Market Overview:

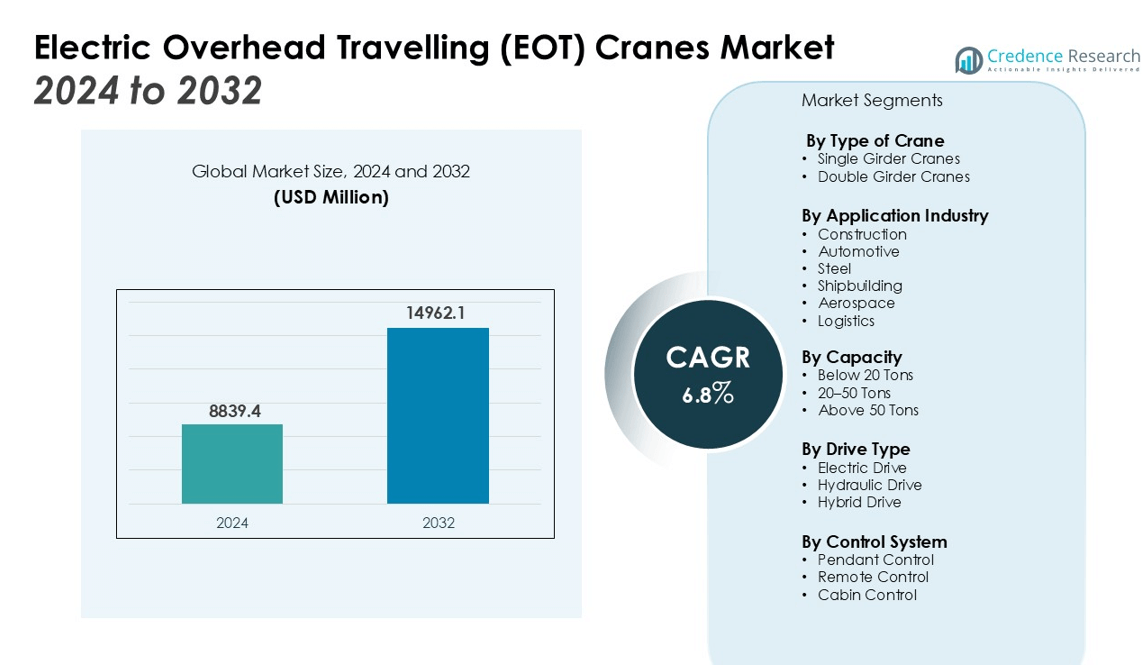

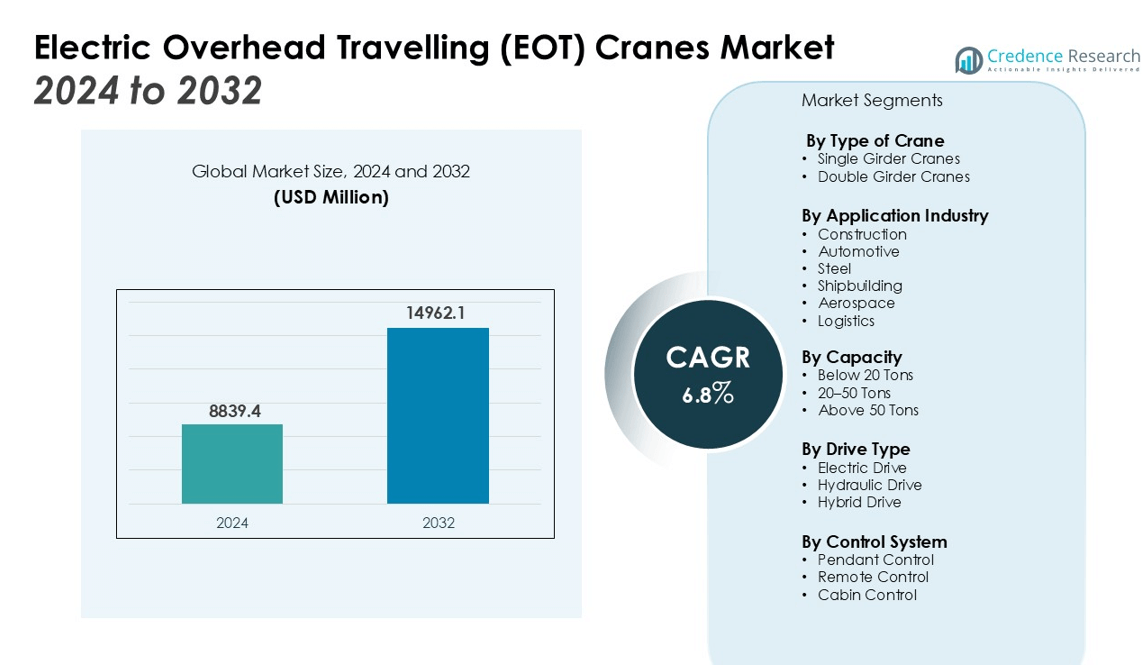

The Electric Overhead Travelling (EOT) Cranes Market size was valued at USD 8839.4 million in 2024 and is anticipated to reach USD 14962.1 million by 2032, at a CAGR of 6.8% during the forecast period (2024-2032).

| REPORT ATTRIBUTE |

DETAILS |

| Historical Period |

2020-2023 |

| Base Year |

2024 |

| Forecast Period |

2025-2032 |

| Electric Overhead Travelling (EOT) Cranes Market Size 2024 |

USD 8839.4 million |

| Electric Overhead Travelling (EOT) Cranes Market, CAGR |

6.8% |

| Electric Overhead Travelling (EOT) Cranes Market Size 2032 |

USD 14962.1 million |

The demand for EOT cranes is primarily fueled by the rapid expansion of infrastructure projects such as roads, bridges, railways, and ports, along with sustained growth in the construction, automotive, steel, and shipbuilding industries. Technological advancements, including automation, remote operation capabilities, and improved load management systems, are enhancing operational efficiency, safety, and lifespan, further boosting adoption. The need to reduce manual labor, minimize downtime, and improve precision in heavy material handling is prompting industries to replace conventional systems with modern EOT cranes.

Asia-Pacific holds the largest share of the market, supported by industrialization, urbanization, and significant infrastructure investments in countries like China, India, and Japan. North America shows steady growth, driven by manufacturing expansion and warehouse automation, while Europe benefits from consistent construction and manufacturing activity. Emerging economies in the Middle East, Africa, and South America are also witnessing gradual adoption, supported by industrial growth and urban development initiatives. Growing emphasis on sustainable manufacturing and energy-efficient equipment is further influencing purchasing decisions across global markets.

Market Insights:

- The Electric Overhead Travelling (EOT) Cranes Market is valued at USD 8,839.4 million and is projected to reach USD 14,962.1 million, growing at a CAGR of 6.8% during the forecast period.

- Infrastructure expansion in roads, bridges, railways, and ports, along with growth in construction, automotive, steel, and shipbuilding industries, is driving consistent demand.

- Advancements such as automation, remote operation, and intelligent load management are improving efficiency, safety, and service life.

- Heavy industries including steel, automotive, aerospace, and shipbuilding are increasingly adopting EOT cranes for high-capacity and precise lifting operations.

- High initial investment and maintenance costs remain key barriers, particularly for small and medium-sized enterprises.

- Asia-Pacific leads with 43% market share due to rapid industrialization, urbanization, and government-backed infrastructure initiatives.

- Rising focus on sustainability, energy-efficient equipment, and smart technologies presents strong opportunities for future growth across global markets.

Access crucial information at unmatched prices!

Request your sample report today & start making informed decisions powered by Credence Research Inc.!

