Market Overview:

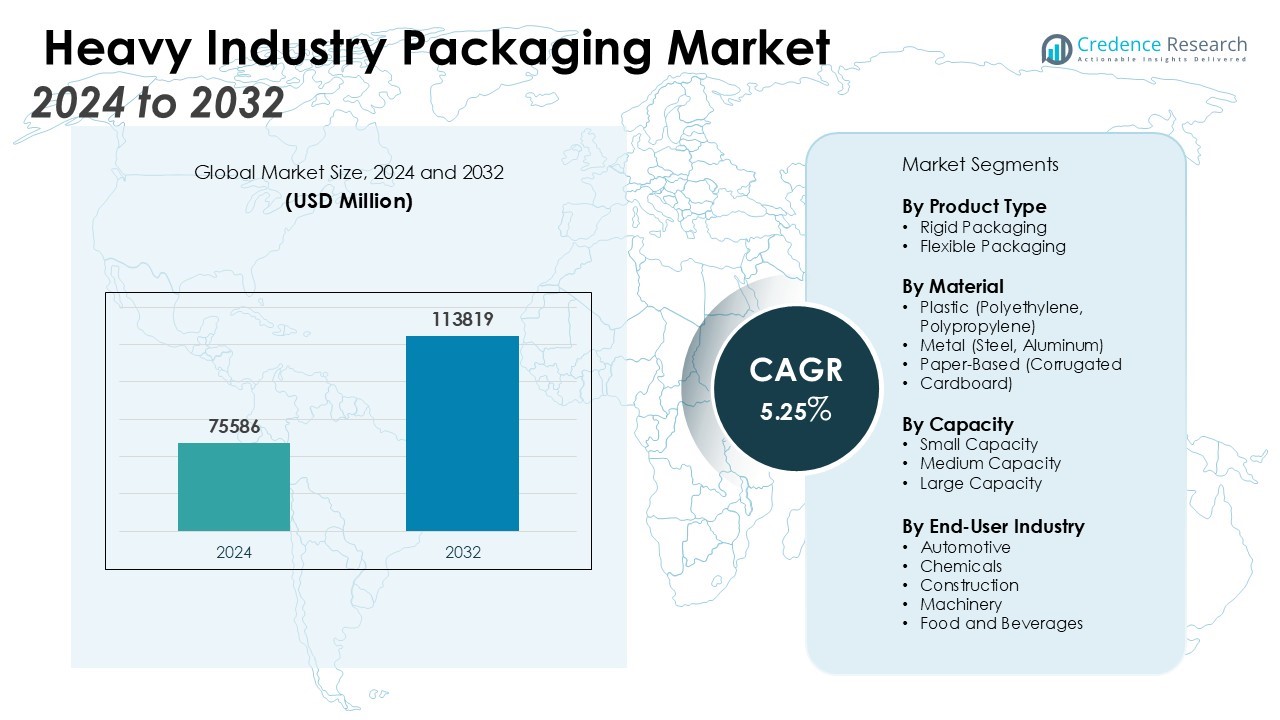

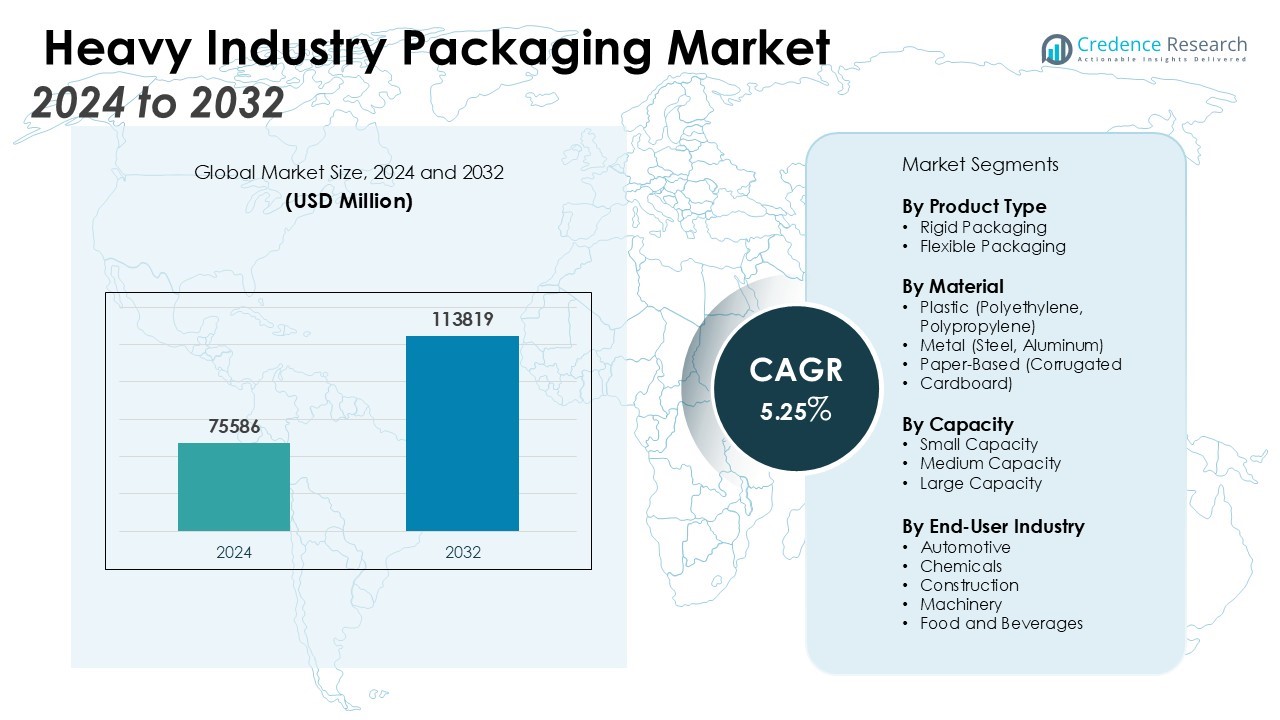

The Heavy Industry Packaging Market size was valued at USD 75586 million in 2024 and is anticipated to reach USD 113819 million by 2032, at a CAGR of 5.25% during the forecast period (2024-2032).

| REPORT ATTRIBUTE |

DETAILS |

| Historical Period |

2020-2024 |

| Base Year |

2024 |

| Forecast Period |

2025-2032 |

| Heavy Industry Packaging Market Size 2024 |

USD 75586 Million |

| Heavy Industry Packaging Market, CAGR |

5.25% |

| Heavy Industry Packaging Market Size 2032 |

USD 113819 Million |

Key drivers fueling the market include the rising need for sustainable packaging solutions, innovations in packaging materials such as recyclable plastics and corrugated boxes, and the demand for cost-effective packaging solutions that reduce waste and improve logistics efficiency. Additionally, advancements in automated packaging systems, driven by technological developments, are enhancing packaging speeds and reducing labor costs, further supporting market expansion. The focus on circular economy principles is also prompting companies to prioritize packaging recyclability and reuse, aligning with global environmental goals.

Geographically, North America and Europe hold dominant market shares due to the well-established industrial sectors and stringent regulations around packaging sustainability. However, the Asia-Pacific region is anticipated to witness the highest growth rate, driven by rapid industrialization, growing manufacturing capabilities, and expanding demand from emerging economies like China and India. This region is increasingly adopting sustainable packaging practices and witnessing a surge in infrastructure development, contributing to the rise in heavy industry packaging requirements. The growing e-commerce sector in this region further accelerates demand for efficient packaging solutions.

Access crucial information at unmatched prices!

Request your sample report today & start making informed decisions powered by Credence Research Inc.!

Download Sample

Market Insights:

- The Heavy Industry Packaging Market was valued at USD 75,586 million in 2024 and is expected to reach USD 113,819 million by 2032, growing at a CAGR of 5.25%. This growth is driven by increasing demand for durable, cost-effective, and sustainable packaging solutions.

