Market Overview:

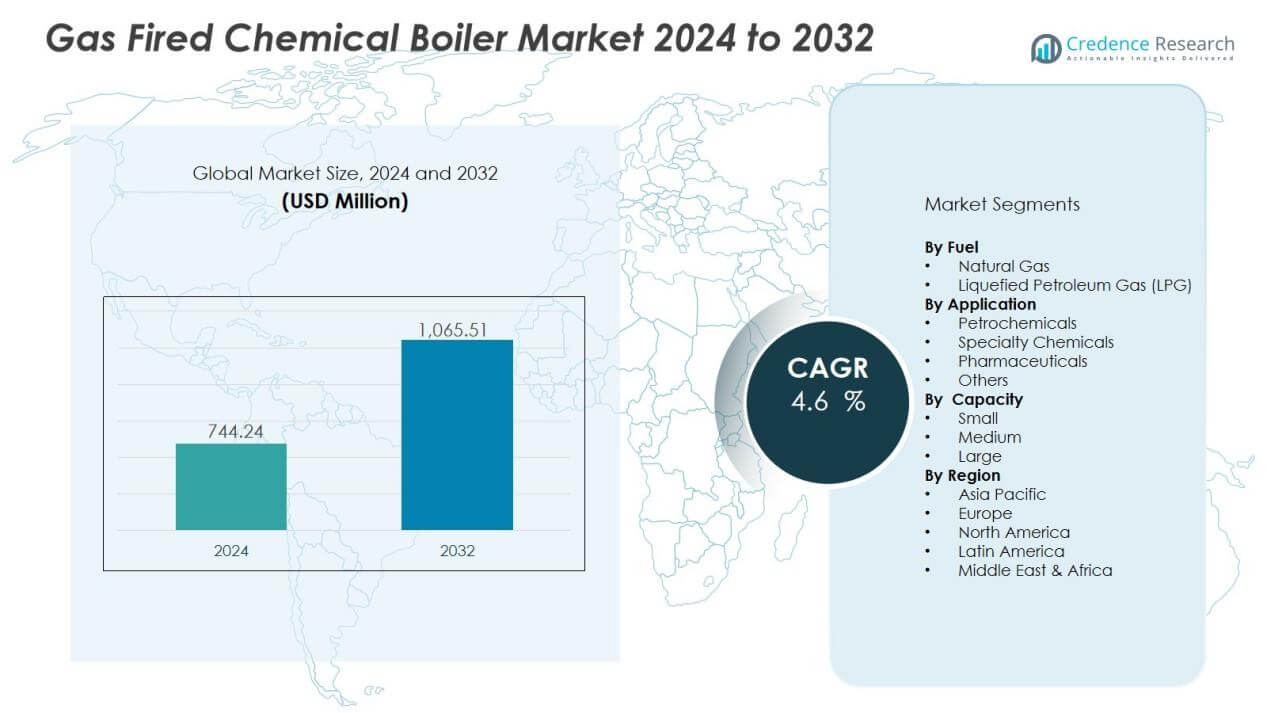

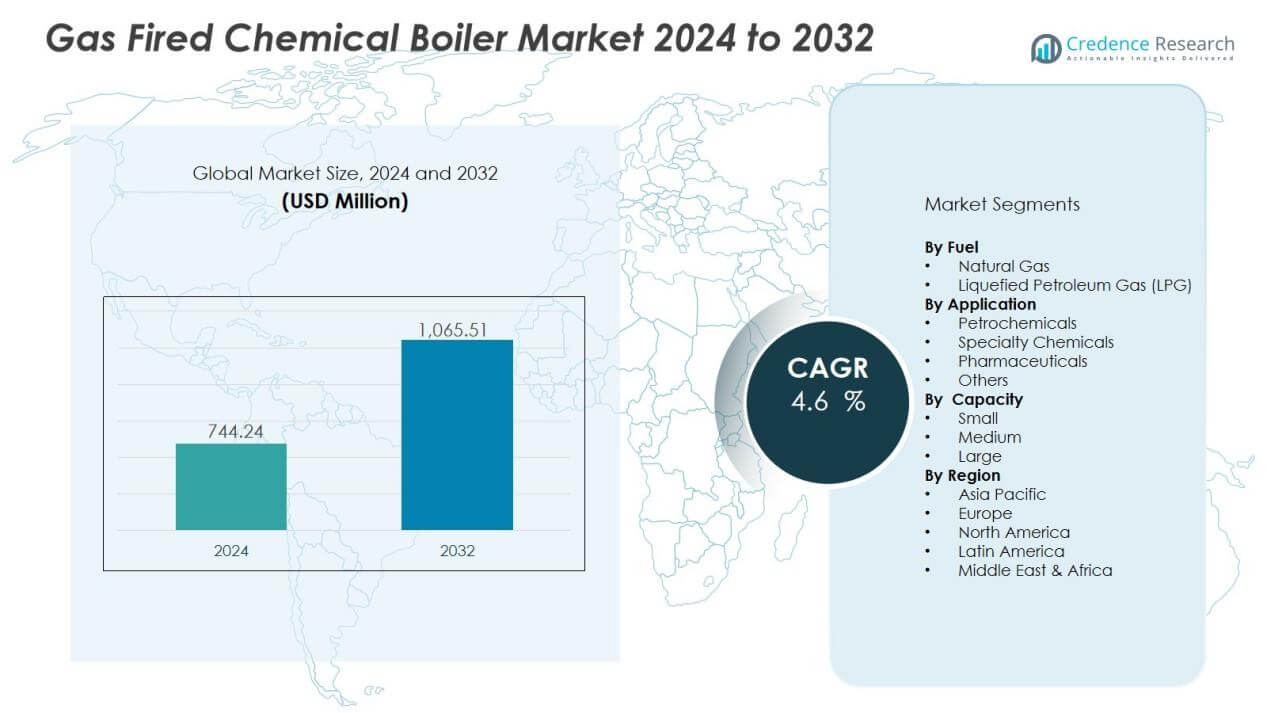

The gas fired chemical boiler market size was valued at USD 744.24 million in 2024 and is anticipated to reach USD 1,065.51 million by 2032, at a CAGR of 4.6 % during the forecast period (2024-2032).

| REPORT ATTRIBUTE |

DETAILS |

| Historical Period |

2020-2023 |

| Base Year |

2024 |

| Forecast Period |

2025-2032 |

| Gas Fired Chemical Boiler Market Size 2024 |

USD 744.24 Million |

| Gas Fired Chemical Boiler Market, CAGR |

4.6% |

| Gas Fired Chemical Boiler Market Size 2032 |

USD 1,065.51 Million |

Key drivers include rising energy consumption across chemical processing industries and strict environmental standards requiring cleaner fuel options. Gas fired boilers provide higher thermal efficiency, lower emissions compared to coal or oil, and reliable performance in large-scale operations. Expanding industrialization, combined with the need for reduced carbon footprints, is encouraging chemical manufacturers to adopt advanced boiler systems. Technological upgrades, such as integration with automation and smart monitoring systems, further strengthen adoption.

Regionally, Asia-Pacific dominates the market, driven by rapid chemical production growth in China, India, and Southeast Asia. North America follows, supported by modernization of industrial infrastructure and strict emission regulations. Europe maintains a notable share due to strong policies on energy efficiency and sustainability. Meanwhile, Latin America and the Middle East & Africa present emerging opportunities, fueled by expanding industrial bases and rising investments in chemical processing industries.

Market Insights:

- The gas fired chemical boiler market was valued at USD 744.24 million in 2024 and is expected to reach USD 1,065.51 million by 2032, growing at a CAGR of 4.6% during 2024–2032.

- Rising energy demand from chemical processing industries drives adoption, supported by the need for reliable steam generation and operational efficiency.

- Strict emission regulations and the push for cleaner fuel alternatives strengthen the market, with natural gas emerging as the preferred choice over coal and oil.

- Technological advancements such as automation, smart monitoring, and predictive maintenance enhance efficiency and extend boiler lifespan.

- Asia-Pacific held 41% share in 2024, led by China, India, and Southeast Asia with rapid industrialization and government-backed clean energy initiatives.

- North America accounted for 27% share, supported by modernization of chemical plants, replacement of older systems, and strong regulatory frameworks.

- Europe captured 21% share, shaped by the EU’s energy transition policies and high adoption of energy-efficient systems across Germany, France, and the U.K.

Access crucial information at unmatched prices!

Request your sample report today & start making informed decisions powered by Credence Research Inc.!

Download Sample

Market Drivers:

Rising Energy Demand Across the Chemical Industry:

The chemical industry continues to expand globally, increasing the need for reliable and efficient steam generation. Gas fired boilers serve this demand by offering stable output and consistent performance across varied chemical processes. The gas fired chemical boiler market benefits from the steady growth of chemical manufacturing hubs in Asia-Pacific and other emerging regions. It supports industries requiring continuous heating, distillation, and processing applications.

- For Instance, Thermax Onsite Energy Solutions Limited (TOESL), a subsidiary of Thermax, announced the commissioning of a biomass-based steam plant in Dahej, Gujarat. The plant was built for the Thermax Chemical division, not BASF India. Delivering 8 tons of steam per hour, the boiler is fueled by agro-waste to support the company’s own manufacturing processes

Stricter Emission Regulations and Cleaner Fuel Preference:

Governments worldwide enforce regulations targeting reduced greenhouse gas emissions and improved energy efficiency. Gas fired boilers align with these regulations, producing fewer emissions compared to coal or oil-based alternatives. The gas fired chemical boiler market gains momentum from industries seeking to meet compliance standards without sacrificing operational efficiency. It positions natural gas as a preferred fuel choice for chemical manufacturers focused on sustainability.

- For instance, DuPont’s Spruance facility in Virginia converted from coal to natural gas with Veolia, reducing greenhouse gas emissions by over 100,000 metric tons of CO2e per year and improving boiler heat rate efficiency by 40%.

Technological Advancements and Integration of Smart Systems:

Manufacturers are introducing advanced boiler designs with automation, remote monitoring, and predictive maintenance features. These innovations enhance performance, reduce downtime, and extend system lifespan. The gas fired chemical boiler market experiences growth as industries prioritize solutions that combine efficiency with modern digital capabilities. It ensures higher reliability in large-scale chemical production facilities that demand continuous operation.

Growing Industrialization in Emerging Economies:

Rapid industrialization in regions such as Asia-Pacific, Latin America, and the Middle East accelerates adoption of gas fired boilers. Expanding chemical and allied industries require efficient energy solutions to sustain production growth. The gas fired chemical boiler market benefits from investments in infrastructure and energy projects within these developing economies. It strengthens its position as an essential component of industrial growth strategies in these regions.

Market Trends:

Market Trends:

Increasing Shift Toward Energy Efficiency and Low-Emission Technologies:

Industries are prioritizing boilers that combine high efficiency with low environmental impact. Manufacturers are focusing on advanced combustion technologies that reduce fuel consumption and emissions while maintaining output. The gas fired chemical boiler market reflects this trend, with companies investing in models that meet stricter environmental standards. It aligns with global sustainability goals and supports industries under pressure to minimize carbon footprints. Demand is further supported by government incentives encouraging cleaner industrial energy systems. This trend strengthens the long-term position of gas fired boilers against alternative fuel options.

- For Instance, The Bosch UL-S steam boiler series is presented as a highly efficient model capable of achieving very high efficiency with optional equipment like an integrated economizer. It is designed for applications such as industrial chemical plants, offers particularly low emissions of less than 50 mg NOₓ, and can be adapted to run on climate-neutral fuels like hydrogen.

Rising Integration of Automation and Smart Monitoring Systems:

The adoption of automation and digital monitoring tools is becoming a defining trend in industrial boiler operations. Advanced systems enable real-time tracking, predictive maintenance, and improved energy management. The gas fired chemical boiler market benefits from this shift, as industries seek to reduce downtime and optimize production costs. It allows operators to achieve greater reliability and safety in chemical processing environments. Remote monitoring also ensures compliance with regulatory requirements while enhancing overall efficiency. Growing investment in Industry 4.0 technologies accelerates this trend and creates opportunities for advanced boiler solutions.

- For instance, Miura’s BL Micro Controller Boiler Control System provides continuous monitoring of 11 different boiler management parameters including steam pressure, flue gas temperature, water conductivity, and flame current.

Market Challenges Analysis:

High Operational Costs and Dependence on Natural Gas Prices:

The gas fired chemical boiler market faces challenges due to fluctuating natural gas prices. Volatile fuel costs increase operational expenses and limit profitability for chemical manufacturers. It creates uncertainty in long-term planning for industries heavily dependent on energy-intensive processes. High maintenance and servicing costs further add to the burden, especially for older boiler models. Companies must balance efficiency gains with rising expenses to remain competitive. This challenge restrains adoption in price-sensitive regions and smaller chemical facilities.

Stringent Regulations and Rising Competition from Alternatives:

Governments are enforcing strict emission rules that increase compliance costs for boiler operators. The gas fired chemical boiler market must adapt to evolving standards while maintaining cost-effectiveness. It also faces competition from renewable energy and electric boiler technologies that align with sustainability goals. Growing focus on hydrogen-based systems and biofuel alternatives creates pressure on gas-fired solutions. Industries evaluating long-term strategies may shift toward cleaner options with lower regulatory risks. These factors collectively slow down adoption in markets moving aggressively toward decarbonization.

Market Opportunities:

Expanding Demand in Emerging Industrial Economies:

Rapid growth of chemical production in Asia-Pacific, Latin America, and the Middle East creates significant opportunities for boiler manufacturers. Expanding industrial facilities require reliable energy systems to sustain high-volume operations. The gas fired chemical boiler market benefits from these developments by offering efficient and scalable solutions. It positions natural gas as a cost-effective alternative to coal or oil in regions with increasing environmental concerns. Government-backed infrastructure projects and industrial investments further drive adoption. These factors open long-term growth avenues for boiler suppliers targeting developing economies.

Innovation in Clean Technologies and Hybrid Systems:

Ongoing research into cleaner combustion systems and integration of hybrid energy solutions presents strong opportunities. The gas fired chemical boiler market can leverage advances in automation, digital monitoring, and low-NOx burners to strengthen efficiency. It enables industries to meet emission norms while reducing operating costs. Partnerships between technology providers and boiler manufacturers enhance the scope for product innovation. Rising adoption of smart energy systems in chemical facilities supports this trend. Market participants that adapt early to such innovations can capture competitive advantages in global markets.

Market Segmentation Analysis:

By Fuel:

The gas fired chemical boiler market is segmented by natural gas and liquefied petroleum gas (LPG). Natural gas dominates due to its cost-effectiveness, high availability, and lower emission profile compared to other fuels. LPG finds application in areas with limited pipeline access, supporting chemical facilities in remote or smaller regions. It strengthens adoption in industries requiring flexible energy solutions. Demand for natural gas-based boilers continues to rise in countries investing in clean energy policies. It remains the preferred option for large-scale industrial users seeking efficiency and compliance.

- For instance, BASF’s Geismar facility operates conventional boilers producing superheated steam at 615 psig, where moving 60,000 lb/hr of steam production from conventional boilers to their HRSG resulted in annual fuel savings of $195,000 with an 8% efficiency advantage.

By Capacity:

Capacity segments include small, medium, and large boilers catering to varied industrial requirements. Large-capacity boilers dominate chemical production plants that operate continuous, high-volume processes. Medium capacity units serve mid-sized facilities with balanced output and efficiency needs. The gas fired chemical boiler market also benefits from small boilers adopted by specialty chemical producers and laboratories. It ensures energy flexibility and cost optimization across different operational scales. Regional demand varies, with Asia-Pacific favoring large-scale boilers and developed markets adopting diverse capacities.

- For Instance, INEOS’s Project ONE ethane cracker in Antwerp received million worth of furnaces in 2025, each weighing 6,000 tons and measuring 60 meters high to support large-scale ethylene production of 1.45 million tons annually

By Application:

Key applications span across petrochemicals, specialty chemicals, pharmaceuticals, and allied industries. Petrochemicals hold a leading share as they require consistent and high-pressure steam supply. Specialty chemicals and pharmaceuticals adopt boilers for heating, distillation, and process efficiency. The gas fired chemical boiler market benefits from expanding downstream chemical industries worldwide. It supports production processes that demand uninterrupted and reliable energy sources. Demand from diverse applications enhances its long-term growth prospects in global markets.

Segmentations:

By Fuel:

- Natural Gas

- Liquefied Petroleum Gas (LPG)

By Capacity:

By Application:

- Petrochemicals

- Specialty Chemicals

- Pharmaceuticals

- Others

By Region:

- North America

- Europe

- Germany

- France

- U.K.

- Italy

- Spain

- Rest of Europe

- Asia Pacific

- China

- Japan

- India

- South Korea

- South-east Asia

- Rest of Asia Pacific

- Latin America

- Brazil

- Argentina

- Rest of Latin America

- Middle East & Africa

- GCC Countries

- South Africa

- Rest of the Middle East and Africa

Regional Analysis:

Asia-Pacific:

Asia-Pacific held 41% market share in 2024, making it the leading regional market. China, India, and Southeast Asia drive demand with rapid industrialization and expansion of chemical production hubs. The gas fired chemical boiler market in this region grows on the back of supportive government initiatives and abundant natural gas availability. It benefits from large-scale infrastructure projects and rising investment in energy-efficient technologies. Industrial clusters in China and India contribute significantly to adoption across chemical manufacturing. Local and international players continue to expand presence through joint ventures and supply agreements.

