Market Overview:

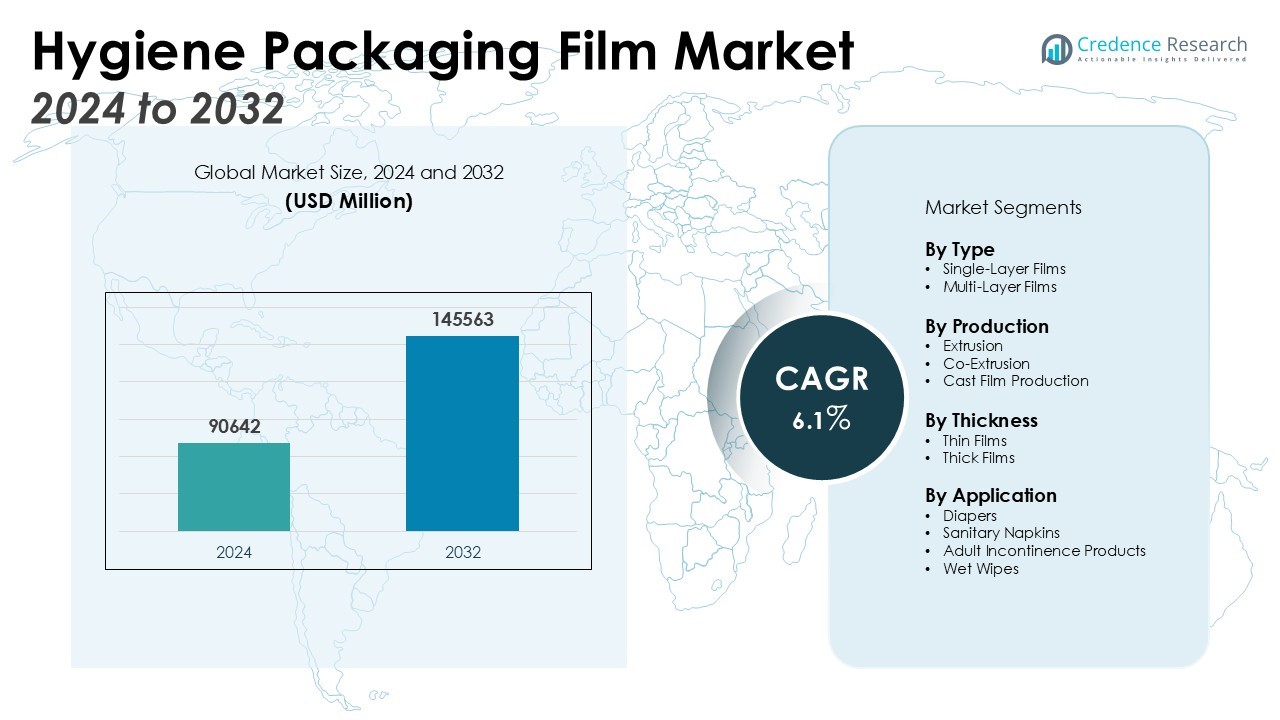

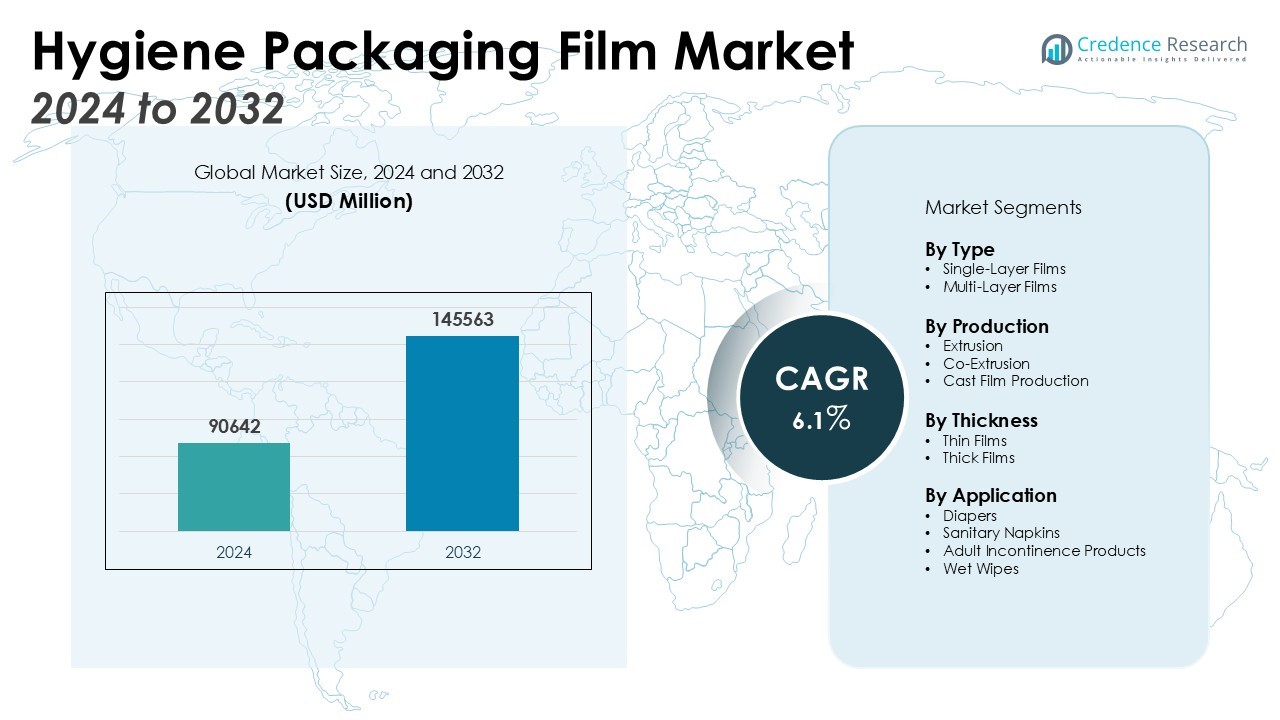

The Hygiene Packaging Film Market size was valued at USD 90642 million in 2024 and is anticipated to reach USD 145563 million by 2032, at a CAGR of 6.1% during the forecast period (2024-2032).

| REPORT ATTRIBUTE |

DETAILS |

| Historical Period |

2020-2024 |

| Base Year |

2024 |

| Forecast Period |

2025-2032 |

| Hygiene Packaging Film Market Size 2024 |

USD 90642 Million |

| Hygiene Packaging Film Market, CAGR |

6.1% |

| Hygiene Packaging Film Market Size 2032 |

USD 145563 Million |

Key drivers shaping the Hygiene Packaging Film Market include the growing adoption of advanced film materials to ensure product safety, integrity, and barrier protection. Manufacturers are increasingly focused on sustainable and biodegradable films, aligning with global environmental regulations and consumer preferences. Technological advancements, such as improved breathability, softness, and printability of films, are intensifying competition and enabling differentiation among leading brands. Strategic collaborations and investments in R&D further fuel innovation and accelerate the shift toward eco-friendly packaging. Increasing regulatory scrutiny on single-use plastics is prompting companies to adopt circular economy practices and develop recyclable packaging film solutions.

Regionally, Asia Pacific dominates the Hygiene Packaging Film Market due to rapid urbanization, rising healthcare awareness, and population growth in countries such as China and India. North America and Europe maintain strong market shares, supported by established hygiene product manufacturers and high consumer standards for safety and quality. Emerging economies in Latin America and the Middle East are also witnessing increased market penetration.

Access crucial information at unmatched prices!

Request your sample report today & start making informed decisions powered by Credence Research Inc.!

Download Sample

Market Insights:

- The Hygiene Packaging Film Market was valued at USD 90,642 million in 2024 and is expected to reach USD 145,563 million by 2032, growing at a CAGR of 6.1% from 2024 to 2032.

- Increased demand for disposable hygiene products such as diapers and sanitary napkins continues to drive the market. Packaging materials that ensure safety and integrity are in high demand, fueling the need for advanced film solutions.

- Environmental concerns and consumer preference for eco-friendly alternatives have prompted manufacturers to focus on biodegradable and recyclable packaging films. This trend is aligned with global sustainability efforts and regulatory demands.

- Technological innovations in film properties, such as enhanced breathability, softness, and anti-microbial features, are playing a crucial role in differentiating products in the market, offering better protection and convenience.

- Rising investments in research and development are accelerating the creation of high-performance, sustainable packaging solutions. Companies are strategically collaborating to develop next-generation films that meet evolving market needs.

- The Hygiene Packaging Film Market faces challenges such as increasing raw material costs and global supply chain disruptions, which impact production costs and market stability.

- Asia Pacific dominates the market with a 40% share, driven by population growth, urbanization, and rising healthcare awareness in countries like China and India, fueling the demand for hygiene packaging films.

Market Drivers:

Growing Demand for Disposable Hygiene Products

The Hygiene Packaging Film Market is driven by the growing global demand for disposable hygiene products, including diapers, sanitary napkins, and adult incontinence products. These products require high-quality packaging that ensures safety, integrity, and hygiene. As population growth and aging demographics continue, the demand for such products remains strong. Manufacturers are focused on creating films that offer superior barrier protection. This growth in hygiene product consumption is fueling the demand for innovative packaging solutions.

Shift Toward Sustainable and Biodegradable Packaging Solutions

Environmental concerns are reshaping the Hygiene Packaging Film Market. With increasing consumer demand for eco-friendly alternatives, manufacturers are developing sustainable and biodegradable packaging films. These solutions help reduce the environmental footprint of hygiene products. Governments and brands are pushing for recyclable packaging materials to align with stricter regulations. The shift toward sustainability is becoming a key driver for packaging innovation in the market.

- For instance, Taghleef Industries’ NATIVIA® biobased film is certified to fully biodegrade within six months under industrial composting, meeting EN 13432 standards.

Technological Innovations in Film Properties

Advancements in film technology are enhancing the performance and appeal of hygiene packaging. Innovations such as improved breathability, softness, and anti-microbial properties are attracting consumer interest. These technological developments enable packaging films to offer better product protection while maintaining high functionality. Brands are focusing on delivering packaging that enhances convenience without compromising product quality or consumer satisfaction.

- For instance, BASF’s ecovio® 70 PS14H6 biopolymer coating for food packaging is certified home-compostable under the OK Compost Home standard, allowing paper-based packs with this coating to withstand boiling water temperatures of up to 100°C while remaining fully compostable, supporting both functionality and environmental performance.

Strategic Investments in Research and Development

Investment in research and development is a critical driver in the Hygiene Packaging Film Market. Manufacturers are prioritizing R&D to create high-performance, sustainable packaging solutions. Strategic partnerships and collaborations with research firms are accelerating innovation. These investments are enabling the creation of next-generation films that cater to evolving market needs, giving manufacturers a competitive edge. The focus on R&D supports the continued growth and diversification of the market.

Market Trends:

Rising Adoption of Sustainable and Eco-Friendly Packaging Solutions

A major trend in the Hygiene Packaging Film Market is the growing preference for sustainable and eco-friendly packaging options. With increasing awareness of environmental issues, consumers are demanding products with reduced environmental impact. Manufacturers are responding by investing in biodegradable, recyclable, and compostable film materials. This shift aligns with global regulatory efforts to reduce plastic waste and carbon footprints. Packaging that minimizes plastic usage and promotes a circular economy is gaining traction in the market. Innovations such as plant-based packaging films and the use of recycled materials are driving the demand for sustainable alternatives in the hygiene sector.

- For instance, ExxonMobil collaborated with equipment suppliers to develop a fully recyclable thermoformed packaging film composed of 95% polyethylene (PE) content, rigorously tested for high oxygen barrier and enhanced puncture resistance while maintaining excellent machinability on Multivac R245 machine.

Technological Advancements in Film Design and Functionality

Technological innovations in film design are enhancing the functionality and appeal of hygiene packaging. The development of advanced films with superior barrier properties, such as improved moisture resistance and breathability, is a key trend. These innovations are particularly important for hygiene products, where maintaining product integrity and hygiene standards is crucial. New film technologies also enable better printability, which enhances branding and consumer engagement. The integration of features like anti-microbial coatings and improved softness further differentiates products in the competitive market. As manufacturers continue to innovate, the focus on improving film functionality and meeting consumer demands for convenience and quality will shape future market growth.

- For instance, Amcor’s multi-layer cast extrusion technology for medical films achieves up to 11 discrete layers in a single film, enabling tailored barriers and durability for medical packaging applications.

Market Challenges Analysis:

Environmental Concerns and Regulatory Pressures

One of the significant challenges facing the Hygiene Packaging Film Market is the increasing pressure to adopt environmentally sustainable practices. Governments and regulatory bodies across the globe are implementing stricter policies regarding plastic waste and the environmental impact of packaging materials. While there is a growing shift toward sustainable and biodegradable films, the transition presents hurdles such as higher costs and limited availability of eco-friendly materials. Manufacturers must balance compliance with sustainability goals while maintaining product performance and cost-effectiveness. The challenge lies in meeting both regulatory requirements and consumer demand for eco-friendly packaging solutions.

Rising Raw Material Costs and Supply Chain Disruptions

The Hygiene Packaging Film Market faces challenges related to rising raw material costs and supply chain disruptions. Fluctuations in the prices of key materials like polyethylene, polypropylene, and other polymers impact production costs. These increases can strain profit margins and create pricing pressures in the market. Additionally, global supply chain disruptions, caused by geopolitical factors or environmental events, affect the timely delivery of raw materials. Manufacturers must adapt by diversifying supply sources and investing in long-term partnerships to secure material availability and mitigate cost increases. These factors complicate the stability of the market and create uncertainties for industry players.

Market Opportunities:

Environmental Concerns and Regulatory Pressures

One of the significant challenges facing the Hygiene Packaging Film Market is the increasing pressure to adopt environmentally sustainable practices. Governments and regulatory bodies across the globe are implementing stricter policies regarding plastic waste and the environmental impact of packaging materials. While there is a growing shift toward sustainable and biodegradable films, the transition presents hurdles such as higher costs and limited availability of eco-friendly materials. Manufacturers must balance compliance with sustainability goals while maintaining product performance and cost-effectiveness. The challenge lies in meeting both regulatory requirements and consumer demand for eco-friendly packaging solutions.

Rising Raw Material Costs and Supply Chain Disruptions

The Hygiene Packaging Film Market faces challenges related to rising raw material costs and supply chain disruptions. Fluctuations in the prices of key materials like polyethylene, polypropylene, and other polymers impact production costs. These increases can strain profit margins and create pricing pressures in the market. Additionally, global supply chain disruptions, caused by geopolitical factors or environmental events, affect the timely delivery of raw materials. Manufacturers must adapt by diversifying supply sources and investing in long-term partnerships to secure material availability and mitigate cost increases. These factors complicate the stability of the market and create uncertainties for industry players.

Market Segmentation Analysis:

By Type:

The market is primarily divided into flexible films, including both single-layer and multi-layer films. Multi-layer films dominate the market due to their superior barrier properties, which ensure product safety and integrity. These films provide enhanced protection against moisture, oxygen, and contaminants, making them ideal for hygiene products like diapers and sanitary napkins. Single-layer films, while less costly, are gaining traction due to their ease of production and lower environmental impact.

- For instance, Dow’s INNATE™ TF-BOPE single-layer films demonstrated triple the puncture resistance of traditional blown PE films, enhancing both durability and product safety for packaging applications.