- Rising demand for sustainable packaging is a key driver, with companies adopting recyclable plastics and biodegradable materials to reduce carbon footprints and meet environmental regulations.

- Technological advancements, including impact-resistant plastics and multi-layered films, are enhancing durability and protection, supporting the growth of the market.

- The Asia-Pacific region is expected to experience the highest growth due to rapid industrialization and increasing demand from emerging economies like China and India.

- High raw material and manufacturing costs pose challenges, with fluctuating prices for plastics and metals impacting production costs and market competitiveness.

- Regulatory compliance for sustainability adds complexity to packaging manufacturing, increasing innovation and operational costs.

- North America holds 35% of the market, Europe 30%, and Asia-Pacific 25%, with Asia-Pacific poised for the highest growth.

Market Drivers:

Increasing Demand for Sustainable Packaging Solutions

The growing emphasis on environmental sustainability is one of the key drivers of the Heavy Industry Packaging Market. Companies are under increasing pressure to adopt eco-friendly packaging solutions due to stringent regulations and rising consumer expectations. The shift towards recyclable and biodegradable packaging materials, such as corrugated cardboard and recycled plastics, aligns with global sustainability efforts. This shift not only reduces the carbon footprint but also meets regulatory requirements, contributing to the market’s growth.

Technological Advancements in Packaging Materials

Innovation in packaging materials is another important driver for the Heavy Industry Packaging Market. The development of high-strength, lightweight materials has enabled packaging solutions to withstand the demands of heavy industry logistics while reducing weight and material costs. Advanced materials such as impact-resistant plastics and multi-layered films enhance durability and provide superior protection for heavy and sensitive goods during transit. These innovations drive efficiency and cost-effectiveness in packaging, making it a preferred choice in various industrial sectors.

- For instance, Mondi’s triple-wall corrugated board boxes are designed to safely transport loads of up to 1,000kg per container for shipping engines or gear units, providing a lightweight solution compared to traditional wood or metal crates.

Demand for Cost-Effective and Efficient Packaging

The need for cost-effective packaging solutions that streamline logistics and reduce operational costs plays a crucial role in the market’s expansion. Heavy industries such as automotive, construction, and chemicals require packaging that ensures safety and efficiency during transportation and storage. Packaging solutions that minimize waste, reduce material usage, and optimize space contribute to overall cost savings. The market benefits from packaging systems that enhance operational efficiency, enabling businesses to achieve faster production and reduced overhead costs.

- For instance, Kao has made available 423 refill products as of December 2023, supporting the shift to refillable packaging formats across its household and personal care product lines.

Rising E-Commerce and Industrial Growth in Emerging Markets

The Heavy Industry Packaging Market is also fueled by the rapid industrialization and expanding e-commerce sectors in emerging markets like Asia-Pacific, particularly China and India. The increasing demand for goods in bulk and the rise of international trade create a need for packaging that supports large-scale logistics operations. These regions are investing heavily in infrastructure and manufacturing capabilities, further accelerating the demand for durable, secure, and sustainable packaging solutions. The shift towards online retail and consumer demand for timely delivery further emphasizes the need for efficient and reliable packaging.

Market Trends:

Adoption of Smart Packaging Solutions

One of the key trends in the Heavy Industry Packaging Market is the adoption of smart packaging technologies. These solutions incorporate features such as RFID tags, sensors, and QR codes to improve inventory management, tracking, and traceability of heavy industrial goods. These innovations allow for real-time monitoring of product conditions, such as temperature, humidity, and shock, ensuring the safe delivery of sensitive or perishable items. By providing greater transparency and control over the supply chain, smart packaging enhances logistics efficiency, reduces losses, and improves overall customer satisfaction. Companies in the market are increasingly investing in smart packaging to meet the growing demand for automated, data-driven operations in industries like automotive, construction, and chemicals.

- For instance, Siemens equipped 2,000 transport containers with SIMATIC RFID transponders in its industrial automation divisions, enabling fully automated materials handling and digitalization across two major European manufacturing facilities.

Growing Focus on Sustainability and Circular Economy

Another significant trend shaping the Heavy Industry Packaging Market is the growing emphasis on sustainability and the circular economy. Companies are actively exploring ways to reduce packaging waste and use recycled, biodegradable, or recyclable materials to minimize their environmental impact. Packaging solutions are increasingly designed to be reusable, reducing the need for single-use plastics and promoting a more sustainable packaging lifecycle. This trend is supported by stricter regulations and consumer preferences for eco-friendly products, driving manufacturers to innovate in sustainable packaging technologies. The shift towards sustainable packaging solutions is not only driven by environmental considerations but also by the need to reduce long-term operational costs related to waste disposal and material sourcing.

- For instance, Mauser Packaging Solutions operates “Recover Syst-M”, a global collection and reconditioning network that gives new life to tens of millions of IBCs and plastic and steel drums annually, with its reuse program helping customers avoid more than 1.5 million metric tons of carbon emissions in 2019 alone.

Market Challenges Analysis:

High Cost of Raw Materials and Manufacturing

A significant challenge for the Heavy Industry Packaging Market is the high cost of raw materials and manufacturing processes. The packaging industry heavily relies on materials such as plastic, metals, and specialized corrugated boards, all of which have seen price increases due to global supply chain disruptions and rising raw material costs. These price fluctuations affect the overall production costs, limiting the ability of manufacturers to offer affordable packaging solutions. This cost pressure often results in higher prices for end consumers, making it difficult for companies to balance profitability with market competitiveness. The need for investment in more advanced manufacturing technologies also adds to the financial strain.

Regulatory Compliance and Sustainability Requirements

The ever-evolving regulatory landscape poses another challenge to the Heavy Industry Packaging Market. Strict environmental regulations aimed at reducing waste and encouraging recycling require companies to adopt more sustainable practices. Compliance with these regulations often involves significant investments in research and development to create eco-friendly packaging solutions. Companies must continuously innovate and ensure their products meet these regulatory standards, which can be resource-intensive. This not only increases operational costs but also adds complexity to the packaging design and manufacturing processes, especially for industries with specialized packaging needs.

Market Opportunities:

Expansion of E-Commerce and Global Trade

A key opportunity for the Heavy Industry Packaging Market lies in the expansion of e-commerce and global trade. The increasing demand for bulk goods and the need for efficient logistics and transportation solutions create a significant growth opportunity for packaging providers. Packaging that ensures the safe transport of heavy industrial products is becoming increasingly important in global supply chains. As e-commerce continues to expand, particularly in emerging markets, there will be heightened demand for robust, cost-effective, and sustainable packaging solutions that can accommodate a wide range of industrial goods. This trend offers packaging companies the chance to develop innovative solutions that cater to the needs of a growing, interconnected global market.

Advancements in Sustainable and Eco-Friendly Packaging

The growing focus on sustainability offers substantial opportunities for the Heavy Industry Packaging Market. With increasing regulations and consumer demand for eco-friendly solutions, the market presents a chance to develop packaging materials that meet environmental standards while maintaining strength and durability. Packaging companies can capitalize on the shift towards biodegradable, recyclable, and reusable materials to align with global sustainability efforts. This shift not only appeals to eco-conscious consumers but also allows companies to differentiate themselves through innovative packaging solutions that support the circular economy, opening new business avenues in various industrial sectors.

Market Segmentation Analysis:

By Product Type

The market is dominated by rigid packaging solutions, such as drums, barrels, and containers, due to their durability and ability to withstand the heavy weights and stresses encountered during transportation and storage. Flexible packaging solutions, including bags and pouches, also show significant demand, particularly for lighter or bulk products. These product types cater to the logistics needs of industries like chemicals, automotive, and construction, where reliable packaging is crucial for safety and efficiency.

- For instance, Chemco Group’s new stretch film line has an annual production capacity of over 1,000 tons, supporting large-scale logistics and industrial demands.

By Material

Plastic dominates the Heavy Industry Packaging Market, driven by its versatility, strength, and cost-effectiveness. Polyethylene and polypropylene are commonly used materials due to their durability and resistance to chemicals. Metal packaging, particularly steel and aluminum, also holds a significant share, favored for packaging heavy and hazardous materials. Paper-based materials, such as corrugated cardboard, continue to gain traction due to their sustainability and recyclability, appealing to the growing demand for eco-friendly packaging solutions.

- For instance, Dow Inc. produces high-density polyethylene (HDPE) containers with impact strength exceeding 30kJ/m², widely adopted for shipping industrial chemicals.

By Capacity

The market is segmented into small, medium, and large capacity packaging. Large capacity packaging solutions, such as bulk containers and palletized packaging, are in high demand for industries that handle heavy, bulk products like chemicals and machinery. Medium and small capacity packaging is more common in industries like automotive and construction, where specific components or parts need to be securely packaged and transported. The shift towards customized capacity solutions to accommodate various logistical needs continues to influence market growth.

Segmentations:

- By Product Type

- Rigid Packaging

- Flexible Packaging

- By Material

- Plastic (Polyethylene, Polypropylene)

- Metal (Steel, Aluminum)

- Paper-Based (Corrugated Cardboard)

- By Capacity

- Small Capacity

- Medium Capacity

- Large Capacity

- By End-User Industry

- Automotive

- Chemicals

- Construction

- Machinery

- Food and Beverages

- By Region

- North America

- Europe

- Germany

- France

- U.K.

- Italy

- Spain

- Rest of Europe

- Asia Pacific

- China

- Japan

- India

- South Korea

- South-east Asia

- Rest of Asia Pacific

- Latin America

- Brazil

- Argentina

- Rest of Latin America

- Middle East & Africa

- GCC Countries

- South Africa

- Rest of the Middle East and Africa

Regional Analysis:

North America: Leading Innovation and Demand

North America holds 35% of the Heavy Industry Packaging Market, driven by well-established industrial sectors in the United States and Canada. The region experiences high demand for durable and cost-effective packaging solutions across industries such as automotive, chemicals, and construction. Strict regulatory frameworks, particularly in environmental sustainability, have accelerated the adoption of eco-friendly and recyclable packaging solutions. The presence of key industry players and advancements in packaging technologies further strengthen North America’s market position, supporting innovation in packaging materials and systems that enhance operational efficiency.

Europe: Sustainability and Regulatory Compliance

Europe accounts for 30% of the Heavy Industry Packaging Market, supported by stringent environmental regulations and a growing demand for sustainable solutions. The region’s packaging industry is heavily influenced by eco-conscious consumer preferences and governmental policies that promote recycling and waste reduction. Countries like Germany, France, and the UK are at the forefront of adopting recyclable, biodegradable, and reusable packaging materials. The European market also sees substantial demand from the automotive, machinery, and construction sectors, which require robust packaging solutions to handle heavy and bulky products efficiently, while complying with sustainability standards.

Asia-Pacific: Rapid Industrialization and Emerging Opportunities

The Asia-Pacific region holds 25% of the Heavy Industry Packaging Market, primarily driven by rapid industrialization and urbanization in emerging economies like China and India. This region is increasingly becoming a hub for manufacturing, with significant investments in infrastructure development and production capabilities. The growing demand for heavy industry packaging in sectors such as automotive, chemicals, and machinery is boosting the market. Additionally, the shift towards sustainable packaging practices in response to both regulatory pressures and consumer preferences presents new growth opportunities for packaging providers in this dynamic and diverse market.

Shape Your Report to Specific Countries or Regions & Enjoy 30% Off!

Key Player Analysis:

- Amcor plc

- Berry Global, Inc.

- Greif Inc.