Download Sample

Market Drivers:

Rising Infrastructure Development and Industrial Expansion

The Electric Overhead Travelling (EOT) Cranes Market is gaining strong momentum due to rapid infrastructure development and industrial expansion across emerging and developed economies. Large-scale projects in transportation, energy, and manufacturing sectors are creating substantial demand for advanced material handling solutions. Governments are increasing investments in roadways, railways, ports, and industrial zones, boosting the requirement for high-capacity cranes. It plays a critical role in improving project timelines, reducing manual labor, and ensuring operational safety in complex construction environments.

- For instance, two Liebherr 340 EC-B 16 flat-top cranes are being utilized in the construction of the 453-meter-long Rahmede Valley Bridge in Germany.

Technological Advancements Enhancing Operational Efficiency

Integration of automation, remote-control capabilities, and intelligent load management systems is transforming the operational efficiency of EOT cranes. The Electric Overhead Travelling (EOT) Cranes Market benefits from innovations that enhance precision, reduce downtime, and extend equipment lifespan. Advanced monitoring systems enable predictive maintenance, minimizing unexpected failures and operational disruptions. It is also evolving to support higher load capacities with improved energy efficiency, aligning with modern industry requirements for sustainable operations.

- For instance, Liebherr has expanded its all-terrain crane portfolio with the LTM 1300-6.3, a model with a lifting capacity of 300 tonnes.

Growing Adoption in Heavy Industries and Manufacturing

Heavy industries such as steel, automotive, shipbuilding, and aerospace are driving consistent demand for EOT cranes. The Electric Overhead Travelling (EOT) Cranes Market supports these sectors by offering robust lifting capabilities and adaptability to various production environments. Increased focus on large-scale manufacturing and assembly processes necessitates cranes capable of handling heavy loads with accuracy and reliability. It provides a cost-effective solution for improving productivity and ensuring compliance with stringent safety standards.

Emphasis on Safety, Compliance, and Cost Optimization

Strict regulatory frameworks governing workplace safety are prompting industries to adopt advanced EOT crane systems. The Electric Overhead Travelling (EOT) Cranes Market is responding with designs that meet international safety standards and incorporate features to minimize operational hazards. Industries are seeking solutions that lower labor dependency while reducing maintenance and operational costs. It helps organizations optimize resource utilization and achieve higher returns on capital investments.

Market Trends:

Integration of Automation, Digitalization, and Smart Monitoring

The Electric Overhead Travelling (EOT) Cranes Market is experiencing a clear shift toward automation, digitalization, and advanced monitoring technologies. Manufacturers are equipping cranes with remote-control systems, IoT-enabled sensors, and AI-driven load management tools to improve precision, reduce downtime, and optimize operational safety. It is enabling predictive maintenance capabilities, allowing operators to identify and address potential failures before they cause costly interruptions. Integration of digital twins and real-time data analytics is helping industries enhance efficiency and streamline asset management. The focus on reducing human intervention while improving productivity is accelerating adoption across sectors. Demand for cranes with energy-efficient motors and regenerative braking systems is also growing in alignment with sustainability targets.

- For instance, Danieli Centro Cranes offers a regenerative braking system that captures and returns energy to the grid, providing a return on investment in approximately 1 year by cutting overall electricity consumption.

Customization and Expansion into Emerging Industrial Applications

The Electric Overhead Travelling (EOT) Cranes Market is witnessing rising demand for customized solutions tailored to specific industry requirements. It is adapting to diverse operational environments, from compact manufacturing facilities to large-scale heavy industrial plants. Increased investment in specialized cranes for sectors such as aerospace, renewable energy, and advanced manufacturing is expanding the application scope. Demand for high-capacity, corrosion-resistant, and weather-proof designs is growing in regions with challenging environmental conditions. Integration of modular designs is allowing easier scalability and quicker installation, supporting faster project execution. It is also aligning with industry preferences for flexible and cost-effective solutions that can evolve with operational needs.

- For instance, Liebherr is supplying its RL 900 series offshore cranes for wind power platforms in the Baltic Sea.

Market Challenges Analysis:

High Initial Investment and Maintenance Costs

The Electric Overhead Travelling (EOT) Cranes Market faces challenges due to the substantial initial investment required for procurement and installation. It demands significant capital outlay, which can deter small and medium-sized enterprises from adoption. Regular maintenance, inspections, and compliance with safety standards add recurring expenses, impacting total cost of ownership. Specialized components and skilled labor for repairs can further increase operational costs. Industries with budget constraints may opt for less advanced alternatives, slowing adoption in certain segments. Economic fluctuations and uncertain project pipelines also influence purchasing decisions.

Operational Constraints and Skilled Workforce Shortage

The Electric Overhead Travelling (EOT) Cranes Market encounters operational limitations in environments with restricted space, variable weather conditions, or high installation complexity. It requires skilled operators and maintenance personnel to ensure safe and efficient functioning. Shortages of trained workforce in emerging economies can lead to operational inefficiencies and safety risks. Strict regulatory compliance in different regions can delay installation and increase administrative costs. Downtime during repairs or upgrades can disrupt critical industrial operations. Limited adaptability in older crane models to integrate with modern automation systems also poses challenges for modernization efforts.

Market Opportunities:

Rising Demand from Expanding Infrastructure and Industrial Projects

The Electric Overhead Travelling (EOT) Cranes Market holds strong growth potential due to accelerating infrastructure development and industrial expansion worldwide. It is well-positioned to benefit from large-scale investments in transportation networks, renewable energy facilities, and manufacturing hubs. Growing adoption in ports, warehouses, and logistics centers is creating new revenue streams. The demand for cranes capable of handling higher loads with enhanced precision is increasing in sectors such as automotive, steel, and shipbuilding. Government initiatives to boost domestic manufacturing are also encouraging upgrades to advanced material handling systems. Emerging economies in Asia-Pacific, Africa, and Latin America are expected to generate substantial opportunities for market expansion.

Adoption of Smart Technologies and Sustainable Solutions

The Electric Overhead Travelling (EOT) Cranes Market is poised to gain from advancements in automation, IoT integration, and energy-efficient designs. It offers opportunities for manufacturers to develop intelligent cranes with predictive maintenance, remote monitoring, and digital twin capabilities. The shift toward sustainable operations is driving interest in cranes with regenerative braking systems and low-energy motors. Demand for customizable, modular cranes tailored to industry-specific needs is rising. Expansion in specialized applications, such as aerospace manufacturing and wind turbine assembly, presents lucrative avenues. Partnerships between global manufacturers and regional distributors can further enhance market penetration in high-growth regions.

Market Segmentation Analysis:

By Type of Crane

The Electric Overhead Travelling (EOT) Cranes Market is segmented into single girder and double girder types. Single girder cranes are widely chosen for light to medium-duty applications due to their lower cost, easier installation, and space efficiency. Double girder cranes dominate in heavy-duty operations, offering higher load capacity, greater span, and increased durability. It serves industries that require tailored solutions to meet specific operational needs and performance requirements.

- For instance, ABUS Kransysteme GmbH provides a flexible single girder travelling crane, the ELK, with a lifting capacity of up to 16 tons.

By Application Industry

The market caters to construction, automotive, steel, shipbuilding, aerospace, and logistics sectors. Construction and steel industries account for significant demand due to their need for high-capacity lifting equipment in large-scale projects. Automotive and aerospace sectors use EOT cranes for precise material handling in production and assembly lines. Shipbuilding applications benefit from their ability to move oversized components efficiently, while logistics and warehousing adopt them to improve workflow efficiency. It continues to expand its role in sectors focused on operational accuracy and productivity.

- For instance, the Taisun gantry crane at the Yantai Raffles Shipyard in China set a world record by lifting a single vessel module weighing 20,133 metric tons.

