1. Introduction

1.1. Report Description

1.2. Purpose of the Report

1.3. USP & Key Offerings

1.4. Key Benefits for Stakeholders

1.5. Target Audience

1.6. Report Scope

1.7. Regional Scope

2. Scope and Methodology

2.1. Objectives of the Study

2.2. Stakeholders

2.3. Data Sources

2.3.1. Primary Sources

2.3.2. Secondary Sources

2.4. Market Estimation

2.4.1. Bottom-Up Approach

2.4.2. Top-Down Approach

2.5. Forecasting Methodology

3. Executive Summary

4. Introduction

4.1. Overview

4.2. Key Industry Trends

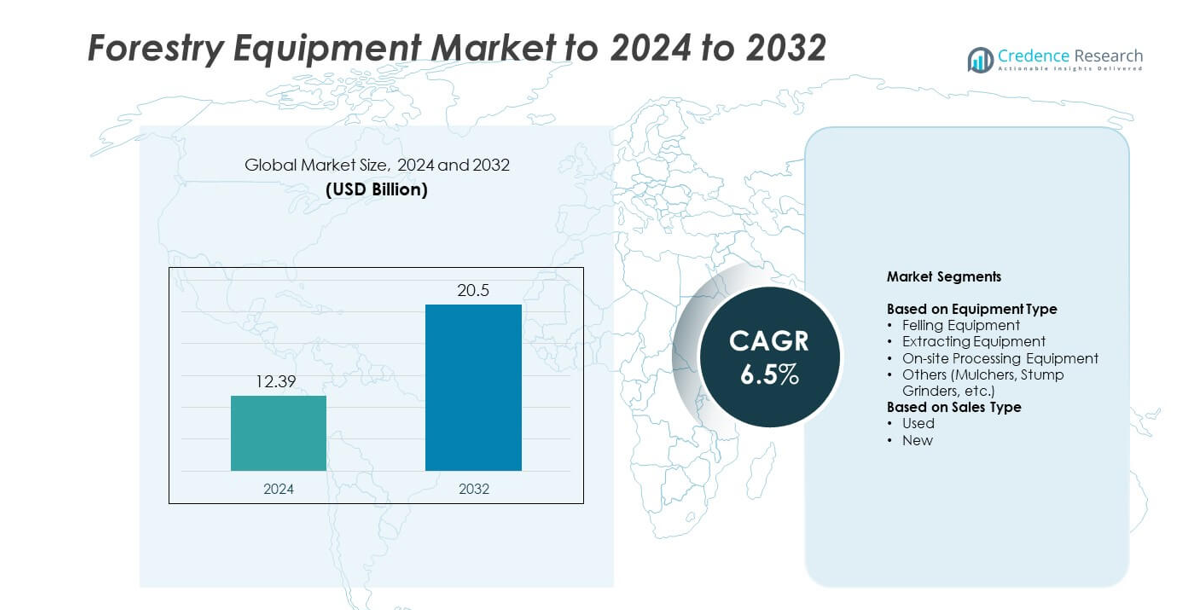

5. Global Forestry Equipment Market

5.1. Market Overview

5.2. Market Performance

5.3. Impact of COVID-19

5.4. Market Forecast

6. Market Breakup by Equipment Type

6.1. Felling Equipment

6.1.1. Market Trends

6.1.2. Market Forecast

6.1.3. Revenue Share

6.1.4. Revenue Growth Opportunity

6.2. Extracting Equipment

6.2.1. Market Trends

6.2.2. Market Forecast

6.2.3. Revenue Share

6.2.4. Revenue Growth Opportunity

6.3. On-site Processing Equipment

6.3.1. Market Trends

6.3.2. Market Forecast

6.3.3. Revenue Share

6.3.4. Revenue Growth Opportunity

6.4. Others (Mulchers, Stump Grinders, etc.)

6.4.1. Market Trends

6.4.2. Market Forecast

6.4.3. Revenue Share

6.4.4. Revenue Growth Opportunity

7. Market Breakup by Sales Type

7.1. Used

7.1.1. Market Trends

7.1.2. Market Forecast

7.1.3. Revenue Share

7.1.4. Revenue Growth Opportunity

7.2. New

7.2.1. Market Trends

7.2.2. Market Forecast

7.2.3. Revenue Share

7.2.4. Revenue Growth Opportunity

8. Market Breakup by Region

8.1. North America

8.1.1. United States

8.1.1.1. Market Trends

8.1.1.2. Market Forecast

8.1.2. Canada

8.1.2.1. Market Trends

8.1.2.2. Market Forecast

8.2. Asia-Pacific

8.2.1. China

8.2.2. Japan

8.2.3. India

8.2.4. South Korea

8.2.5. Australia

8.2.6. Indonesia

8.2.7. Others

8.3. Europe

8.3.1. Germany

8.3.2. France

8.3.3. United Kingdom

8.3.4. Italy

8.3.5. Spain

8.3.6. Russia

8.3.7. Others

8.4. Latin America

8.4.1. Brazil

8.4.2. Mexico

8.4.3. Others

8.5. Middle East and Africa

8.5.1. Market Trends

8.5.2. Market Breakup by Country

8.5.3. Market Forecast

9. SWOT Analysis

9.1. Overview

9.2. Strengths

9.3. Weaknesses

9.4. Opportunities

9.5. Threats

10. Value Chain Analysis

11. Porter’s Five Forces Analysis

11.1. Overview

11.2. Bargaining Power of Buyers

11.3. Bargaining Power of Suppliers

11.4. Degree of Competition

11.5. Threat of New Entrants

11.6. Threat of Substitutes

12. Price Analysis

13. Competitive Landscape

13.1. Market Structure

13.2. Key Players

13.3. Profiles of Key Players

13.3.1. Deere & Company (U.S.)

13.3.1.1. Company Overview

13.3.1.2. Product Portfolio

13.3.1.3. Financials

13.3.1.4. SWOT Analysis

13.3.2. Komatsu Ltd. (Japan)

13.3.2.1. Company Overview

13.3.2.2. Product Portfolio

13.3.2.3. Financials

13.3.2.4. SWOT Analysis

13.3.3. STIHL HOLDING AG & Co. KG (Germany)

13.3.3.1. Company Overview

13.3.3.2. Product Portfolio

13.3.3.3. Financials

13.3.3.4. SWOT Analysis

13.3.4. Tigercat International Inc. (Canada)

13.3.4.1. Company Overview

13.3.4.2. Product Portfolio

13.3.4.3. Financials

13.3.4.4. SWOT Analysis

13.3.5. Hitachi Construction Machinery Co. Ltd. (Japan)

13.3.5.1. Company Overview

13.3.5.2. Product Portfolio

13.3.5.3. Financials

13.3.5.4. SWOT Analysis

13.3.6. Ponsse Oyj (Finland)

13.3.6.1. Company Overview

13.3.6.2. Product Portfolio

13.3.6.3. Financials

13.3.6.4. SWOT Analysis

13.3.7. Vermeer Corporation (U.S.)

13.3.7.1. Company Overview

13.3.7.2. Product Portfolio

13.3.7.3. Financials

13.3.7.4. SWOT Analysis

13.3.8. Husqvarna Group (Sweden)

13.3.8.1. Company Overview

13.3.8.2. Product Portfolio

13.3.8.3. Financials

13.3.8.4. SWOT Analysis

13.3.9. MARUYAMA Mfg. Co., Inc. (Japan)

13.3.9.1. Company Overview

13.3.9.2. Product Portfolio

13.3.9.3. Financials

13.3.9.4. SWOT Analysis

13.3.10. J.C. Bamford Excavators Limited (U.K.)

13.3.10.1. Company Overview

13.3.10.2. Product Portfolio

13.3.10.3. Financials

13.3.10.4. SWOT Analysis

13.3.11. Logset Oy (Finland)

13.3.11.1. Company Overview

13.3.11.2. Product Portfolio

13.3.11.3. Financials

13.3.11.4. SWOT Analysis

13.3.12. Caterpillar Inc. (U.S.)

13.3.12.1. Company Overview

13.3.12.2. Product Portfolio

13.3.12.3. Financials

13.3.12.4. SWOT Analysis

13.3.13. Rottne Industri (Sweden)

13.3.13.1. Company Overview

13.3.13.2. Product Portfolio

13.3.13.3. Financials

13.3.13.4. SWOT Analysis

13.3.14. Yantai Lansu Co., Ltd. (China)

13.3.14.1. Company Overview

13.3.14.2. Product Portfolio

13.3.14.3. Financials

13.3.14.4. SWOT Analysis

13.3.15. Waratah (Canada)

13.3.15.1. Company Overview

13.3.15.2. Product Portfolio

13.3.15.3. Financials

13.3.15.4. SWOT Analysis

13.3.16. MOROOKA Co., Ltd. (Japan)

13.3.16.1. Company Overview

13.3.16.2. Product Portfolio

13.3.16.3. Financials

13.3.16.4. SWOT Analysis

14. Research Methodology