Market Overview:

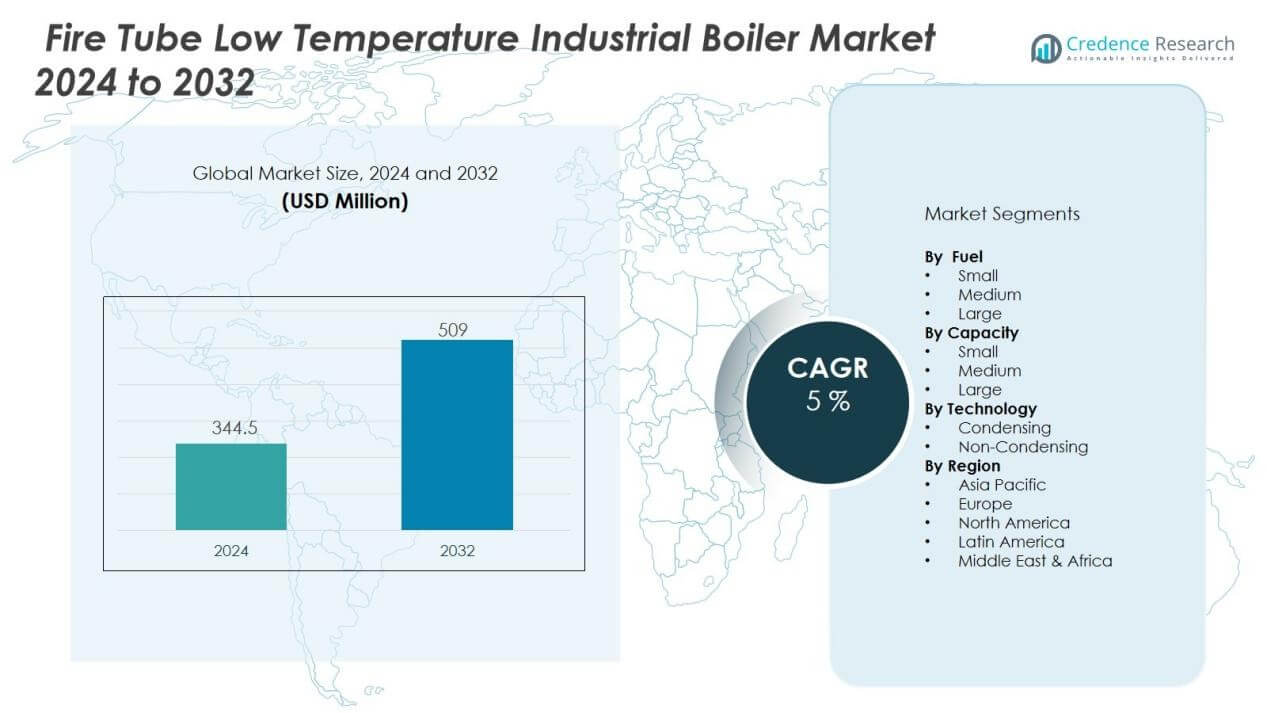

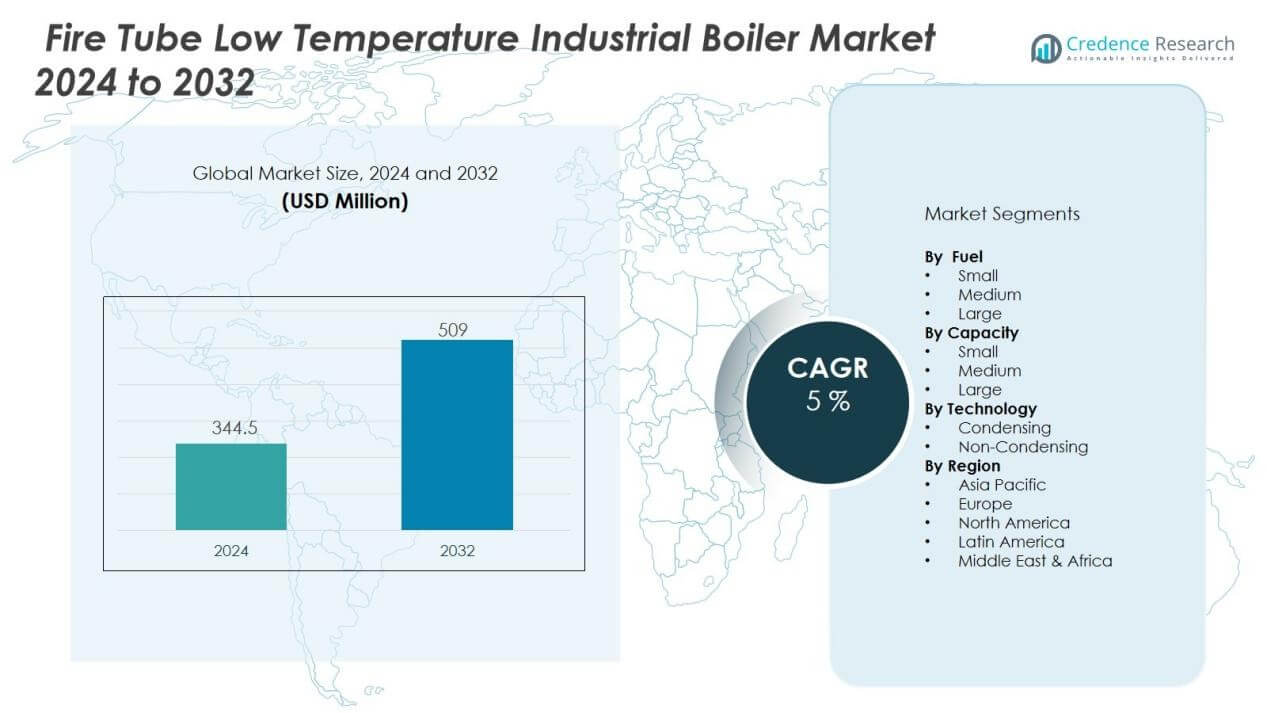

The fire tube low temperature industrial boiler market size was valued at USD 344.5 million in 2024 and is anticipated to reach USD 509 million by 2032, at a CAGR of 5 % during the forecast period (2024-2032).

| REPORT ATTRIBUTE |

DETAILS |

| Historical Period |

2020-2023 |

| Base Year |

2024 |

| Forecast Period |

2025-2032 |

| Fire Tube Low Temperature Industrial Boiler Market Size 2024 |

USD 344.5 Million |

| Fire Tube Low Temperature Industrial Boiler Market, CAGR |

5% |

| Fire Tube Low Temperature Industrial Boiler Market Size 2032 |

USD 509 Million |

Key drivers include the global shift toward sustainability and regulatory emphasis on emission reduction. Industries are replacing traditional boilers with advanced condensing models that operate efficiently under low-temperature conditions, reducing carbon footprints and energy expenses. Technological developments, such as smart monitoring systems and modular boiler designs, further enhance system performance and safety. These innovations are helping manufacturers meet strict environmental and safety standards while strengthening the value proposition for end users.

Regionally, Europe leads the market, supported by stringent emission regulations and early adoption of green technologies. North America follows, driven by regulatory incentives and industrial automation, which encourage energy-efficient heating systems. Asia-Pacific is expected to record the fastest growth, fueled by rapid industrialization, manufacturing expansion, and increasing sustainability efforts in China, India, and Southeast Asia. Emerging markets in Latin America and the Middle East & Africa also show potential, supported by infrastructure development and growing energy efficiency initiatives.

Market Insights:

- The fire tube low temperature industrial boiler market was valued at USD 344.5 million in 2024 and is projected to reach USD 509 million by 2032, growing at a CAGR of 5%.

- Rising demand for energy efficiency and cost optimization is driving adoption as industries aim to reduce fuel use and operational expenses.

- Strict emission regulations are pushing manufacturers and end-users toward eco-friendly condensing models that comply with global standards.

- Technological advancements such as smart monitoring systems, modular designs, and enhanced safety features are improving system reliability and performance.

- Industries are transitioning toward sustainable heating solutions, replacing conventional boilers with low-temperature condensing systems aligned with carbon reduction goals.

- High upfront investment and ongoing maintenance requirements remain challenges, particularly for small and medium enterprises in emerging economies.

- Europe leads with 38% share in 2024 due to strict emission rules, North America follows with 27% share supported by incentives, and Asia-Pacific with 22% share is expanding fastest through rapid industrialization and manufacturing growth.

Access crucial information at unmatched prices!

Request your sample report today & start making informed decisions powered by Credence Research Inc.!

Download Sample

Market Drivers:

Rising Demand for Energy Efficiency and Cost Optimization:

The fire tube low temperature industrial boiler market is benefiting from industries focusing on reducing operational expenses while meeting sustainability targets. High-efficiency boilers consume less fuel, which lowers energy bills and supports long-term cost savings. It allows manufacturers and industrial facilities to balance environmental responsibility with profitability. The combination of reduced consumption and improved efficiency continues to drive widespread adoption.

- For instance, Cleaver-Brooks achieved significant efficiency improvements with their CBEX-3W firetube boiler featuring proprietary EX technology, which delivers 3% O₂ across a 10:1 turndown range and requires 85% increased heat transfer compared to plain tubes through extended heat transfer surfaces

Strict Emission Regulations Supporting Cleaner Technologies:

Governments worldwide are tightening environmental policies to cut industrial emissions, creating strong demand for advanced boiler systems. The fire tube low temperature industrial boiler market gains traction as it offers compliance with stringent standards while delivering reliable performance. Manufacturers are upgrading to eco-friendly solutions that limit greenhouse gas output. This regulatory landscape is shaping investment decisions and accelerating the replacement of outdated systems.

- For Instance, Cleaver-Brooks markets its CBEX Elite firetube boiler as an ultra-low NOx solution, with some models designed to achieve emissions as low as <5 ppm NOx without the use of Selective Catalytic Reduction (SCR) technology.

Technological Advancements Driving Product Innovation

Modern boilers are equipped with smart monitoring tools, modular designs, and improved safety features. The fire tube low temperature industrial boiler market benefits from these innovations that enhance efficiency, reduce downtime, and extend service life. It helps operators manage performance in real time, ensuring greater operational control. Technological progress is making these systems attractive across diverse industries seeking reliability.

Industrial Transition Toward Sustainable Heating Solutions:

Industries are steadily replacing conventional high-temperature boilers with low-temperature condensing systems that align with global sustainability goals. The fire tube low temperature industrial boiler market is gaining momentum as companies pursue carbon reduction strategies. It is seen as a practical path to achieving environmental certifications and corporate sustainability commitments. The market continues to grow as industries prioritize sustainable heating technologies in their production processes.

Market Trends:

Integration of Smart Monitoring and Automation Features:

The fire tube low temperature industrial boiler market is witnessing a strong trend toward digital integration. Smart monitoring tools and automation systems are being adopted to improve performance, ensure safety, and minimize downtime. It allows operators to track efficiency metrics, detect faults early, and optimize fuel use in real time. Remote monitoring capabilities are gaining popularity, especially in industries with large-scale heating demands. Manufacturers are also embedding predictive maintenance features that extend system life and reduce repair costs. This digital shift aligns with broader industry moves toward Industry 4.0 and energy-efficient automation.

- For Instance, Bosch Thermotechnology offers its Control 8000 automation platform, which enables operators to remotely monitor and control medium and large heating systems in commercial and industrial settings.

Shift Toward Modular and Sustainable Boiler Designs:

The fire tube low temperature industrial boiler market is moving toward modular configurations that provide scalability and easier installation. It enables industries to expand capacity without significant downtime or large upfront costs. The growing emphasis on sustainability is pushing demand for eco-friendly materials and designs that minimize emissions. Compact and flexible boiler units are being preferred by small and medium facilities due to space optimization. The adoption of condensing technology is also strengthening, helping industries meet stricter emission and efficiency standards. This trend underscores the market’s transition to sustainable heating solutions that balance performance and environmental goals.

- For Instance, Bosch Thermotechnology offers its Control 8000 automation platform, which enables operators to remotely monitor and control medium and large heating systems in commercial and industrial settings.

Market Challenges Analysis:

High Initial Investment and Maintenance Barriers:

The fire tube low temperature industrial boiler market faces challenges related to high upfront costs. Advanced condensing models, smart monitoring systems, and modular designs require significant capital investment. It often deters small and medium enterprises from adopting these technologies despite long-term savings. Routine maintenance and specialized servicing further add to operational expenses. Industries with tight budgets may delay replacement or continue using older, less efficient boilers. This cost-related barrier limits market penetration in emerging economies and among resource-constrained industries.

Regulatory Complexity and Limited Awareness in Developing Regions:

The fire tube low temperature industrial boiler market also struggles with regulatory complexity across different countries. Compliance with emission norms and safety standards varies, creating uncertainty for manufacturers and end-users. It increases the burden on companies to adapt products for multiple markets. Limited awareness of advanced technologies in developing regions restricts adoption and slows modernization. Many industries continue to rely on conventional boilers due to familiarity and lower initial investment. This uneven pace of adoption challenges the market’s global growth potential.

Market Opportunities:

Expansion Potential in Emerging Economies and Industrial Sectors:

The fire tube low temperature industrial boiler market holds significant opportunities in rapidly industrializing regions. Growing investments in manufacturing, food processing, and chemical industries are creating demand for efficient heating systems. It offers industries in Asia-Pacific, Latin America, and the Middle East a cost-effective way to align with sustainability goals. Government incentives supporting energy-efficient equipment further encourage adoption. Expanding infrastructure projects and rising energy costs make low-temperature boilers an attractive replacement for older systems. This creates a strong pathway for manufacturers to capture new markets and expand their global footprint.

Growing Adoption of Green Technologies and Digital Solutions:

The fire tube low temperature industrial boiler market is positioned to benefit from the global shift toward green technologies. Rising pressure to meet net-zero targets is driving industries to adopt eco-friendly boiler systems. It provides opportunities for manufacturers to innovate with hybrid designs, renewable fuel integration, and reduced emission models. The growing role of smart monitoring and predictive maintenance also supports long-term adoption. Companies that integrate digital tools with sustainable features are likely to strengthen competitiveness. These opportunities underline the market’s future direction toward clean and digitally enabled heating solutions.

Market Segmentation Analysis:

By Capacity:

The fire tube low temperature industrial boiler market is segmented by capacity into small, medium, and large units. Small and medium-capacity boilers are widely adopted by food processing, pharmaceuticals, and small manufacturing plants due to their cost efficiency and compact design. Large-capacity boilers dominate heavy industries such as chemicals, power generation, and metallurgy where continuous heating demand is critical. It is expected that demand for medium-capacity boilers will rise further with the expansion of mid-sized industrial facilities.

- For Instance, Fulton manufactures the VSRT-30, a 30 HP Vertical Spiral Rib Tubeless Steam Boiler, which was introduced in 2018. The VSRT series is known for its compact footprint and high steam quality, which can reach 99.75%.

By Fuel:

Segmentation by fuel includes natural gas, oil, coal, and others. Natural gas-based boilers lead the market due to their cleaner combustion and cost advantages compared to traditional coal-fired models. Oil-fired units hold steady demand in regions with established oil infrastructure, while coal-fired boilers continue to decline under environmental pressure. It is clear that natural gas and renewable-compatible models are set to gain stronger traction in future years.

- For Instance, A 660 MW ultra-supercritical circulating fluidized bed (CFB) boiler, developed by Dongfang Boiler Co., Ltd. for the Pingshuo Power Plant in China, was reported to operate with key parameters meeting its design requirements, which are in this range, following a successful 168-hour full-load trial

By Technology:

By technology, the market is divided into condensing and non-condensing boilers. Condensing boilers dominate the fire tube low temperature industrial boiler market due to their superior efficiency and compliance with emission regulations. Non-condensing units still find use in cost-sensitive industries but face declining adoption. It is evident that ongoing regulations and sustainability goals will continue to favor condensing technology, shaping the long-term outlook of this segment.

Segmentations:

By Capacity:

By Fuel:

- Natural Gas

- Oil

- Coal

- Others

By Technology

- Condensing

- Non-Condensing

By Region:

- North America

- Europe

- UK

- France

- Germany

- Italy

- Spain

- Russia

- Belgium

- Netherlands

- Austria

- Sweden

- Poland

- Denmark

- Switzerland

- Rest of Europe

- Asia Pacific

- China

- Japan

- South Korea

- India

- Australia

- Thailand

- Indonesia

- Vietnam

- Malaysia

- Philippines

- Taiwan

- Rest of Asia Pacific

- Latin America

- Brazil

- Argentina

- Peru

- Chile

- Colombia

- Rest of Latin America

- Middle East

- UAE

- KSA

- Israel

- Turkey

- Iran

- Rest of Middle East

- Africa

- Egypt

- Nigeria

- Algeria

- Morocco

- Rest of Africa

Regional Analysis:

Europe:

Europe accounts for 38% share of the fire tube low temperature industrial boiler market in 2024, making it the leading region. The dominance is supported by stringent emission regulations and early adoption of green technologies. Countries such as Germany, the UK, and France are driving demand through strict compliance frameworks and industrial modernization initiatives. It benefits from government incentives that promote energy efficiency and carbon reduction. Strong investments in advanced heating systems by manufacturing and processing industries further sustain growth. The region continues to set benchmarks for innovation and environmental responsibility in boiler adoption.

North America:

North America holds 27% share of the fire tube low temperature industrial boiler market in 2024, positioning it as the second-largest region. Strong regulatory incentives and industrial automation trends support growth in the United States and Canada. It benefits from replacement demand, where older conventional boilers are being phased out for condensing models. The region is also witnessing investments in smart factories and sustainable industrial operations. Presence of leading boiler manufacturers strengthens availability of advanced systems. Energy-efficient equipment adoption aligns with the region’s long-term environmental and economic priorities.

Asia-Pacific:

Asia-Pacific represents 22% share of the fire tube low temperature industrial boiler market in 2024, and it is expected to expand at the fastest pace. Rapid industrialization in China, India, and Southeast Asia is fueling demand for reliable and efficient heating solutions. It gains momentum from growing manufacturing capacity, infrastructure development, and rising energy efficiency requirements. Governments in the region are promoting sustainable technologies to reduce environmental impact. Expanding food processing, chemicals, and textile sectors are key adopters of advanced boilers. This growth positions Asia-Pacific as a central hub for future market expansion.

Shape Your Report to Specific Countries or Regions & Enjoy 30% Off!

Key Player Analysis:

- Babcock & Wilcox

- Clayton Industries

- Babcock Wanson

- Cleaver-Brooks

- Fulton

- EPCB Boiler

- Hurst Boiler & Welding

- Johnston Boiler

- IHI Corporation

- Miura America

Competitive Analysis:

The fire tube low temperature industrial boiler market is characterized by strong competition among global and regional players. Key companies include Babcock & Wilcox, Clayton Industries, Babcock Wanson, Cleaver-Brooks, Fulton, EPCB Boiler, Hurst Boiler & Welding, and Johnston Boiler. These firms compete through advanced product portfolios, innovation in condensing technology, and integration of smart monitoring systems. It is shaped by rising demand for energy-efficient solutions that meet strict emission standards, prompting companies to expand R&D investments. Partnerships with industrial end-users and focus on modular, scalable designs help strengthen market presence. Regional manufacturers leverage cost-effective solutions to capture share in emerging economies, while global leaders maintain dominance through technological expertise and wide distribution networks. The market dynamic emphasizes efficiency, compliance, and sustainability, making competitive strategies centered on performance and reliability critical for long-term growth.

Recent Developments:

- In September 2025, Babcock & Wilcox announced compliance regained with NYSE listing standards following a successful stock price recovery.

- In May 2025, Clayton Industries showcased its innovative CrossMod® affordable home solutions and highlighted developer partnerships at the Berkshire Hathaway Shareholder Meeting.

- In June 2025, Babcock Wanson acquired Danish company Chr. Møller A/S to expand its decarbonisation and energy transition solution offering in the European market.

Report Coverage:

The research report offers an in-depth analysis based on Capacity, Fuel, Technology and Region. It details leading Market players, providing an overview of their business, product offerings, investments, revenue streams, and key applications. Additionally, the report includes insights into the competitive environment, SWOT analysis, current Market trends, as well as the primary drivers and constraints. Furthermore, it discusses various factors that have driven Market expansion in recent years. The report also explores Market dynamics, regulatory scenarios, and technological advancements that are shaping the industry. It assesses the impact of external factors and global economic changes on Market growth. Lastly, it provides strategic recommendations for new entrants and established companies to navigate the complexities of the Market.

Future Outlook:

- The fire tube low temperature industrial boiler market will continue to benefit from the global push toward decarbonization and energy efficiency.

- Rising demand from industries such as food processing, chemicals, and textiles will drive adoption of low-temperature condensing systems.

- Manufacturers will focus on smart monitoring, predictive maintenance, and automation to improve operational control and system reliability.

- Government policies supporting emission reduction and energy savings will expand opportunities across developed and emerging economies.

- The replacement of conventional boilers with advanced condensing models will remain a key growth factor.

- Hybrid systems integrating renewable energy sources such as biomass and solar heating will gain traction.

- Compact and modular designs will be preferred by small and medium enterprises due to easier installation and scalability.

- Asia-Pacific will emerge as the fastest-expanding region, supported by rapid industrialization and sustainability goals.

- Collaborations between technology providers and industrial users will strengthen innovation and accelerate adoption of eco-friendly boilers.

- The market will evolve toward long-term sustainability by balancing cost savings, energy performance, and environmental impact.