North America:

North America accounted for 27% market share in 2024, supported by strong chemical and petrochemical industries. The U.S. dominates the region with modernization of industrial infrastructure and emphasis on cleaner energy systems. The gas fired chemical boiler market benefits from strict regulatory frameworks promoting low-emission technologies. It also gains traction from replacement demand as industries upgrade older coal-based systems. Canada and Mexico contribute through growing investments in chemical and allied industries. The presence of advanced manufacturing facilities further supports steady expansion across the region.

Europe:

Europe recorded 21% market share in 2024, reflecting strong sustainability-focused policies and advanced chemical industries. Germany, France, and the U.K. lead demand with strict emission norms and preference for natural gas-based systems. The gas fired chemical boiler market in Europe is shaped by the EU’s energy transition policies and industry-specific emission regulations. It benefits from technological innovation and high adoption of smart energy solutions. Southern and Eastern Europe also show growth potential as industries expand chemical production capacities. It remains an important region for premium and high-efficiency boiler solutions.

Shape Your Report to Specific Countries or Regions & Enjoy 30% Off!

Key Player Analysis:

- Fulton

- CleaverBrooks

- Weil-McLain

- Yamazaki Machinery Works, Ltd

- Zhejiang Sanhua Boiler Group Co., Ltd

- Bosch Industriekessel GmbH

- Clayton Industries

- Miura Boiler Co., Ltd

- PowerFlame

- Zhuhai Huayi Boiler Co., Ltd

- Cochran

- Babcock Wilcox Enterprises

Competitive Analysis:

The gas fired chemical boiler market is characterized by strong competition among global and regional players. Key companies include Fulton, CleaverBrooks, Weil-McLain, Yamazaki Machinery Works, Ltd, Zhejiang Sanhua Boiler Group Co., Ltd, Bosch Industriekessel GmbH, Clayton Industries, Miura Boiler Co., Ltd, PowerFlame, and Zhuhai Huayi Boiler Co., Ltd. These companies focus on expanding product portfolios with energy-efficient and low-emission boiler systems tailored for chemical applications. It emphasizes technological innovation, with firms investing in automation, digital monitoring, and smart control solutions to enhance reliability and efficiency. Strategic collaborations, mergers, and distribution partnerships help players strengthen their market presence globally. Regional manufacturers gain traction in emerging economies by offering cost-effective solutions aligned with local energy requirements. Competitive intensity remains high, with leading companies differentiating through quality, compliance with emission standards, and after-sales service networks that ensure long-term customer loyalty.

Recent Developments:

- In April 2025, Zhejiang Sanhua introduced innovative products such as the R290 brazed plate heat exchanger and energy-efficient HVAC solutions at the China Refrigeration Expo.

- In July 2025, Bosch Industriekessel GmbH completed the acquisition of Johnson Controls’ residential and light commercial HVAC business, nearly doubling its Home Comfort division revenue and workforce.

Report Coverage:

The research report offers an in-depth analysis based on Fuel, Capacity, Application and Region. It details leading Market players, providing an overview of their business, product offerings, investments, revenue streams, and key applications. Additionally, the report includes insights into the competitive environment, SWOT analysis, current Market trends, as well as the primary drivers and constraints. Furthermore, it discusses various factors that have driven Market expansion in recent years. The report also explores Market dynamics, regulatory scenarios, and technological advancements that are shaping the industry. It assesses the impact of external factors and global economic changes on Market growth. Lastly, it provides strategic recommendations for new entrants and established companies to navigate the complexities of the Market.

Future Outlook:

- The gas fired chemical boiler market will see strong adoption in Asia-Pacific as industrialization accelerates.

- It will experience steady demand in North America, supported by modernization of chemical processing facilities.

- Europe will continue to focus on energy-efficient gas fired boilers aligned with strict sustainability targets.

- Latin America and the Middle East & Africa will emerge as attractive regions due to rising chemical output.

- Technological innovation in automation, low-NOx burners, and hybrid systems will enhance competitiveness.

- It will benefit from growing demand for cleaner fuel alternatives over coal and oil-based boilers.

- Integration of digital monitoring and predictive maintenance will improve operational efficiency for end users.

- Stricter regulatory norms worldwide will push industries toward adopting advanced low-emission boiler models.

- Partnerships between boiler manufacturers and energy solution providers will expand global market reach.

- It will remain a critical component for chemical manufacturers seeking reliable and efficient steam generation.

Market Trends:

Market Trends: