Market Overview:

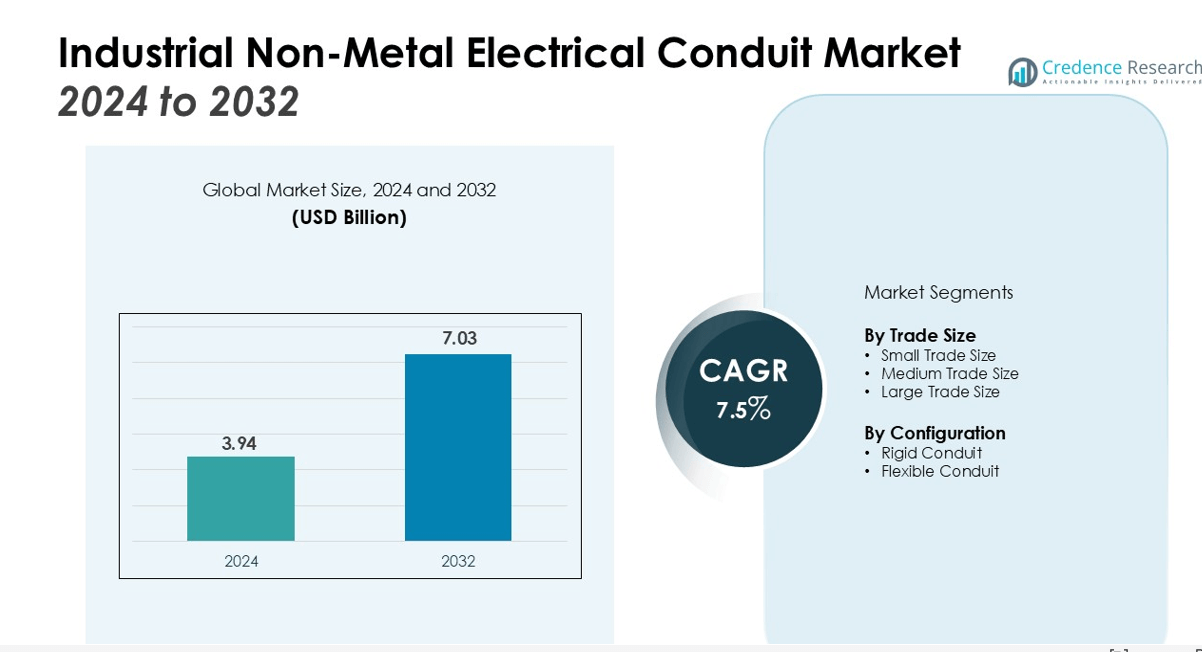

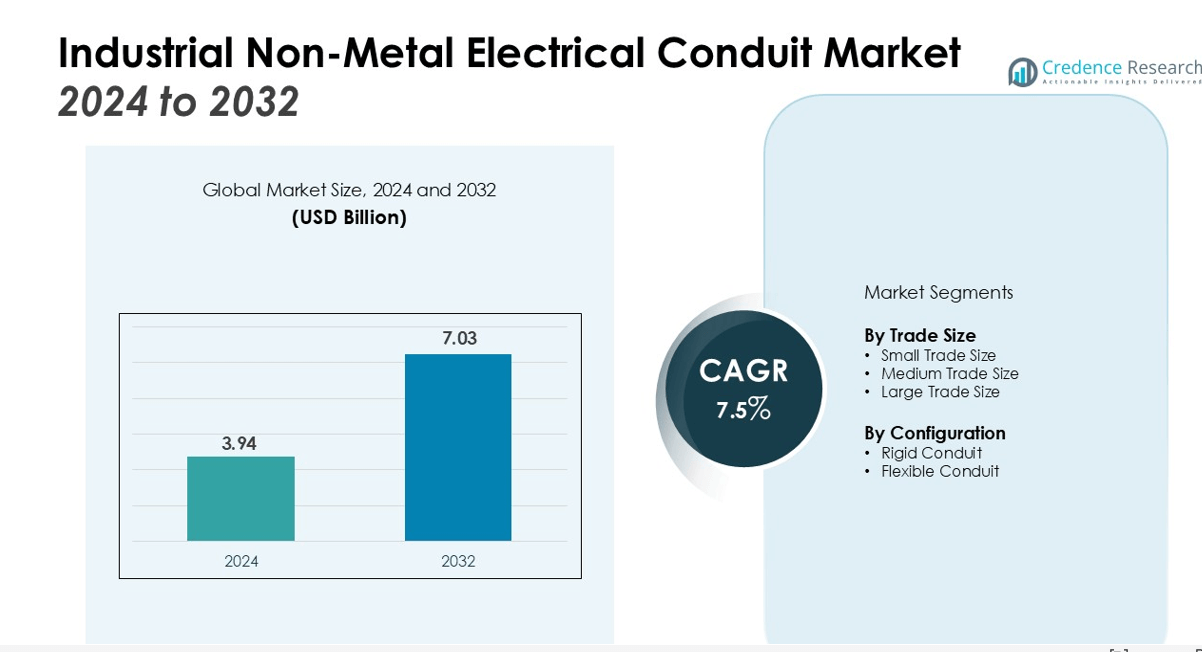

The Industrial Non-Metal Electrical Conduit Market size was valued at USD 3.94 billion in 2024 and is anticipated to reach USD 7.03 billion by 2032, at a CAGR of 7.5% during the forecast period (2024-2032).

| REPORT ATTRIBUTE |

DETAILS |

| Historical Period |

2020-2023 |

| Base Year |

2024 |

| Forecast Period |

2025-2032 |

| Industrial Non-Metal Electrical Conduit Market Size 2024 |

USD 3.94 billion |

| Industrial Non-Metal Electrical Conduit Market, CAGR |

7.5% |

| Industrial Non-Metal Electrical Conduit Market Size 2032 |

USD 7.03 billion |

Key drivers of the market include stringent industrial safety regulations, the growing focus on energy-efficient infrastructure, and the need for enhanced fire safety in industrial applications. Additionally, technological advancements in the production of non-metal electrical conduits, such as the development of high-performance, fire-retardant, and UV-resistant materials, are driving market expansion. The shift toward green and sustainable building practices also encourages the use of non-metal conduits, as they contribute to eco-friendly solutions. Furthermore, increased demand for non-metal conduits in renewable energy projects, such as solar and wind installations, is further fueling market growth.

Regionally, North America and Europe dominate the market, supported by the presence of established industrial infrastructure and stringent regulatory standards. The Asia-Pacific region, however, is expected to exhibit the highest growth due to rapid industrialization, urbanization, and infrastructure development in emerging economies like China and India. The region is also seeing a rise in government initiatives and investments in the construction and energy sectors, further boosting demand for industrial non-metal electrical conduits.

Access crucial information at unmatched prices!

