| REPORT ATTRIBUTE |

DETAILS |

| Historical Period |

2020-2023 |

| Base Year |

2024 |

| Forecast Period |

2025-2032 |

| Chile Plastic Welding Equipment Market Size 2024 |

USD 37.38 Million |

| Chile Plastic Welding Equipment Market, CAGR |

4.97% |

| Chile Plastic Welding Equipment Market Size 2032 |

USD 55.10 Million |

Market Overview

Chile Plastic Welding Equipment market size was valued at USD 37.38 million in 2024 and is anticipated to reach USD 55.10 million by 2032, at a CAGR of 4.97% during the forecast period (2024-2032).

The Chile Plastic Welding Equipment market is experiencing steady growth, driven by increasing industrialization and the rising adoption of plastic materials in sectors such as automotive, construction, and electronics. The demand for lightweight, durable, and cost-effective plastic components is fueling the use of advanced welding technologies, including ultrasonic, hot plate, and extrusion welding. Government initiatives supporting infrastructure development and the growing focus on sustainable manufacturing practices are further boosting market expansion. Additionally, the integration of automation and digital control systems in welding equipment enhances precision and productivity, attracting investments from end-use industries. The trend toward customized and high-performance plastic products is also encouraging the adoption of innovative welding solutions. As Chile’s manufacturing sector modernizes, the need for efficient and reliable plastic joining techniques is expected to remain strong, reinforcing the market’s upward trajectory throughout the forecast period.

The geographical landscape of the Chile Plastic Welding Equipment market is shaped by the industrial presence and infrastructure development across key regions such as Santiago, Valparaíso, Concepción, and Antofagasta. Santiago leads in terms of demand due to its strong manufacturing base and early adoption of automation technologies. Valparaíso and Concepción also contribute significantly, driven by growth in the packaging, electronics, and automotive sectors. Meanwhile, Antofagasta, though less diversified, supports demand through mining-related applications. The market is highly competitive and features both global and regional players offering a wide range of manual, semi-automatic, and fully automatic plastic welding solutions. Prominent companies operating in this market include Emerson Electric Co., Leister Technologies AG, RITMO S.p.A., Bielomatik Leuze GmbH & Co. KG, Frimo Group GmbH, and Herrmann Ultraschalltechnik GmbH & Co. KG. These players focus on innovation, product quality, and expanding service networks to meet the evolving needs of Chile’s growing industrial sectors.

Access crucial information at unmatched prices!

Request your sample report today & start making informed decisions powered by Credence Research Inc.!

Download Sample

Market Insights

- The Chile Plastic Welding Equipment market was valued at USD 37.38 million in 2024 and is expected to reach USD 55.10 million by 2032, growing at a CAGR of 4.97% during the forecast period.

- The global plastic welding equipment market was valued at USD 11,340.00 million in 2024 and is projected to reach USD 19,842.36 million by 2032, growing at a CAGR of 7.24% from 2024 to 2032.

- Technological advancements, such as the adoption of automated and robotic welding systems, are driving market growth.

- Increasing demand from the automotive and electronics sectors is further boosting the need for advanced welding equipment.

- Sustainability trends are encouraging the development of energy-efficient and eco-friendly welding solutions.

- The market faces challenges from high initial investment costs and a shortage of skilled workforce in the region.

- Santiago leads the market in demand, followed by Valparaíso and Concepción, with each region having specific industrial focuses driving growth.

- Key players like Emerson Electric Co., Leister Technologies AG, and RITMO S.p.A. are strengthening their positions through technological innovation and strategic partnerships.

