Market Overview

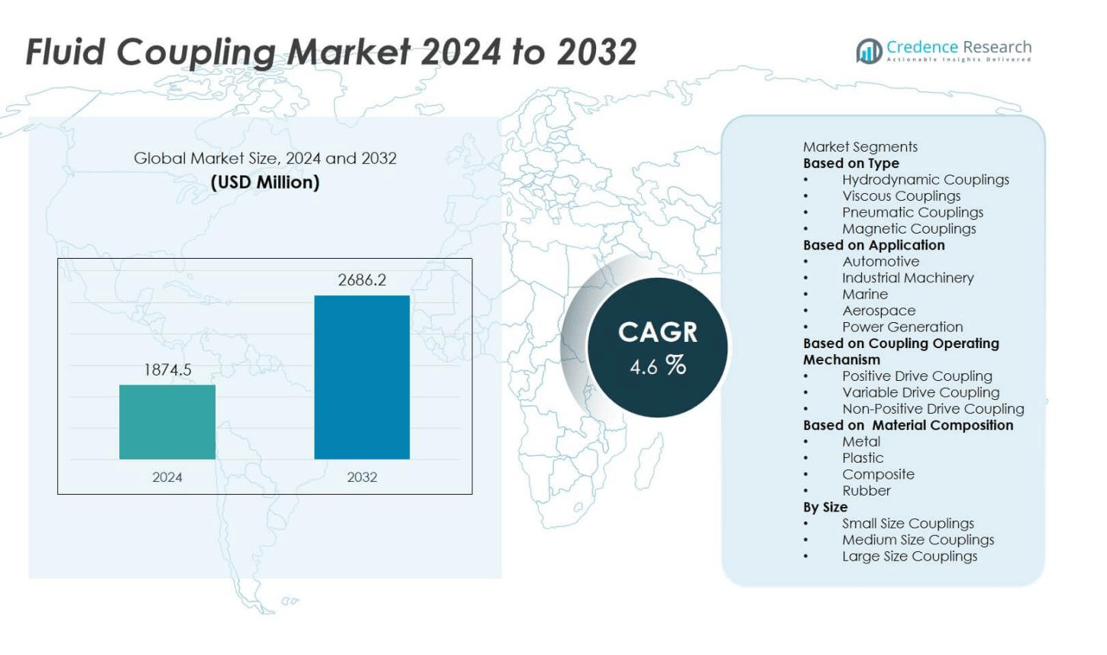

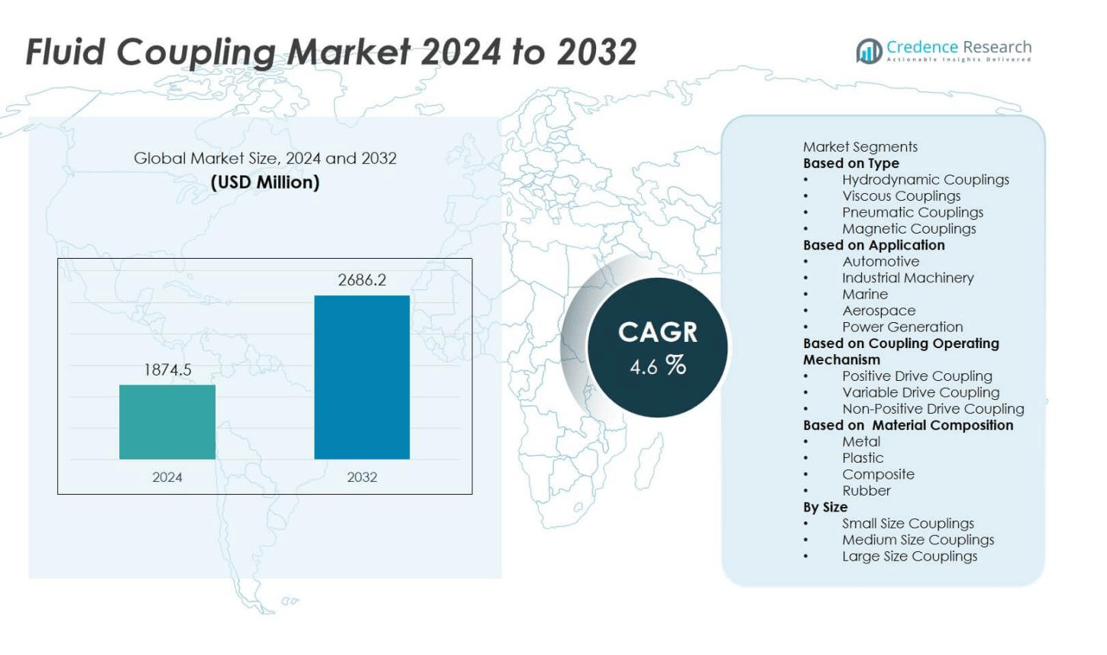

Fluid Coupling Market size was valued at USD 1,874.5 million in 2024 and is projected to reach USD 2,686.2 million by 2032, expanding at a CAGR of 4.6% during the forecast period.

| REPORT ATTRIBUTE |

DETAILS |

| Historical Period |

2020-2023 |

| Base Year |

2024 |

| Forecast Period |

2025-2032 |

| Fluid Coupling Market Size 2024 |

USD 1,874.5 million |

| Fluid Coupling Market, CAGR |

4.6% |

| Fluid Coupling Market Size 2032 |

USD 2,686.2 million |

The Fluid Coupling Market grows through rising demand for energy-efficient torque transmission, expansion of industrial and infrastructure projects, and adoption in renewable energy facilities requiring stable load control. It benefits from technological advancements that enhance durability, thermal capacity, and integration with predictive maintenance systems. Trends include the use of lightweight, high-strength materials to improve efficiency, increasing customization for industry-specific requirements, and integration of smart monitoring for real-time performance insights.

The Fluid Coupling Market demonstrates a strong global presence, with significant demand across North America, Europe, Asia-Pacific, Latin America, and the Middle East & Africa. North America benefits from advanced industrial automation and modernization of heavy machinery, while Europe’s demand is driven by renewable energy projects and marine engineering. Asia-Pacific leads growth through rapid industrialization, infrastructure expansion, and strong mining and manufacturing activities. Latin America and the Middle East & Africa witness increasing adoption in mining, cement, oil, and gas industries, supported by ongoing infrastructure development. Key players shaping the competitive landscape include Voith, known for high-performance coupling solutions; KTR Systems, offering technologically advanced and customized products; and Danfoss, leveraging innovation to enhance energy efficiency.

Access crucial information at unmatched prices!

Request your sample report today & start making informed decisions powered by Credence Research Inc.!

Download Sample

Market Insights

- The Fluid Coupling Market was valued at USD 1,874.5 million in 2024 and is projected to reach USD 2,686.2 million by 2032, registering a CAGR of 4.6% during the forecast period.

- The market grows with rising demand for energy-efficient torque transmission systems that reduce mechanical stress and improve operational reliability in industrial, mining, marine, and power generation applications.

- Key trends include the integration of smart monitoring and predictive maintenance technologies, adoption of lightweight and high-strength materials, and increasing customization to meet specific industry requirements.

- Competitive dynamics are shaped by major players such as Voith, KTR Systems, Danfoss, Honeywell, and Haldex, focusing on technological advancements, global distribution networks, and expansion into emerging markets.

- Restraints include high maintenance requirements in harsh environments and growing competition from alternative drive technologies such as variable frequency drives and direct drive systems.

- Regional demand is strong in Asia-Pacific due to rapid industrialization and infrastructure projects, while North America and Europe benefit from modernization of machinery and renewable energy adoption. Latin America and the Middle East & Africa see growth from mining, cement, oil, and gas sectors.