By Capacity

The market is classified into cranes below 20 tons, between 20–50 tons, and above 50 tons. Cranes below 20 tons are suited for manufacturing and maintenance activities requiring frequent but lighter lifts. The 20–50 ton segment is popular in medium-scale industrial operations for its balance between capacity and flexibility. Heavy-duty cranes above 50 tons are essential for steel production, shipyards, and major infrastructure projects where maximum load handling is critical. It is advancing toward integrating higher capacities with enhanced automation and safety technologies.

Segmentations:

By Type of Crane

- Single Girder Cranes

- Double Girder Cranes

By Application Industry

- Construction

- Automotive

- Steel

- Shipbuilding

- Aerospace

- Logistics

By Capacity

- Below 20 Tons

- 20–50 Tons

- Above 50 Tons

By Drive Type

- Electric Drive

- Hydraulic Drive

- Hybrid Drive

By Control System

- Pendant Control

- Remote Control

- Cabin Control

By Region

- North America

- Europe

- UK

- France

- Germany

- Italy

- Spain

- Russia

- Belgium

- Netherlands

- Austria

- Sweden

- Poland

- Denmark

- Switzerland

- Rest of Europe

- Asia Pacific

- China

- Japan

- South Korea

- India

- Australia

- Thailand

- Indonesia

- Vietnam

- Malaysia

- Philippines

- Taiwan

- Rest of Asia Pacific

- Latin America

- Brazil

- Argentina

- Peru

- Chile

- Colombia

- Rest of Latin America

- Middle East

- UAE

- KSA

- Israel

- Turkey

- Iran

- Rest of Middle East

- Africa

- Egypt

- Nigeria

- Algeria

- Morocco

- Rest of Africa

Regional Analysis:

Asia-Pacific Leading with Industrial and Infrastructure Growth

Asia-Pacific accounted for 43% of the Electric Overhead Travelling (EOT) Cranes Market, driven by rapid industrialization, urbanization, and large-scale infrastructure investments. It benefits from strong demand in China, India, and Japan, where manufacturing, construction, and logistics sectors are expanding at a fast pace. Government programs promoting industrial corridors, smart cities, and port modernization are boosting crane adoption. Industries in the region are increasingly investing in advanced material handling systems to enhance productivity and operational safety. The presence of a strong manufacturing base and cost-effective production capabilities supports both domestic consumption and export potential.

North America Experiencing Steady Growth with Technological Adoption

North America represented 27% of the Electric Overhead Travelling (EOT) Cranes Market, supported by advanced manufacturing facilities, warehouse automation, and infrastructure renewal projects. It benefits from the integration of smart technologies, predictive maintenance tools, and energy-efficient systems that align with sustainability goals. Expanding e-commerce networks are driving investment in distribution and logistics infrastructure, creating further demand. The region also shows strong adoption in heavy industries such as automotive, aerospace, and steel manufacturing. Regulatory emphasis on workplace safety standards is encouraging modernization of existing crane fleets.

Europe and Emerging Markets Showing Diversified Opportunities

Europe held 20% of the Electric Overhead Travelling (EOT) Cranes Market, driven by ongoing construction activity, modernization of manufacturing plants, and adoption of automation in industrial operations. It is supported by stringent safety regulations and a strong focus on efficiency improvements. Emerging markets in the Middle East, Africa, and Latin America are witnessing growing adoption due to urban development, port expansion, and energy sector projects. Industrial diversification in these regions is increasing the requirement for robust, high-capacity cranes. Strategic partnerships between international manufacturers and local distributors are helping accelerate market penetration in these high-potential areas.

Shape Your Report to Specific Countries or Regions & Enjoy 30% Off!