- Mondi plc

- Sonoco Products Company

- WestRock Company

- Smurfit Kappa Group

- International Paper Company

- Mauser Packaging Solutions

- Ball Corporation

- Crown Holdings, Inc.

- DS Smith plc

Competitive Analysis:

The Heavy Industry Packaging Market is highly competitive, with key players such as Amcor plc, Berry Global, Inc., and Greif Inc. leading the charge. These companies offer a range of innovative packaging solutions designed to meet the needs of various industries, including automotive, chemicals, and construction. The market is driven by demand for durable, cost-effective packaging that ensures the safety and efficiency of heavy goods during transportation and storage. Companies are focusing on sustainability, investing in eco-friendly materials and technologies to reduce environmental impact. The growing demand for smart packaging solutions, which integrate RFID and sensor technology, is further intensifying competition. Market players are expanding their production capabilities and focusing on product customization to meet the unique requirements of different end-user industries. This competitive landscape encourages continuous innovation, efficiency improvements, and better customer service, allowing companies to maintain or improve their market position.

Recent Developments:

- In June 2025, Amcor launched a new, more sustainable Perflex® shrink bag with a built-in handle for Butterball’s turkey breast, achieving a 22% reduction in carbon footprint compared to traditional packaging.

- In July 2025, Amcor announced an investment to expand production of post-consumer recycled content packaging at its Nicholasville, Kentucky facility, reinforcing its sustainability initiatives.

- In June 2024, Sonoco Products Company announced on June 24, 2024, an agreement to acquire Eviosys (Europe’s leading food can and closure manufacturer) for approximately $3.9 billion.

Market Concentration & Characteristics:

The Heavy Industry Packaging Market is moderately concentrated, with a few dominant players such as Amcor plc, Berry Global, and Greif Inc. holding a significant share. These companies control a large portion of the market due to their extensive product portfolios, strong distribution networks, and investments in innovative packaging technologies. However, the market also features numerous smaller players that offer specialized and cost-effective solutions tailored to specific industries, increasing the overall competitive landscape. The market is characterized by a strong focus on sustainability, with companies striving to meet growing regulatory demands for eco-friendly packaging materials. Technological advancements, particularly in smart and automated packaging, are driving innovation and creating opportunities for new entrants. The focus on reducing production costs, enhancing operational efficiency, and improving packaging functionality continues to shape the dynamics of the market.

Report Coverage:

The research report offers an in-depth analysis based on Product Type, Material, Capacity, End-User Industry and Region. It details leading market players, providing an overview of their business, product offerings, investments, revenue streams, and key applications. Additionally, the report includes insights into the competitive environment, SWOT analysis, current market trends, as well as the primary drivers and constraints. Furthermore, it discusses various factors that have driven market expansion in recent years. The report also explores market dynamics, regulatory scenarios, and technological advancements that are shaping the industry. It assesses the impact of external factors and global economic changes on market growth. Lastly, it provides strategic recommendations for new entrants and established companies to navigate the complexities of the market.

Future Outlook:

- The Heavy Industry Packaging Market is experiencing a shift towards sustainable materials, with increased adoption of recyclable and biodegradable options.

- Technological advancements, such as automation and smart packaging solutions, are enhancing efficiency and traceability in packaging processes.

- The demand for customized packaging solutions is rising, driven by the need for tailored protection and branding in various industries.

- E-commerce growth is influencing packaging design, emphasizing the need for durable and cost-effective solutions for online retail.

- Regulatory pressures are prompting companies to innovate in packaging to meet environmental standards and reduce waste.

- The Asia-Pacific region is witnessing significant growth, attributed to industrialization and expanding manufacturing capabilities.

- Collaborative efforts between packaging manufacturers and end-users are fostering innovation and meeting specific industry requirements.

- The integration of digital technologies in packaging is improving supply chain visibility and product authenticity.

- Companies are investing in research and development to create packaging solutions that balance functionality, sustainability, and cost-effectiveness.

- The market is becoming more competitive, with both established players and new entrants focusing on innovation and customer-centric solutions.