- Future growth opportunities lie in emerging economies with expanding industrial bases and renewable energy projects, supported by innovations in coupling designs that improve thermal capacity, efficiency, and durability.

Market Drivers

Rising Demand for Energy-Efficient Power Transmission Solutions

The Fluid Coupling Market benefits from growing emphasis on energy conservation across industrial and mining sectors. It enables smooth power transmission, reducing mechanical shock and extending equipment life. Industries adopt these systems to optimize torque control and minimize energy losses in high-load applications. Governments and organizations promote efficiency standards, encouraging modernization of drive systems. Manufacturers introduce advanced designs with improved fluid dynamics to meet these expectations. This shift supports cost savings and operational reliability, making energy-efficient couplings a preferred choice in heavy-duty operations.

- For instance, Voith developed its TurboBelt 780 TPXL coupling for mining conveyors, achieving a 3% improvement in energy efficiency and extending service life beyond 50,000 operational hours under continuous load.

Expansion of Infrastructure and Industrial Projects Worldwide

Large-scale infrastructure development in transportation, energy, and manufacturing sectors drives consistent demand for fluid couplings. They serve critical roles in conveyors, crushers, and heavy machinery, ensuring controlled start-up and overload protection. Rapid urbanization and industrialization in emerging economies increase investment in cement, steel, and construction equipment. It supports continuous operation in demanding environments with minimal downtime. The versatility of these couplings across industries strengthens their relevance in capital-intensive projects. Growth in public and private sector investments sustains the market’s upward trajectory.

- For instance, KTR Systems supplied over 1,200 ROTEX couplings for a European steel plant upgrade, enabling machinery to handle torque loads up to 12,000 Nm with reduced start-up times by 18%.

Adoption in Renewable Energy and Sustainable Operations

Renewable energy projects increasingly integrate fluid couplings in wind turbines, biomass plants, and hydroelectric facilities to ensure stable torque transmission. These systems reduce stress on gearboxes and generators, extending operational life and enhancing reliability. It supports the integration of variable speed drives, improving performance under fluctuating loads. Energy producers focus on sustainable technologies that align with emission reduction goals. The adaptability of couplings in harsh and variable operating conditions reinforces their role in renewable energy infrastructure. Expanding global clean energy capacity creates long-term opportunities in the market.

Technological Advancements Enhancing Operational Reliability

Continuous innovation in fluid coupling design focuses on better materials, improved sealing, and optimized internal flow channels. These improvements enhance heat dissipation, load-handling capacity, and durability in demanding industrial environments. It reduces maintenance needs, lowering total cost of ownership for end-users. Integration of condition monitoring and predictive maintenance technologies further improves operational efficiency. Manufacturers invest in research to deliver couplings that perform reliably under extreme temperature and load variations. This commitment to performance innovation supports wider adoption in industries where equipment uptime is critical.

Market Trends

Integration of Smart Monitoring and Predictive Maintenance Capabilities

The Fluid Coupling Market is witnessing a clear trend toward incorporating smart sensors and monitoring systems into coupling assemblies. These solutions track parameters such as temperature, vibration, and torque to detect potential issues early. It allows maintenance teams to address wear or imbalance before failures occur. This proactive approach reduces downtime and extends the operational lifespan of connected equipment. Manufacturers are aligning designs with Industry 4.0 practices to enable seamless data integration. The emphasis on predictive maintenance strengthens operational reliability across critical industries.

- For instance, Danfoss integrated condition monitoring modules into its VLT Drive couplings, enabling real-time tracking of vibration levels up to 200 mm/s² and temperature up to 125°C, reducing unplanned downtime by over 400 operational hours annually in industrial conveyor systems.