By Production:

The Hygiene Packaging Film Market can be segmented based on production methods such as extrusion, co-extrusion, and cast film production. Co-extrusion is the most widely used method, allowing manufacturers to create multi-layer films with superior protection and durability. Extrusion continues to be popular for its cost-effectiveness in producing single-layer films. Cast film production is favored for its flexibility and use in applications requiring high transparency and surface finish.

- For instance, Mid South Extrusion upgraded their film line with the installation of a new 6-in. (150mm) Davis-Standard extruder, enabling the company to process a broader range of HDPE, LDPE, and LLDPE films and boost throughput while maintaining continuous operation on a line that has been in use for nearly 30 years.

By Thickness:

The market is also segmented by film thickness, which varies depending on the intended application. Thinner films are commonly used in low-cost products, while thicker films offer enhanced durability and barrier protection for high-performance hygiene products. Manufacturers are increasingly focused on producing films that balance optimal thickness with sustainability, using lightweight but strong materials to reduce environmental impact without compromising product safety.

Segmentations:

- By Type:

- Single-Layer Films

- Multi-Layer Films

- By Production:

- Extrusion

- Co-Extrusion

- Cast Film Production

- By Thickness:

- By Application:

- Diapers

- Sanitary Napkins

- Adult Incontinence Products

- Wet Wipes

- By Region:

- North America

- Europe

- Germany

- France

- U.K.

- Italy

- Spain

- Rest of Europe

- Asia Pacific

- China

- Japan

- India

- South Korea

- South-east Asia

- Rest of Asia Pacific

- Latin America

- Brazil

- Argentina

- Rest of Latin America

- Middle East & Africa

- GCC Countries

- South Africa

- Rest of the Middle East and Africa

Regional Analysis:

Asia Pacific: Leading Market Share Driven by Population Growth and Urbanization

Asia Pacific holds the largest market share in the Hygiene Packaging Film Market, accounting for 40% of global demand in 2024. This dominance is fueled by rapid urbanization and significant population growth in countries like China, India, and Southeast Asian nations. The region’s growing disposable income and heightened awareness of hygiene standards lead to increased consumption of disposable hygiene products such as diapers and sanitary products. Manufacturers are expanding their production capacity in the region to cater to the surging demand for hygiene packaging films. With urban areas seeing the highest consumption rates, the market shows strong potential for continued growth in the coming years.

North America: Strong Market Share Supported by Technological Advancements

North America holds a substantial share of the Hygiene Packaging Film Market, contributing 25% to the global market. The region’s growth is driven by advancements in packaging technologies, including biodegradable and sustainable films. The United States, in particular, leads the demand due to its well-established hygiene product industry and high consumer expectations for safety and quality. Strict environmental regulations and a growing shift toward eco-friendly packaging solutions are influencing manufacturers to adopt more sustainable practices. Furthermore, the rise of e-commerce and home delivery services continues to increase the need for efficient and secure packaging solutions in the region.

Europe: Growing Market Share Focused on Sustainability and Eco-Friendly Solutions

Europe holds a significant share of the Hygiene Packaging Film Market, accounting for 20% of global demand. The region’s growth is largely driven by increasing consumer preference for sustainable and eco-friendly packaging solutions. European regulatory frameworks are among the most stringent globally, encouraging manufacturers to invest in recyclable and biodegradable packaging materials. The demand for high-performance packaging films that align with both functional and environmental needs is on the rise. Leading hygiene product manufacturers and a strong focus on sustainability are key factors propelling market expansion in this region.

Shape Your Report to Specific Countries or Regions & Enjoy 30% Off!

Key Player Analysis:

- Trioplast

- Polifilm Group

- S.B Packaging

- Berry Global Group

- KRIS PlexiPacks

- Venture Industries

- Lyondell Basell

- Granitol

- Amerplast

Competitive Analysis:

The Hygiene Packaging Film Market is highly competitive, with key players striving to differentiate themselves through innovation and sustainability. Leading companies include Amcor, Berry Global, and Mondi Group, which dominate the market with their extensive portfolios of multi-layer films that offer superior barrier properties and performance. These companies invest heavily in research and development to create eco-friendly, biodegradable, and recyclable packaging solutions in response to growing environmental concerns. Competition is also intensified by emerging players focusing on cost-effective, flexible film options. These newer entrants often target niche markets, such as low-cost hygiene packaging or products catering to specific regional demands. Strategic partnerships and acquisitions are common in the industry, as established players seek to expand their product offerings and regional presence. With increasing demand for sustainable packaging and advanced film technologies, companies are continually innovating to maintain a competitive edge in the Hygiene Packaging Film Market.

Recent Developments:

- In July 2025, KRIS Flexi Packs launched innovative laminated 3D pouch packaging specifically engineered to tackle the challenges of India’s monsoon season for FMCG supply chains and consumer goods.

- In March 2025, LyondellBasell announced an investment to expand propylene production capacity at its Channelview Complex near Houston, with construction commencing in the third quarter of 2025 and projected startup in late 2028.

- In April 2025, LyondellBasell entered into a strategic distribution agreement with Nexeo Plastics, selecting it to distribute its Engineered Polymer portfolio throughout Europe starting April 1, 2025.

Market Concentration & Characteristics:

The Hygiene Packaging Film Market is moderately concentrated, with a few dominant players controlling a significant share. Major companies like Amcor, Berry Global, and Mondi Group lead the market due to their extensive production capacities, technological innovations, and strong distribution networks. The market exhibits characteristics of high competition, driven by the demand for sustainable, high-performance packaging solutions. While large players dominate the global market, regional manufacturers cater to local needs with cost-effective and customized film products. The industry is witnessing a growing focus on eco-friendly materials, pushing manufacturers to invest in sustainable film technologies. The market is also marked by continuous innovation, with companies focusing on enhancing film properties, such as barrier protection, breathability, and softness, to meet evolving consumer demands and regulatory standards. This dynamic competitive environment encourages both established and emerging players to pursue strategic growth and technological advancements.

Report Coverage:

The research report offers an in-depth analysis based on Type, Production, Thickness, Application and Region. It details leading market players, providing an overview of their business, product offerings, investments, revenue streams, and key applications. Additionally, the report includes insights into the competitive environment, SWOT analysis, current market trends, as well as the primary drivers and constraints. Furthermore, it discusses various factors that have driven market expansion in recent years. The report also explores market dynamics, regulatory scenarios, and technological advancements that are shaping the industry. It assesses the impact of external factors and global economic changes on market growth. Lastly, it provides strategic recommendations for new entrants and established companies to navigate the complexities of the market.

Future Outlook:

- The market is expected to experience sustained growth, driven by increasing consumer demand for hygiene products and advancements in packaging technologies.

- Technological innovations, such as the development of breathable films and antimicrobial coatings, are anticipated to enhance product performance and appeal.

- Sustainability trends are influencing the industry, with a growing emphasis on biodegradable and recyclable packaging materials to meet environmental standards.

- Emerging markets, particularly in Asia Pacific, are projected to contribute significantly to market expansion due to rising disposable incomes and urbanization.

- The demand for single-use hygiene products is expected to remain strong, supporting the need for efficient and cost-effective packaging solutions.

- Regulatory pressures are likely to increase, prompting manufacturers to adopt eco-friendly practices and comply with stringent environmental regulations.

- Strategic partnerships and collaborations among industry players are anticipated to foster innovation and enhance market competitiveness.

- The rise of e-commerce is expected to drive demand for packaging that ensures product safety and integrity during transit.

- Consumer preferences are shifting towards packaging that offers convenience, portability, and hygiene assurance.

- Investment in research and development is expected to continue, focusing on creating packaging solutions that balance performance, cost, and environmental impact.