Report Scope

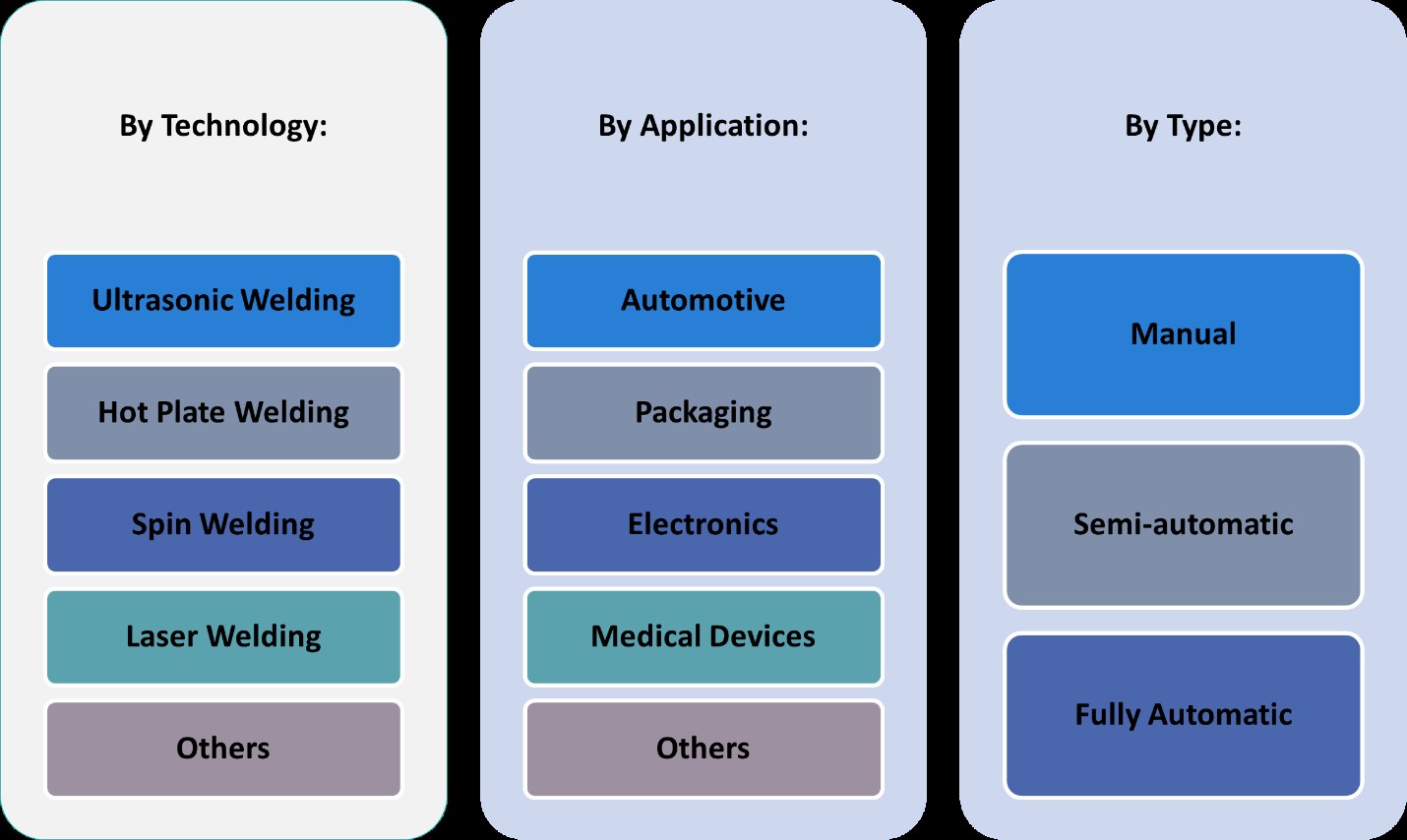

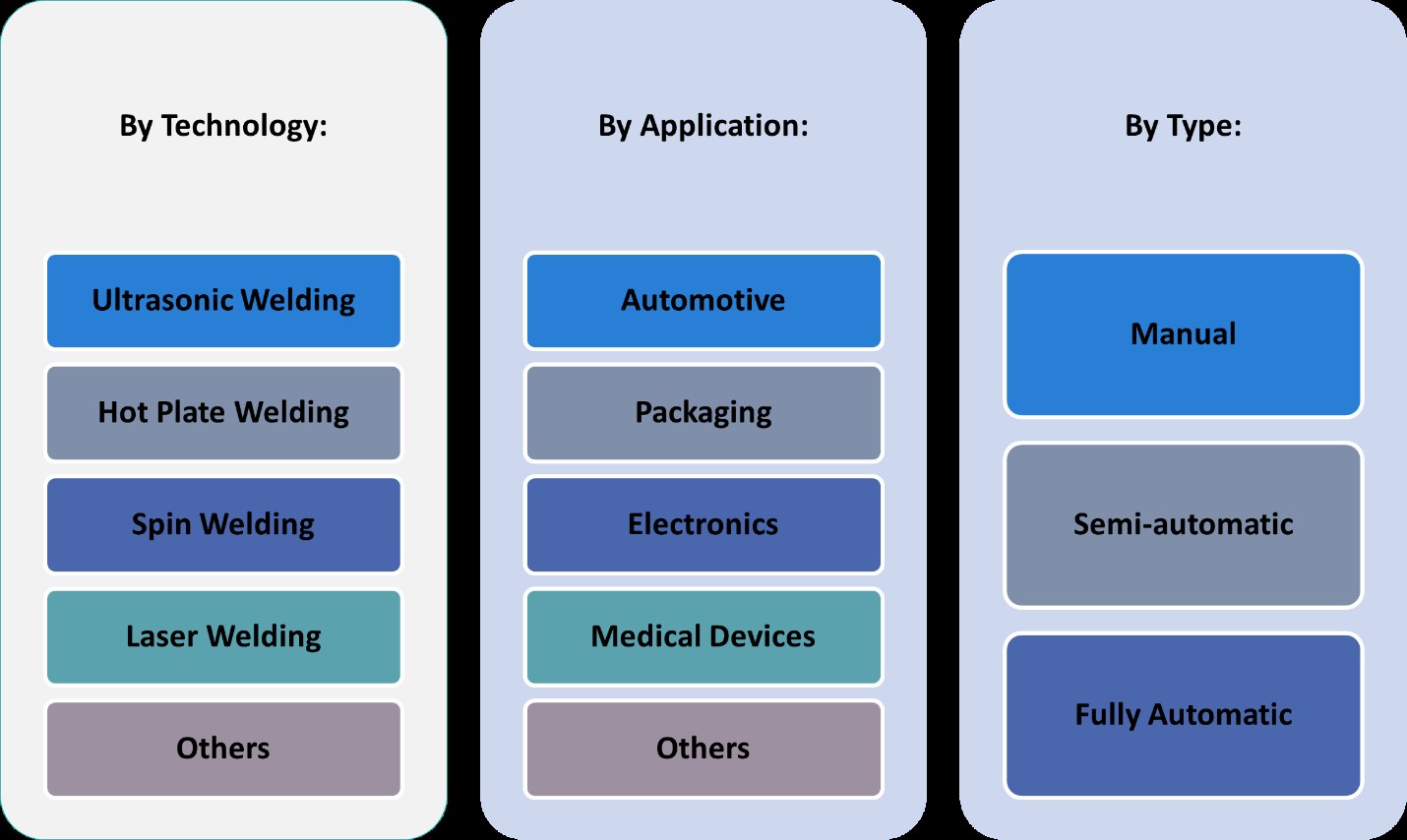

This report segments the Chile Plastic Welding Equipment Market as follows:

Market Drivers

Emphasis on Sustainability and Cost-Efficiency

The market is also benefitting from a heightened emphasis on sustainability and cost-efficiency in manufacturing processes. Plastic welding offers a cleaner and more efficient alternative to mechanical fastening or adhesive bonding, reducing material waste and improving recyclability. For instance, environmental agencies in Chile report that businesses are increasingly adopting welding techniques that minimize waste and enhance the recyclability of plastic components. In Chile, businesses are under increasing pressure to comply with environmental regulations and reduce their carbon footprint, making plastic welding an attractive option. Furthermore, the long-term cost benefits of using high-quality welding equipment—through reduced maintenance, improved product durability, and minimal material loss—are encouraging companies to invest in advanced systems. As sustainability becomes a central focus in industrial operations, the role of plastic welding equipment in supporting eco-friendly and economically viable production methods will continue to grow.

Technological Advancements and Automation Integration

Technological advancements in plastic welding equipment are playing a pivotal role in market growth. Manufacturers are increasingly incorporating automation, digital interfaces, and precision control systems into welding machinery, enhancing performance, consistency, and safety. For instance, reports from industrial associations in Chile indicate a growing adoption of automated plastic welding systems in high-volume manufacturing environments to improve productivity and reduce labor dependency. These improvements are particularly valuable in high-volume manufacturing environments, where speed and quality are critical. In Chile, industries are gradually embracing Industry 4.0 practices, which include the integration of smart machines and data-driven operations. This trend has led to a growing preference for automated plastic welding solutions that reduce labor dependency while increasing productivity. Additionally, innovations in welding techniques—such as infrared and hot gas welding—are expanding the range of applications and materials that can be effectively joined, further driving market demand.