Shift Toward Lightweight and High-Strength Material Adoption

Manufacturers are increasingly adopting advanced alloys and composite materials in fluid couplings to improve performance without increasing weight. This shift enhances energy efficiency by lowering rotational inertia and reducing strain on motors. It enables better thermal performance, allowing couplings to operate effectively in high-temperature environments. Lighter yet stronger materials also improve installation flexibility and reduce handling time. The trend supports longer service intervals and lower maintenance requirements. Industry players are investing in material innovation to meet evolving demands in heavy-duty and high-speed applications.

- For instance, KTR Systems introduced a coupling variant using high-strength aluminum alloy with a density of 2.7 g/cm³, cutting overall weight by 36 kg per unit while maintaining a torque capacity of 15,000 Nm, enabling easier installation and improved system efficiency in marine propulsion systems.

Rising Customization for Industry-Specific Requirements

The demand for application-specific fluid couplings is increasing across industries such as mining, marine, and power generation. Manufacturers design customized torque characteristics, mounting configurations, and cooling features to match operational needs. It enables optimal performance under diverse load conditions and operating environments. This customization helps reduce operational costs and enhances safety in high-risk applications. Companies with strong engineering capabilities gain a competitive advantage through specialized solutions. The trend reflects a growing preference for tailored coupling systems over standard configurations.

Expansion of Usage in Renewable and Alternative Energy Projects

Renewable energy facilities are adopting fluid couplings to ensure smooth torque transfer and protect generators from overload conditions. It supports stable operation in wind turbines, hydro plants, and biomass power stations where load variations are common. The adaptability of these couplings to fluctuating speeds and torque demands makes them well-suited for clean energy infrastructure. Demand is further supported by global initiatives promoting sustainable energy production. Manufacturers are enhancing product designs to withstand environmental challenges in remote installations. The trend strengthens the market’s presence in the evolving energy landscape.

Market Challenges Analysis

High Maintenance Requirements in Harsh Operating Environments

The Fluid Coupling Market faces challenges in applications where dust, moisture, and extreme temperatures accelerate wear. These conditions increase the frequency of inspections, oil replacement, and seal changes, raising operational costs. It becomes difficult for end-users in remote or resource-limited sites to maintain optimal performance without interruptions. Downtime caused by maintenance impacts productivity in industries such as mining, cement, and marine operations. The need for specialized skills and tools to service couplings adds to the complexity. Manufacturers must address these issues through improved sealing technologies and longer-lasting lubrication systems.

Rising Competition from Alternative Drive Technologies

The growing adoption of variable frequency drives (VFDs) and direct drive systems presents a significant competitive challenge for the Fluid Coupling Market. These alternatives offer precise speed control, lower energy consumption, and reduced maintenance needs. It pressures traditional fluid coupling manufacturers to innovate and demonstrate cost-effectiveness over the long term. Industries focused on energy efficiency targets increasingly evaluate electronic and mechanical alternatives. The shift toward electrification in industrial and mobile equipment further limits certain applications for fluid couplings. Overcoming this challenge requires continuous design improvements, integration of smart features, and value-driven performance benefits.

Market Opportunities

Growth Potential in Emerging Industrial Economies

The Fluid Coupling Market has strong opportunities in rapidly industrializing regions such as Asia-Pacific, Latin America, and parts of Africa. Expanding manufacturing capacity, mining activities, and infrastructure projects in these regions create sustained demand for reliable power transmission systems. It supports industries that require equipment capable of handling high torque and variable loads with minimal downtime. Government-led investments in transportation, energy, and construction further boost adoption. The rising need for cost-effective, durable, and easy-to-maintain solutions positions fluid couplings as an attractive choice. Companies that establish local manufacturing and service networks can strengthen their market penetration.

Expansion into Renewable Energy and High-Efficiency Applications

Global focus on clean energy and operational efficiency opens significant growth avenues for the Fluid Coupling Market. Renewable energy plants, including wind, hydro, and biomass facilities, require torque control solutions to protect critical components from overloads. It provides stable and efficient performance in variable speed conditions, enhancing system reliability. The trend toward upgrading industrial systems for higher efficiency aligns with the adoption of advanced couplings. Integration with smart monitoring systems enhances their appeal for industries aiming to reduce operational risks. Manufacturers that tailor products to meet sustainability and efficiency goals can capture emerging opportunities in modern energy and industrial sectors.

Market Segmentation Analysis:

By Type

The Fluid Coupling Market is segmented by type into constant-fill and variable-fill designs, each serving distinct operational needs. Constant-fill couplings offer simplicity and cost-effectiveness, making them ideal for applications with steady load conditions. It delivers consistent torque transmission without complex adjustments, supporting reliable performance in conveyors, crushers, and fans. Variable-fill couplings provide adjustable torque control, enabling smooth acceleration and overload protection in high-inertia machinery. This flexibility is essential in industries such as mining, steel, and power generation, where load variations are frequent. Growing demand for operational efficiency and equipment protection sustains interest in both categories, with variable-fill designs gaining momentum for their adaptability.

- For instance, Voith’s TurboBelt 780 TPXL variable-fill coupling, used in large mining conveyors, handles torque loads up to 1,200,000 Nm and achieves start-up times under 45 seconds, significantly improving operational throughput in bulk material handling.

By Application

The market serves diverse applications including mining, power generation, cement, marine, and industrial manufacturing. Mining operations depend on fluid couplings to handle heavy-duty conveyor systems and crushers under challenging environmental conditions. It ensures gradual load application, reducing mechanical stress and extending equipment life. In power generation, couplings safeguard turbines, pumps, and fans from torque fluctuations, enhancing reliability. Marine applications leverage their ability to provide smooth start-up and absorb shock loads in propulsion systems. Expanding industrial automation and infrastructure projects across emerging economies further strengthen demand in manufacturing and processing industries.

- For instance, KTR’s MONOLASTIC® one‑piece flexible flange couplings support torque ratings up to 7,800 Nm, while maintaining a mass moment of inertia of approximately 0.00599 kg·m² at speeds up to 6,000 rpm—facilitating robust performance with reduced vibration in hydraulic pump drives

By Coupling Operating Mechanism

Segmentation by coupling operating mechanism includes centrifugal, hydraulic, and hydrodynamic systems. Centrifugal couplings engage automatically at a set rotational speed, offering simplicity for smaller machinery and auxiliary drives. It minimizes manual intervention while providing dependable engagement. Hydraulic and hydrodynamic couplings dominate in heavy-duty applications, enabling controlled torque transmission and effective shock absorption. These mechanisms are favored in sectors requiring precise load management and protection from sudden load changes. Technological advancements in these systems focus on improving thermal capacity, efficiency, and integration with monitoring tools. The growing need for high-performance solutions in critical operations supports the development and adoption of advanced operating mechanisms across industries.

Segments:

Based on Type

- Hydrodynamic Couplings

- Viscous Couplings

- Pneumatic Couplings

- Magnetic Couplings

Based on Application

- Automotive

- Industrial Machinery

- Marine

- Aerospace

- Power Generation

Based on Coupling Operating Mechanism

- Positive Drive Coupling

- Variable Drive Coupling

- Non-Positive Drive Coupling

Based on Material Composition

- Metal

- Plastic

- Composite

- Rubber

By Size

- Small Size Couplings

- Medium Size Couplings

- Large Size Couplings

Based on the Geography:

- North America

- Europe

- UK

- France

- Germany

- Italy

- Spain

- Russia

- Belgium

- Netherlands

- Austria

- Sweden

- Poland

- Denmark

- Switzerland

- Rest of Europe

- Asia Pacific

- China

- Japan

- South Korea

- India

- Australia

- Thailand

- Indonesia

- Vietnam

- Malaysia

- Philippines

- Taiwan

- Rest of Asia Pacific

- Latin America

- Brazil

- Argentina

- Peru

- Chile

- Colombia

- Rest of Latin America

- Middle East

- UAE

- KSA

- Israel

- Turkey

- Iran

- Rest of Middle East

- Africa

- Egypt

- Nigeria

- Algeria

- Morocco

- Rest of Africa

Regional Analysis

North America

North America accounts for 24% of the Fluid Coupling Market, supported by its strong industrial base and advanced manufacturing practices. The region’s demand is driven by sectors such as mining, power generation, marine, and oil and gas, where fluid couplings are integral for reliable torque transmission. It benefits from high adoption of advanced variable-fill couplings in energy-intensive applications, enhancing efficiency and reducing operational downtime. The United States leads the market, with Canada contributing steadily through its mining and marine operations. Stringent energy efficiency standards push industries to upgrade to modern coupling designs with better thermal capacity and monitoring capabilities. Continuous investment in industrial automation and infrastructure modernization sustains the region’s growth trajectory.

Europe

Europe holds 22% of the Fluid Coupling Market, with demand concentrated in Germany, the UK, France, and Italy. The region benefits from a strong presence of heavy manufacturing, marine engineering, and renewable energy projects. It maintains a high level of technological adoption, with industries favoring smart couplings integrated with predictive maintenance systems. Energy transition policies in the European Union encourage modernization of drive systems to improve efficiency and reduce emissions. The marine industry in countries like Norway and the Netherlands supports demand for robust couplings capable of withstanding harsh operating conditions. Expansion in offshore wind power further drives specialized coupling requirements.

Asia-Pacific

Asia-Pacific leads the Fluid Coupling Market with 38% share, driven by rapid industrialization and infrastructure development. China, India, and Japan are key contributors, with strong demand from mining, steel, cement, and manufacturing sectors. It gains momentum from large-scale investments in power generation and renewable energy facilities, where fluid couplings ensure stable performance under varying loads. The mining and materials processing industries in Australia and Indonesia also significantly contribute to regional growth. Rising adoption of industrial automation and modernization of equipment strengthens the position of advanced coupling technologies. Local manufacturing capabilities and cost advantages make the region a hub for both production and consumption.

Latin America

Latin America represents 9% of the Fluid Coupling Market, with Brazil, Mexico, and Chile as primary markets. The region’s demand is supported by mining, cement, and marine industries requiring reliable torque control solutions in heavy-duty operations. It benefits from ongoing investment in infrastructure and industrial expansion, particularly in resource-rich economies. Couplings are widely used in conveyor systems, crushers, and bulk material handling equipment across mining operations. Growing adoption of energy-efficient and low-maintenance designs improves operational reliability in challenging environments. Partnerships with global manufacturers enhance technology transfer and product availability.

Middle East & Africa

The Middle East & Africa accounts for 7% of the Fluid Coupling Market, primarily serving oil and gas, mining, and power generation industries. It is driven by the need for durable and high-performance couplings that operate reliably in extreme temperatures and dusty environments. The Gulf states invest in industrial diversification, creating opportunities for advanced torque control solutions. South Africa’s mining sector, along with energy projects in Egypt and Morocco, adds to the demand base. Manufacturers focus on delivering couplings with superior sealing and cooling systems to match the region’s environmental challenges. Expanding infrastructure and energy projects continue to create long-term growth potential.

Shape Your Report to Specific Countries or Regions & Enjoy 30% Off!

