Market Overview

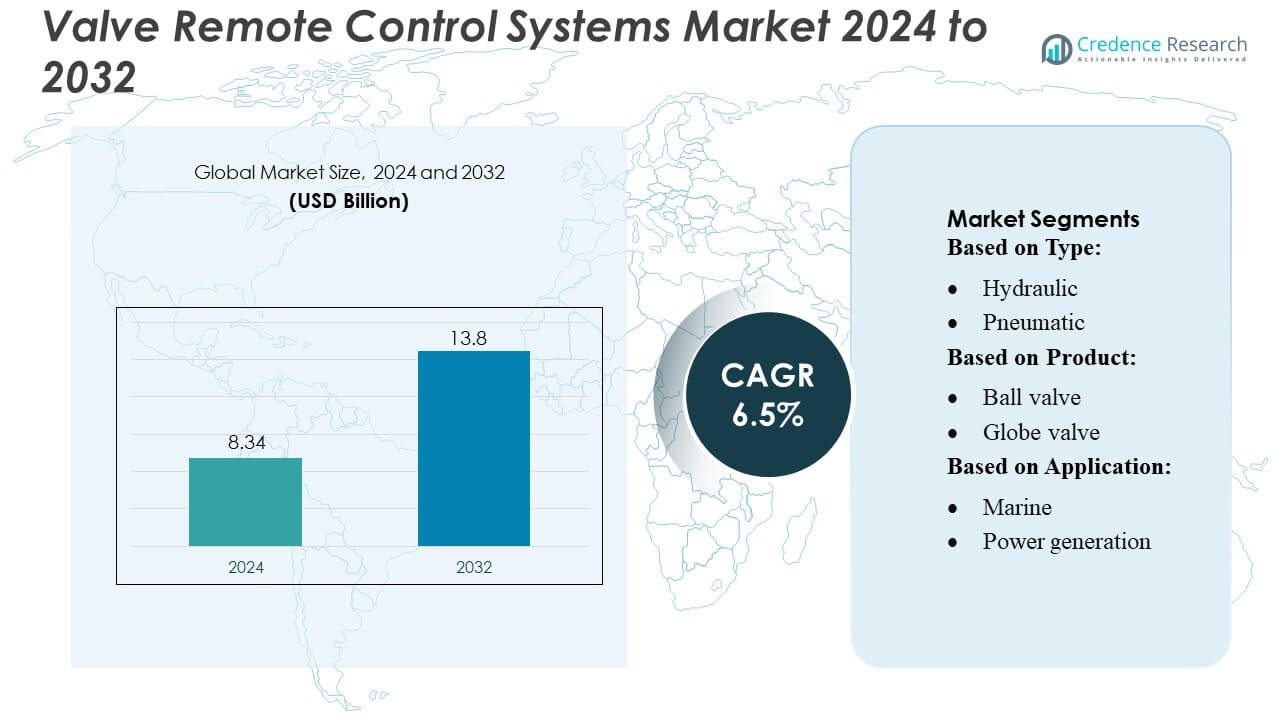

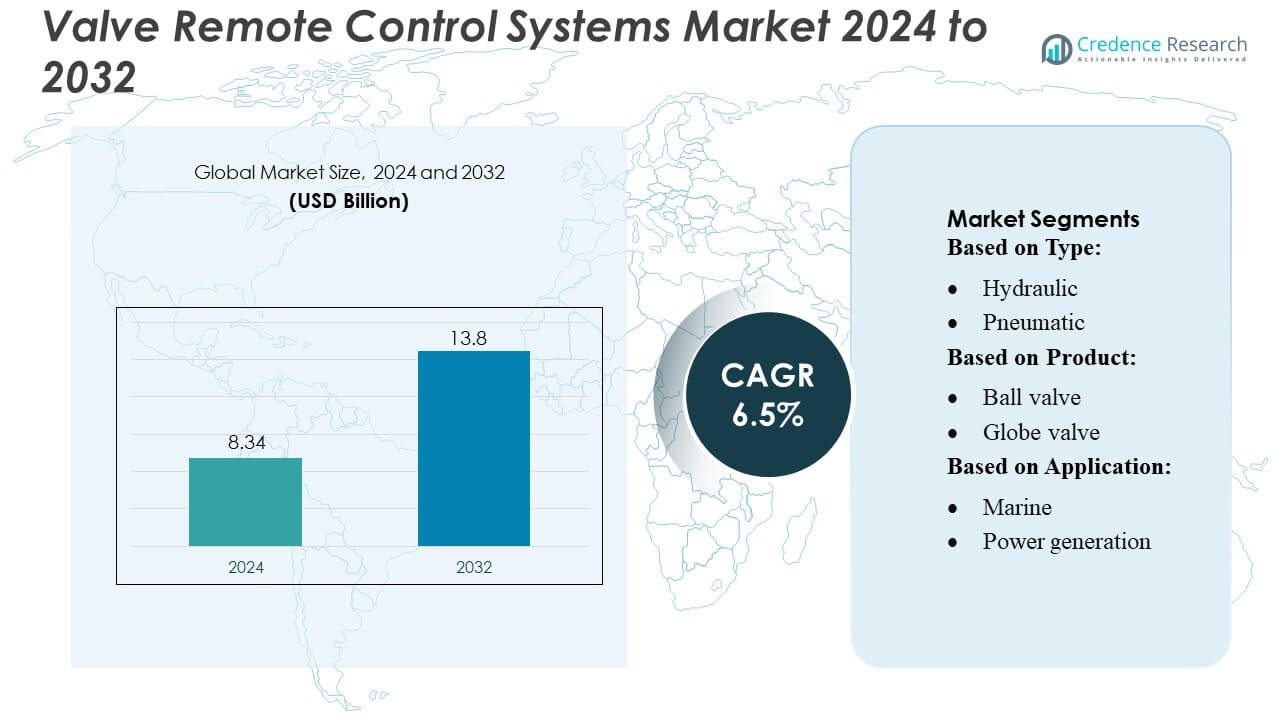

Valve Remote Control Systems Market size was valued USD 8.34 billion in 2024 and is anticipated to reach USD 13.8 billion by 2032, at a CAGR of 6.5% during the forecast period.

| REPORT ATTRIBUTE |

DETAILS |

| Historical Period |

2020-2023 |

| Base Year |

2024 |

| Forecast Period |

2025-2032 |

| Valve Remote Control Systems Market Size 2024 |

USD 8.34 Billion |

| Valve Remote Control Systems Market, CAGR |

6.5% |

| Valve Remote Control Systems Market Size 2032 |

USD 13.8 Billion |

The Valve Remote Control Systems Market is highly competitive, with key players including Honeywell International, Inc., Velan Inc., AVK Holding A/S, Emerson Electric Co., Burkert Fluid Control System, Alfa Laval AB, Eaton, Flowserve Corporation, Valvitalia SpA, and IMI plc. These companies drive the market through continuous innovation, development of energy-efficient and IoT-enabled valve solutions, and expansion into high-growth regions. North America emerges as the leading region, capturing approximately 30% of the global market, supported by advanced industrial automation, digital integration, and robust infrastructure development. Strong adoption in power generation, chemical processing, marine, and water treatment industries further consolidates the region’s dominance, while manufacturers focus on R&D, strategic partnerships, and retrofit solutions to enhance reliability, operational efficiency, and compliance with stringent safety standards.

Access crucial information at unmatched prices!

Request your sample report today & start making informed decisions powered by Credence Research Inc.!

Download Sample

Market Insights

- The Valve Remote Control Systems Market size was valued at USD 8.34 billion in 2024 and is anticipated to reach USD 13.8 billion by 2032, growing at a CAGR of 6.5% during the forecast period.

- Increasing industrial automation and demand for energy-efficient, IoT-enabled valve systems are driving adoption across power generation, chemical, marine, and water treatment sectors.

- Electric and ball valve segments dominate the market due to their precision, reliability, and ease of integration with digital control platforms.

- North America holds the largest regional share at approximately 30%, followed by Asia Pacific with significant growth driven by rapid industrialization, infrastructure expansion, and retrofitting projects in China, India, and Japan.

- The market remains highly competitive, with leading players focusing on R&D, smart valve innovations, strategic partnerships, and digital integration, while challenges include high upfront costs and technical complexity in installation and maintenance.

Market Segmentation Analysis:

By Type

In the Valve Remote Control Systems Market, the Electric segment dominates, accounting for approximately 40% of market share, driven by its precision, energy efficiency, and ease of integration with digital control systems. Hydraulic systems follow closely, favored for heavy-duty industrial operations requiring high force and reliability. Pneumatic systems are preferred in lightweight and fast-response applications, while electro-hydraulic variants are gaining traction in hybrid operations that demand both precision and high torque. The growth in electric systems is primarily fueled by increasing automation trends, rising adoption of smart factories, and the need for remote monitoring capabilities in industrial environments.

- For instance, Honeywell’s “HercuLine” electric actuators deliver high‑torque rotary motion — ranging from 10 to 300 lb‑ft (≈ 14 to 407 N·m) — enabling quarter‑turn valve operations under heavy load while maintaining tight positional control and low maintenance requirements.

By Product

Among valve types, Ball valves lead the market with roughly 35% share due to their versatility, low maintenance, and rapid on/off control capabilities. Globe valves and butterfly valves hold notable positions in process control and flow regulation applications, whereas gate valves and diaphragm valves are preferred in high-pressure or corrosive fluid systems. Check valves and safety valves maintain steady demand for protective and backflow prevention functions. The dominance of ball valves is driven by industries seeking robust, compact solutions that support remote operation and seamless integration with automated process control systems.

- For instance, Velan’s “Securaseal TE‑150/300/600” metal‑seated ball valve supports pressures up to 1,480 psig (≈ 102 bar) and temperatures up to 1,000 °F (538 °C), making it suitable for demanding chemical, oil & gas, and slurry‑handling operations.

By Application

In terms of applications, the Power generation segment commands the largest share at approximately 30%, benefiting from the critical need for precise flow control, safety compliance, and system automation in power plants. Marine and chemical industries follow, leveraging remote valve systems to ensure operational safety and efficiency in complex pipelines. Water and wastewater treatment and refinery sectors are expanding due to increasing environmental regulations and infrastructure modernization. Market growth is propelled by rising industrial automation, digital monitoring adoption, and demand for reliable, remote-operated valves capable of reducing operational downtime.

Key Growth Drivers

- Increasing Industrial Automation

The growing adoption of automation across manufacturing, power generation, chemical, and marine industries is a major growth driver. Valve remote control systems enable precise flow management, real-time monitoring, and remote operation, reducing manual intervention and enhancing operational efficiency. The integration with digital control systems and industrial IoT platforms allows predictive maintenance and energy optimization, driving demand. Industries seeking to improve safety, reduce downtime, and maintain regulatory compliance are increasingly deploying remote-controlled valves, reinforcing consistent market expansion.

- For instance, AVK’s intelligent control‑valve Series 859, when equipped with the ACMO PMD communication module, delivers auto‑adaptive PID control and data‑logging — enabling automated regulation of pressure and flow in water networks without manual intervention.

- Expansion of Power and Energy Infrastructure

The expansion and modernization of power generation, oil & gas, and chemical processing infrastructure are fueling demand for valve remote control systems. These valves provide reliable operation in high-pressure, high-temperature, and hazardous environments, ensuring safety and process efficiency. The shift toward renewable energy projects, including hydropower and biomass plants, further amplifies adoption. Investments in large-scale industrial projects require automated and remote-operable valves, making infrastructure development a critical factor contributing to steady market growth.

- For instance, Emerson’s Fisher easy‑Drive 200R electric actuator, designed for butterfly and ball valves, operates on 11–30 VDC power and consumes under 0.4 watts in holding mode.

- Rising Demand for Safety and Operational Efficiency

Industries increasingly prioritize safety, regulatory compliance, and operational efficiency, boosting the adoption of remote valve systems. Remote operation reduces the risk of human error in hazardous conditions, while enabling continuous monitoring and emergency shutdown capabilities. Advanced systems offer automated diagnostics, alarm notifications, and integration with SCADA platforms, enhancing process reliability. The demand for energy-efficient, low-maintenance solutions further supports growth, as industries aim to optimize costs while ensuring uninterrupted operations, particularly in high-stakes environments like refineries, power plants, and marine applications.

Key Trends & Opportunities

- Integration with Digital Platforms and IoT

The trend toward digitalization and IoT integration is reshaping the valve remote control systems market. Smart valves equipped with sensors and connectivity features allow real-time data collection, predictive maintenance, and remote diagnostics. These systems enhance operational transparency and reduce downtime, providing a competitive advantage. Opportunities exist for manufacturers to develop AI-enabled controllers and cloud-connected solutions that support industrial automation and energy management, driving adoption across sectors such as chemical processing, water treatment, and power generation.

- For instance, Bürkert’s AirLINE Type 8652 valve island now offers pressure‑line sensors and extended diagnostics including switching‑cycle counters and switching‑time measurement, enabling predictive maintenance and early detection of supply‑pressure fluctuations — enhancing process safety and reliability.

- Demand for Energy-Efficient and Compact Designs

There is growing interest in energy-efficient, lightweight, and compact valve designs. Innovations in electric and electro-hydraulic systems enable reduced energy consumption, faster actuation, and smaller installation footprints. These designs are particularly attractive for offshore, marine, and urban infrastructure projects where space and power efficiency are critical. Manufacturers are investing in advanced materials, torque optimization, and modular solutions, offering opportunities to meet evolving industrial requirements while reducing operational costs and carbon footprints, supporting sustainability goals.

- For instance, Alfa Laval has advanced the market’s shift toward energy‑efficient, compact valve solutions through its updated “Unique DV‑ST UltraPure” diaphragm valve line. Its new stainless‑steel “SS/SL” actuator is 42% lighter, 25% more compact, and 17% shorter in height than standard models.

- Rising Retrofit and Modernization Projects

A notable opportunity exists in retrofitting and modernizing legacy industrial plants. Aging infrastructure often relies on manual or outdated valve systems, prompting industries to upgrade to remote-controlled solutions. Retrofit projects allow for seamless integration with existing pipelines, SCADA systems, and industrial IoT platforms. These upgrades improve safety, reduce maintenance costs, and enhance operational efficiency, presenting vendors with growth potential in both developed and emerging markets where modernization of industrial facilities is ongoing.

Key Challenges

- High Initial Investment and Installation Costs

The high upfront cost of advanced valve remote control systems, including installation, integration with automation platforms, and commissioning, is a key market challenge. Small and medium-sized enterprises often face budget constraints, delaying adoption. Additionally, complex installation in retrofitting projects can increase downtime and operational disruption. Manufacturers must balance cost with performance and demonstrate long-term ROI to encourage adoption, as high capital expenditure remains a barrier, particularly in cost-sensitive markets or smaller-scale industrial applications.

- Technical Complexity and Maintenance Requirements

Valve remote control systems require skilled personnel for installation, programming, and maintenance. The complexity of integrating electric, hydraulic, or electro-hydraulic systems with SCADA or IoT platforms can pose operational challenges. Improper handling may lead to malfunctions, affecting safety and reliability. Furthermore, maintenance of high-precision actuators and sensors demands regular inspection and calibration. These technical challenges can limit adoption in industries lacking trained staff or robust support infrastructure, highlighting the need for training programs and after-sales service to mitigate operational risks.

Regional Analysis

North America:

North America leads the Valve Remote Control Systems Market with a share of approximately 30%, driven by rapid industrial automation, advanced manufacturing, and energy infrastructure expansion. The U.S. and Canada are witnessing high adoption of electric and electro-hydraulic systems across power generation, chemical, and marine sectors. Increasing investments in smart factories, digital integration, and retrofitting of legacy plants support growth. Strict regulatory compliance and safety standards further accelerate deployment. Market expansion is also supported by local manufacturers providing innovative, energy-efficient solutions tailored to the region’s technologically advanced industrial environment.

Europe:

Europe accounts for nearly 25% of the market, supported by industrial modernization, stringent safety regulations, and the adoption of smart valve systems across power, chemical, and water treatment sectors. Germany, the U.K., and France drive demand through investments in renewable energy, offshore infrastructure, and process automation. Advanced manufacturing ecosystems and integration with IoT and SCADA systems enhance operational efficiency, while retrofit projects in aging facilities offer growth opportunities. European end-users increasingly prefer energy-efficient, compact, and digitally integrated valve solutions, reinforcing steady market expansion across the region.

Asia Pacific:

Asia Pacific holds around 28% of the market, led by rapid industrialization, infrastructure development, and expanding power generation capacities in China, India, and Japan. The region’s chemical, water treatment, and marine sectors increasingly adopt remote-controlled valves to enhance safety, efficiency, and automation. Growth is accelerated by government-led industrial modernization initiatives, rising energy demand, and foreign investments in smart factories. Increasing retrofit projects and the transition to digital industrial platforms create opportunities for electric and electro-hydraulic systems. Cost-effective manufacturing and localized production also strengthen the region’s competitive advantage.

Latin America:

Latin America captures about 7% of the market, supported by industrial modernization and increasing automation in chemical, marine, and water treatment applications. Brazil and Mexico lead regional adoption, driven by investments in power generation, refinery upgrades, and infrastructure development. Rising demand for safety, efficiency, and remote monitoring in industrial plants boosts valve system deployment. Challenges include limited local manufacturing and dependency on imports, but opportunities exist in retrofitting legacy facilities, government-led infrastructure projects, and increasing awareness of digital integration benefits, positioning the region for gradual market growth.

Middle East & Africa:

The Middle East & Africa represents roughly 10% of the market, driven by the oil & gas, water treatment, and power sectors. Countries such as Saudi Arabia, UAE, and South Africa are investing in remote-controlled valve systems to enhance operational safety and process efficiency in harsh environmental conditions. The focus on digitalization, industrial automation, and energy-efficient infrastructure projects contributes to market growth. Expanding industrial projects and retrofitting of legacy systems further create opportunities, though adoption is moderated by economic fluctuations and high initial system costs.

Market Segmentations:

By Type:

By Product:

By Application:

By Geography

- North America

- Europe

- Germany

- France

- U.K.

- Italy

- Spain

- Rest of Europe

- Asia Pacific

- China

- Japan

- India

- South Korea

- South-east Asia

- Rest of Asia Pacific

- Latin America

- Brazil

- Argentina

- Rest of Latin America

- Middle East & Africa

- GCC Countries

- South Africa

- Rest of the Middle East and Africa

Competitive Landscape

The Valve Remote Control Systems Market include Honeywell International, Inc., Velan Inc., AVK Holding A/S, Emerson Electric Co., Burkert Fluid Control System, Alfa Laval AB, Eaton, Flowserve Corporation, Valvitalia SpA, and IMI plc. The Valve Remote Control Systems Market is highly competitive, driven by continuous technological innovation, increasing automation, and the demand for energy-efficient solutions. Companies focus on differentiating their offerings through smart, IoT-enabled valves, advanced actuators, and remote monitoring capabilities that enhance operational safety and reduce maintenance costs. Strategic initiatives such as mergers, acquisitions, and collaborations help expand market presence and regional reach. Investment in R&D enables the development of reliable, high-performance products that comply with stringent industrial regulations across sectors such as power generation, chemical, marine, and water treatment, strengthening overall market competitiveness.

Key Player Analysis

- Honeywell International, Inc.

- Velan Inc.

- AVK Holding A/S

- Emerson Electric Co.

- Burkert Fluid Control System

- Alfa Laval AB

- Eaton

- Flowserve Corporation

- Valvitalia SpA

- IMI plc

Recent Developments

- In February 2025, Crestron Electronics, a global home automation leader, announced new product updates, features, and integrations at Integrated Systems Europe (ISE) 2025. These innovations aim to enhance smart living by offering unified, intuitive smart home experiences for homeowners.

- In February 2024, Yokogawa Solution Service Corporation completed the installation of a remote monitoring system for Japan’s largest offshore wind farm, the Ishikari Bay New Port Offshore Wind Farm. The system uses Yokogawa’s OpreX™ Collaborative Information Server to centrally manage data from the wind turbines, onshore facilities, and storage batteries.

- In June 2023, Honeywell International, Inc. and Fokker Services signed a memorandum of agreement making Fokker a channel partner and service center for Honeywell’s pre-cooler control valve (PCCV) repair and overhaul services.

Shape Your Report to Specific Countries or Regions & Enjoy 30% Off!

Report Coverage

The research report offers an in-depth analysis based on Type, Product, Application and Geography. It details leading market players, providing an overview of their business, product offerings, investments, revenue streams, and key applications. Additionally, the report includes insights into the competitive environment, SWOT analysis, current market trends, as well as the primary drivers and constraints. Furthermore, it discusses various factors that have driven market expansion in recent years. The report also explores market dynamics, regulatory scenarios, and technological advancements that are shaping the industry. It assesses the impact of external factors and global economic changes on market growth. Lastly, it provides strategic recommendations for new entrants and established companies to navigate the complexities of the market.

Future Outlook

- Adoption of smart and IoT-enabled valve systems will continue to rise across industrial sectors.

- Demand for energy-efficient and compact valve designs will increase in infrastructure and manufacturing projects.

- Integration with advanced industrial automation and SCADA platforms will drive operational efficiency.

- Retrofit and modernization of legacy plants will create significant growth opportunities.

- Expansion of power generation, chemical, and water treatment facilities will boost market adoption.

- Remote monitoring and predictive maintenance capabilities will become standard features in new systems.

- Rising safety and regulatory compliance requirements will accelerate deployment in hazardous environments.

- Digitalization and AI-enabled control solutions will enhance precision and reduce operational downtime.

- Offshore and marine projects will increasingly require high-performance, reliable remote valve systems.

- Regional growth in Asia Pacific and the Middle East will outpace other markets due to industrialization and infrastructure development.