Growing Industrialization and Infrastructure Development

Chile’s growing industrial base and ongoing infrastructure development projects are significantly driving the demand for plastic welding equipment. With increasing investments in transportation, water management, and energy infrastructure, there is a rising requirement for durable plastic components such as pipes, fittings, and panels. These components often require efficient welding techniques for strong and leak-proof joints, making plastic welding equipment indispensable in various public and private sector projects. The Chilean government’s efforts to enhance industrial productivity and modernize facilities across key sectors such as construction and utilities are further contributing to the adoption of advanced welding technologies. This industrial upsurge is fostering a favorable environment for the plastic welding equipment market to grow consistently during the forecast period.

Rising Demand from Automotive and Electronics Sectors

The increasing use of plastic materials in the automotive and electronics sectors is another major driver fueling the growth of Chile’s plastic welding equipment market. Automakers are focusing on manufacturing lightweight vehicles to improve fuel efficiency and reduce carbon emissions. This shift has led to a greater reliance on plastic components that require precise and reliable welding solutions. Similarly, the electronics industry is witnessing heightened demand for compact, durable, and thermally stable plastic housings and parts. Plastic welding technologies such as ultrasonic and laser welding are essential for assembling intricate electronic components without damaging sensitive parts. As the automotive and electronics sectors continue to evolve and expand in Chile, the need for efficient and technologically advanced plastic welding equipment is expected to rise in tandem.

Market Trends

Emphasis on Sustainability and Eco-Friendly Practices

There is a growing trend towards sustainability in Chile’s plastic welding equipment market. Manufacturers are focusing on developing environmentally friendly models that are energy-efficient and reduce operational costs. For instance, government initiatives such as the Chilean Plastics Pact have encouraged manufacturers to develop energy-efficient and environmentally friendly welding models. This shift aligns with the global push towards sustainable manufacturing practices and the reduction of carbon footprints. The adoption of eco-friendly welding processes is not only beneficial for the environment but also enhances the market appeal of plastic welding equipment among environmentally conscious consumers and businesses.

Technological Advancements and Automation Integration

The Chilean plastic welding equipment market is experiencing a significant shift towards automation and digitalization. Manufacturers are increasingly adopting advanced technologies such as inverter-based welding machines and robotic welding systems, which enhance efficiency and precision in welding processes. The integration of artificial intelligence (AI) and the Internet of Things (IoT) into welding equipment allows for real-time monitoring, predictive maintenance, and precise control over the welding process. These technological advancements are driving the demand for modern plastic welding solutions across various industries in Chile.

Rising Demand from Automotive and Electronics Sectors

The automotive and electronics sectors in Chile are witnessing increased demand for plastic welding equipment. In the automotive industry, the trend towards lightweight vehicles for improved fuel efficiency is driving the use of plastic components, which require precise and reliable welding solutions. Similarly, the electronics industry demands compact and durable plastic housings and parts, necessitating advanced welding technologies such as ultrasonic and laser welding. As these sectors continue to grow, the need for efficient plastic welding equipment is expected to rise correspondingly.

Customization and Industry-Specific Solutions

Customization is becoming a significant trend in Chile’s plastic welding equipment market. Industries are seeking tailor-made welding solutions that cater to their specific requirements. This demand for customized equipment is driven by the need for specialized applications in various sectors, including healthcare, consumer goods, and construction. Manufacturers are responding by offering plastic welding machines that are designed to meet the unique needs of different industries, thereby enhancing their competitiveness and market reach

Market Challenges Analysis

High Initial Investment and Limited Skilled Workforce

One of the primary challenges in the Chile Plastic Welding Equipment market is the high initial investment required for advanced machinery and supporting infrastructure. For instance, reports indicate that Small and medium-sized enterprises (SMEs), which form a significant portion of Chile’s industrial base, often face financial constraints that limit their ability to adopt modern welding technologies. The cost of importing high-quality equipment, coupled with installation, maintenance, and training expenses, can be prohibitive. Additionally, the shortage of a skilled workforce capable of operating and maintaining sophisticated plastic welding systems further hampers market growth. Many companies struggle to find technicians trained in newer techniques such as ultrasonic, laser, or hot plate welding, leading to operational inefficiencies. As a result, several end-use industries continue to rely on conventional or semi-automated methods, which can limit the full potential of automation and precision offered by modern equipment.

Regulatory Constraints and Environmental Concerns

Regulatory challenges and environmental concerns also pose significant hurdles to market expansion. Chile has been increasingly enforcing environmental regulations to reduce industrial pollution and promote sustainable practices. While plastic welding is more eco-friendly compared to other joining methods, it still involves energy-intensive processes and the handling of synthetic materials. Companies must ensure compliance with emissions standards, proper waste disposal, and the use of recyclable materials, all of which require additional investment in compliant technologies and processes. Moreover, fluctuating global prices of raw materials and trade restrictions can affect the supply chain, causing delays in equipment procurement and production timelines. These regulatory and environmental obligations, although essential, can slow down the pace of technology adoption and innovation within the plastic welding equipment market, particularly among smaller players with limited financial and technical resources.

Market Opportunities

The Chile Plastic Welding Equipment market presents promising growth opportunities, driven by the rising demand for lightweight and durable plastic components across various industries. As Chile continues to invest in infrastructure modernization, the need for high-performance plastic piping systems in sectors such as water treatment, construction, and energy is increasing. These applications rely heavily on efficient and reliable plastic welding techniques to ensure long-term structural integrity and leak resistance. Additionally, the automotive and electronics sectors in Chile are gradually transitioning toward advanced manufacturing practices, creating a favorable environment for the adoption of innovative welding solutions such as ultrasonic, laser, and infrared welding. This technological shift, supported by the country’s growing industrial base, opens up avenues for manufacturers to introduce automation-integrated and energy-efficient welding systems tailored to industry-specific requirements.

Another opportunity lies in the rising focus on sustainability and regulatory compliance. With stricter environmental regulations encouraging the use of recyclable materials and energy-efficient equipment, businesses are actively seeking eco-friendly plastic welding solutions. Manufacturers that invest in R&D to develop low-emission, precision-based, and cost-effective systems will be well-positioned to capture market share. Moreover, the growing awareness and training initiatives related to Industry 4.0 technologies in Chile offer a chance for suppliers to provide not only equipment but also technical services, software integration, and after-sales support. This value-added approach can help companies build long-term relationships with clients across automotive, construction, packaging, and consumer goods sectors. By aligning product innovation with Chile’s industrial and environmental goals, plastic welding equipment manufacturers can successfully tap into a market that is increasingly driven by quality, efficiency, and sustainability.

Market Segmentation Analysis:

By Type:

The Chile Plastic Welding Equipment market is segmented by type into manual, semi-automatic, and fully automatic systems. Among these, semi-automatic systems hold a significant share due to their balance between affordability and operational efficiency, making them ideal for small to medium-sized enterprises. Manual welding equipment is still in use, particularly in low-volume applications or sectors with limited automation capabilities, such as maintenance services and small fabrication workshops. However, with the rise of Industry 4.0 and increasing demand for precision and repeatability, fully automatic welding systems are gaining momentum, especially in industries requiring consistent high-quality welds. These systems are being adopted across large manufacturing units in Chile, where productivity and minimal error margins are critical. As companies look to enhance efficiency and reduce labor costs, the shift toward fully automated and digitally controlled welding systems is expected to intensify. This trend reflects Chile’s gradual yet steady move toward automation in its industrial landscape, offering substantial growth potential for high-tech equipment manufacturers.

By Application:

Based on application, the market includes electronics, packaging, automotive, medical devices, and others. The automotive sector accounts for a notable share due to the increasing use of plastic components in vehicle manufacturing, aimed at reducing overall weight and enhancing fuel efficiency. Precision welding techniques like ultrasonic and laser welding are extensively utilized in this segment. The electronics industry also presents strong demand for plastic welding equipment, especially for assembling intricate plastic housings and enclosures. Meanwhile, the packaging industry leverages hot plate and heat sealing equipment for mass production of containers, films, and pouches. The medical devices segment is emerging as a promising area, driven by the need for sterile and hermetically sealed plastic parts, where non-contaminating welding methods are essential. Other applications, including construction and consumer goods, contribute to steady market demand. With each sector demanding specialized solutions, the diversity in applications is encouraging manufacturers to offer tailored welding systems to cater to the evolving needs of Chile’s industrial landscape.

Segments:

Based on Type:

- Manual

- Semi-automatic

- Fully Automatic

Based on Application:

- Electronics

- Packaging

- Automotive

- Medical Devices

- Others

Based on Technology:

- Ultrasonic Welding

- Hot Plate Welding

- Spin Welding

- Laser Welding

- Others

Based on the Geography:

- Santiago

- Valparaíso

- Concepción

Regional Analysis

Santiago

Santiago, the capital and economic hub of Chile, dominates the plastic welding equipment market with an estimated 45% share. This dominance is primarily attributed to the city’s high concentration of manufacturing industries, infrastructure development projects, and a well-established automotive and electronics sector. Santiago’s industrial ecosystem fosters the adoption of advanced plastic welding technologies, including fully automated systems that enhance production efficiency and product consistency. The city’s access to technical expertise, skilled labor, and R&D centers also contributes to the growing demand for innovative welding solutions. Furthermore, government investments in smart infrastructure and sustainable manufacturing practices encourage companies in Santiago to adopt energy-efficient and precision-based welding equipment. As a result, Santiago remains a key growth engine for the national market, attracting major equipment suppliers and system integrators.

Valparaíso

Valparaíso holds approximately 20% of the Chilean plastic welding equipment market. The region benefits from its strategic coastal location and active port, which supports its packaging, shipping, and maritime industries. These sectors rely on durable plastic components and containers, where plastic welding equipment is essential for fabrication and sealing processes. Valparaíso’s industrial base, though smaller than Santiago’s, is gradually modernizing, and the demand for semi-automatic welding systems is growing as businesses seek improved efficiency without the high investment of full automation. Additionally, local government efforts to promote sustainable development and industrial diversification are driving increased adoption of environmentally friendly welding technologies. While Valparaíso’s growth rate is moderate, its long-term potential remains strong due to continued infrastructural development and expanding logistics and marine sectors.

Concepción

Concepción accounts for around 15% of the market share, supported by its role as a growing industrial and educational center in southern Chile. The city hosts several industrial parks and has a notable presence in the automotive and electronics manufacturing sectors, both of which depend on precise and reliable plastic welding systems. Demand for ultrasonic and laser-based welding equipment is on the rise, especially among manufacturers focusing on high-performance applications. Additionally, Concepción’s universities and technical institutes contribute to a steady flow of skilled technicians and engineers, facilitating the region’s transition to more advanced manufacturing methods. As more businesses invest in expanding their production capabilities, the region is expected to increase its market share in the coming years.

Antofagasta

Antofagasta holds an estimated 10% of the plastic welding equipment market and is primarily driven by demand from the mining and energy sectors, both of which require specialized plastic components such as piping and containment systems. Though less industrially diverse than other regions, the use of high-density polyethylene (HDPE) pipes in mining operations boosts the demand for butt fusion and extrusion welding machines. Additionally, the harsh environmental conditions in northern Chile necessitate durable and high-performance plastic welding applications. The region’s market is relatively niche, but steady investments in mining infrastructure and environmental protection are expected to support consistent demand for plastic welding equipment tailored to the unique needs of Antofagasta’s industrial landscape.

Key Player Analysis

- Emerson Electric Co.

- Leister Technologies AG

- RITMO S.p.A.

- Bielomatik Leuze GmbH & Co. KG

- Frimo Group GmbH

- Herrmann Ultraschalltechnik GmbH & Co. KG

- DRADER Manufacturing Industries Ltd.

- HPT Hochwertige Plastikteile GmbH

- CHN-TOP Machinery Group

- Telsonic AG

Competitive Analysis

The Chile Plastic Welding Equipment market is competitive, with several global and regional players driving innovation and technological advancements. Leading companies such as Emerson Electric Co., Leister Technologies AG, RITMO S.p.A., Bielomatik Leuze GmbH & Co. KG, Frimo Group GmbH, Herrmann Ultraschalltechnik GmbH & Co. KG, DRADER Manufacturing Industries Ltd., HPT Hochwertige Plastikteile GmbH, CHN-TOP Machinery Group, and Telsonic AG are key participants. These companies focus on offering a diverse range of plastic welding technologies, including ultrasonic, laser, and hot plate welding systems, to cater to various industrial applications such as automotive, electronics, and packaging. To maintain a competitive edge, these players invest heavily in research and development to enhance product efficiency, precision, and energy consumption. They also emphasize offering after-sales services and customer support, including training and technical assistance, to build long-term relationships with clients. Strategic partnerships, mergers, and acquisitions are common tactics to expand their product portfolio and geographical reach. The market is also seeing an increasing trend towards automation, with major players introducing fully automated systems to meet the growing demand for high-volume production and consistency. Despite the competitive environment, these companies are positioning themselves for growth by aligning with Chile’s industrial modernization and sustainability goals.

Recent Developments

- In March 2025, Leister transferred its laser plastic welding business to Hymson Novolas AG, a subsidiary of Hymson Laser Technology Group Co. Ltd. The transition ensures continuity and further development of existing product lines, with a new Laser Technology Center established in Switzerland. Leister will now focus more on its core competencies: plastic welding (hot air, infrared) and industrial process heat.

- In February 2025, Herrmann continues to set industry standards with its ultrasonic welding solutions, particularly for medical devices and sensitive components. The company emphasizes individualized process development, intelligent process control, and digital quality monitoring for reproducible, high-strength welds. Herrmann will showcase new applications and integration options at K 2025, focusing on automation and sustainability in medical and packaging industries.

- In January 2025, Dukane highlighted its patented Q-Factor, Melt-Match®, Low Amplitude Preheat, and Ultra-High Frequency (260–400 Hz) vibration welding technologies, emphasizing their leadership in process control and diagnostics.

- In May 2024, Emerson launched the Branson™ GLX-1 Laser Welder, designed for the automated assembly of small, intricate plastic parts. The GLX-1 features a compact, modular design suitable for cleanroom environments, advanced servo-based actuation, and the ability to “un-weld” plastics for closed-loop recycling. It uses Simultaneous Through-Transmission Infrared® (STTlr) laser-welding technology for high efficiency, weld strength, and aesthetics. Enhanced connectivity, security, and data collection features support Industry 4.0 integration.

Market Concentration & Characteristics

The Chile Plastic Welding Equipment market exhibits moderate concentration, with a mix of global and regional players dominating the landscape. Key international companies such as Emerson Electric Co., Leister Technologies AG, and RITMO S.p.A. hold significant market share, while local firms also contribute to the competition. The market is characterized by a diverse range of products, including manual, semi-automatic, and fully automatic welding systems, catering to industries like automotive, packaging, electronics, and medical devices. The focus is on technological innovation, with increasing adoption of energy-efficient, high-precision welding solutions. These technologies enable manufacturers to improve productivity and reduce costs, making them attractive to companies across various sectors. The market is also marked by a shift toward automation, driven by the demand for high-volume production and consistent quality. Despite the competition, companies that invest in R&D and offer customized solutions are likely to maintain a competitive edge in this evolving market.

Shape Your Report to Specific Countries or Regions & Enjoy 30% Off!

Report Coverage

The research report offers an in-depth analysis based on Type, Application, Technology and Geography. It details leading market players, providing an overview of their business, product offerings, investments, revenue streams, and key applications. Additionally, the report includes insights into the competitive environment, SWOT analysis, current market trends, as well as the primary drivers and constraints. Furthermore, it discusses various factors that have driven market expansion in recent years. The report also explores market dynamics, regulatory scenarios, and technological advancements that are shaping the industry. It assesses the impact of external factors and global economic changes on market growth. Lastly, it provides strategic recommendations for new entrants and established companies to navigate the complexities of the market.

Future Outlook

- The Chile plastic welding equipment market is expected to witness steady growth due to increasing demand across various industries such as automotive, construction, and packaging.

- Advancements in technology, such as automated and robotic welding systems, will enhance the precision and efficiency of plastic welding processes.

- The market will likely see a rise in the adoption of energy-efficient and eco-friendly plastic welding equipment as industries focus on sustainability.

- The growing construction and infrastructure sectors in Chile will drive demand for plastic welding equipment used in piping and insulation applications.

- Strong government regulations and policies promoting the use of environmentally friendly materials will further stimulate the demand for advanced plastic welding solutions.

- The rising trend of product customization will encourage the development of flexible and versatile welding equipment suitable for different plastic materials.

- Increased awareness regarding the benefits of plastic welding over traditional joining methods will boost the market growth.

- The market will see enhanced competition, with both local and international players introducing innovative products and solutions.

- The demand for lightweight and durable plastic products, particularly in the automotive sector, will be a significant driver for welding equipment.

- As Chile continues to expand its industrial base, the need for robust plastic welding equipment will remain critical for maintaining quality and productivity in manufacturing processes.