Key Player Analysis:

- Columbus Mckinnon Corporation

- Uesco Cranes

- Konecranes

- Abuscranes

- K2 Cranes

- Terex

- KITO GROUP

- Harrington Hoists Inc

- Terex Corporation

- Altech Industries

- Liebherr Group

- KONE Cranes

- Mammoet

- Hitachi Sumitomo Heavy Industries Construction Crane

Competitive Analysis:

The Electric Overhead Travelling (EOT) Cranes Market features a competitive landscape with global and regional players focusing on product innovation, capacity expansion, and strategic partnerships. Leading companies emphasize advanced automation, IoT integration, and energy-efficient designs to meet evolving industry requirements. It is characterized by strong competition among established brands offering comprehensive product portfolios and after-sales services to secure long-term contracts. Manufacturers are investing in research and development to enhance load capacity, operational safety, and customization options. Strategic mergers, acquisitions, and collaborations are enabling players to expand their geographic presence and strengthen distribution networks. Regional manufacturers are competing on cost efficiency and tailored solutions, targeting niche applications and emerging markets. Competitive differentiation is increasingly driven by technology adoption, compliance with international safety standards, and the ability to deliver high-performance cranes with reduced lifecycle costs.

Recent Developments:

- In June 2025, Konecranes introduced its new E-Hybrid Rubber-Tired Gantry (RTG) crane and an electric empty container handler at the TOC Europe exhibition.

- In August 2025, KITO CROSBY announced a new partnership with Harrington Hoists, which will now offer eepos brand modular aluminum crane systems through its sales networks in the USA, Mexico, and South America.

Market Concentration & Characteristics:

The Electric Overhead Travelling (EOT) Cranes Market exhibits a moderately consolidated structure, with a few major global players holding significant market shares alongside a wide base of regional manufacturers. It is defined by high entry barriers due to substantial capital requirements, advanced technological expertise, and strict safety regulations. Leading companies focus on innovation, customization, and integration of smart technologies to maintain a competitive edge. The market serves diverse industries with varying capacity needs, from light-duty manufacturing to heavy industrial applications. Demand patterns are influenced by infrastructure development, industrial expansion, and the adoption of energy-efficient, automated solutions. Competitive dynamics are shaped by product quality, reliability, after-sales support, and compliance with international safety standards.

Report Coverage:

The research report offers an in-depth analysis based on Type of Crane, Application Industry, Capacity, Drive Type, Control System and Region. It details leading market players, providing an overview of their business, product offerings, investments, revenue streams, and key applications. Additionally, the report includes insights into the competitive environment, SWOT analysis, current market trends, as well as the primary drivers and constraints. Furthermore, it discusses various factors that have driven market expansion in recent years. The report also explores market dynamics, regulatory scenarios, and technological advancements that are shaping the industry. It assesses the impact of external factors and global economic changes on market growth. Lastly, it provides strategic recommendations for new entrants and established companies to navigate the complexities of the market.

Future Outlook:

- Adoption of automation, IoT connectivity, and AI-driven monitoring systems will enhance operational efficiency and safety in EOT crane operations.

- Demand for customized crane designs will grow to meet industry-specific requirements in sectors such as aerospace, renewable energy, and heavy manufacturing.

- Integration of predictive maintenance technologies will reduce downtime and extend equipment life cycles.

- Sustainability goals will drive the development of energy-efficient cranes equipped with regenerative braking systems and low-consumption motors.

- Expansion of infrastructure projects in emerging economies will create significant growth opportunities for manufacturers and service providers.

- Rising investments in smart factories and Industry 4.0 initiatives will boost the need for advanced material handling systems.

- Strategic partnerships between global manufacturers and regional distributors will expand market reach and accelerate adoption in high-potential regions.

- Development of modular and scalable crane systems will support faster installation and flexibility in industrial layouts.

- Increasing enforcement of workplace safety regulations will stimulate demand for cranes with advanced safety features and compliance certifications.

- Growth in sectors such as logistics, shipbuilding, and steel production will continue to reinforce market demand for high-capacity, precision lifting solutions.