Market Overview

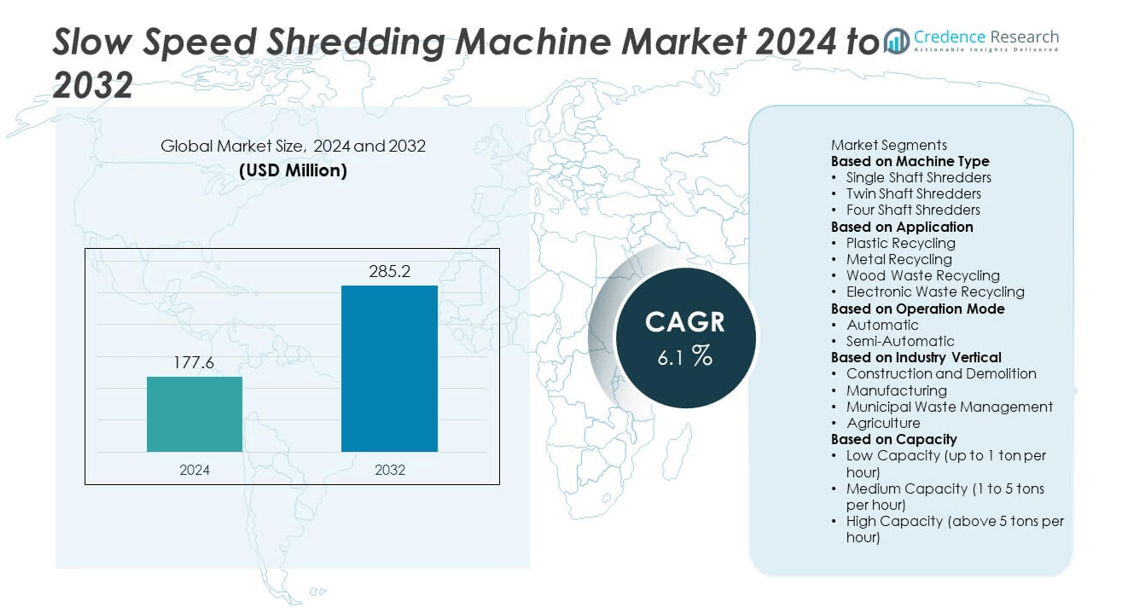

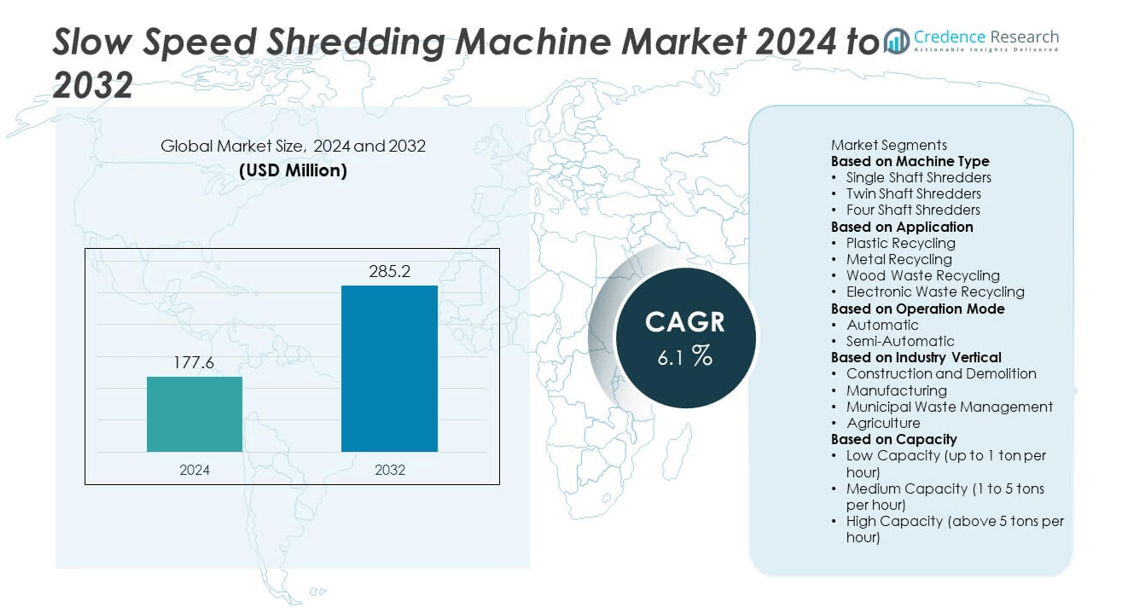

The Slow Speed Shredding Machine Market was valued at USD 177.6 million in 2024 and is projected to reach USD 285.2 million by 2032, expanding at a CAGR of 6.1% during the forecast period.