Key Player Analysis

- Haldex

- Voith

- Falk

- Wuxi Lianrong

- KTR Systems

- Demag

- Honeywell

- Burgaflex

- Danfoss

- Kang Jin

Competitive Analysis

The Fluid Coupling Market features a competitive landscape led by Voith, KTR Systems, Danfoss, Honeywell, Haldex, Demag, Falk, Burgaflex, Wuxi Lianrong, and Kang Jin, each leveraging distinct strengths to maintain market position. Voith holds a strong reputation for high-performance and durable coupling solutions tailored for heavy-duty applications in mining, power generation, and marine sectors. KTR Systems focuses on innovative designs and customized products, catering to specific operational needs across industrial machinery. Danfoss emphasizes energy-efficient technologies and integration of advanced monitoring features, aligning with industry trends toward sustainable operations. Honeywell leverages its broad industrial portfolio and technological expertise to deliver couplings with high reliability and precision performance. Haldex maintains a niche presence through specialized torque transmission products for targeted markets. Demag and Falk offer robust solutions for material handling and heavy equipment, supported by established global networks. Burgaflex, Wuxi Lianrong, and Kang Jin strengthen the market with cost-effective manufacturing and regional supply capabilities, enhancing availability and price competitiveness. Leading players invest in R&D, expand distribution channels, and pursue strategic partnerships to meet rising demand across diverse industries while addressing evolving performance, efficiency, and environmental requirements.

Recent Developments

- In July 2025, Burgaflex integrated Design Bending into its group. This new unit focuses on producing complex bent components for non‑fluid applications, expanding capabilities beyond their traditional fluid systems offerings

- In April 2025, Burgaflex participated in Bauma 2025 in Munich (April 7–13), where they showcased their latest developments across BMS (Bus Management Systems), TMS, HVAC systems, and next-gen technologies involving hydrogen, R290, CO₂, and water‑glycol applications.

- In April 2025, Danfoss Power Solutions launched the X1P family of open‑circuit piston pumps in April 2025. These pumps are built on the new X1 platform and target medium‑power mobile machinery, including skid steer loaders, compact excavators, and telehandlers.

Market Concentration & Characteristics

The Fluid Coupling Market demonstrates a moderately consolidated structure, with a mix of global leaders and regional manufacturers competing through technology, quality, and service capabilities. Large players such as Voith, KTR Systems, Danfoss, Honeywell, and Haldex dominate with advanced product portfolios, strong distribution networks, and established brand credibility. It is characterized by high product reliability requirements, as fluid couplings operate in demanding industrial, mining, marine, and power generation environments. The market emphasizes durability, torque control precision, and energy efficiency, driving continuous innovation in materials, sealing systems, and thermal performance. Regional manufacturers, particularly in Asia-Pacific, strengthen competition by offering cost-effective solutions and localized service support. Customers prioritize solutions that minimize downtime, extend equipment life, and integrate with modern monitoring technologies. Regulatory standards on energy efficiency and operational safety influence product development and adoption trends, ensuring that competitive advantage often depends on technological advancement, customization capabilities, and long-term maintenance performance

Report Coverage

The research report offers an in-depth analysis based on Type, Application, Coupling Operating Mechanism, Material Composition, Size and Geography. It details leading market players, providing an overview of their business, product offerings, investments, revenue streams, and key applications. Additionally, the report includes insights into the competitive environment, SWOT analysis, current market trends, as well as the primary drivers and constraints. Furthermore, it discusses various factors that have driven market expansion in recent years. The report also explores market dynamics, regulatory scenarios, and technological advancements that are shaping the industry. It assesses the impact of external factors and global economic changes on market growth. Lastly, it provides strategic recommendations for new entrants and established companies to navigate the complexities of the market.

Future Outlook

- The market will expand with increasing adoption of energy-efficient torque transmission systems in industrial applications.

- Demand will grow in renewable energy projects requiring reliable load control solutions.

- Manufacturers will focus on advanced materials to improve durability and reduce weight.

- Integration of smart monitoring and predictive maintenance features will become more common.

- Customized coupling designs will gain traction to meet specific industry needs.

- Asia-Pacific will remain the fastest-growing region due to rapid industrialization.

- Replacement and retrofit projects will drive sales in mature industrial markets.

- Competitive pressure will encourage continuous innovation in thermal and sealing technologies.

- Partnerships between global and regional players will strengthen supply chain capabilities.

- Sustainability initiatives will influence design priorities and product development strategies.