Market Overview:

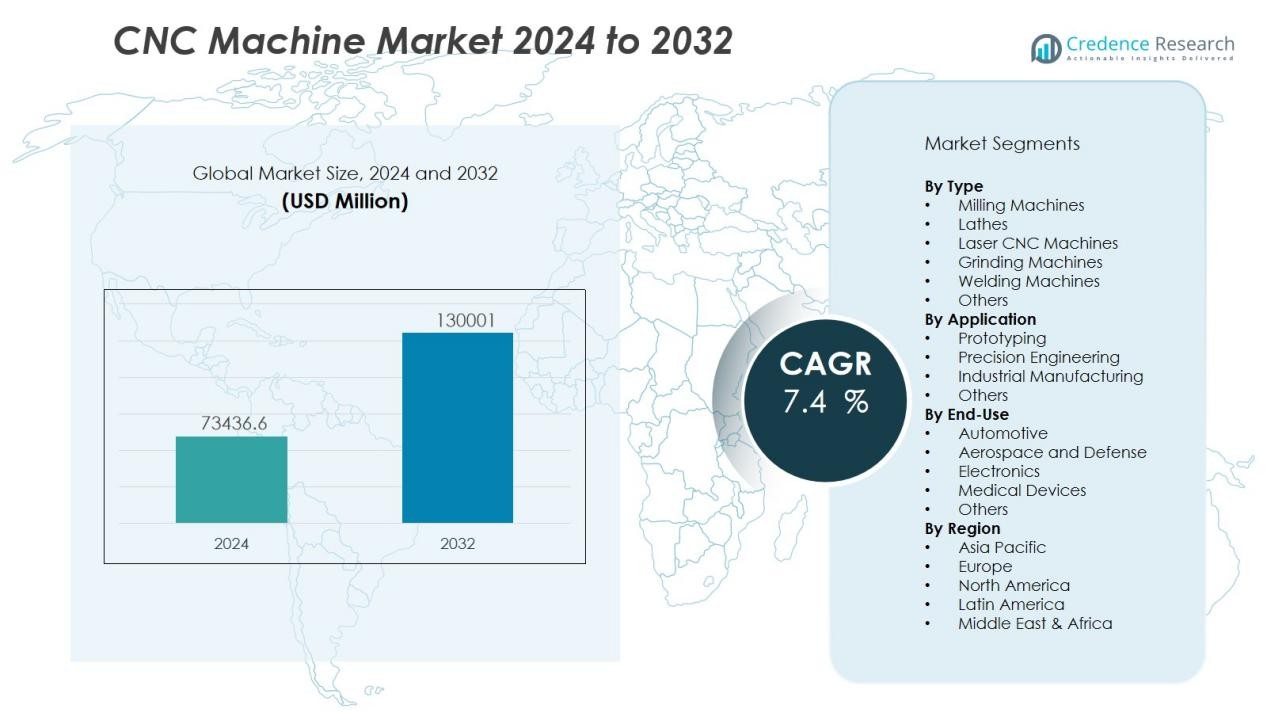

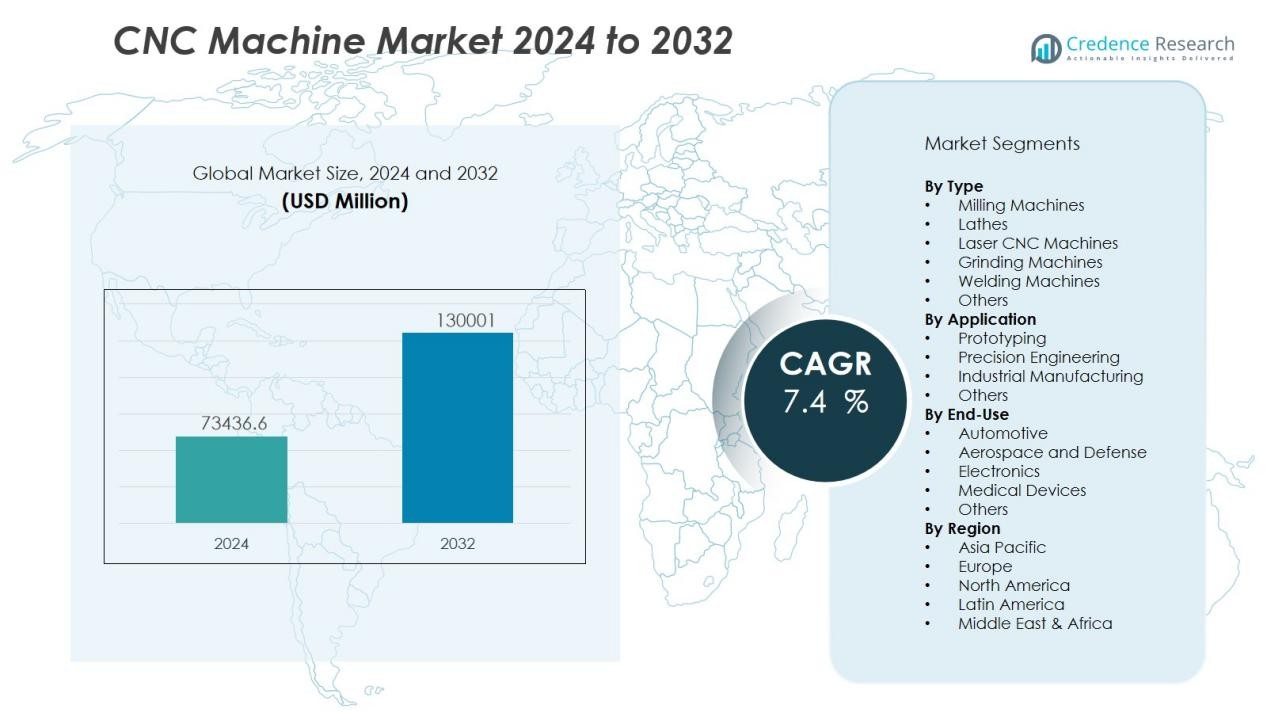

The Computer Numerical Control (CNC) Machine Market size was valued at USD 73436.6 million in 2024 and is anticipated to reach USD 130001 million by 2032, at a CAGR of 7.4 % during the forecast period (2024-2032).

| REPORT ATTRIBUTE |

DETAILS |

| Historical Period |

2020-2024 |

| Base Year |

2024 |

| Forecast Period |

2025-2032 |

| CNC Machine Market Size 2024 |

USD 73436.6 Million |

| CNC Machine Market, CAGR |

7.4 % |

| CNC Machine Market Size 2032 |

USD 130001 Million |

The market is fueled by expanding industrial automation, rising demand for mass customization, and advancements in multi-axis CNC technology. Growth in sectors such as aerospace, automotive, and medical devices is increasing the need for high-performance machining capabilities. The integration of IoT and AI for predictive maintenance and process optimization is enhancing operational efficiency. Additionally, the shift toward sustainable manufacturing practices and the need for reduced waste and energy consumption are encouraging industries to adopt CNC machines with higher precision and optimized material usage.

Asia-Pacific dominates the CNC machine market due to its strong manufacturing base, rapid industrialization, and government initiatives supporting smart manufacturing in countries like China, Japan, and India. Europe holds a significant share, driven by advanced engineering capabilities and high adoption rates in automotive and aerospace sectors. North America continues to grow steadily, supported by technological innovation, modernization of legacy manufacturing facilities, and strong demand from defense and medical industries.

Access crucial information at unmatched prices!

Request your sample report today & start making informed decisions powered by Credence Research Inc.!

Download Sample

Market Insights:

- The CNC machine market was valued at USD 73,436.6 million in 2024 and is projected to reach USD 130,001 million by 2032, growing at a CAGR of 7.4% from 2024 to 2032.

- Rising demand for high-precision machining in aerospace, automotive, and electronics industries is driving market growth through improved accuracy and reduced scrap rates.

- Expansion of industrial automation and integration of IoT and AI for real-time monitoring are enhancing reliability and reducing downtime.

- Growing adoption of CNC machines for mass customization enables flexible production and supports high-mix, small-batch manufacturing models.

- High initial investment, maintenance costs, and shortage of skilled operators remain significant challenges for market expansion.

- Asia-Pacific leads the market with strong manufacturing infrastructure, government support, and rapid industrialization in China, Japan, South Korea, and India.

- Europe and North America maintain significant shares, supported by advanced engineering expertise, technological innovation, and modernization of production facilities.

Market Drivers:

Rising Demand for Precision and Efficiency in Manufacturing:

The CNC machine market is driven by the growing requirement for high-precision and efficient production processes across industries such as aerospace, automotive, and electronics. CNC machines enable manufacturers to achieve consistent accuracy while reducing production errors and scrap rates. It supports complex geometries and tight tolerances that are challenging to achieve with manual methods. The emphasis on shorter production cycles and high-quality output continues to boost demand.

- For instance, Lockheed Martin achieved a 10X improvement in accuracy and consistency of commercial robots in airframe manufacturing through integration with Xaba’s xCognition AI-powered CNC control system.

Expansion of Industrial Automation and Smart Manufacturing:

Automation advancements are accelerating adoption in the CNC machine market, with industries seeking to optimize throughput and minimize human intervention. CNC systems are increasingly integrated with sensors, IoT connectivity, and AI-driven process control for real-time monitoring and predictive maintenance. It improves equipment reliability and reduces operational downtime. The transition toward Industry 4.0 standards is reinforcing this trend across both developed and emerging economies.

- For instance, FANUC’s new Series 500i-A CNC control delivers 2.7 times higher CPU processing power than previous models, while Okuma’s OSP-AI fault diagnostics system enables self-diagnosis of machine operating conditions to minimize downtime due to machine outages.

Growing Application in Mass Customization and Flexible Production:

The shift toward mass customization is influencing investment in the CNC machine market, as manufacturers need versatile equipment to handle diverse product variations. CNC technology enables rapid programming changes, allowing production lines to adapt without extensive retooling. It supports small-batch, high-mix manufacturing models that meet evolving consumer preferences. This capability is essential for sectors facing dynamic demand cycles and short product lifespans.

Government Support and Investments in Manufacturing Infrastructure;

Proactive government policies and capital investments are fostering growth in the CNC machine market. Initiatives promoting advanced manufacturing, skill development, and technology adoption are expanding market opportunities. It benefits from subsidies, tax incentives, and infrastructure development in industrial clusters. Such measures enhance competitiveness, particularly in regions aiming to strengthen domestic manufacturing capabilities.

Market Trends:

Integration of Advanced Digital Technologies and Automation:

The CNC machine market is witnessing a strong trend toward integration of advanced digital tools, automation, and intelligent control systems. Manufacturers are adopting IoT-enabled CNC machines for real-time monitoring, predictive maintenance, and process optimization. It is also leveraging AI and machine learning algorithms to enhance cutting precision, reduce tool wear, and improve overall operational efficiency. The use of multi-axis and hybrid CNC machines is growing to support complex manufacturing requirements in aerospace, defense, and medical sectors. Demand for automation-friendly CNC equipment is rising in response to labor shortages and the push for cost efficiency. The trend is aligning with the broader Industry 4.0 movement, which promotes connected and data-driven manufacturing ecosystems.

- For instance, DMG MORI’s 5-axis CNC machines achieved exceptional precision with accuracy of less than 15 µm in space while handling workpieces weighing up to 40 tonnes.

Shift Toward Sustainable and Flexible Manufacturing Solutions:

Sustainability and adaptability are emerging as key priorities in the CNC machine market. Manufacturers are investing in energy-efficient CNC systems that lower power consumption and reduce environmental impact. It is enabling material optimization through precision machining, minimizing waste generation. Flexible CNC solutions that support rapid reprogramming are gaining traction to meet shorter product life cycles and high product variability. The growing focus on sustainable manufacturing is influencing equipment design, with features aimed at improving recyclability and extending machine lifespan. Markets with high demand for custom, low-volume production are increasingly adopting CNC technology to stay competitive. This shift is reinforcing the role of CNC machines as a core element in future-ready manufacturing strategies.

- For instance, CAMPRO Precision Machinery implemented comprehensive sustainability measures achieving 755.4 tons CO2 reduction annually through energy-efficient lighting, solar energy systems, and waste reduction programs across manufacturing operations.

Market Challenges Analysis:

High Initial Investment and Maintenance Costs:

The CNC machine market faces a significant challenge from the high capital investment required for advanced equipment. Small and medium-sized enterprises often struggle to allocate resources for purchasing and upgrading CNC systems. It also demands ongoing expenditure for maintenance, calibration, and operator training to ensure peak performance. The cost barrier can delay adoption in price-sensitive markets. Rising prices of precision components and software licenses further add to operational expenses. These financial constraints can limit the pace of technological adoption, especially in developing regions.

Skilled Labor Shortage and Technological Complexity:

A shortage of skilled operators and technicians is another major hurdle for the CNC machine market. Complex programming, system integration, and troubleshooting require specialized expertise. It becomes challenging for companies to maintain consistent productivity without trained personnel. The learning curve for advanced multi-axis and automated CNC systems can be steep, impacting operational efficiency during implementation phases. Rapid technological evolution also means skills need frequent upgrading, which strains training resources. Limited access to technical education and industry-specific training programs intensifies this workforce gap.

Market Opportunities:

Adoption of Industry 4.0 and Smart Manufacturing:

The CNC machine market holds strong opportunities through the integration of Industry 4.0 technologies and smart manufacturing practices. IoT-enabled CNC machines, AI-driven process optimization, and advanced analytics are creating new avenues for efficiency gains. It allows manufacturers to implement predictive maintenance, optimize tool usage, and improve product quality in real time. The growing push for fully connected factories is driving demand for CNC systems that seamlessly integrate with digital production lines. Industries such as aerospace, medical devices, and automotive are well-positioned to capitalize on these advancements. This trend is expected to expand the market’s penetration in both established and emerging economies.

Rising Demand from Emerging Markets and Niche Applications:

Emerging economies are offering significant growth potential for the CNC machine market due to rapid industrialization and infrastructure development. Rising investments in manufacturing clusters, coupled with favorable government incentives, are fostering adoption. It is also creating opportunities in niche applications such as precision medical implants, customized automotive parts, and high-performance aerospace components. The flexibility of CNC systems to handle diverse materials and complex designs positions them as a preferred choice in specialized sectors. Expansion of SMEs into export-oriented production further boosts demand. These factors are likely to open new revenue streams for market participants.

Market Segmentation Analysis:

By Type:

The CNC machine market is segmented by type into milling machines, lathes, laser machines, grinding machines, welding machines, and others. Milling machines hold a dominant position due to their versatility in handling complex geometries and high-precision tasks. Lathes are widely used for rotational parts manufacturing in automotive and aerospace industries. Laser CNC machines are gaining momentum for their ability to deliver fine cutting with minimal material waste. Grinding and welding CNC systems cater to specialized applications that demand superior surface finish and structural integrity. It continues to evolve with multi-axis and hybrid machines integrating additive and subtractive manufacturing.

- For instance, advanced laser cutting systems now achieve cutting accuracies of ±0.05 mm, enabling exact replication of intricate geometries with minimal kerf width and heat-affected zone.

By Application;

Key applications include prototyping, precision engineering, industrial manufacturing, and others. Prototyping benefits from CNC’s rapid setup and ability to produce accurate models before mass production. Precision engineering applications demand tight tolerances, which CNC systems deliver consistently. Industrial manufacturing remains the largest application segment, driven by the need for high-volume, uniform production. It supports critical industries where performance and durability are essential.

- For instance, GE Aerospace allocated $30 million to expand CNC production at their Pune plant, successfully training over 5,000 local engineers and operators in precision aerospace manufacturing processes while achieving tenfold output growth through advanced CNC machining technologies.

By End Use:

End-use segments include automotive, aerospace and defense, electronics, medical devices, and others. Automotive manufacturing leads adoption due to the need for mass production of complex parts with consistent quality. Aerospace and defense rely on CNC technology for high-performance components that meet stringent safety and quality standards. Electronics manufacturing benefits from CNC’s precision in producing miniaturized and intricate components. It is also gaining adoption in medical device manufacturing for custom implants and surgical instruments.

Segmentations:

By Type:

- Milling Machines

- Lathes

- Laser CNC Machines

- Grinding Machines

- Welding Machines

- Others

By Application:

- Prototyping

- Precision Engineering

- Industrial Manufacturing

- Others

By End Use:

- Automotive

- Aerospace and Defense

- Electronics

- Medical Devices

- Others

By Region:

- North America

- Europe

- Germany

- France

- U.K.

- Italy

- Spain

- Rest of Europe

- Asia Pacific

- China

- Japan

- India

- South Korea

- South-east Asia

- Rest of Asia Pacific

- Latin America

- Brazil

- Argentina

- Rest of Latin America

- Middle East & Africa

- GCC Countries

- South Africa

- Rest of the Middle East and Africa

Regional Analysis:

Asia-Pacific :

Asia-Pacific holds the largest market share of the CNC machine market, supported by rapid industrial growth and robust manufacturing infrastructure. China, Japan, and South Korea lead production, driven by strong demand from automotive, electronics, and aerospace sectors. It benefits from government initiatives promoting advanced manufacturing technologies and Industry 4.0 adoption. Investments in smart factories and automation are accelerating the shift toward high-precision CNC systems. India is emerging as a significant contributor due to its expanding industrial base and favorable investment climate. The region’s competitive manufacturing costs and skilled workforce continue to attract global players.

Europe’s :

Europe accounts for a substantial market share in the CNC machine market, supported by its strong engineering capabilities and focus on innovation. Germany, Italy, and Switzerland remain leading hubs for precision machinery and high-end CNC equipment. It thrives on demand from aerospace, defense, and luxury automotive manufacturing. Stringent quality standards and sustainability regulations are influencing the development of energy-efficient and environmentally responsible CNC systems. The presence of established OEMs and advanced R&D facilities further enhances competitiveness. Eastern European countries are gaining traction as production outsourcing destinations within the region.

