Market Overview:

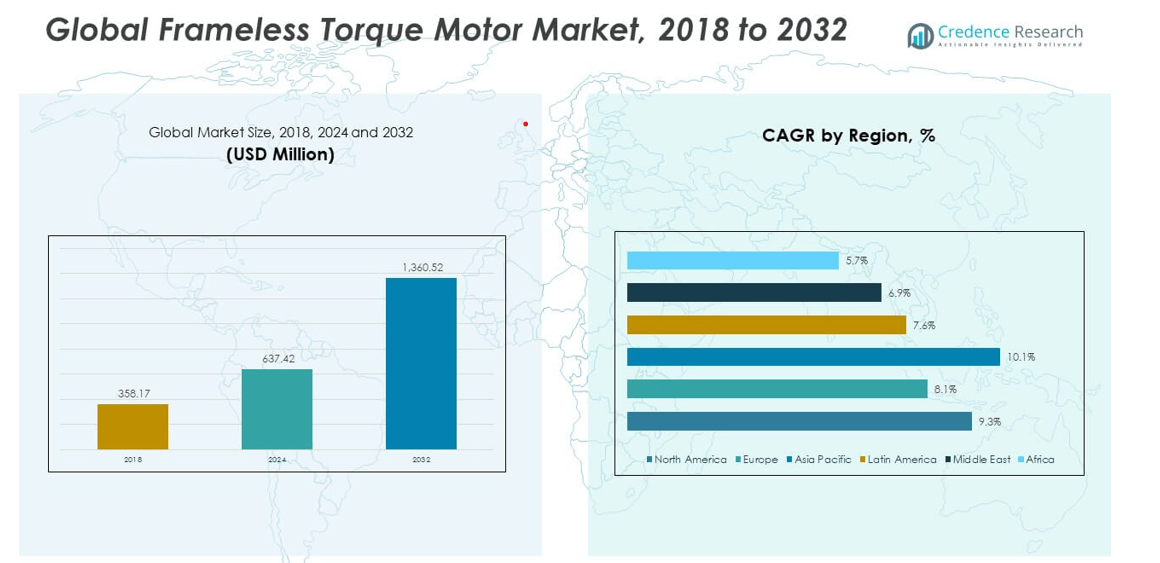

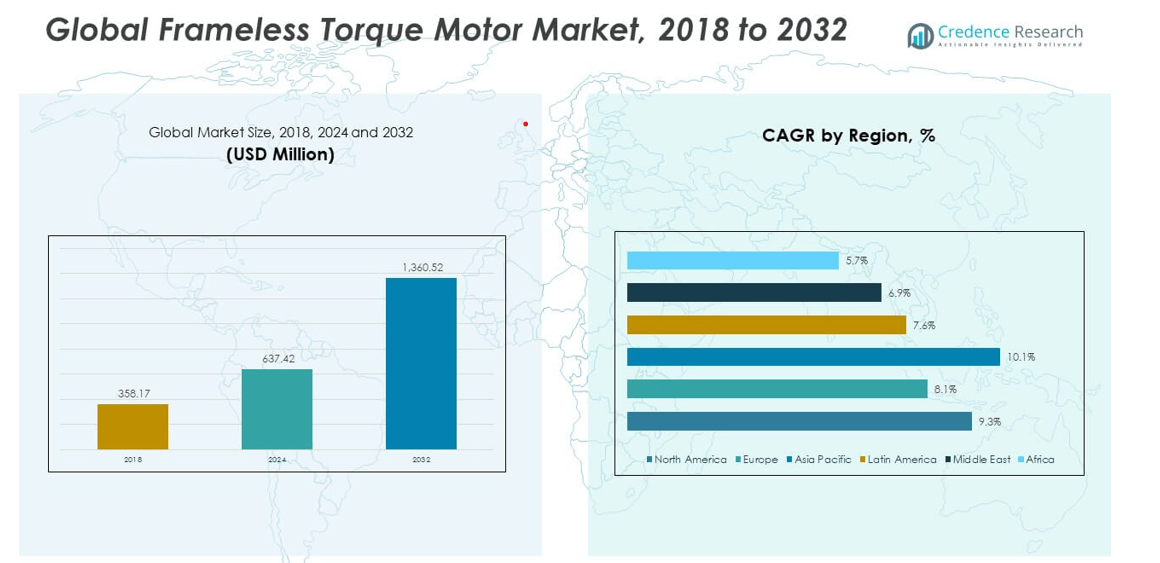

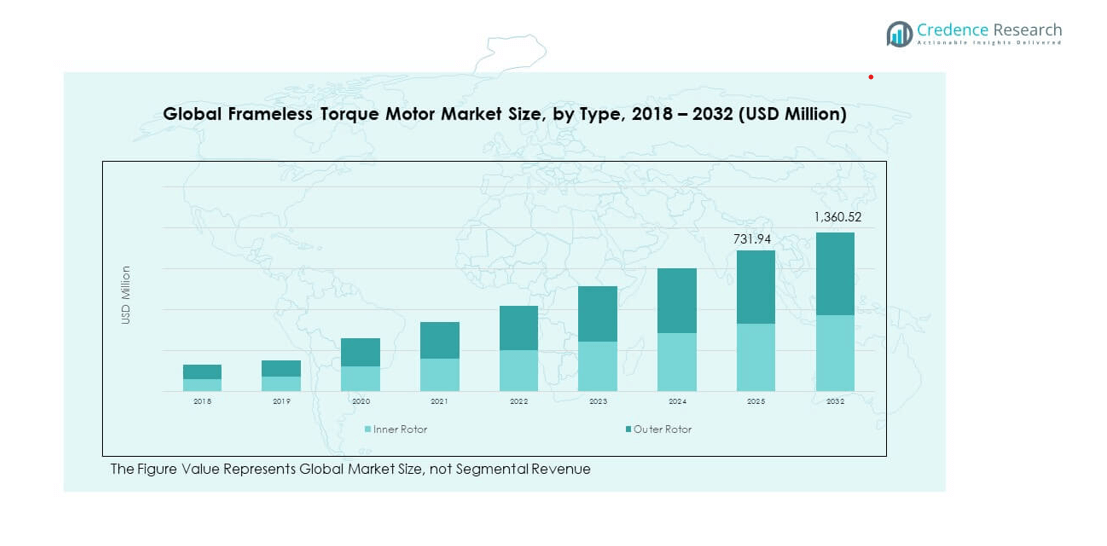

The Global Frameless Torque Motor Market size was valued at USD 358.17 million in 2018, increased to USD 637.42 million in 2024, and is anticipated to reach USD 1,360.52 million by 2032, at a CAGR of 9.26% during the forecast period.

| REPORT ATTRIBUTE |

DETAILS |

| Historical Period |

2020-2023 |

| Base Year |

2024 |

| Forecast Period |

2025-2032 |

| Frameless Torque Motor Market Size 2024 |

USD 637.42 million |

| Frameless Torque Motor Market, CAGR |

9.26% |

| Frameless Torque Motor Market Size 2032 |

USD 1,360.52 million |

The market is driven by the rising demand for compact, high-performance motion control solutions in robotics, aerospace, and industrial automation. Manufacturers prefer frameless torque motors for their high torque density, efficiency, and ability to integrate directly into mechanical systems. Growth in collaborative robots, electric vehicles, and precision machinery boosts adoption. The market benefits from increasing investment in automation technologies and the transition toward energy-efficient motor systems in manufacturing and defense sectors.

North America leads the global Frameless Torque Motor Market due to strong robotics adoption and advanced manufacturing infrastructure. Europe follows closely with significant contributions from Germany, France, and Italy driven by industrial modernization and automation initiatives. Asia-Pacific emerges as the fastest-growing region, fueled by rapid industrialization in China, South Korea, and Japan. Expanding automotive production, electronics assembly, and government support for smart factories enhance regional growth potential.

Market Insights:

- The Global Frameless Torque Motor Market was valued at USD 358.17 million in 2018, reached USD 637.42 million in 2024, and is projected to attain USD 1,360.52 million by 2032, growing at a CAGR of 9.26% during the forecast period.

- Asia Pacific dominates with a 38% share, driven by rapid industrialization, automation expansion, and high manufacturing output in China, Japan, and South Korea.

- North America holds about 27%, supported by strong automation in aerospace, defense, and industrial robotics, while Europe captures 21%, led by Germany, Italy, and France emphasizing energy-efficient technologies.

- Asia Pacific remains the fastest-growing region, driven by smart factory investments, government-backed automation programs, and expanding EV production across emerging economies.

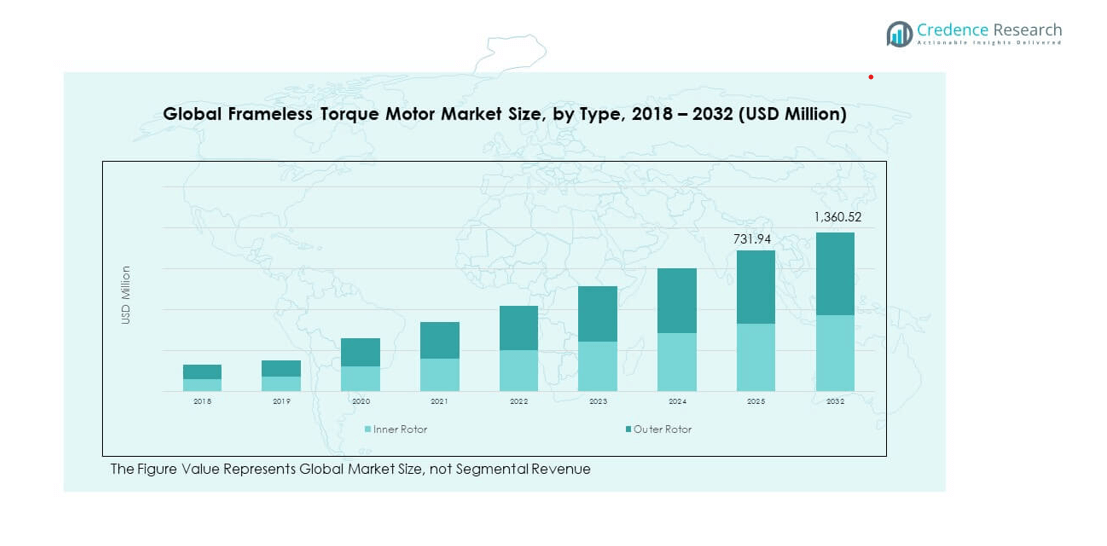

- Based on the chart, inner rotor motors account for nearly 65% of total market share due to higher torque density and precision applications, while outer rotor motors represent about 35%, used mainly in low-speed, high-torque systems.

Access crucial information at unmatched prices!

Request your sample report today & start making informed decisions powered by Credence Research Inc.!

Download Sample

Market Drivers:

Rising Demand for High-Precision Motion Control in Robotics and Automation

The Global Frameless Torque Motor Market experiences steady growth driven by automation across manufacturing and robotics. Industries seek compact, efficient, and high-torque solutions to support precise positioning and seamless motion control. These motors enable direct integration into robotic joints, reducing weight and mechanical losses. Adoption increases in industrial robots, cobots, and automated assembly systems. Precision and repeatability offered by frameless torque motors strengthen operational accuracy. Manufacturers in electronics and automotive sectors deploy these systems for consistent production output. The shift toward flexible production lines further supports their demand. High performance in limited space makes them ideal for modern automation needs.

- For instance, Allied Motion’ Megaflux™ series offers continuous stall torques up to 181 Nm in diameters up to 330 mm, enabling direct integration in robot joints. These motors enable direct integration into robotic joints, reducing weight and mechanical losses. Adoption increases in industrial robots, cobots, and automated assembly systems.

