design to precise application requirements in sectors like aerospace, medical, and automotive production. This trend facilitates highly specialized heat treatment protocols for unique alloy compositions and product geometries. Modern manufacturers prefer solutions designed for their specific process flows, incorporating required throughput, temperature ranges, and chamber configurations. Customizable features improve product consistency and operational familiarity, lowering training costs for technical staff. Companies value partnerships with suppliers offering rapid prototyping and dedicated engineering support, reducing time-to-market for new offerings. Innovative control interfaces adapt to various production environments, accommodating shifts in market demand across regions. Customization remains a pivotal factor distinguishing premium products from standard configurations, enabling companies to compete effectively in niche and mass markets.

- For instance, SECO/WARWICK’s Vector vacuum furnace platform has been supplied in customized formats for aviation manufacturers, offering working chamber modifications (such as a 1000x400x1000 mm work space) and special cooling and gas handling systems to meet stringent aerospace process requirements.

Eco-Friendly Materials and Circular Economy Adoption in Furnace Design

The carbonitriding vacuum furnace market is witnessing greater attention to recyclable materials, low-impact designs, and programs supporting a circular economy model. Leading manufacturers incorporate reusable, modular components that simplify maintenance and upgrade cycles. Energy-efficient insulation materials further reduce resource consumption, supporting broader environmental goals. Companies are piloting waste minimization systems and investigating secondary material processing to lower costs and ecological footprints. Customer preference for sustainable production options intensifies competitive differentiation among suppliers. The market’s alignment with circular economy principles is making it a preferred choice for organizations complying with global sustainability initiatives. Furnace manufacturers offering eco-friendly materials and design are positioned to attract new clients and maintain current relationships with key industry stakeholders.

- For instance, Codere SA is a furnace manufacturer with ISO 14001 environmental certification, reflecting strict management of environmental responsibilities in their design and production processes. Codere’s batch furnace systems are built in compliance with ISO 9001 and ISO 14001.

Supply Chain Optimization and Regionalization Trends Affecting Adoption

Changes in global supply chain strategies have a pronounced impact on the carbonitriding vacuum furnace market’s momentum. Organizations value furnace suppliers who demonstrate agility in sourcing raw materials and delivering finished equipment. Regional supply hubs and localized distribution networks facilitate faster installations and minimize transport risks. Companies prioritize supply partners who maintain reliable inventories of critical components, reducing production delays and managing costs. Reshoring trends in advanced manufacturing nations support regional adoption, creating demand for domestically built and serviced equipment. Market leaders leverage optimized logistics and vendor transparency to enhance customer satisfaction and deliver on promised timelines. Supply chain optimization addresses operational challenges, helping maintain growth and stability in an evolving industry landscape.

Market Challenges

Complexity of Advanced Furnace Technology Creating Skills and Training Challenges

Deploying state-of-the-art carbonitriding vacuum furnaces often presents skills and training challenges for industrial organizations. The operation requires specialized knowledge in metallurgy, process control, and maintenance. Skilled technician shortages complicate new installations and operational reliability. Companies dedicate increasing resources to workforce development, partnering with equipment suppliers for tailored training modules. Detailed operating procedures and safety guidelines must be strictly followed to avoid process disruptions and maintain product quality. Regulatory bodies require documentation of operator competency for certification purposes, elevating standards across regions. The carbonitriding vacuum furnace market faces ongoing hurdles in scaling technical expertise to match technological advancements. Supplier support and hands-on training programs help mitigate these issues, but maintaining a qualified workforce remains a persistent challenge.

High Capital Investment and Maintenance Costs Impacting Accessibility

Capital investment and maintenance requirements pose significant market challenges for small and medium-sized enterprises adopting carbonitriding vacuum furnaces. Advanced technology and precision engineering result in high upfront costs, which may restrict access for budget-constrained buyers. Ongoing expenses associated with parts, repairs, and system upgrades foster reluctance among some organizations. Cost-benefit analyses must account for long-term savings and operational efficiency, but immediate financial constraints remain a critical barrier. Financing solutions and extended payment terms are increasingly available, aiming to broaden market participation. The carbonitriding vacuum furnace market must balance technological innovation with cost-effective offerings to engage a wider variety of clients without compromising on essential capabilities.

Market Opportunity

Expansion into Emerging Manufacturing Sectors Driving New Applications

Growth in the electric vehicle, renewable energy, and advanced electronics industries unlocks a range of market opportunities for carbonitriding vacuum furnace solutions. These sectors demand innovative heat treatment systems capable of producing reliable and high-strength materials for complex components. Collaboration with research centers and development teams accelerates the creation of new alloy formulas and fabrication processes. Flexible furnace models allow manufacturers to serve multiple markets and adapt quickly to shifting product demand. Upgrades in existing facilities utilize modular equipment to enhance scalability and operational range. Market participants building partnerships with these emerging industries gain early access to new business segments and strengthen their portfolios for continued growth.

Globalization and Strategic Alliances Shaping Long-Term Market Opportunities

The carbonitriding vacuum furnace market benefits from ongoing globalization initiatives and strategic industrial alliances focusing on technology exchange. International collaborations facilitate knowledge sharing, fostering accelerated development of next-generation furnace features. Supply agreements with multinational corporations ensure steady demand for high-quality thermal systems and diversify risk. Market leaders launch joint ventures and co-development programs targeting shared infrastructure and novel process capabilities. Geographic expansion, especially in Asia Pacific and Latin American regions, increases sales channels and improves brand visibility. These opportunities support long-term business sustainability and encourage continued investment in future-ready equipment and industry solutions.

Market Segmentation Analysis:

By Type

The Carbonitriding Vacuum Furnace Market is characterized by a diverse array of furnace types designed to cater to various heat treatment requirements. Single-chamber carburizing furnaces provide compact, efficient solutions ideal for steady, standardized processing needs, while dual-chamber designs boost productivity with separate zones for heating and cooling. Multi-chamber furnaces serve industries with high-volume, continuous production, ensuring rapid cycle turnaround and uniform quality. Vacuum nitriding furnaces are appreciated for their precision in generating wear-resistant, corrosion-proof surfaces, and are favored for specialty steels and aerospace components. Brazing furnaces meet unique assembly requirements, facilitating the joining of dissimilar metals in critical sectors like power generation and electronics. Custom and specialized furnaces stand out for their tailored features, supporting military, renewable energy, and niche industrial needs by optimizing designs for non-standard cycles and materials.

- For instance, Ipsen’s TurboTreater® single-chamber vacuum furnace (model H3636) supports loads up to 1,500 lb (≈680 kg) and achieves temperature uniformity within ±5 °C with quench pressures reaching 15 bar, as verified in Ipsen’s official product specifications and installation case studies.

By Application / End-Use Industry

The Carbonitriding Vacuum Furnace Market supports a broad base of end-use industries, each with distinct thermal processing demands. Automotive manufacturers rely on these furnaces for gears, shafts, and bearings critical to wear resistance and longevity in vehicles. The aerospace industry seeks precision and reliability for flight safety components, using these furnaces to ensure compliance and traceability. Industrial machinery producers apply carbonitriding technology to components in heavy-duty applications, reducing downtime and maximizing functional lifespan. Tooling and power generation sectors utilize vacuum furnaces to enhance edge retention and mechanical properties under high stress and cyclic operations. Metallurgical, chemical, military, renewable energy, and electric vehicle manufacturing each leverage advanced furnace technology to drive innovation, efficiency, and performance throughout their production cycles.

By Price

The market spectrum for Carbonitriding Vacuum Furnaces comprises low, medium, and high price segments, reflecting the needs and resources of various buyers. Low-priced furnaces target small and medium-sized enterprises requiring basic, reliable heat treatment without extensive customization or automation. Medium-priced systems address organizations that balance operational efficiency with affordability, integrating more advanced controls and features, yet remaining accessible. High-end furnace installations are chosen by industry leaders in automotive, aerospace, and military sectors prioritizing cutting-edge technology, full automation, extensive customization, and superior energy efficiency. This range enables adaptability and broad market penetration, allowing manufacturers to serve core mass market needs alongside demanding premium segments.

- For instance, Nabertherm’s compact laboratory and small workshop furnace models such as the LH..DB series are publicly marketed with volumes of 120 or 216 liters and maximum temperatures up to 1,300°C, minimizing equipment footprint for SMEs and enabling application in both conventional and additive manufacturing use cases.

Segmentation:

By Type

- Single-Chamber Carburizing Furnaces

- Dual-Chamber Carburizing Furnaces

- Multi-Chamber Furnaces

- Vacuum Nitriding Furnaces

- Brazing Furnaces

- Custom and Specialized Furnaces

By Application / End-Use Industry

- Automotive Industry

- Aerospace Industry

- Industrial Machinery

- Tooling

- Power Generation

- Metallurgical Industry

- Chemical Industry

- Military / Defense

- Renewable Energy

- Electric Vehicle (EV) Manufacturing

By Price

By Region

- North America

- Europe

- Germany

- France

- U.K.

- Italy

- Spain

- Rest of Europe

- Asia Pacific

- China

- Japan

- India

- South Korea

- South-east Asia

- Rest of Asia Pacific

- Latin America

- Brazil

- Argentina

- Rest of Latin America

- Middle East & Africa

- GCC Countries

- South Africa

- Rest of the Middle East and Africa

Regional Analysis:

Asia Pacific

Asia Pacific holds the highest market share in the Carbonitriding Vacuum Furnace Market, accounting for approximately 43% of global revenue. Rapid industrialization in China, India, and Southeast Asia is creating significant demand for advanced heat treatment technologies, especially within automotive, electronics, and heavy industry sectors. The region’s dominance stems from expanding manufacturing capabilities, cost-competitive labor, and strong investments in infrastructure, driving robust adoption across established and emerging verticals. Companies in Asia Pacific continue to benefit from government initiatives supporting high-performance material development and localized production, cementing the region’s leadership in both volume and technology deployment.

North America

North America remains a core market for the Carbonitriding Vacuum Furnace Market, commanding roughly 29% of overall market share. The presence of advanced aerospace, automotive, and defense industries drives sustained investment in high-quality heat treatment solutions. Its growth is underpinned by strict regulatory standards on material performance, safety, and environmental compliance. The United States, in particular, leads with technological innovation and a focus on energy efficiency. North American manufacturers are pushing the adoption of automated, digitally integrated furnace systems to support the next generation of manufacturing and value-added technical services.

Europe and Other Regions

Europe constitutes nearly 18–20% of the Carbonitriding Vacuum Furnace Market, dominated by Germany, France, Italy, and the United Kingdom due to strong automotive and precision engineering sectors. The region emphasizes sustainable industrial processes and material innovation, favoring vacuum furnace adoption for eco-friendly operations. Latin America and the Middle East & Africa currently represent smaller but steadily expanding market shares, collectively in the 5–10% range. These areas see growing interest as local manufacturing scales and awareness of advanced heat treatment advantages spreads through infrastructure and energy sector development.

Shape Your Report to Specific Countries or Regions & Enjoy 30% Off!

Key Player Analysis:

- SECO/WARWICK

- Ipsen International GmbH

- ECM Technologies

- ALD Vacuum Technologies GmbH

- Aichelin Group

- Surface Combustion

- NITREX

- Gasbarre Products, Inc.

- BMI Fours Industriels

- CAN-ENG Furnaces International

- TAV Vacuum Furnaces

- Solar Manufacturing

- Tenova

- PVA TePla

- VAC AERO

Competitive Analysis:

The Carbonitriding Vacuum Furnace Market is moderately concentrated, with several key players driving the competitive landscape. Leading companies include Gasbarre Products, Inc., SECO/WARWICK, Aichelin Group, ECM Technologies, Ipsen, and ALD Vacuum Technologies. These players maintain strong market positions through advanced technology development, extensive product portfolios, and global distribution networks. The market rewards innovation, with many competitors investing heavily in automation, energy-efficient furnace designs, and integration of Industry 4.0 features for real-time monitoring and process optimization. It competes not only on product capabilities but also on after-sales service, customization options, and customer support, which influence buyer decisions in industries requiring precise and reliable heat treatment. The Carbonitriding Vacuum Furnace Market faces competition from alternative methods such as traditional carburizing and nitriding but extends its lead due to superior control, uniformity, and quality outcomes. Small and midsize manufacturers increasingly seek partnerships with established players to access cutting-edge technologies, reinforcing the competitive dynamics.

Recent Developments:

- In August 2025, Bodycote, a major player in heat treatment, announced the acquisition and installation of a new CaseMaster Evolution vacuum furnace at its Siechnice plant. This advanced two-chamber vacuum furnace, with oil cooling capability, reflects Bodycote’s commitment to expanding its technological base and offering improved carbonitriding treatments to its clients.

- In November 2024, ECM Group finalized the acquisition of Vacuum Service & Maintenance, an Italy-based company specializing in maintenance of industrial vacuum systems and furnaces. This acquisition strengthens ECM Group’s technical service offering within the carbonitriding vacuum furnace sector and expands its footprint in European markets.

Report Coverage:

The research report offers an in-depth analysis based on type, application/end-use and price. It details leading market players, providing an overview of their business, product offerings, investments, revenue streams, and key applications. Additionally, the report includes insights into the competitive environment, SWOT analysis, current market trends, as well as the primary drivers and constraints. Furthermore, it discusses various factors that have driven market expansion in recent years. The report also explores market dynamics, regulatory scenarios, and technological advancements that are shaping the industry. It assesses the impact of external factors and global economic changes on market growth. Lastly, it provides strategic recommendations for new entrants and established companies to navigate the complexities of the market.

Future Outlook:

- Technological advancements in automation and digital controls will influence future adoption, enhancing precision and operational uptime for manufacturers.

- Demand from automotive and aerospace sectors will continue shaping the Carbonitriding Vacuum Furnace Market, driven by the need for advanced heat-treated components.

- Energy efficiency and sustainability will remain top priorities, prompting further investment in eco-friendly designs and low-emission systems.

- Growing industrialization in emerging markets, especially Southeast Asia and India, is expected to expand the global customer base and drive market penetration.

- Customization trends will accelerate, with manufacturers developing tailored solutions to meet precise sector and component requirements.

- Integration of IoT and data analytics will optimize process monitoring, supporting predictive maintenance and longer equipment life cycles.

- Regulatory pressures focused on environmental compliance will encourage innovation in cleaner, more efficient furnace technologies.

- Collaboration between established players and local partners will promote knowledge transfer and regional manufacturing excellence.

- Shift towards Industry 4.0 will deepen, enabling smarter production and superior quality control across all key industries.

- Competitive landscape will remain dynamic, with new entrants and strategic alliances reshaping supply networks and expanding global reach.