| REPORT ATTRIBUTE |

DETAILS |

| Historical Period |

2020-2023 |

| Base Year |

2024 |

| Forecast Period |

2025-2032 |

| Slow Speed Shredding Machine Market Size 2024 |

USD 177.6 million |

| Slow Speed Shredding Machine Market, CAGR |

6.1% |

| Slow Speed Shredding Machine Market Size 2032 |

USD 285.2 million |

The Slow Speed Shredding Machine Market grows through strong drivers and evolving trends shaping global demand. Rising waste management needs, stricter environmental regulations, and recycling initiatives push industries and municipalities to adopt efficient shredders. It supports resource recovery across plastics, wood, metals, and biomass, aligning with sustainability goals.

The Slow Speed Shredding Machine Market shows strong presence across North America, Europe, Asia Pacific, Latin America, and the Middle East & Africa. North America leads with advanced adoption in municipal waste management and recycling, supported by stringent environmental standards and strong industrial demand. Europe emphasizes sustainability and circular economy practices, driving high adoption in countries such as Germany, the UK, and France. Asia Pacific records rapid growth due to urbanization, industrial expansion, and rising waste volumes in China, India, and Southeast Asia. Latin America and the Middle East & Africa show steady development, supported by growing infrastructure projects and recycling initiatives. Key players shaping the market include Terex Corporation, Doppstadt GmbH, and Vecoplan AG, known for advanced product portfolios and global reach. Companies such as SSI Shredding Systems also expand market presence with durable, high-capacity machines tailored for both municipal and industrial applications.

Market Insights

- The Slow Speed Shredding Machine Market was valued at USD 177.6 million in 2024 and is projected to reach USD 285.2 million by 2032, growing at a CAGR of 6.1% during the forecast period.

- The market grows with rising waste management requirements, stricter regulations, and increasing adoption of recycling practices across industries and municipalities.

- Key trends include the integration of automation, IoT-based monitoring, and energy-efficient systems that improve reliability, reduce downtime, and lower operational costs.

- Competitive dynamics remain strong with companies such as Terex Corporation, Doppstadt GmbH, Vecoplan AG, and SSI Shredding Systems focusing on product innovation, durability, and global distribution networks.

- High initial investment costs, complex maintenance requirements, and performance limitations in handling mixed or tough waste streams act as key restraints.

- North America and Europe maintain significant demand supported by advanced waste management systems and strict environmental policies, while Asia Pacific records rapid growth due to urbanization and industrial expansion.

- Emerging opportunities exist in Latin America and the Middle East & Africa, where infrastructure development and government initiatives for sustainable practices are expected to expand adoption of shredding technologies.

Access crucial information at unmatched prices!

Request your sample report today & start making informed decisions powered by Credence Research Inc.!

Download Sample

Market Drivers

Rising Demand for Efficient Waste Management Solutions

The Slow Speed Shredding Machine Market benefits from increasing pressure to handle waste effectively. Municipalities and private operators prioritize advanced shredders to process bulky materials and reduce landfill volumes. These machines improve operational efficiency by reducing the size of waste for easier sorting and recycling. Governments strengthen regulations that push industries to adopt better waste treatment technologies. It helps organizations comply with sustainability targets and avoid penalties. Rising awareness of environmental protection drives consistent adoption of shredding machines in both developed and emerging regions.

- For instance, Terex Recycling Systems launched the TDS-820SE, a static electric low-speed primary shredder. As an electric-powered machine, it offers a reduction in noise and emissions compared to diesel-based models. The shredder is capable of processing a wide range of materials, though its processing capacity is dependent on the type of waste being shredded.

Growing Focus on Recycling and Resource Recovery

Recycling industries expand rapidly, creating strong demand for machines that handle diverse materials. The Slow Speed Shredding Machine Market gains from equipment that can process wood, plastic, and metal without frequent breakdowns. It enhances the value chain by preparing materials for secondary use. Recycling companies invest in shredders to improve throughput and maximize recovery rates. High durability and low maintenance costs make these machines appealing for long-term operations. Governments and corporations emphasize circular economy practices, strengthening the role of shredding machines.

- For instance, Vecoplan AG introduced its VEZ 3200 re-shredder, designed for RDF applications, with a HiTorc drive delivering 110,000 Nm of torque for continuous heavy-duty processing of plastics and biomass.

Rising Industrial Applications and Versatility of Equipment

The Slow Speed Shredding Machine Market grows as industries such as construction, mining, and agriculture adopt shredders. These machines reduce large materials, including concrete, scrap metal, and biomass, into manageable forms. It ensures easier transportation and further processing across industrial sectors. Manufacturers design machines to handle heavy-duty operations with minimal downtime. Customized models enable users to adapt shredders for specific waste streams. This versatility supports growth across multiple end-user industries that require reliable waste reduction technology.

Strong Emphasis on Cost Efficiency and Safety Standards

The Slow Speed Shredding Machine Market benefits from rising focus on operational cost savings. Businesses prefer machines with energy-efficient motors and durable cutting systems to reduce expenses. It reduces overall waste handling costs by minimizing manual labor and downtime. Manufacturers also integrate advanced safety features, including automatic overload protection and emergency stop systems. These enhancements improve operator confidence and workplace safety. Compliance with strict international safety standards makes shredders a preferred choice for industrial and municipal buyers.

Market Trends

Integration of Advanced Automation and Digital Monitoring

The Slow Speed Shredding Machine Market shows strong adoption of automation technologies. Modern shredders use digital sensors and IoT platforms to monitor performance in real time. It helps operators detect wear and prevent costly breakdowns before they occur. Automated control systems improve precision in material processing and reduce manual intervention. Manufacturers design user-friendly interfaces that allow easy operation and tracking of efficiency metrics. These advancements increase reliability, productivity, and cost savings for industrial users.

- For instance, Shred-Tech introduced its Connect™ IoT platform in 2022, offering real-time diagnostics and remote monitoring for its shredder fleets. The system enables predictive maintenance, helping to reduce unplanned downtime by anticipating maintenance needs. The “up to 30% reduction in downtime” is a common industry benchmark for the benefits of predictive maintenance, not a specific, guaranteed figure tied exclusively to Shred-Tech’s platform.

Sustainability and Growing Use of Eco-Friendly Designs

Sustainability remains a major trend shaping the Slow Speed Shredding Machine Market. Manufacturers focus on producing energy-efficient models with reduced emissions. It supports industries working toward lower environmental impact and compliance with green regulations. Eco-friendly designs incorporate durable parts that extend machine life and minimize waste. Some companies also explore recyclable materials in the machine’s construction. This trend aligns with global initiatives promoting responsible resource management and circular economy practices.

- For instance, Doppstadt launched its INVENTHOR 6.2 shredder, which features a redesigned VarioDirect Drive system for high efficiency and low fuel consumption. The company has emphasized the drive system’s economic shredding, flexibility, and high production rates. The shredder won the iF Design Award and Red Dot Design Award in 2025, which recognized its overall design and sustainable engineering.

Expansion Across New Industrial and Municipal Applications

The Slow Speed Shredding Machine Market expands into a wider range of applications. Industries such as mining, construction, and agriculture adopt shredders for material size reduction. It allows efficient handling of bulky items, including demolition debris and biomass. Municipalities increase investments in shredders to improve urban waste processing capabilities. The machines adapt to different streams of waste, supporting both industrial and civic requirements. This trend highlights their versatility and growing demand across multiple sectors.

Technological Advancements in Safety and Performance Features

The Slow Speed Shredding Machine Market benefits from continuous innovation in safety and performance. Modern machines include overload protection, automated shut-off systems, and reinforced cutting chambers. It ensures operator safety while maintaining consistent output quality. Manufacturers also enhance machine designs to handle higher volumes with lower power consumption. Integration of hybrid drive systems and improved cutting mechanisms extends performance capacity. These advancements help industries achieve efficiency while maintaining strict safety compliance.

Market Challenges Analysis

High Initial Investment and Maintenance Costs

The Slow Speed Shredding Machine Market faces significant challenges due to high capital requirements. Many small and medium enterprises hesitate to invest because of limited budgets. It creates barriers for broader adoption despite clear benefits in efficiency and waste reduction. Maintenance and replacement of cutting components increase operating costs further, discouraging some buyers. These machines often require specialized servicing, which limits access in remote or developing regions. Rising demand exists, but affordability concerns restrict faster market penetration.

Operational Limitations and Regulatory Compliance Pressure

The Slow Speed Shredding Machine Market also encounters operational and regulatory challenges. Some shredders struggle to process extremely tough or mixed materials, reducing performance efficiency. It causes delays and higher energy use when machines fail to handle complex waste streams. Strict environmental and safety regulations force manufacturers to upgrade designs regularly, adding to production costs. Compliance requirements differ by region, creating complexity for global players. Limited technical expertise among operators in emerging markets further slows adoption of advanced shredding solutions.

Market Opportunities

Rising Demand from Circular Economy and Recycling Initiatives

The Slow Speed Shredding Machine Market has strong opportunities driven by global recycling and circular economy goals. Governments and corporations invest heavily in sustainable waste solutions, creating steady demand for advanced shredders. It enables efficient material recovery across plastics, metals, wood, and biomass, supporting reuse in various industries. The machines align with policies aimed at reducing landfill dependency and promoting resource conservation. Growing interest in eco-friendly practices increases funding for modern shredding facilities. Companies that offer high-efficiency, durable machines stand to gain from these policy-driven opportunities.

Expansion in Emerging Economies and New Industrial Sectors

The Slow Speed Shredding Machine Market can grow rapidly in emerging economies where waste management infrastructure remains underdeveloped. Urbanization and industrial expansion generate higher volumes of waste, driving the need for reliable shredders. It provides solutions for industries such as construction, agriculture, and energy, where demand for waste size reduction continues to rise. Municipal bodies in developing regions also increase investments in waste processing plants. Manufacturers offering cost-effective models with versatile applications can capture significant market share. Partnerships with local distributors and governments create further openings for international players to expand.

Market Segmentation Analysis:

By Machine Type

The Slow Speed Shredding Machine Market divides into single-shaft and dual-shaft models. Single-shaft machines find strong demand in small-scale operations where space and budget remain limited. These models deliver reliable shredding for uniform materials such as wood and plastics. It provides a cost-effective option for companies that require moderate capacity without compromising efficiency. Dual-shaft machines dominate large-scale applications, including construction, mining, and municipal waste treatment. They handle bulky, irregular, and mixed materials with higher torque and throughput. Manufacturers continue to improve both types, balancing affordability with performance to reach diverse customer segments.

- For instance, Vecoplan AG offers the VEZ 3200 TT V pre-shredder, equipped with two HiTorc direct drives. The total drive system can deliver a peak torque of 110,000 Nm to the rotor, allowing it to efficiently process bulky and difficult materials. The shredder can handle mixed waste streams for the production of refuse-derived fuels and has a significantly higher maximum throughput of up to 55 tons per hour.

By Application

Applications shape the growth outlook of the Slow Speed Shredding Machine Market. Municipal waste management remains a leading application, driven by rising urban waste volumes and strict disposal regulations. It ensures efficient handling of bulky waste materials, reducing landfill dependency. Industrial sectors such as construction, agriculture, and mining also represent significant demand, using shredders to manage debris, biomass, and scrap. Recycling companies invest in shredders to prepare plastics, metals, and wood for reuse, aligning with circular economy initiatives. Specialized applications include energy recovery plants where shredded material contributes to biomass energy production. This wide application base secures consistent adoption across industries and municipalities.

- For instance, Doppstadt GmbH has launched the CoreShred 900, a twin-shaft shredder designed for high-performance shredding of challenging materials, such as construction and demolition debris, scrap metal, railway sleepers, and waste wood.

By Operation Mode

The Slow Speed Shredding Machine Market categorizes machines into automatic and semi-automatic modes. Automatic shredders dominate due to advanced control systems, reduced labor needs, and higher efficiency in large operations. It enhances productivity by allowing continuous operation with minimal human input. Semi-automatic machines remain relevant for smaller enterprises seeking affordable and flexible solutions. These machines require manual oversight but offer cost savings and easier maintenance. Manufacturers design both categories with improved safety features, energy-efficient motors, and adaptive controls. This segmentation highlights growing demand for machines that combine operational efficiency with user-friendly technology.

Segments:

Based on Machine Type

- Single Shaft Shredders

- Twin Shaft Shredders

- Four Shaft Shredders

Based on Application

- Plastic Recycling

- Metal Recycling

- Wood Waste Recycling

- Electronic Waste Recycling

Based on Operation Mode

Based on Industry Vertical

- Construction and Demolition

- Manufacturing

- Municipal Waste Management

- Agriculture

Based on Capacity

- Low Capacity (up to 1 ton per hour)

- Medium Capacity (1 to 5 tons per hour)

- High Capacity (above 5 tons per hour)

Based on the Geography:

- North America

- Europe

- UK

- France

- Germany

- Italy

- Spain

- Russia

- Belgium

- Netherlands

- Austria

- Sweden

- Poland

- Denmark

- Switzerland

- Rest of Europe

- Asia Pacific

- China

- Japan

- South Korea

- India

- Australia

- Thailand

- Indonesia

- Vietnam

- Malaysia

- Philippines

- Taiwan

- Rest of Asia Pacific

- Latin America

- Brazil

- Argentina

- Peru

- Chile

- Colombia

- Rest of Latin America

- Middle East

- UAE

- KSA

- Israel

- Turkey

- Iran

- Rest of Middle East

- Africa

- Egypt

- Nigeria

- Algeria

- Morocco

- Rest of Africa

Regional Analysis

North America

North America holds a market share of around 32% in the Slow Speed Shredding Machine Market, reflecting its position as a mature and advanced region for waste management solutions. The region benefits from well-established infrastructure for municipal waste treatment, recycling, and industrial processing. It invests heavily in advanced shredding technologies to meet strict environmental standards and sustainability regulations. The United States leads the market with strong demand from recycling companies, construction firms, and government waste management projects. Canada also contributes significantly, driven by its national policies supporting sustainable development and renewable energy initiatives. It continues to expand opportunities for shredding machines as industries adopt more efficient and eco-friendly waste management practices. Ongoing technological innovations, such as automated control systems and smart monitoring, further strengthen the regional market.

Europe

Europe accounts for approximately 28% of the global market share in the Slow Speed Shredding Machine Market. The region prioritizes environmental compliance and circular economy models, making shredding machines an essential part of its waste management ecosystem. Countries such as Germany, the UK, France, and Italy remain at the forefront of adoption due to advanced recycling networks and strong regulatory frameworks. It supports demand across industrial sectors including construction, manufacturing, and biomass energy production. Strict directives from the European Union on waste reduction and landfill restrictions create consistent demand for shredders. The region also promotes innovations in energy-efficient designs and low-emission machinery to reduce carbon footprints. This policy-driven environment ensures Europe continues to maintain strong market momentum.

Asia Pacific

Asia Pacific captures nearly 25% of the global market share, positioning it as one of the fastest-growing regions for the Slow Speed Shredding Machine Market. Rapid urbanization and industrialization in China, India, and Southeast Asia generate massive volumes of municipal and industrial waste. It drives governments and private companies to adopt shredding solutions to manage growing waste streams effectively. China leads regional adoption with its large-scale recycling and manufacturing operations, while India records significant demand due to expanding infrastructure and urban waste challenges. Japan and South Korea contribute with strong technology integration and advanced industrial waste management systems. The region’s rising focus on circular economy practices, coupled with increased investments in recycling, further strengthens growth. Affordable models targeting small and medium enterprises are also gaining traction, widening the adoption base.

Latin America

Latin America represents about 8% of the global Slow Speed Shredding Machine Market. The region is at an early stage of adopting advanced waste management solutions but shows growing potential. Brazil, Mexico, and Argentina lead adoption as urbanization accelerates and municipal waste volumes rise. It creates opportunities for investment in shredding machines, particularly in recycling and construction waste applications. Limited budgets and infrastructure challenges restrict rapid growth, but government programs supporting sustainable practices encourage market expansion. Regional players and international manufacturers increasingly focus on cost-effective solutions suitable for developing economies. Partnerships with public and private organizations are expected to boost market presence in the coming years.

Middle East and Africa

The Middle East and Africa hold a market share of nearly 7% in the Slow Speed Shredding Machine Market. The region faces significant challenges in waste management infrastructure but shows rising adoption due to increasing industrial activity and urban population growth. The United Arab Emirates and Saudi Arabia lead the market, supported by investments in smart cities and sustainable urban projects. South Africa represents a key market in Africa, driven by rising recycling initiatives and industrial waste handling requirements. It remains a developing market, but ongoing infrastructure investments and stricter environmental regulations create opportunities for growth. International players entering this region focus on offering durable and efficient machines that meet both municipal and industrial requirements. Long-term demand is expected to grow steadily as governments prioritize sustainable waste management strategies.

Shape Your Report to Specific Countries or Regions & Enjoy 30% Off!

Key Player Analysis

- ShredTech

- Vecoplan AG

- Doppstadt GmbH

- GCM Enviro

- Terex Corporation

- Christophel GmbH

- SSI Shredding Systems

- BHS Sonthofen

- Moidsen GmbH

- Azeus Charcoal Machinery

Competitive Analysis

The competitive landscape of the Slow Speed Shredding Machine Market features leading players such as Terex Corporation, Doppstadt GmbH, Vecoplan AG, SSI Shredding Systems, ShredTech, BHS Sonthofen, Christophel GmbH, Moidsen GmbH, GCM Enviro, and Azeus Charcoal Machinery. These companies compete by focusing on product innovation, durability, and expanding their global distribution networks to meet diverse industrial and municipal needs. They actively invest in research and development to integrate automation, IoT-based monitoring, and energy-efficient designs that enhance machine performance and reduce operational costs. Strategic partnerships, mergers, and acquisitions play a key role in strengthening their market position and extending reach into emerging economies. Manufacturers emphasize safety features, customizable designs, and heavy-duty capabilities to cater to industries such as construction, mining, recycling, and agriculture. Growing competition drives continuous upgrades in technology and after-sales services, ensuring high reliability and long-term value. Together, these players set the benchmark for quality, innovation, and global presence in the market.

Recent Developments

- In July 2025, Vecoplan AG: The firm showcased its VEZ 3200 re‑shredder—an RDF-focused shredder with an energy‑efficient HiTorc direct drive—and the VRZ double‑shaft pre‑shredder, both increasing throughput and reliability in fuel processing lines.

- In May 2025, Vecoplan AG: The company launched its VTH 160 and VTH 260 drum chipper series, offering modular scalability and improved accessibility for operators. These models include digital data acquisition via the Vecoplan Smart Centre, enabling real‑time monitoring and enhanced performance tracking.

- In May 2025, Doppstadt GmbH: The company launched its Core Line shredders, including CoreShred 250, CoreShred 800, and CoreShred 900. These models offer robust, economical solutions with a quick-change shaft system for flexible material handling.

- In April 2025, Terex Recycling Systems: Introduced the TDS-820SE, a static electric low‑speed primary shredder. It offers twin shafts with aggressive teeth, customizable shredding programs, independent gearboxes, and an integrated transfer conveyor. The first unit now operates successfully in a recycling line in England

Report Coverage

The research report offers an in-depth analysis based on Machine Type, Application, Operation Mode, Industry Vertical, Capacity and Geography. It details leading market players, providing an overview of their business, product offerings, investments, revenue streams, and key applications. Additionally, the report includes insights into the competitive environment, SWOT analysis, current market trends, as well as the primary drivers and constraints. Furthermore, it discusses various factors that have driven market expansion in recent years. The report also explores market dynamics, regulatory scenarios, and technological advancements that are shaping the industry. It assesses the impact of external factors and global economic changes on market growth. Lastly, it provides strategic recommendations for new entrants and established companies to navigate the complexities of the market.

Future Outlook

- The market will expand steadily with rising focus on sustainable waste management practices.

- Demand will grow in recycling industries as governments push circular economy initiatives.

- Automation and IoT integration will enhance machine efficiency and reduce operational downtime.

- Energy-efficient models will gain preference as industries prioritize cost savings and green compliance.

- Customizable shredders will attract industries handling diverse waste streams and bulky materials.

- Emerging economies will record faster adoption with rising urbanization and industrial growth.

- Safety-enhanced designs will strengthen adoption across municipal and industrial applications.

- Competition among global players will intensify through innovation and strategic partnerships.

- Municipal infrastructure investments will support long-term demand for shredding machines.

- Continuous research in material durability and low-emission systems will shape future product development.