Expanding Adoption in Aerospace and Defense Applications

Aerospace manufacturers increasingly adopt frameless torque motors for advanced control in satellites, drones, and defense systems. The motors deliver reliability under extreme conditions while ensuring low noise and vibration. They support mission-critical tasks such as flight control, radar positioning, and satellite tracking. Lightweight construction enhances payload efficiency in space and aerial applications. The market benefits from government investments in unmanned aerial systems and precision-guided technologies. The motors’ adaptability to harsh environments supports growing demand across aviation platforms. The Global Frameless Torque Motor Market thrives due to rising aerospace projects focusing on compact electromechanical actuation. Enhanced performance standards continue to boost installations across high-end defense systems.

- For instance, NUM AG’ TMX series includes frameless torque motors with stator diameters of 140 mm and 291 mm, hollow-shaft rotors using NdFeB magnets, optimized for direct-drive machine tools.

Shift Toward Compact and Energy-Efficient Machinery Design

Manufacturers redesign mechanical systems to meet energy efficiency and compactness targets. Frameless torque motors contribute to these objectives by eliminating external housings and gear assemblies. Their direct-drive design minimizes energy loss and enhances responsiveness. Equipment makers integrate them into machine tools, packaging equipment, and robotic actuators for better efficiency. The design flexibility allows custom integration for specific applications. The trend aligns with sustainability goals, emphasizing reduced energy consumption in production units. The market’s progress accelerates with supportive regulations favoring low-emission technologies. The Global Frameless Torque Motor Market benefits from global initiatives targeting efficient industrial performance.

Technological Advancements in Motor Materials and Magnetic Systems

Continuous innovation in electromagnetic materials and coil configurations drives motor performance. Manufacturers adopt high-energy rare earth magnets to boost torque density and reduce size. Advanced thermal management systems improve heat dissipation, ensuring longer operational life. Enhanced control algorithms deliver smoother torque and higher stability under load fluctuations. Industry players invest in research to reduce cogging torque and enhance precision. The integration of advanced sensors enables better monitoring and predictive maintenance. These developments strengthen the reliability of frameless torque motors in complex automation systems. The Global Frameless Torque Motor Market gains traction with each step toward smarter and durable designs.

Market Trends:

Integration of Frameless Torque Motors in Collaborative Robots and Cobots

Collaborative robots continue transforming industrial operations through safe, flexible, and adaptive automation. Frameless torque motors provide the torque density and responsiveness required for joint actuation and smooth human–machine interaction. Their compact design supports lighter and more agile cobot configurations. Manufacturers emphasize torque accuracy to ensure safety during close human operation. The trend accelerates in sectors like electronics, healthcare, and logistics. Growth in small and mid-sized manufacturing units boosts adoption. Integration with smart sensors enhances feedback control and positioning accuracy. The Global Frameless Torque Motor Market evolves alongside rising cobot utilization worldwide.

- For instance, solutions leveraging frameless motor kits offer through-holes and compact form-factors enabling torque densities of 30–50 Nm/kg in humanoid robotics. Their compact design supports lighter and more agile cobot configurations.

Adoption of Direct Drive Technology in Machine Tools and Equipment

Direct drive integration improves precision, speed, and dynamic control in machine tools. Frameless torque motors allow spindle and rotary table actuation without belts or gears, reducing backlash and wear. This trend increases efficiency in CNC machining, semiconductor processing, and inspection systems. High stiffness and accuracy appeal to industries demanding micron-level precision. Manufacturers gain reduced maintenance needs and longer service life. Automation solution providers integrate these motors for smoother and quieter operations. The Global Frameless Torque Motor Market grows with expanding industrial preference for direct-drive machinery technology. This trend redefines performance benchmarks in high-end mechanical systems.

- For instance, in direct-drive systems using frameless motors, no-load speed and torque ranges are achieved without gearboxes, enhancing reliability and reducing downtime. This trend increases efficiency in CNC machining, semiconductor processing, and inspection systems. High stiffness and accuracy appeal to industries demanding micron-level precision.