Request your sample report today & start making informed decisions powered by Credence Research Inc.!

Download Sample

Market Insights:

- The Industrial Non-Metal Electrical Conduit Market is valued at USD 3.94 billion in 2024 and is projected to reach USD 7.03 billion by 2032, growing at a CAGR of 7.5%.

- Stringent industrial safety regulations are driving demand, with non-metal conduits meeting safety standards, especially in sectors like oil and gas, manufacturing, and construction.

- Technological innovations, such as fire-retardant, UV-resistant, and corrosion-resistant materials, are improving the performance and durability of non-metal conduits.

- The growing emphasis on sustainable construction practices is increasing the adoption of non-metallic conduits, which contribute to energy-efficient and eco-friendly building solutions.

- North America holds a 35% market share, with strong demand in the U.S. and Canada, particularly in energy, construction, and smart infrastructure sectors.

- Europe accounts for 30% of the market, driven by stringent environmental regulations and a focus on renewable energy and sustainable construction.

- The Asia-Pacific region holds a 25% market share, with rapid industrialization and urbanization in countries like China and India, driving demand for non-metal conduits.

Market Drivers:

Stringent Industrial Safety Regulations

Industrial Non-Metal Electrical Conduit Market growth is driven by increasing safety regulations across various industries. Governments globally are enforcing stringent rules to protect workers from electrical hazards, such as electric shocks and fires. Non-metal conduits, known for their insulation and fire-resistant properties, play a crucial role in meeting these safety standards. Their use is becoming mandatory in sectors like oil and gas, manufacturing, and construction to minimize the risk of electrical accidents, contributing significantly to market expansion.

- For instance, Atkore International’s PVC conduit is classified with a UL 94V-0 flame rating, where testing confirms the material stops burning within 10 seconds after a flame is applied.

Growing Demand for Energy-Efficient Infrastructure

The rising demand for energy-efficient infrastructure further fuels the Industrial Non-Metal Electrical Conduit Market. Non-metallic conduits offer a cost-effective and energy-efficient solution for electrical installations, particularly in residential and industrial buildings. These conduits help reduce energy loss due to their insulating properties, improving the overall energy efficiency of electrical systems. The market’s growth aligns with global efforts to enhance energy conservation in both new and retrofitted buildings.

Technological Advancements in Material Development

Technological advancements in material science are boosting the performance of non-metal electrical conduits, driving their demand in various industrial sectors. Innovations such as fire-retardant, UV-resistant, and corrosion-resistant materials make non-metal conduits more durable and versatile. These enhanced properties make them suitable for use in harsh environments, including chemical plants, refineries, and outdoor installations. As a result, industries increasingly prefer non-metallic options for long-term, reliable solutions.

- For instance, Champion Fiberglass Inc. developed the Flame Shield® Phenolic Conduit, which is engineered to maintain circuit integrity for 2 hours while withstanding temperatures of 1,850°F, meeting the UL2196 fire rating standard.

Shift Towards Sustainable and Green Building Practices

A strong shift towards sustainable and eco-friendly construction practices is another key driver for the Industrial Non-Metal Electrical Conduit Market. The growing emphasis on green building certifications and sustainable construction methods has led to a rise in demand for non-metallic conduit solutions. These products are recyclable and contribute to reduced environmental impact, aligning with both regulatory requirements and consumer demand for green building materials. This trend significantly supports market growth across various global regions.

Market Trends:

Growing Adoption of Smart Infrastructure and Automation

The Industrial Non-Metal Electrical Conduit Market is witnessing a shift towards smart infrastructure and automation in various industries. Non-metal conduits, with their ability to support digital systems and sensors, are being increasingly integrated into smart buildings and factories. These conduits facilitate the installation of advanced technologies like IoT devices, building automation systems, and energy management tools. As industries focus on automation and digital transformation, demand for reliable and flexible conduit systems is expected to rise. Non-metal conduits offer advantages like flexibility, ease of installation, and protection against electromagnetic interference, making them suitable for use in smart grids and automated processes.

- For instance, Honeywell’s building automation technologies are now featured in more than 10 million buildings worldwide.

Focus on Sustainability and Eco-Friendly Solutions

Sustainability trends continue to shape the Industrial Non-Metal Electrical Conduit Market. With increasing concerns over environmental impact, industries are turning to eco-friendly materials in construction and electrical installations. Non-metallic conduits, often made from recyclable plastic or composite materials, are being favored for their low environmental footprint compared to traditional metal alternatives. The growing emphasis on green building certifications, such as LEED and BREEAM, drives this shift as non-metal conduits align with energy-efficient and sustainable construction practices. Furthermore, advancements in the recyclability and durability of these materials ensure that they meet both regulatory standards and consumer demand for sustainable solutions.

- For instance, Ledes, a manufacturer of sustainable PVC conduits, produces products that meet advanced technological specifications for safety and durability; their conduits feature a UL 94V-0 fire rating, which ensures a flame is extinguished within 5 seconds of the fire source being removed.

Market Challenges Analysis:

Price Volatility of Raw Materials

The Industrial Non-Metal Electrical Conduit Market faces challenges related to the price volatility of raw materials. Many non-metallic conduits are manufactured using polymers and composites, which are heavily influenced by fluctuations in petroleum prices. These price variations can affect the cost of production, making it difficult for manufacturers to maintain stable pricing. This volatility often leads to unpredictable costs for businesses and challenges in budgeting for long-term projects. Companies are forced to adjust pricing strategies, which can impact profitability and demand for non-metal conduits in price-sensitive markets.

Regulatory and Compliance Challenges

Strict regulations and compliance requirements across regions present significant challenges for the Industrial Non-Metal Electrical Conduit Market. While these standards are essential for ensuring safety and quality, they can increase operational costs and complexity. Manufacturers must continually invest in meeting local and international regulatory standards, particularly for fire resistance, durability, and environmental impact. Variations in regulatory requirements across different countries complicate market entry for global players, leading to delays in product development and distribution. These challenges require ongoing adjustments in product design and testing to ensure compliance with evolving industry standards.

Market Opportunities:

Expansion in Emerging Markets

The Industrial Non-Metal Electrical Conduit Market holds significant growth potential in emerging markets. Rapid urbanization and infrastructure development in regions such as Asia-Pacific, Latin America, and the Middle East are driving demand for reliable and cost-effective electrical conduit solutions. As these regions experience economic growth and industrialization, the need for advanced electrical infrastructure and safety standards increases. Non-metallic conduits, with their cost-effectiveness and resistance to environmental factors, are well-positioned to meet these demands. Manufacturers have an opportunity to expand their presence by catering to these growing markets, providing sustainable solutions that align with local construction and regulatory requirements.

Increasing Focus on Renewable Energy and Green Construction

The growing emphasis on renewable energy projects and sustainable building practices presents a key opportunity for the Industrial Non-Metal Electrical Conduit Market. As industries and governments worldwide focus on reducing carbon footprints, the demand for eco-friendly materials in construction increases. Non-metal conduits, being recyclable and energy-efficient, align with green building standards and renewable energy initiatives. These conduits are particularly useful in solar and wind energy installations, where they offer protection for electrical systems in harsh environmental conditions. This growing trend in renewable energy and green construction further drives the adoption of non-metal electrical conduits, creating new opportunities for growth.

Market Segmentation Analysis:

By Trade Size

The market is categorized by trade size, ranging from smaller conduits used in residential and light commercial installations to larger conduits designed for heavy industrial applications. Small to medium trade sizes dominate the market due to their widespread use in residential and commercial buildings, driven by increased construction activities. Larger trade sizes, however, are gaining traction in industrial and energy sectors, particularly in the oil and gas industry, where higher capacity conduits are needed for extensive electrical installations.

- For instance, in commercial buildings, Atkore supplies Electrical Metallic Tubing (EMT) in trade sizes beginning at 1/2 inch, with a standard 10-foot conduit length used to safeguard electrical wiring runs.

By Configuration

Non-metal electrical conduits are available in various configurations, such as rigid and flexible. Rigid configurations are primarily used in permanent installations, providing durable protection for electrical wiring in industrial applications. They are widely adopted in manufacturing plants, construction, and power generation facilities. Flexible configurations, on the other hand, offer versatility and ease of installation, making them ideal for areas that require frequent movement or modifications, such as in commercial or residential settings. The growing demand for flexible conduits in industrial automation and robotics is also contributing to the segment’s expansion.

- For instance, Electri-Flex produces a line of nearly 50 distinct types of “Liquatite” flexible conduits, including halogen-free options that are UL listed and designed to self-extinguish, enhancing safety in enclosed spaces like data centers.

Segmentations:

By Trade Size

- Small Trade Size

- Medium Trade Size

- Large Trade Size

By Configuration

- Rigid Conduit

- Flexible Conduit

By Region

- North America

- Europe

- UK

- France

- Germany

- Italy

- Spain

- Russia

- Belgium

- Netherlands

- Austria

- Sweden

- Poland

- Denmark

- Switzerland

- Rest of Europe

- Asia Pacific

- China

- Japan

- South Korea

- India

- Australia

- Thailand

- Indonesia

- Vietnam

- Malaysia

- Philippines

- Taiwan

- Rest of Asia Pacific

- Latin America

- Brazil

- Argentina

- Peru

- Chile

- Colombia

- Rest of Latin America

- Middle East

- UAE

- KSA

- Israel

- Turkey

- Iran

- Rest of Middle East

- Africa

- Egypt

- Nigeria

- Algeria

- Morocco

- Rest of Africa

Regional Analysis:

North America: Dominance and Demand for Advanced Solutions

North America holds a market share of 35% in the Industrial Non-Metal Electrical Conduit Market. The region benefits from a well-established industrial infrastructure and strict regulatory environment. The U.S. and Canada show strong demand for non-metal conduits, driven by sectors such as construction, automotive, and energy. Non-metallic conduits are preferred for their fire resistance and durability in industrial environments like manufacturing plants and power stations. The region’s increasing focus on smart infrastructure and green building initiatives further supports demand for these solutions.

Europe: Stringent Standards and Growing Adoption in Sustainable Construction

Europe accounts for a market share of 30% in the Industrial Non-Metal Electrical Conduit Market. The region is driven by stringent environmental and safety standards, along with a growing emphasis on sustainability. Non-metal conduits, offering recyclability and lower environmental impact, are gaining traction in green building projects across countries like Germany, France, and the UK. The market is further supported by investments in renewable energy and industrial automation, where non-metal conduits provide long-term reliability and performance, enhancing their adoption.

Asia-Pacific: Rapid Growth and Infrastructure Development

The Asia-Pacific region commands a market share of 25% in the Industrial Non-Metal Electrical Conduit Market. Driven by rapid industrialization, urbanization, and infrastructure development, demand for non-metallic conduits is expanding, especially in China, India, and Southeast Asia. The rising construction and energy needs in the region are key drivers, with non-metallic conduits offering durability and ease of installation. The growing focus on safety standards, combined with the increasing adoption of renewable energy, presents significant growth opportunities for the market in this region.

Shape Your Report to Specific Countries or Regions & Enjoy 30% Off!

Key Player Analysis:

- ASTRAL Limited

- ABB

- Anamet Electrical, Inc.

- Atkore

- Legrand

- Champion Fiberglass, Inc.

- CANTEX INC.

- Hubbell

- Electri-Flex Company

- Wienerberger AG

- HellermannTyton

- Schneider Electric

Competitive Analysis:

The Industrial Non-Metal Electrical Conduit Market is competitive, with key players such as Atkore International, General Electric, and Hubbell Incorporated leading the market. These companies maintain a strong market position by offering high-quality, innovative products that meet industry standards for safety, performance, and durability. They focus on advancements in materials, such as fire-retardant and UV-resistant conduits, to cater to diverse industrial applications. Smaller regional players also contribute by offering competitive pricing and specialized solutions for industries like oil and gas or renewable energy. The market’s competition is shaped by factors like technological innovation, regulatory compliance, and the growing demand for sustainable products, prompting ongoing product development and strategic partnerships.

Recent Developments:

- In June 2025, ABB broadened its large robot portfolio by introducing four new models at the Automatica 2025 trade fair in Munich, including the IRB 6730S, IRB 6750S, and IRB 6760, all powered by its energy-efficient OmniCore controller.

- In August 2025, Astral Limited announced its strategic acquisition of an 80% stake in NEXELON Chem Private Limited to secure its raw material supply chain for CPVC resin and enhance operational self-sufficiency.

Report Coverage:

The research report offers an in-depth analysis based on Trade Size, Configuration and Region. It details leading market players, providing an overview of their business, product offerings, investments, revenue streams, and key applications. Additionally, the report includes insights into the competitive environment, SWOT analysis, current market trends, as well as the primary drivers and constraints. Furthermore, it discusses various factors that have driven market expansion in recent years. The report also explores market dynamics, regulatory scenarios, and technological advancements that are shaping the industry. It assesses the impact of external factors and global economic changes on market growth. Lastly, it provides strategic recommendations for new entrants and established companies to navigate the complexities of the market.

Future Outlook:

- The demand for industrial non-metal electrical conduits will continue to rise due to the increasing emphasis on industrial safety regulations and energy-efficient infrastructure.

- Technological advancements in conduit materials, such as fire-retardant and UV-resistant options, will drive product innovation and expand application areas.

- The shift toward sustainable construction practices will boost the adoption of non-metal conduits, as they are eco-friendly and recyclable.

- Growing investments in renewable energy projects, such as wind and solar, will create significant opportunities for non-metal conduit solutions.

- Expansion of the smart infrastructure and automation sectors will fuel demand for flexible and durable conduit solutions in industrial and commercial applications.

- Rising construction activities in emerging economies, especially in Asia-Pacific, will contribute to the continued growth of the market.

- The development of green building certifications and eco-friendly regulations will enhance the demand for non-metallic electrical conduits in construction projects.

- Increasing urbanization and industrialization in developing regions will drive the need for cost-effective, high-performance conduit systems.

- Regional players will focus on strengthening their distribution networks and offering tailored solutions to meet local demand.

- Manufacturers will continue to invest in R&D to develop new materials and improve conduit performance for demanding industrial environments.