North America’s :

North America holds a significant market share of the CNC machine market, driven by advanced manufacturing practices and high adoption of automation. The United States leads the region, supported by strong demand from aerospace, defense, and medical device sectors. It benefits from technological innovations, including AI-powered machining and additive manufacturing integration. Canada and Mexico contribute through their growing automotive and industrial equipment manufacturing capabilities. Investments in modernizing aging production facilities are fueling equipment upgrades. Trade agreements and supply chain integration with global markets strengthen regional competitiveness.

Shape Your Report to Specific Countries or Regions & Enjoy 30% Off!

Key Player Analysis:

- Siemens AG

- Ramco Specialties Inc.

- Bonsai Technologies Private Limited

- Versatech LLC

- Komatsu Ltd.

- Yamazaki Mazak Corporation

- Sandvik

- Amada Machine Tools Co. Ltd

- ANCA Group

- Okuma Corporation

- Hyundai WIA

Competitive Analysis:

The CNC machine market is highly competitive, with leading players focusing on innovation, precision, and automation to strengthen their market position. Key companies include Siemens AG, Ramco Specialties Inc., Bonsai Technologies Private Limited, Versatech LLC, Komatsu Ltd., Yamazaki Mazak Corporation, and Sandvik. It is characterized by continuous advancements in multi-axis capabilities, integration of IoT and AI, and development of energy-efficient solutions. Major players invest heavily in R&D to meet the evolving needs of industries such as automotive, aerospace, and electronics. Strategic partnerships, mergers, and acquisitions are common to expand global reach and enhance product portfolios. Competition is driven by the ability to deliver customized, high-performance solutions while maintaining cost efficiency. The presence of both global leaders and regional manufacturers creates a dynamic market landscape with opportunities for differentiation through technological excellence and application-specific expertise.

Recent Developments:

- In June 2025, Siemens AG released an AI-enhanced toolset for EDA and PCB design during the Design Automation Conference.

- In June 2025, Ramco Specialties Inc. saw Pro Towels, a Pittsburgh-based supplier, acquire its “Lifestyles by Ramco” division to expand dye sublimation capacity and move into lifestyle and home décor products, intending to improve production efficiency and lead times.

- In August 2025, Komatsu Ltd. and Pronto announced a strategic partnership, launching the Komatsu Smart Quarry Autonomous system for quarry-size haul trucks in North America.

Market Concentration & Characteristics:

The CNC machine market is moderately concentrated, with a mix of global leaders and regional manufacturers competing through technological innovation and product differentiation. It features established players with strong brand recognition, extensive distribution networks, and advanced R&D capabilities. Competition centers on precision, automation integration, energy efficiency, and customization to meet industry-specific requirements. Strategic partnerships, acquisitions, and product launches are common to expand market presence and address evolving customer demands. The market also exhibits high entry barriers due to significant capital investment, technical expertise, and compliance with quality standards. Emerging players focus on niche applications and cost-effective solutions to capture share in competitive segments.

Report Coverage:

The research report offers an in-depth analysis based on Type, Application, End Use and Region. It details leading Market players, providing an overview of their business, product offerings, investments, revenue streams, and key applications. Additionally, the report includes insights into the competitive environment, SWOT analysis, current Market trends, as well as the primary drivers and constraints. Furthermore, it discusses various factors that have driven Market expansion in recent years. The report also explores Market dynamics, regulatory scenarios, and technological advancements that are shaping the industry. It assesses the impact of external factors and global economic changes on Market growth. Lastly, it provides strategic recommendations for new entrants and established companies to navigate the complexities of the Market.

Future Outlook:

- Demand for CNC machines will increase with the expansion of smart manufacturing and Industry 4.0 adoption across multiple sectors.

- Integration of AI, IoT, and real-time data analytics will enhance process efficiency and reduce downtime in production environments.

- Hybrid CNC systems combining additive and subtractive manufacturing will gain traction for complex and customized applications.

- Energy-efficient CNC machines will see higher adoption to meet sustainability goals and regulatory requirements.

- Aerospace, medical devices, and precision engineering industries will drive demand for high-accuracy, multi-axis CNC solutions.

- Emerging markets in Asia, Latin America, and Eastern Europe will experience strong growth supported by industrialization and infrastructure investments.

- The adoption of cloud-based CNC programming and remote monitoring will streamline operations and improve productivity.

- Demand for compact, portable CNC machines will rise to support SMEs and on-site manufacturing requirements.

- Advanced materials such as composites and high-performance alloys will expand CNC application scope in high-end industries.

- Continuous skill development programs will become essential to address the shortage of trained CNC operators and programmers.