Increasing Customization for Specialized Industry Applications

Industries demand tailored torque motor solutions suited to unique mechanical designs. Manufacturers respond with customizable rotor-stator configurations, mounting options, and torque ranges. Aerospace and defense sectors require motors with radiation-resistant materials and enhanced insulation. Robotics and semiconductor industries need lightweight, compact units with low inertia. Custom-engineered solutions strengthen OEM partnerships and increase production flexibility. Companies develop application-specific models to achieve seamless fit and high torque stability. The Global Frameless Torque Motor Market reflects this customization trend through growing client-specific engineering solutions. Innovation in design and modularity continues to shape competitive differentiation.

Rise of Smart Manufacturing and Industrial IoT Integration

Digital transformation reshapes industrial automation through connected systems and data-driven decision-making. Frameless torque motors integrated with IoT-enabled controllers enhance real-time monitoring and predictive analytics. Smart sensors collect torque, vibration, and temperature data for maintenance scheduling. Connectivity supports energy optimization and remote supervision across manufacturing networks. The shift toward Industry 4.0 fosters demand for intelligent motor solutions. Smart factories deploy such motors to increase uptime and throughput. The Global Frameless Torque Motor Market benefits from this convergence of hardware and digital intelligence. This trend advances operational visibility and long-term reliability.

Market Challenges Analysis:

High Manufacturing Costs and Complex Integration Requirements

Production of frameless torque motors involves advanced magnetic materials and precision machining, leading to high costs. Complex integration into OEM equipment requires specialized technical expertise and design modifications. Smaller manufacturers face challenges in sourcing high-grade components and maintaining tolerance accuracy. Limited standardization across applications adds to engineering complexity. The need for custom housings and rotor-stator alignment increases project timelines. These factors restrict adoption among cost-sensitive sectors and small enterprises. The Global Frameless Torque Motor Market encounters slower penetration in regions with limited automation budgets. It remains dependent on large-scale industries with strong R&D capacities.

Thermal Management and Performance Optimization Issues in High-Torque Applications

Operating frameless torque motors at high torque generates heat, affecting performance stability. Effective cooling systems are essential to avoid thermal expansion and demagnetization. Manufacturers invest in advanced insulation materials and heat dissipation designs to overcome these challenges. Inadequate thermal control limits lifespan and efficiency. Integration in compact assemblies complicates ventilation, demanding innovative design approaches. Variations in ambient conditions also impact reliability in outdoor or aerospace operations. Continuous testing and monitoring increase operational costs for end-users. The Global Frameless Torque Motor Market faces sustained R&D pressure to balance torque density with thermal reliability.

Market Opportunities:

Expansion of Robotics, Automation, and Electric Mobility Sectors

Rising investment in industrial automation, medical robotics, and electric vehicles presents major opportunities. Frameless torque motors deliver compact, efficient, and torque-rich performance suited for these dynamic sectors. Integration in autonomous systems and robotic arms enhances precision and reliability. Automotive electrification further fuels adoption in power steering, propulsion, and actuation systems. Manufacturers targeting multi-industry solutions stand to gain broader market access. The Global Frameless Torque Motor Market benefits from growing global initiatives favoring automated and sustainable production. Ongoing innovation ensures alignment with future mobility and robotic trends.

Emergence of Advanced Manufacturing and Additive Production Methods

Additive manufacturing supports cost-effective prototyping and complex motor designs. 3D printing enables lightweight components, improved heat management, and flexible geometries. Manufacturers leverage digital twins and simulation for efficient design validation. These innovations accelerate product development cycles and reduce material waste. Integration of such technologies enhances competitiveness and scalability across production lines. The Global Frameless Torque Motor Market gains momentum as manufacturing becomes more adaptive and digitally driven. The opportunity strengthens with increasing demand for agile production and localized supply chains.

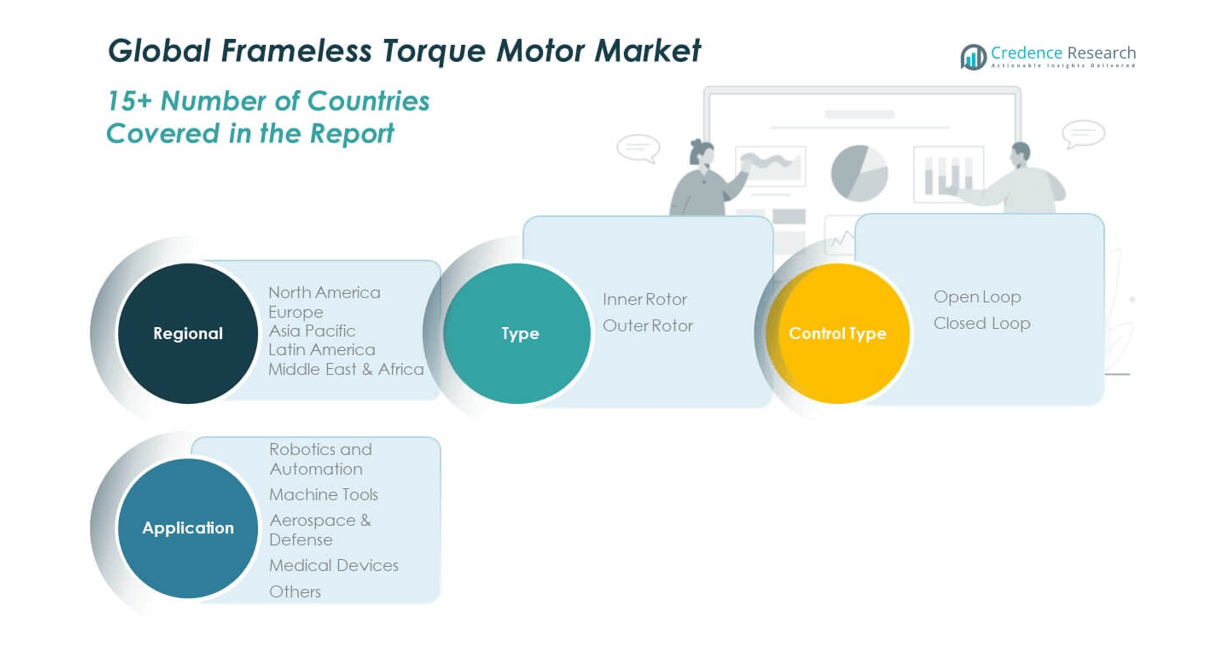

Market Segmentation Analysis:

By Type

The Global Frameless Torque Motor Market is segmented into inner rotor and outer rotor motors. Inner rotor motors dominate due to their high torque density, compact design, and efficiency in high-speed applications. These are widely used in robotics, automation, and precision machining systems where space optimization is critical. Outer rotor motors gain momentum in applications requiring stable torque at lower speeds. Their design ensures smoother performance and superior heat dissipation, making them ideal for heavy-duty and aerospace systems. Growing demand across industrial and defense sectors continues to enhance the adoption of both motor types.

- For instance, Sierra Motion offers frameless in-runner motors with stator outer diameters ranging from 38 mm up to 165 mm and rated torques from 0.17 N·m up to 6.16 N·m. These are widely used in robotics, automation, and precision machining systems where space optimization is critical. Outer rotor motors gain momentum in applications requiring stable torque at lower speeds.

By Control Type

The market is categorized into open loop and closed loop systems. Closed loop control holds a larger share due to its superior accuracy, real-time feedback, and torque regulation capabilities. Industries favor this type for advanced robotics and CNC machinery requiring high precision. Open loop systems remain relevant in cost-sensitive operations that need simple and reliable performance without complex feedback mechanisms. The Global Frameless Torque Motor Market benefits from the growing use of closed loop systems in modern automated and motion-control environments.

- For instance, basic frameless BLDC kits with brushless direct-drive construction can be deployed without encoders for fixed-speed or low-precision tasks. The Global Frameless Torque Motor Market benefits from the growing use of closed loop systems in modern automated and motion-control environments.

By Application

The market finds applications in robotics and automation, machine tools, aerospace and defense, medical devices, and others. Robotics and automation lead due to rising factory automation and collaborative robot deployment. Machine tools utilize frameless motors for high-speed spindles and rotary tables. Aerospace and defense integrate them in actuation and guidance systems. Medical devices adopt compact, low-vibration designs for imaging and surgical tools. Continuous innovation sustains broad application growth across industries.

Segmentation:

By Type

By Control Type

By Application

- Robotics and Automation

- Machine Tools

- Aerospace & Defense

- Medical Devices

- Others

By Region

- North America

- Europe

- Germany

- France

- U.K.

- Italy

- Spain

- Rest of Europe

- Asia Pacific

- China

- Japan

- India

- South Korea

- South-east Asia

- Rest of Asia Pacific

- Latin America

- Brazil

- Argentina

- Rest of Latin America

- Middle East & Africa

- GCC Countries

- South Africa

- Rest of the Middle East and Africa

Regional Analysis:

North America

The North America Frameless Torque Motor Market size was valued at USD 98.58 million in 2018, increased to USD 172.55 million in 2024, and is anticipated to reach USD 369.92 million by 2032, at a CAGR of 9.3% during the forecast period. North America holds around 27% of the global share, supported by strong automation adoption and advanced manufacturing systems. The U.S. leads regional growth through high integration of robotics and precision motion systems in industries such as aerospace, defense, and automotive. Key players invest in R&D to enhance torque density and thermal performance, fueling product innovation. Canada and Mexico contribute with expanding industrial automation and investments in energy-efficient systems. Favorable regulations and government incentives accelerate production efficiency upgrades. The Global Frameless Torque Motor Market benefits from continuous technological progress and high adoption across industrial and defense applications in North America.

Europe

The Europe Frameless Torque Motor Market size was valued at USD 75.70 million in 2018, reached USD 128.20 million in 2024, and is projected to attain USD 251.86 million by 2032, at a CAGR of 8.1%. Europe accounts for approximately 21% of the total market share. Germany, France, and Italy drive the region’s dominance with advanced automation and robotics industries. The region’s emphasis on industrial efficiency and energy conservation boosts motor adoption. European manufacturers integrate frameless torque motors into machine tools and aerospace systems for high precision and performance. Stringent environmental standards encourage compact, low-emission designs. R&D partnerships between industry and academic institutions further enhance innovation. The Global Frameless Torque Motor Market benefits from Europe’s engineering expertise and focus on sustainability-driven production.

Asia Pacific

The Asia Pacific Frameless Torque Motor Market size was valued at USD 152.70 million in 2018, grew to USD 282.04 million in 2024, and is forecasted to reach USD 639.61 million by 2032, expanding at a CAGR of 10.1%. The region holds the largest share, accounting for nearly 38% of the global market. China, Japan, and South Korea dominate due to robust manufacturing, automation, and electronics industries. The rapid rise of smart factories and government initiatives promoting industrial automation fuel strong demand. India and Southeast Asia show accelerating growth through investments in robotics and electric mobility. Expanding EV production and high-precision machining applications drive market expansion. The Global Frameless Torque Motor Market thrives in Asia Pacific, supported by rapid industrialization and widespread adoption of advanced motion systems.

Latin America

The Latin America Frameless Torque Motor Market size was valued at USD 16.52 million in 2018, reached USD 29.03 million in 2024, and is estimated to reach USD 54.66 million by 2032, registering a CAGR of 7.6%. The region represents about 6% of the global market. Brazil and Mexico lead in industrial automation, automotive assembly, and electronics manufacturing. Expanding production capacity and growing awareness of energy-efficient motors contribute to steady adoption. Government initiatives for industrial modernization and local manufacturing competitiveness support further development. The Global Frameless Torque Motor Market grows moderately in Latin America, driven by small and mid-sized enterprises upgrading automation technologies. The demand for compact, reliable motors is expected to strengthen regional adoption.

Middle East

The Middle East Frameless Torque Motor Market size was valued at USD 9.79 million in 2018, rose to USD 15.90 million in 2024, and is projected to reach USD 28.49 million by 2032, growing at a CAGR of 6.9%. The region captures about 4% of global market share. GCC countries lead adoption with strong investments in smart city infrastructure, renewable energy, and defense systems. Expanding aerospace programs and industrial automation projects create new opportunities. Manufacturers focus on integrating advanced torque motors into precision manufacturing and oilfield automation. Israel and Turkey show growing adoption in robotics and semiconductor industries. The Global Frameless Torque Motor Market maintains steady growth in the Middle East, supported by strategic diversification and industrial digitalization initiatives.

Africa

The Africa Frameless Torque Motor Market size was valued at USD 4.87 million in 2018, expanded to USD 9.71 million in 2024, and is projected to reach USD 15.98 million by 2032, at a CAGR of 5.7%. The region accounts for about 3% of the global market. South Africa leads adoption with manufacturing modernization and mining automation projects. Egypt and Nigeria experience gradual growth with investments in infrastructure and renewable energy sectors. Limited industrial automation infrastructure restrains faster adoption, yet awareness of energy-efficient solutions is improving. Partnerships with international technology firms help transfer innovation and manufacturing capabilities. The Global Frameless Torque Motor Market grows gradually across Africa, supported by emerging opportunities in mining, logistics, and renewable applications.

Shape Your Report to Specific Countries or Regions & Enjoy 30% Off!

Key Player Analysis:

- Kollmorgen

- Tecnotion

- ETEL

- Moog Inc.

- Parker Hannifin

- ABB Ltd.

- Allied Motion Technologies Inc.

- AMETEK Inc.

- Nidec Corporation

- Rockwell Automation Inc.

Competitive Analysis:

The Global Frameless Torque Motor Market is moderately consolidated, with competition driven by technology, performance, and customization capabilities. Leading companies such as Kollmorgen, Tecnotion, Moog Inc., ABB Ltd., and Parker Hannifin focus on developing high-torque, compact, and energy-efficient designs. It benefits from strategic collaborations between OEMs and automation solution providers. Manufacturers prioritize advancements in magnetic materials, cooling systems, and sensor integration to enhance product reliability. Competitive intensity remains high as players expand their global footprint through mergers, partnerships, and localized production facilities to meet growing automation demand.

Recent Developments:

- In September 2025, Tecnotion launched its QMT series torque motors, marking a substantial expansion of its direct drive portfolio. This product launch is confirmed on Tecnotion’s official website and through their public news releases, emphasizing improved mechanical compatibility and performance for machine tooling applications.

- In 2024, ETEL introduced the TMC torque motor series, offering up to 120% more torque in the same footprint as previous models and a significantly wider speed range. The TMC series rollout is verified by ETEL’s official product pages and technical documentation, which detail the models, core innovations, and direct drive suitability.

- In July 2022, Kollmorgen introduced the TBM2G series of robot-ready frameless servo motors, targeting collaborative, surgical, aerospace, and industrial robotics. The TBM2G line offers high-performance torque in a compact package, designed to lower joint weight and enhance energy efficiency. This launch is validated by multiple technical news portals and the company’s official statements.

Report Coverage:

The research report offers an in-depth analysis based on Type (Inner Rotor, Outer Rotor) and Control Type (Open Loop, Closed Loop). It details leading market players, providing an overview of their business, product offerings, investments, revenue streams, and key applications. Additionally, the report includes insights into the competitive environment, SWOT analysis, current market trends, as well as the primary drivers and constraints. Furthermore, it discusses various factors that have driven market expansion in recent years. The report also explores market dynamics, regulatory scenarios, and technological advancements that are shaping the industry. It assesses the impact of external factors and global economic changes on market growth. Lastly, it provides strategic recommendations for new entrants and established companies to navigate the complexities of the market.

Future Outlook:

- Growing demand for robotics and automation will continue driving adoption across industries.

- Integration with Industry 4.0 technologies will expand smart manufacturing applications.

- Advancements in magnetic materials and cooling systems will enhance motor efficiency.

- Increased customization will strengthen OEM partnerships and specialized designs.

- Electric mobility and aerospace sectors will create high-growth opportunities.

- Miniaturization trends will support compact system development in medical and defense uses.

- Sustainability goals will push for eco-efficient and low-power motor designs.

- Regional manufacturing expansion will reduce supply chain dependency.

- AI-based predictive maintenance will become standard in industrial systems.

- Rising investments in automation infrastructure will sustain long-term market momentum.