Market Overview

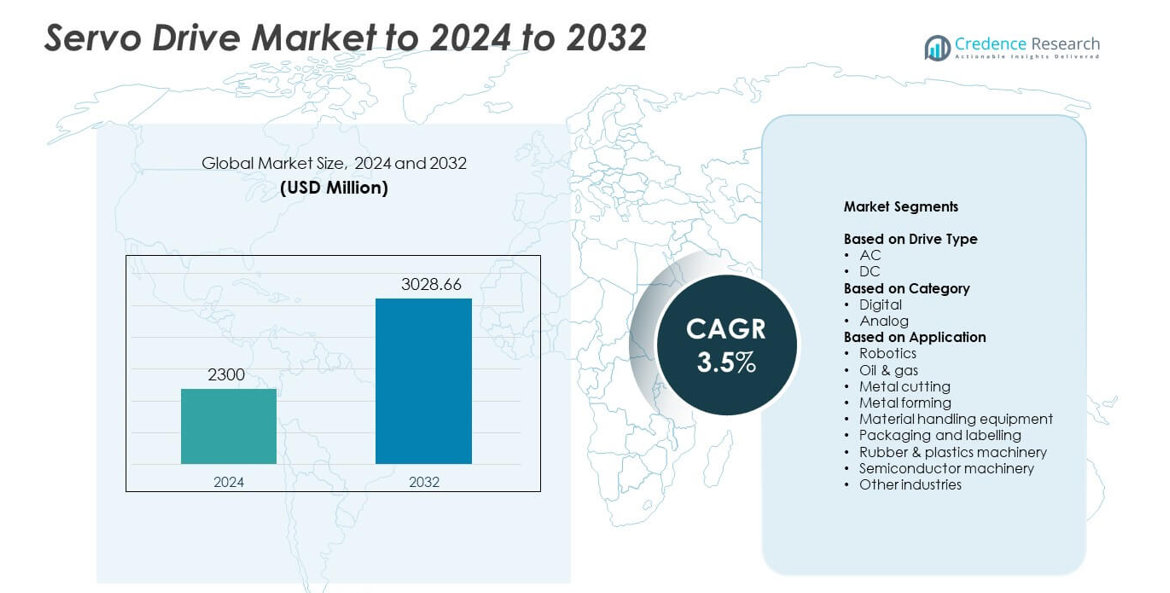

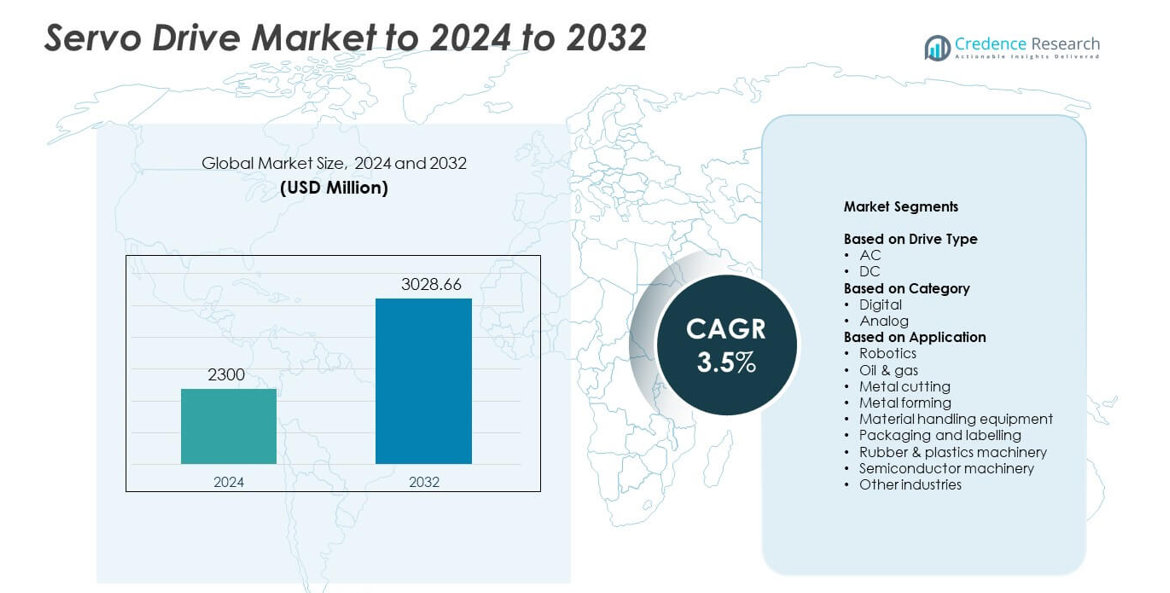

Servo Drive Market size was valued USD 2300 million in 2024 and is anticipated to reach USD 3028.66 million by 2032, at a CAGR of 3.5% during the forecast period.

| REPORT ATTRIBUTE |

DETAILS |

| Historical Period |

2020-2023 |

| Base Year |

2024 |

| Forecast Period |

2025-2032 |

| Servo Drive Market Size 2024 |

USD 2300 million |

| Servo Drive Market, CAGR |

3.5% |

| Servo Drive Market Size 2032 |

USD 3028.66 million |

The Servo Drive Market includes major players such as Danfoss, Delta Electronics, Beckhoff Automation, DMM Technology, Advanced Motion Controls, C&M Robotics, and ABB, each expanding their presence through advanced digital drive platforms and strong integration with automation systems. These companies focus on precision control, energy-efficient designs, and smart features to support growing demand from robotics, packaging, metal processing, and semiconductor equipment. North America emerged as the leading region in 2024 with a 34% share, driven by strong adoption of automation, robotics expansion, and continuous modernization of industrial facilities across key manufacturing sectors.

Market Insights

- The Servo Drive Market reached USD 2300 million in 2024 and is projected to hit USD 3028.66 million by 2032 at a CAGR of 3.5%.

- Rising automation adoption in robotics, metal processing, and packaging drives strong demand for high-precision servo systems across global manufacturing.

- Smart factory trends expand the use of digital servo drives with IoT connectivity, real-time monitoring, and energy-efficient motion control.

- Leading players focus on advanced control features and integrated drive platforms, while high installation and integration costs remain key restraints.

- North America led the market with 34% share, Asia Pacific held 31%, Europe captured 28%, and robotics emerged as the dominant application segment.

Access crucial information at unmatched prices!

Request your sample report today & start making informed decisions powered by Credence Research Inc.!

Download Sample

Market Segmentation Analysis:

By Drive Type

AC drives held the dominant position in 2024 with about 72% share. Strong adoption came from their high efficiency, wide speed control range, and lower maintenance needs in industrial motion systems. AC drives support automation in robotics, packaging, and CNC machinery, which boosts demand across factories upgrading to precise motion control. DC drives remained smaller due to higher upkeep and limited use in legacy equipment, but they continued to serve niche applications needing smooth torque at low speeds.

- For instance, ABB’s ACS880 industrial AC drives cover a continuous power range from 0.55 to 6000 kW for high-performance motor control.

By Category

Digital drives led the market in 2024 with nearly 81% share. Demand increased as manufacturers shifted toward advanced servo systems offering real-time monitoring, precision tuning, and seamless integration with PLCs and industrial networks. Digital platforms helped improve productivity and reduce downtime through automated diagnostics. Analog drives maintained a limited share due to basic functionality and lack of compatibility with smart factory systems, but they stayed relevant in low-cost retrofits and simple motion tasks.

- For instance, Mitsubishi Electric’s MELSERVO-J5 servo amplifiers support 1 Gbps CC-Link IE TSN communication with a command cycle of 31.25 μs and a speed frequency response of 3.5 kHz.

By Application

Robotics emerged as the leading application in 2024 with around 29% share. Growth was driven by rising automation in assembly, welding, and pick-and-place tasks across automotive, electronics, and logistics sectors. Servo drives enabled precise speed and position control, which enhanced robot accuracy and cycle time. Material handling, metal cutting, and packaging also showed strong demand as industries adopted high-performance motion systems to improve throughput. Semiconductor machinery expanded with increasing wafer fabrication needs, while oil and gas, rubber, and plastics applications showed steady use in controlled processing tasks.

Key Growth Drivers

Rising Automation Adoption

Manufacturers increased automation across production lines to improve accuracy, speed, and efficiency. Servo drives supported this shift with precise motion control required in robotics, CNC tools, and packaging systems. Strong demand came from factories upgrading to smarter systems that reduce errors and downtime. Industries such as automotive, electronics, and food processing expanded servo usage as part of digital transformation strategies. This trend positioned automation growth as a leading driver for servo drive adoption.

- For instance, Rockwell Automation’s Kinetix 5700 servo drive platform delivers a unified power range from 1.6 to 112 kW for large automated machines.

Expansion of Robotics Across Industries

Robotics gained strong traction in assembly, welding, inspection, and logistics tasks. Servo drives enabled high-precision movement and speed control that matched rising performance needs in multi-axis robotic systems. Companies adopted robots to solve labor shortages, boost safety, and maintain consistent output. Growing installation of collaborative robots further accelerated servo demand due to enhanced control needs. Robotics growth remained a major driver as sectors moved toward flexible and scalable automation models.

- For instance, Yaskawa’s Sigma-7 SERVOPACK servo drives achieve a frequency response of 3.1 kHz and reduce axis settling time to under 4 ms for fast robotic motion.

Growing Need for Energy-Efficient Motion Systems

Industries focused on lowering operating costs and meeting energy norms through efficient motion equipment. Servo drives delivered reduced power consumption, improved torque control, and better heat management compared to older systems. Many firms replaced hydraulic and pneumatic units with electric servo systems to gain efficiency and maintain performance. The push toward sustainability, combined with rising electricity costs, strengthened adoption of energy-saving servo solutions across manufacturing units.

Key Trends & Opportunities

Integration of IoT and Smart Control Features

IoT-enabled servo drives gained momentum as factories adopted predictive maintenance and real-time monitoring tools. Smart drives allowed data capture on load, vibration, and cycle performance, improving reliability and reducing downtime. Enhanced communication protocols helped integrate servo systems with MES and cloud platforms. This trend opened new opportunities for advanced diagnostics, remote tuning, and improved optimization across high-speed production environments.

- For instance, Bosch Rexroth’s IndraDrive Cs servo system combines multi-Ethernet communication with continuous power ratings from 50 W to 14 kW for connected motion applications.

Growth of Semiconductor and Electronics Manufacturing

Rising semiconductor production created strong demand for high-precision motion systems. Servo drives supported wafer handling, lithography, and inspection processes that required accurate and stable movement. Electronics assembly lines expanded servo integration in surface-mount and testing equipment. Growing investments in chip fabrication facilities offered long-term opportunities for drive manufacturers to supply advanced motion control systems tailored to clean-room and micro-precision requirements.

- For instance, ASML’s EUV lithography systems position the wafer stage to within roughly 0.25 nanometers, adjusting position about 20,000 times per second during chip production.

Key Challenges

High Initial Investment and Integration Cost

Servo systems involved higher upfront expenses compared to traditional motion solutions. Many small and medium industries faced financial barriers when upgrading machinery due to installation, tuning, and control integration costs. These expenses slowed adoption despite long-term efficiency benefits. Complex setup requirements also increased deployment challenges for firms with limited technical expertise.

Shortage of Skilled Technical Workforce

Advanced servo systems needed trained personnel for configuration, troubleshooting, and maintenance. Many regions faced shortages of technicians experienced in tuning servo parameters, diagnosing faults, and handling digital communication protocols. This gap limited full performance utilization and increased downtime risks. Workforce constraints remained a core challenge for industries transitioning toward smart automated systems.

Regional Analysis

North America

North America held about 34% share in the servo drive market in 2024 due to strong automation adoption across manufacturing, automotive, and electronics sectors. The region saw rising investments in robotics, advanced CNC machines, and motion control upgrades, which increased demand for high-precision servo systems. Growth in semiconductor facilities across the United States further supported servo deployment in wafer handling and inspection tools. Supportive industrial modernization policies and strong presence of key automation vendors helped maintain steady expansion in new installations and retrofit projects.

Europe

Europe captured nearly 28% share in 2024, supported by established industrial automation practices and strong demand from automotive, packaging, and metalworking sectors. Germany, Italy, and France contributed significantly as factories shifted toward digital motion systems with higher accuracy and energy efficiency. The rise of smart factories under Industry 4.0 increased adoption of networked servo drives across production lines. Strong focus on sustainability and reduced operating costs encouraged the replacement of older hydraulic systems with electric servo technologies across multiple industries.

Asia Pacific

Asia Pacific led growth momentum with around 31% share in 2024, driven by large-scale manufacturing expansion in China, Japan, South Korea, and India. The region saw strong uptake of servo drives in electronics assembly, robotics, semiconductor machinery, and high-speed packaging lines. Rapid industrialization and strong government support for automation accelerated deployment across new plants. Increasing investment in chip fabrication and EV production further strengthened regional demand. Competitive pricing from regional suppliers also encouraged widespread adoption across mid-tier manufacturers.

Latin America

Latin America accounted for about 4% share in 2024, with steady growth driven by rising automation in food processing, packaging, and automotive component production. Brazil and Mexico remained key contributors as factories upgraded older machinery to improve reliability and output. Growing interest in robotics for handling, palletizing, and assembly tasks supported demand for servo drives. Limited capital investment slowed broader adoption, but ongoing industrial modernization efforts created opportunities for gradual expansion of motion control systems in the region.

Middle East and Africa

Middle East and Africa held nearly 3% share in 2024, with demand concentrated in oil and gas operations, material handling, and emerging manufacturing clusters. Countries such as the UAE and Saudi Arabia invested in automated systems to improve energy efficiency and operational accuracy. Growth in logistics hubs and industrial diversification programs increased interest in servo-controlled machinery. Adoption remained moderate due to limited industrial base, but long-term opportunities emerged from expanding infrastructure, renewable energy projects, and robotics adoption in specialized applications.

Market Segmentations:

By Drive Type

By Category

By Application

- Robotics

- Oil & gas

- Metal cutting

- Metal forming

- Material handling equipment

- Packaging and labelling

- Rubber & plastics machinery

- Semiconductor machinery

- Other industries

By Geography

- North America

- Europe

- Germany

- France

- U.K.

- Italy

- Spain

- Rest of Europe

- Asia Pacific

- China

- Japan

- India

- South Korea

- South-east Asia

- Rest of Asia Pacific

- Latin America

- Brazil

- Argentina

- Rest of Latin America

- Middle East & Africa

- GCC Countries

- South Africa

- Rest of the Middle East and Africa

Competitive Landscape

The Servo Drive Market features key players such as Danfoss, Delta Electronics, Beckhoff Automation, DMM Technology, Advanced Motion Controls, C&M Robotics, and ABB. The competitive landscape reflects strong focus on advanced motion control technologies, wider product portfolios, and high-performance digital drive platforms. Leading vendors invest in precision control, real-time communication features, and integration with industrial automation networks to meet rising demand from robotics, semiconductor tools, and packaging systems. Companies expand global presence through strategic partnerships, new manufacturing facilities, and enhanced distribution channels. Many competitors strengthen offerings with energy-efficient designs and predictive maintenance capabilities to support smart factory initiatives. Ongoing innovation in multi-axis control, compact form factors, and IoT-enabled monitoring continues to shape market positioning, while sustained investment in R&D helps firms address emerging applications across diverse industrial environments.

Shape Your Report to Specific Countries or Regions & Enjoy 30% Off!

Key Player Analysis

Recent Developments

- In 2025, Danfoss Drives launched the VLT Multiaxis Servo Drive 520, a modular multi-axis servo platform designed for high-performance packaging, material handling, and robotics machines.

- In 2024, ABB introduced a CIP Safety module for its low-voltage drives, adding safe torque off and other safety functions over Ethernet/IP for servo and variable-speed drive applications.

- In 2024, At SPS 2024 in November, Delta introduced the A3-EP Series AC Servo Drive with encoder feedback and SIL3 functional safety, aiming at precise multi-axis servo control for industrial machines

Report Coverage

The research report offers an in-depth analysis based on Drive Type, Category, Application, and Geography. It details leading market players, providing an overview of their business, product offerings, investments, revenue streams, and key applications. Additionally, the report includes insights into the competitive environment, SWOT analysis, current market trends, as well as the primary drivers and constraints. Furthermore, it discusses various factors that have driven market expansion in recent years. The report also explores market dynamics, regulatory scenarios, and technological advancements that are shaping the industry. It assesses the impact of external factors and global economic changes on market growth. Lastly, it provides strategic recommendations for new entrants and established companies to navigate the complexities of the market.

Future Outlook

- The market will grow as industries increase automation across production lines.

- Demand for high-precision motion systems will rise in robotics and CNC tools.

- Smart servo drives with IoT features will see wider adoption in modern factories.

- Energy-efficient servo solutions will gain traction as firms cut operating costs.

- Semiconductor and electronics expansion will boost need for micro-precision motion control.

- Collaborative robots will create new opportunities for advanced multi-axis servo systems.

- Retrofit projects will expand as manufacturers replace outdated hydraulic and pneumatic units.

- Digital servo platforms will grow as Industry 4.0 connectivity becomes standard.

- Regional suppliers will increase competition through cost-effective drive solutions.

- Skill development initiatives will support better adoption and system optimization.