Market Overview:

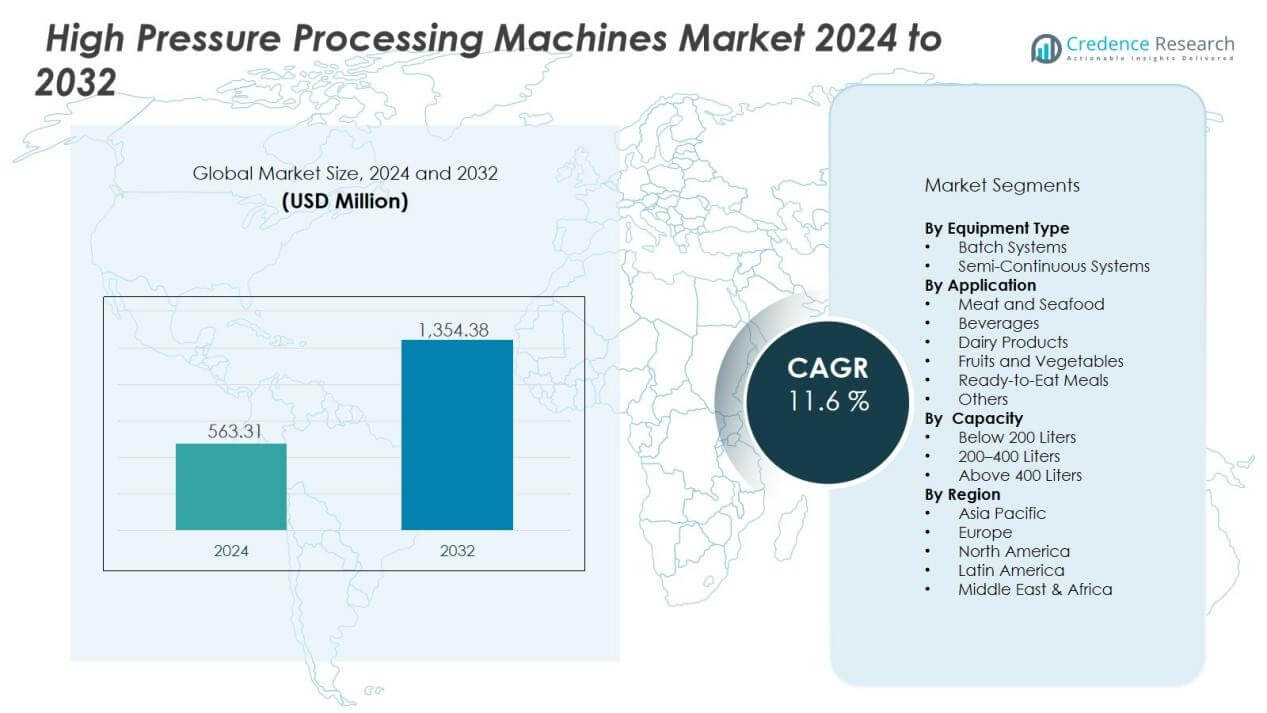

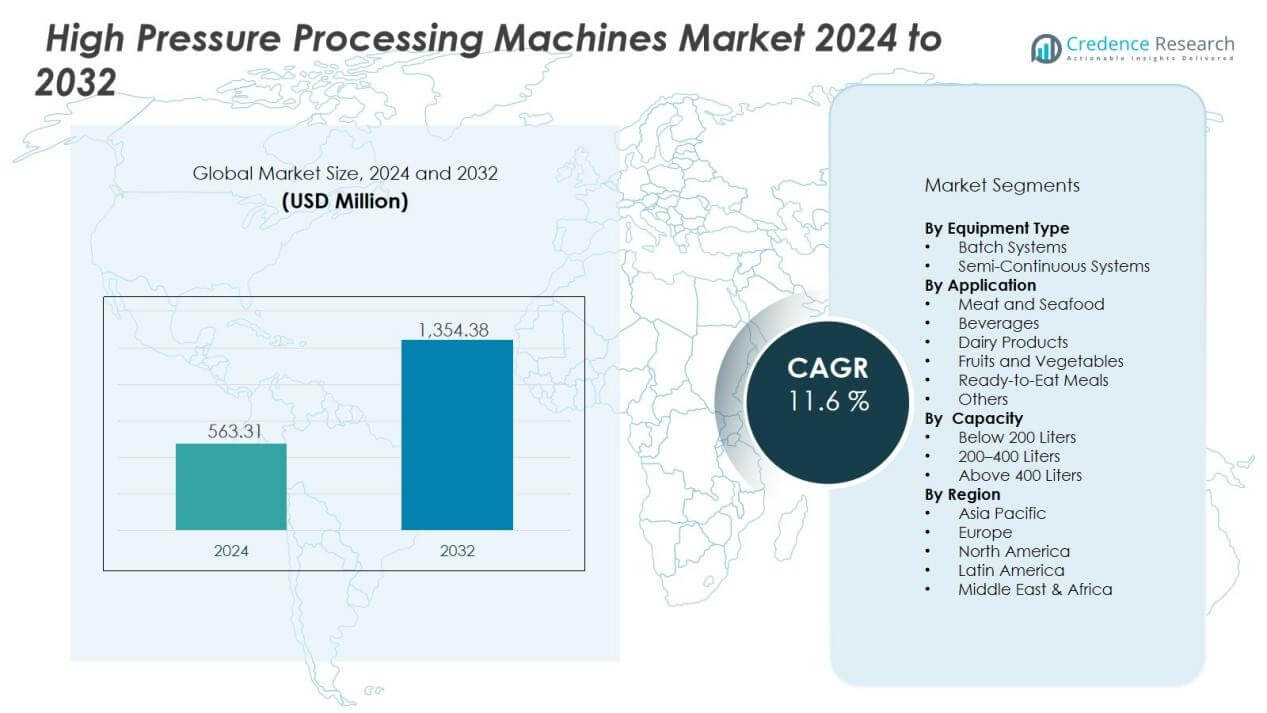

The high pressure processing machines market size was valued at USD 563.31 million in 2024 and is anticipated to reach USD 1,354.38 million by 2032, at a CAGR of 11.6% during the forecast period (2024-2032).

| REPORT ATTRIBUTE |

DETAILS |

| Historical Period |

2020-2023 |

| Base Year |

2024 |

| Forecast Period |

2025-2032 |

| High Pressure Processing Machines Market Size 2024 |

USD 563.31 Million |

| High Pressure Processing Machines Market, CAGR |

11.6% |

| High Pressure Processing Machines Market Size 2032 |

USD 1,354.38 Million |

Key drivers fueling this market include the growing consumer preference for clean-label and preservative-free foods, coupled with stricter food safety regulations. HPP technology offers extended shelf life, maintains nutritional quality, and reduces microbial contamination without the need for chemical additives. Food manufacturers are increasingly investing in HPP machines to meet regulatory standards and strengthen consumer trust, while simultaneously reducing food waste and improving operational efficiency.

Regionally, North America dominates the market due to strong adoption by large-scale food processors and high consumer awareness regarding food safety. Europe follows closely, driven by regulatory support and rising demand for sustainable food technologies. The Asia-Pacific region is projected to record the fastest growth, propelled by expanding food processing industries, rapid urbanization, and increasing consumption of convenience foods in markets such as China, Japan, and India.

Market Insights:

- The high pressure processing machines market was valued at USD 563.31 million in 2024 and is expected to reach USD 1,354.38 million by 2032, growing at a CAGR of 11.6% during 2024–2032.

- Rising demand for clean-label and preservative-free foods drives strong adoption, as consumers prefer products that retain natural taste, color, and nutrients.

- Food safety regulations continue to boost demand, with HPP technology ensuring microbial inactivation without compromising quality.

- Packaged and convenience food categories, including cold-pressed juices and ready-to-eat meals, remain key growth segments supported by busy consumer lifestyles.

- Technological advancements in automation, machine design, and energy efficiency improve operational productivity and reduce processing costs.

- Applications are expanding into seafood, dairy, baby food, and plant-based products, supported by growing use of shared tolling facilities for smaller producers.

- North America led with 38% share in 2024, followed by Europe at 29%, while Asia-Pacific held 22% and is projected to post the fastest growth through rising food processing industries and urbanization.

Access crucial information at unmatched prices!

Request your sample report today & start making informed decisions powered by Credence Research Inc.!

Download Sample

Market Drivers:

Rising Consumer Preference for Clean-Label and Natural Foods:

The high pressure processing machines market is strongly driven by the demand for clean-label, chemical-free products. Consumers are shifting toward foods that retain natural flavors, colors, and nutrients without artificial preservatives. HPP technology enables manufacturers to meet this demand by offering minimally processed products with extended shelf life. It supports the production of juices, meat, seafood, and ready-to-eat meals that align with evolving consumer lifestyles.

- For instance, Hiperbaric reached the milestone of selling 50 units of its Hiperbaric 525 model, the largest and most productive HPP machine on the market, enabling producers to offer high-quality clean-label products with effective pathogen inactivation.

Growing Focus on Food Safety and Regulatory Compliance :

Food safety concerns continue to fuel the adoption of HPP technology worldwide. Regulators demand higher standards for controlling pathogens such as E. coli, Salmonella, and Listeria. The high pressure processing machines market benefits from this trend, as the technology ensures microbial inactivation without altering product quality. It provides manufacturers with a reliable method to comply with stringent food safety regulations across multiple regions.

- For instance, Hiperbaric’s HPP 525 system processes 525 liters per cycle.

Expanding Adoption in Packaged and Convenience Foods :

The global rise in demand for packaged, ready-to-eat, and convenience foods has accelerated the use of HPP machines. Busy lifestyles drive consumers to prefer longer-lasting, high-quality packaged options. The high pressure processing machines market serves this need by offering a solution that extends shelf life while preserving taste and nutrition. It is increasingly applied in premium segments such as cold-pressed juices and gourmet meals.

Technological Advancements and Industry Investment:

Continuous innovation in machine design, automation, and energy efficiency strengthens market growth. Manufacturers invest heavily in advanced systems that reduce operational costs and improve processing efficiency. The high pressure processing machines market gains from partnerships between technology providers and food companies seeking differentiation. It is supported by growing awareness among producers about reducing food waste and enhancing product value through advanced preservation methods.

Market Trends:

Market Trends:

Increasing Integration of HPP in Diverse Food and Beverage Applications:

The high pressure processing machines market is witnessing wider adoption across multiple product categories beyond traditional meat and juices. Food companies apply HPP to seafood, dairy, baby food, and plant-based products to meet demand for safe, nutrient-rich options. It helps extend shelf life while preserving sensory attributes, which appeals to both manufacturers and consumers. Cold-pressed juice brands, premium ready-to-eat meal producers, and dairy processors increasingly view HPP as a differentiator in competitive markets. Start-ups and established brands invest in shared HPP facilities to minimize costs and increase accessibility. This trend broadens the scope of applications, making HPP a mainstream preservation technology rather than a niche solution.

- For instance, Just Made, a cold-pressed juice producer, expanded its capabilities by installing a Hiperbaric 300 HPP system capable of processing 1,410 kg/h, enabling greater production efficiency while preserving juice nutrients and flavor.

Growing Emphasis on Sustainability and Cost-Efficient Operations:

Sustainability is emerging as a core trend shaping the high pressure processing machines market, with manufacturers focusing on energy-efficient systems and waste reduction. Companies aim to lower operating costs by introducing machines with reduced water and energy usage while maintaining high performance. It reflects industry efforts to align with environmental goals and regulatory pressures for sustainable processing solutions. Collaborative business models such as HPP tolling centers support small and mid-sized producers in accessing advanced technology without large capital investments. Machine design improvements also enable faster cycles, reduced downtime, and better throughput. These advancements strengthen the appeal of HPP systems for both global brands and regional food processors.

- For Instance, The JBT Marel Avure QFP 525L-600 HPP system has a maximum throughput of 8,135 pounds per hour at 10 cycles per hour with a 3-minute hold time.

Market Challenges Analysis:

Expanding Applications Across Food and Beverage Categories:

The high pressure processing machines market is experiencing strong traction as adoption moves beyond traditional segments. Food producers increasingly deploy HPP for seafood, dairy, baby food, and plant-based products to ensure safety and freshness. It supports cold-pressed juices, functional beverages, and gourmet ready-to-eat meals by retaining nutrients and flavor while extending shelf life. Start-ups and premium brands use HPP to differentiate their offerings in competitive markets. Shared HPP facilities are also expanding, giving small and medium producers access to advanced preservation methods without heavy capital investment. This expansion demonstrates how HPP is evolving into a standard solution across the food processing industry.

Emphasis on Sustainability, Efficiency, and Collaborative Business Models:

Sustainability remains a defining trend, with manufacturers introducing HPP systems designed to reduce energy and water usage. The high pressure processing machines market benefits from advancements that cut operational costs while enhancing productivity. It encourages producers to align with global sustainability goals and meet stricter environmental regulations. Toll processing centers continue to gain momentum, offering cost-efficient access for businesses hesitant to purchase their own machines. Manufacturers also develop equipment with shorter cycle times, higher throughput, and advanced automation. These innovations strengthen the appeal of HPP technology for both established corporations and emerging food brands.

Market Opportunities:

Rising Demand for Premium and Functional Food Products:

The high pressure processing machines market presents strong opportunities through the growing consumer demand for premium and functional foods. Cold-pressed juices, probiotic beverages, and plant-based products increasingly rely on HPP to deliver freshness and extended shelf life. It enables brands to capture health-conscious consumers seeking natural and nutrient-rich products. Emerging categories such as baby food, pet food, and dietary supplements are also expanding the application base. Manufacturers that invest in HPP can differentiate their portfolios and strengthen brand trust in competitive markets. This opens opportunities for both established players and niche innovators.

Expansion Potential in Emerging Markets and Shared Facilities:

Emerging economies provide significant growth potential due to rising urbanization and expanding food processing industries. The high pressure processing machines market can benefit from increasing demand for packaged convenience foods in Asia-Pacific and Latin America. It supports regional players aiming to improve product safety standards and meet evolving consumer expectations. The growth of shared HPP tolling facilities creates opportunities for small and medium enterprises to access technology without large capital commitments. Partnerships between machine manufacturers and food producers further accelerate adoption. These factors highlight strong untapped potential across both developed and developing markets.

Market Segmentation Analysis:

By Equipment Type:

The high pressure processing machines market is segmented into batch and semi-continuous systems. Batch systems dominate due to their suitability for small and medium-scale production. They offer flexibility for multiple product categories, including juices, dairy, and packaged meals. Semi-continuous systems are gaining traction among large-scale processors aiming to improve throughput and reduce downtime. It supports efficient processing for high-demand segments and aligns with industrial automation trends.

- For instance, Hiperbaric’s batch HPP equipment with up to 450 liters vessel volume allows efficient processing of diverse product categories by treating final packaged foods, ensuring no post-process contamination, with pressure intensities reaching 600 MPa in cycles under 20 seconds for pumpable juices.

By Capacity:

Market segmentation by capacity includes systems below 200 liters, 200–400 liters, and above 400 liters. Machines with 200–400 liters capacity hold a significant share, as they balance affordability with operational efficiency. Small-capacity machines appeal to start-ups and niche producers seeking entry-level adoption. Large-capacity systems above 400 liters find demand in established enterprises with high production volumes. It reflects industry preference for scalable solutions that match diverse processing needs.

- For instance, Wallgoe offers a 200-400 liter concrete cement mixer machine known for its durability and efficiency, widely used in construction and capable of operating with a power motor speed of 30 rotations per minute (rpm) at 3 kW power capacity.

By Application:

Applications span meat, seafood, beverages, dairy, fruits and vegetables, and ready-to-eat meals. Beverages, particularly cold-pressed juices and functional drinks, lead adoption due to high consumer demand for nutrient retention. Meat and seafood producers rely on HPP for microbial safety and shelf-life extension. Dairy and plant-based categories are expanding rapidly with rising consumer interest in natural products. It demonstrates the versatility of HPP across multiple industries with strong long-term growth potential.

Segmentations:

By Equipment Type:

- Batch Systems

- Semi-Continuous Systems

By Capacity:

- Below 200 Liters

- 200–400 Liters

- Above 400 Liters

By Application:

- Meat and Seafood

- Beverages

- Dairy Products

- Fruits and Vegetables

- Ready-to-Eat Meals

- Others

By Region:

- North America

- Europe

- UK

- France

- Germany

- Italy

- Spain

- Russia

- Belgium

- Netherlands

- Austria

- Sweden

- Poland

- Denmark

- Switzerland

- Rest of Europe

- Asia Pacific

- China

- Japan

- South Korea

- India

- Australia

- Thailand

- Indonesia

- Vietnam

- Malaysia

- Philippines

- Taiwan

- Rest of Asia Pacific

- Latin America

- Brazil

- Argentina

- Peru

- Chile

- Colombia

- Rest of Latin America

- Middle East

- UAE

- KSA

- Israel

- Turkey

- Iran

- Rest of Middle East

- Africa

- Egypt

- Nigeria

- Algeria

- Morocco

- Rest of Africa

Regional Analysis:

North America:

North America held 38% market share in 2024, making it the leading region. The high pressure processing machines market in this region benefits from advanced food processing infrastructure and early adoption of innovative technologies. Large-scale food manufacturers integrate HPP into product lines to meet strict food safety regulations and consumer demand for natural products. It supports high consumption of packaged ready-to-eat meals, juices, and meat products. Government emphasis on food safety standards further accelerates the use of HPP systems. Strategic partnerships between equipment manufacturers and major food brands strengthen market penetration and expand applications across the region.

Europe:

Europe accounted for 29% market share in 2024, driven by strict regulatory frameworks and strong demand for premium food categories. The high pressure processing machines market in Europe benefits from consumer preference for clean-label and high-quality products. Food producers adopt HPP to comply with EU food safety directives while catering to health-conscious buyers. It supports growth in cold-pressed beverages, dairy products, and gourmet ready-to-eat meals. Sustainability initiatives also encourage adoption of energy-efficient HPP systems. Growing collaboration between technology suppliers and regional food processors continues to expand the installed base across key markets such as Germany, France, and the UK.

Asia-Pacific:

Asia-Pacific recorded 22% market share in 2024 and is projected to witness the fastest growth. The high pressure processing machines market in this region benefits from rapid urbanization, expanding food processing industries, and changing consumer lifestyles. It supports rising demand for packaged foods and beverages in countries such as China, Japan, and India. Government initiatives to improve food safety standards accelerate technology adoption among regional producers. Shared HPP facilities are emerging, making the technology accessible to small and mid-sized enterprises. Increasing investment from global players and local partnerships further enhances market potential across the region.

Shape Your Report to Specific Countries or Regions & Enjoy 30% Off!

Key Player Analysis:

- American Pasteurization Company (APC)

- Avure Technologies

- Bao Tou KeFa High Pressure Technology Co., Ltd.

- Engineered Pressure Systems International (EPSI)

- HPP Italia S.r.l.

- Hiperbaric S.A.

- Kobe Steel Ltd.

- Next HPP

- Multivac Sepp Haggenmüller SE & Co. KG

- Nordic High-Pressure Processing (NHPP)

- Quintus Technologies AB

- Pulsemaster

Competitive Analysis:

The high pressure processing machines market is characterized by strong competition among global and regional players. Key companies include American Pasteurization Company (APC), Avure Technologies, Bao Tou KeFa High Pressure Technology Co., Ltd., Engineered Pressure Systems International (EPSI), HPP Italia S.r.l., Hiperbaric S.A., Kobe Steel Ltd., and Next HPP. These firms compete through product innovation, advanced machine design, and expanded service offerings. It is shaped by continuous investment in automation, energy efficiency, and large-capacity systems to meet rising industrial demand. Strategic partnerships with food and beverage producers help strengthen market presence and accelerate adoption across applications. Regional expansion into Asia-Pacific and Latin America creates opportunities for players to target emerging food processing industries. Competitive dynamics emphasize cost efficiency, reliability, and strong after-sales support to maintain customer loyalty and secure long-term growth.

Recent Developments:

- In September 2025, the High Pressure Processing (HPP) equipment market continues to grow robustly with Avure Technologies’ HPP machines widely adopted by food processors for products such as ready-to-eat meals, juices, and meats.

- In January 2023, Hiperbaric S.A.’s founding and management team increased their ownership stake to 55%, reshaping the company’s ownership structure significantly.

- In February 2025, Kobe Steel Ltd. initiated new Physical Vapor Deposition (PVD) coating services targeting fuel cell components such as bipolar plates and water electrolyzer parts, expanding its technology market reach.

Report Coverage:

The research report offers an in-depth analysis based on Segment 1, Segment 2, Segment 3, and Segment 3. It details leading Market players, providing an overview of their business, product offerings, investments, revenue streams, and key applications. Additionally, the report includes insights into the competitive environment, SWOT analysis, current Market trends, as well as the primary drivers and constraints. Furthermore, it discusses various factors that have driven Market expansion in recent years. The report also explores Market dynamics, regulatory scenarios, and technological advancements that are shaping the industry. It assesses the impact of external factors and global economic changes on Market growth. Lastly, it provides strategic recommendations for new entrants and established companies to navigate the complexities of the Market.

Future Outlook:

- Demand for high pressure processing machines will expand as consumer preference shifts toward natural, chemical-free foods.

- Food safety regulations will continue to drive adoption across meat, seafood, dairy, and beverage processing industries.

- Cold-pressed juices, plant-based products, and premium ready-to-eat meals will emerge as key growth categories.

- Manufacturers will invest in advanced HPP systems with faster cycle times and improved energy efficiency.

- Shared toll-processing facilities will expand, making technology more accessible for small and mid-sized enterprises.

- Sustainability initiatives will encourage development of machines that reduce water and energy consumption.

- Partnerships between equipment suppliers and food producers will strengthen integration across global markets.

- Emerging economies in Asia-Pacific and Latin America will present strong opportunities due to rising packaged food demand.

- Automation and digital monitoring features will enhance operational efficiency and reduce production costs.

- Innovation in packaging compatible with HPP will support diversification of applications across new product categories.

Market Trends:

Market Trends: