| REPORT ATTRIBUTE |

DETAILS |

| Historical Period |

2020-2023 |

| Base Year |

2024 |

| Forecast Period |

2025-2032 |

| Thermoform Form Fill Seal Machine Market Size 2024 |

USD 956.84 Million |

| Thermoform Form Fill Seal Machine Market, CAGR |

3.58% |

| Thermoform Form Fill Seal Machine Market Size 2032 |

USD 1,293.65 Million |

Market Overview

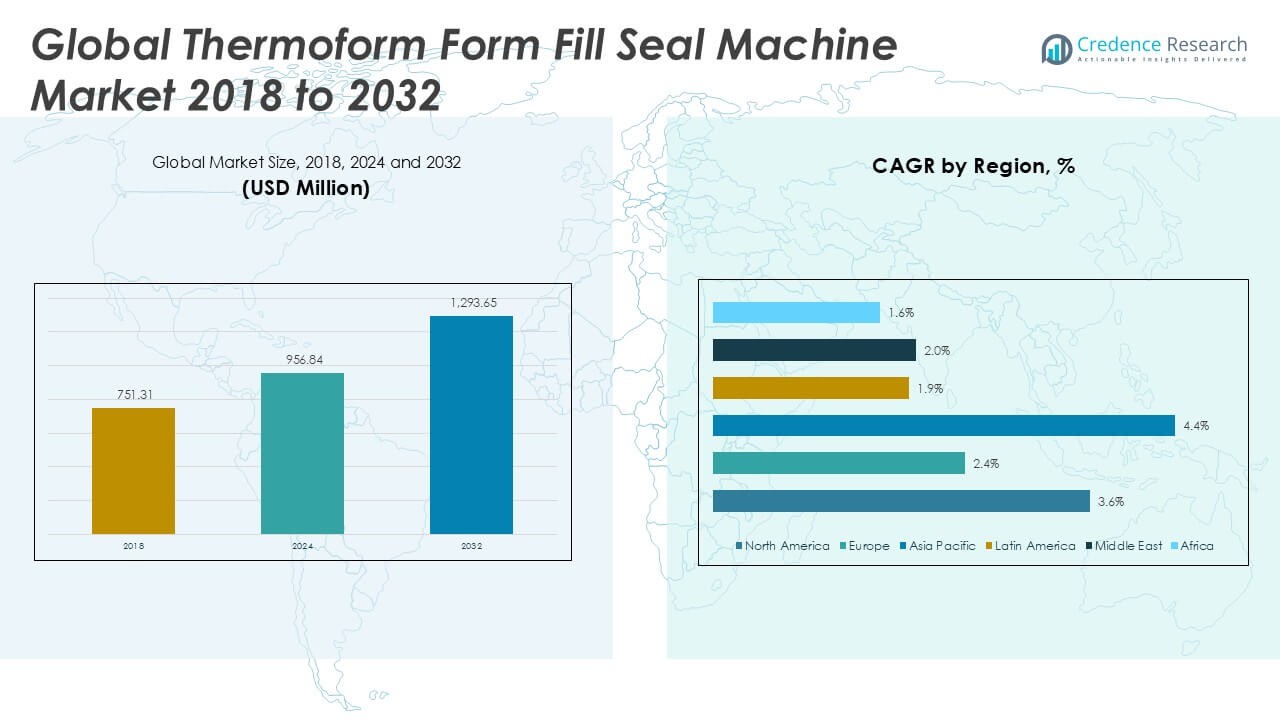

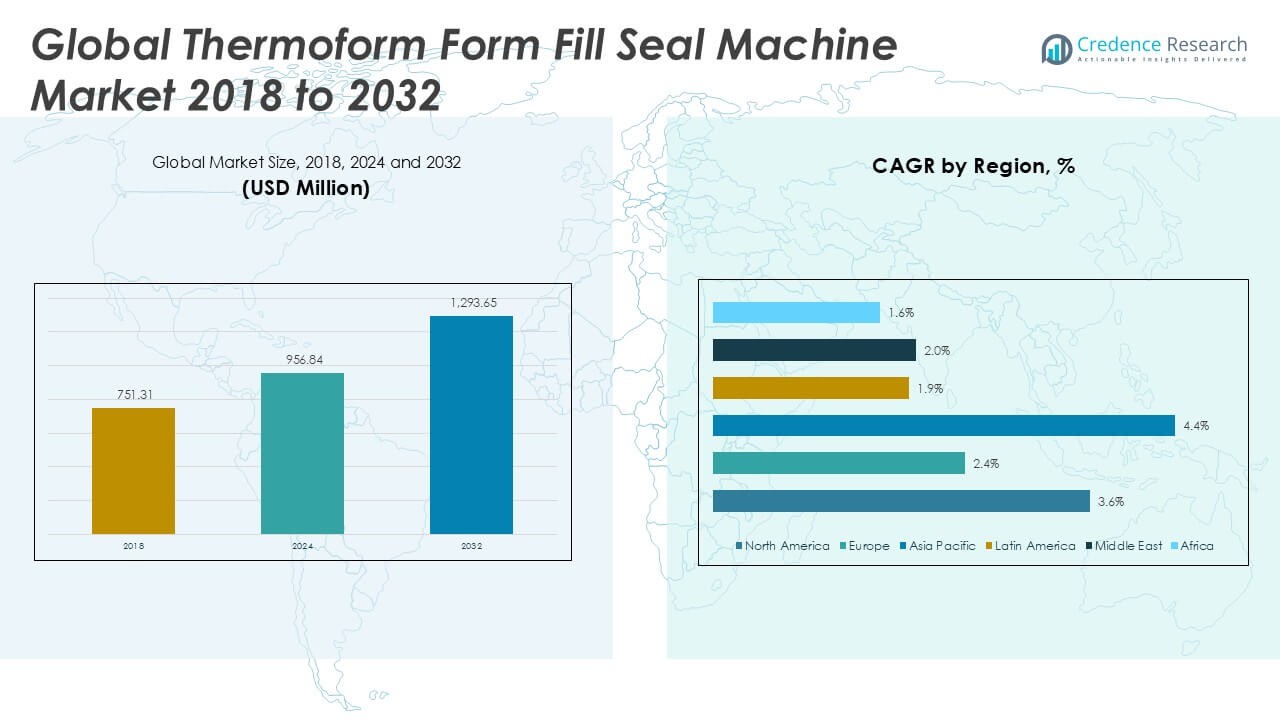

The Thermoform Form Fill Seal Machine Market was valued at USD 751.31 million in 2018 and increased to USD 956.84 million in 2024. The market is anticipated to reach USD 1,293.65 million by 2032, at a compound annual growth rate (CAGR) of 3.58% during the forecast period.

The Thermoform Form Fill Seal Machine Market is driven by increasing demand for efficient, automated packaging solutions in the food, pharmaceutical, and consumer goods sectors. The market benefits from growing emphasis on hygienic packaging, extended shelf life, and operational cost reduction, encouraging manufacturers to adopt advanced form fill seal machines. Trends such as integration of Industry 4.0 technologies, including IoT and automation, are improving productivity, real-time monitoring, and quality assurance. The shift towards sustainable packaging, using recyclable and biodegradable materials, further supports market expansion. Rising regulatory standards for food safety and pharmaceutical packaging drive investment in modern machinery with enhanced sealing and contamination prevention capabilities. Continuous innovation in machine design for flexibility, speed, and ease of operation remains a key trend, meeting diverse packaging requirements. These factors collectively position thermoform form fill seal machines as essential assets for manufacturers seeking reliability, compliance, and competitive advantage.

The Thermoform Form Fill Seal Machine Market demonstrates robust growth across key regions, driven by the strong presence of food, pharmaceutical, and consumer goods industries. North America and Europe show high adoption of advanced packaging machinery, supported by stringent quality standards and technological innovation. Asia Pacific emerges as a major growth engine, with rapid urbanization and expanding manufacturing sectors fueling demand for automated packaging solutions. Latin America, the Middle East, and Africa experience steady growth as industries modernize and shift toward improved packaging technologies. Leading companies such as Amcor PLC, Bosch Packaging Technology, and Huhtamaki Oyj play pivotal roles in shaping the market through extensive product portfolios, global distribution networks, and continuous advancements in packaging technology. Their strategic investments and partnerships further strengthen the global landscape, ensuring the market remains competitive and dynamic.

Access crucial information at unmatched prices!

Request your sample report today & start making informed decisions powered by Credence Research Inc.!

Download Sample

Market Insights

- The Thermoform Form Fill Seal Machine Market was valued at USD 956.84 million in 2024 and is projected to reach USD 1,293.65 million by 2032, with a CAGR of 3.58% during the forecast period.

- Market growth is driven by the rising demand for efficient, automated packaging solutions in food, pharmaceuticals, and consumer goods industries.

- Integration of Industry 4.0 technologies, such as IoT connectivity and real-time monitoring, represents a key trend, enhancing productivity and quality control across production lines.

- Leading players include Amcor PLC, Bosch Packaging Technology, and Huhtamaki Oyj, which compete on innovation, global presence, and comprehensive product portfolios.

- High initial investment costs and the complexity of adopting advanced technology present challenges, especially for small and mid-sized enterprises.

- North America and Europe maintain strong positions due to established food and healthcare sectors, while Asia Pacific shows rapid expansion fueled by urbanization and manufacturing growth.

- Market restraints include frequent regulatory changes, the need for ongoing machine upgrades, and difficulties in adapting to diverse and eco-friendly packaging materials.

Market Drivers

Growing Demand for Automated and Efficient Packaging Solutions Across Industries

The Thermoform Form Fill Seal Machine Market experiences strong momentum from industries that seek automation and efficiency in packaging processes. Food, beverage, pharmaceutical, and personal care companies aim to reduce manual labor, minimize errors, and achieve higher throughput, making advanced packaging equipment a necessity. It offers precise control over packaging parameters, ensuring consistent product quality. Manufacturers value integrated automation, which reduces production costs and downtime. Improved operational efficiency directly enhances profitability, making automated packaging lines a top priority. Rising consumer demand for packaged goods and ready-to-eat foods strengthens the need for reliable, scalable machinery. Companies respond by investing in thermoform form fill seal machines to meet volume, speed, and hygiene requirements.

- For instance, Bosch Packaging Technology supplied 1,000 high-speed Thermoform Form Fill Seal (TFFS) systems worldwide in 2023, with a maximum output capacity of 1,500 packs per minute on certain models.

Emphasis on Hygienic Packaging and Stringent Regulatory Compliance

Strict hygiene standards and evolving regulatory requirements in the food and pharmaceutical sectors push the market forward. Companies face increasing scrutiny regarding packaging integrity, contamination prevention, and product safety. The Thermoform Form Fill Seal Machine Market addresses these concerns by enabling airtight sealing and minimizing human contact during packaging. Modern equipment includes features for traceability, tamper evidence, and easy cleaning, which facilitate compliance with global safety standards. The ability to adapt quickly to changing regulations remains a crucial factor for market participants. Investment in advanced sealing technologies helps brands build consumer trust. Companies prioritize machinery that supports strict quality assurance and meets international standards.

- For instance, Huhtamaki Oyj’s thermoform line at its Hämeenlinna facility has achieved zero product recalls since 2018, processing over 700 million sterile pharmaceutical packages annually.

Integration of Smart Technologies and Digital Transformation

Smart manufacturing trends and digital transformation initiatives create new opportunities for this market. The Thermoform Form Fill Seal Machine Market incorporates Industry 4.0 features, such as IoT connectivity, real-time monitoring, and predictive maintenance. It leverages advanced sensors and control systems for higher accuracy and faster changeovers. Manufacturers can collect and analyze data to optimize production, reduce waste, and prevent downtime. Remote monitoring and diagnostics further improve equipment reliability and operator efficiency. Companies adopting these digital solutions achieve greater transparency, traceability, and process optimization. The demand for smart, connected packaging lines continues to grow.

Transition Towards Sustainable and Flexible Packaging Solutions

Shifts in consumer preference and environmental regulations are fueling a transition toward sustainable and flexible packaging. The Thermoform Form Fill Seal Machine Market responds by supporting biodegradable, recyclable, and lightweight materials. Manufacturers design machines that handle a variety of eco-friendly substrates without sacrificing productivity or quality. It enables packaging customization to reduce excess material usage and support green initiatives. Brands are under pressure to minimize their carbon footprint and packaging waste. The market delivers solutions for both high-volume production and niche, short-run packaging needs. Sustainability and adaptability drive ongoing equipment innovation and influence purchasing decisions.

Market Trends

Expansion of Smart Manufacturing and IoT-Enabled Packaging Solutions

The Thermoform Form Fill Seal Machine Market reflects a clear movement toward smart manufacturing with widespread adoption of IoT and data analytics. Companies deploy connected machines to monitor production lines in real time, enabling data-driven decisions that enhance productivity. It supports predictive maintenance strategies, which reduce downtime and operational costs. Operators benefit from remote access and diagnostics, streamlining troubleshooting and support. Advanced human-machine interfaces improve ease of use and training efficiency. The industry trend emphasizes leveraging digital tools for greater control and traceability, helping manufacturers stay competitive in dynamic markets.

- For instance, Amcor PLC implemented digital monitoring across 23 global production sites in 2023, resulting in a 12% reduction in unplanned line stoppages within the first year.

Growth in Demand for Versatile and Customizable Packaging Capabilities

Rising product diversity across food, beverage, and healthcare sectors drives demand for flexible and customizable packaging machinery. The Thermoform Form Fill Seal Machine Market addresses this by offering modular machines capable of handling various package sizes and designs. It allows manufacturers to quickly adapt to changing consumer preferences and product specifications. High-speed changeover systems and multi-format tooling improve operational flexibility. Producers value the ability to switch between packaging formats with minimal downtime. This trend accelerates investment in machinery that offers scalability and long-term adaptability to evolving market needs.

- For instance, Coesia Group’s FlexLink platform enables format changeovers in less than 5 minutes, supporting over 20 different package types in a single eight-hour shift at a leading European dairy manufacturer.

Increasing Focus on Sustainable Packaging and Material Innovation

Sustainability remains a major trend, pushing the Thermoform Form Fill Seal Machine Market to support new eco-friendly packaging materials and processes. Machine manufacturers design equipment that processes recyclable and biodegradable films without compromising performance. It aligns with global efforts to reduce plastic waste and support circular economy initiatives. Brands seek packaging solutions that meet both functional and environmental requirements. Equipment innovations aim to reduce material usage, energy consumption, and emissions. The market continuously evolves to support new materials while meeting stringent quality standards.

Advancements in Automation, Precision, and User-Friendly Operation

Automation and precision engineering are reshaping how manufacturers approach packaging operations. The Thermoform Form Fill Seal Machine Market integrates robotics, advanced servo controls, and automated inspection systems to improve accuracy and consistency. It delivers faster cycle times and ensures high-quality sealing, reducing the risk of defects. User-friendly interfaces simplify machine operation and maintenance, lowering training requirements. Enhanced safety features and remote monitoring add further value. The industry trend points toward machines that deliver both efficiency and operational simplicity, driving higher adoption rates across end-use sectors.

Market Challenges Analysis

High Initial Investment and Complexity of Technology Adoption

High upfront costs remain a significant barrier for new entrants and small to medium-sized enterprises in the Thermoform Form Fill Seal Machine Market. Advanced machinery often requires substantial capital investment, covering not only equipment but also installation, integration, and employee training. It can deter companies with limited budgets or low production volumes. The complexity of new technologies demands specialized skills for operation and maintenance, which may lead to increased recruitment or outsourcing costs. Extended lead times for delivery and commissioning further complicate market entry. Firms without sufficient resources may struggle to justify or recoup the initial expenditure.

Regulatory Compliance and Operational Flexibility Constraints

Strict regulatory requirements in food, pharmaceutical, and consumer goods sectors present operational challenges. The Thermoform Form Fill Seal Machine Market must keep pace with evolving safety, hygiene, and environmental standards worldwide. Frequent changes in regulations require ongoing machine upgrades or retrofits, increasing costs and operational disruption. It can also create uncertainty for manufacturers, who must balance compliance with the need for flexible production. Adapting machines to handle diverse packaging materials and formats sometimes proves difficult, especially when supporting eco-friendly substrates. Companies face the dual pressure of maintaining compliance while delivering product differentiation and efficiency.

Market Opportunities

Expansion into Emerging Markets and Untapped Industry Segments

Emerging economies offer significant growth potential for the Thermoform Form Fill Seal Machine Market. Rapid urbanization, rising disposable incomes, and increased demand for packaged food and healthcare products drive investments in advanced packaging machinery. It presents manufacturers with opportunities to establish a presence in regions where automation adoption remains low. Government initiatives to modernize local industries further stimulate market expansion. Companies can capitalize on growing awareness of food safety and quality, particularly in Asia-Pacific, Latin America, and the Middle East. Access to new customer bases allows global players to diversify revenue streams and strengthen market share.

Development of Sustainable and Customizable Packaging Solutions

Growing consumer and regulatory focus on sustainability opens new avenues for innovation in the Thermoform Form Fill Seal Machine Market. Equipment manufacturers can introduce machines designed to handle biodegradable and recyclable materials without compromising speed or product integrity. It creates opportunities to support brands pursuing eco-friendly packaging strategies. Advances in machine flexibility enable producers to offer customizable packaging that meets evolving market needs. Integration of smart technologies, such as IoT and automation, positions companies to deliver efficient, adaptive, and environmentally responsible solutions. These developments create a competitive edge and foster long-term customer partnerships.

Market Segmentation Analysis:

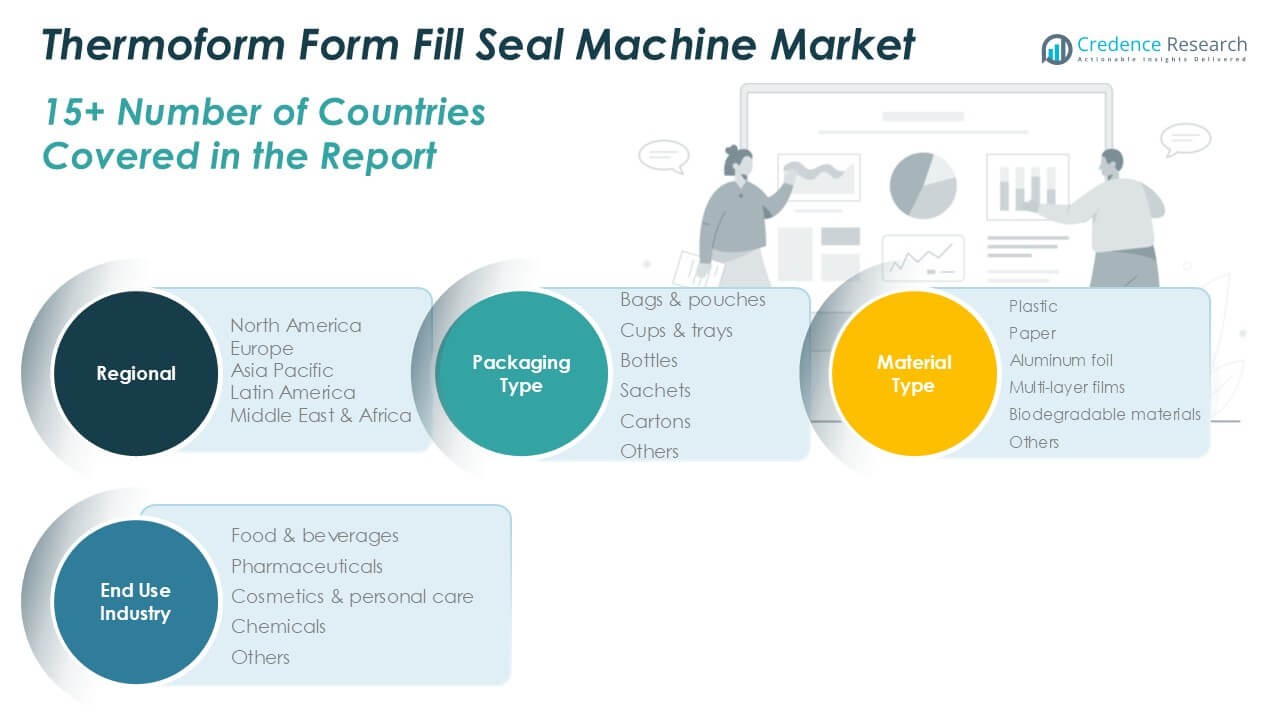

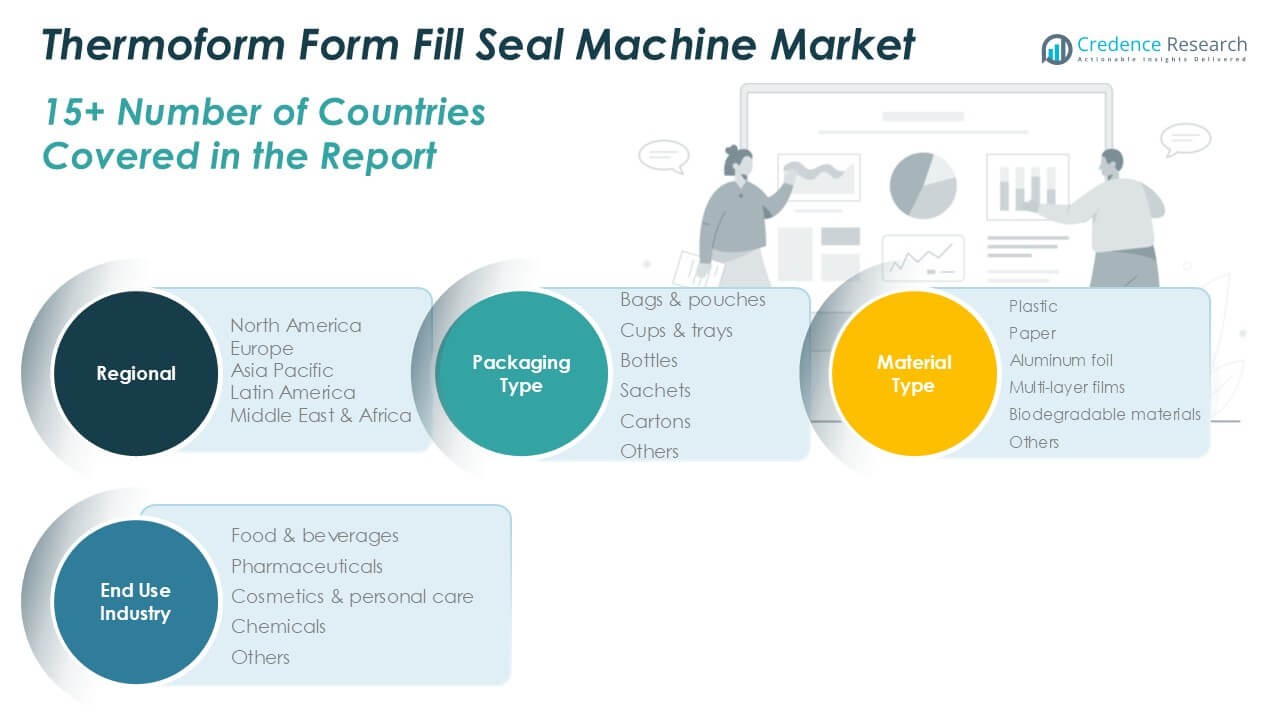

By Packaging Type:

The market includes bags & pouches, cups & trays, bottles, sachets, cartons, and others. Bags & pouches hold a prominent share due to widespread use in food, beverage, and pharmaceutical sectors, where flexibility and cost efficiency are vital. Cups & trays cater to ready-to-eat meals, dairy products, and desserts, offering secure packaging with strong visual appeal. Bottles and sachets address both liquid and portioned product requirements, meeting demand for convenience and on-the-go consumption. Cartons remain a preferred choice for premium and sensitive goods, while the “others” category supports specialized formats for unique industry needs.

- For instance, Anchor Packaging, Inc. produced 930 million thermoformed cups and trays for North American customers in 2023, supplying several major quick service restaurant brands.

By Material Type:

Material type segmentation drives the versatility of the Thermoform Form Fill Seal Machine Market, with plastic maintaining dominance because of its durability, clarity, and ease of processing. Paper continues to gain traction as brands seek eco-friendly alternatives that appeal to environmentally conscious consumers. Aluminum foil is valued for its barrier properties, protecting sensitive products from moisture and contaminants. Multi-layer films enable advanced packaging solutions that combine strength, flexibility, and shelf-life extension. Biodegradable materials represent a growing trend, reflecting global sustainability initiatives and regulatory pressure to reduce plastic waste. The inclusion of other materials demonstrates the market’s ability to innovate and accommodate changing substrate requirements.

- For instance, Mondi Group’s thermoform lines produced 28,000 metric tons of recyclable paper-based packaging in 2023 for use in the food and personal care sectors.

By End Use Industry:

Food & beverages form the largest segment, leveraging the technology for packaging fresh, processed, and ready-to-eat items with a focus on hygiene and shelf stability. Pharmaceuticals depend on these machines for reliable, sterile packaging that meets stringent regulatory standards and safeguards product efficacy. Cosmetics & personal care brands utilize form fill seal machines for attractive and protective packaging of creams, lotions, and personal hygiene products. The chemicals sector values robust and contamination-resistant packaging for liquids, powders, and specialty materials. Other industries, such as household goods and industrial products, further broaden the scope, confirming the market’s role as a critical enabler of modern packaging solutions.

Segments:

Based on Packaging Type:

- Bags & pouches

- Cups & trays

- Bottles

- Sachets

- Cartons

- Others

Based on Material Type:

- Plastic

- Paper

- Aluminum foil

- Multi-layer films

- Biodegradable materials

- Others

Based on End Use Industry:

- Food & beverages

- Pharmaceuticals

- Cosmetics & personal care

- Chemicals

- Others

Based on the Geography:

- North America

- Europe

- UK

- France

- Germany

- Italy

- Spain

- Russia

- Belgium

- Netherlands

- Austria

- Sweden

- Poland

- Denmark

- Switzerland

- Rest of Europe

- Asia Pacific

- China

- Japan

- South Korea

- India

- Australia

- Thailand

- Indonesia

- Vietnam

- Malaysia

- Philippines

- Taiwan

- Rest of Asia Pacific

- Latin America

- Brazil

- Argentina

- Peru

- Chile

- Colombia

- Rest of Latin America

- Middle East

- UAE

- KSA

- Israel

- Turkey

- Iran

- Rest of Middle East

- Africa

- Egypt

- Nigeria

- Algeria

- Morocco

- Rest of Africa

Regional Analysis

North America Thermoform Form Fill Seal Machine Market

North America Thermoform Form Fill Seal Machine Market grew from USD 235.50 million in 2018 to USD 295.58 million in 2024 and is projected to reach USD 401.18 million by 2032, reflecting a compound annual growth rate (CAGR) of 3.6%. North America is holding a 31% market share. The United States leads regional demand, supported by well-established food processing and pharmaceutical sectors that invest in advanced, automated packaging solutions. Canada and Mexico follow with rising adoption in consumer goods and healthcare industries. Regulatory emphasis on food safety and quality assurance strengthens the shift toward modern, hygienic packaging technologies. Manufacturers prioritize productivity and flexibility, making the region a key hub for technological advancements in the market.

Europe Thermoform Form Fill Seal Machine Market

Europe Thermoform Form Fill Seal Machine Market grew from USD 149.18 million in 2018 to USD 180.20 million in 2024 and is anticipated to reach USD 222.94 million by 2032, with a CAGR of 2.4%. Europe accounts for a 18% market share. Major contributors include Germany, France, Italy, and the United Kingdom, each recognized for robust manufacturing, food, and pharmaceutical sectors. Sustainability remains a central focus, driving investments in eco-friendly packaging materials and machinery that supports recyclability and waste reduction. Regulatory standards across the European Union push companies to adopt state-of-the-art equipment that guarantees compliance and product safety. Demand for packaged food and health products sustains steady market growth across the region.

Asia Pacific Thermoform Form Fill Seal Machine Market

Asia Pacific Thermoform Form Fill Seal Machine Market grew from USD 288.76 million in 2018 to USD 383.19 million in 2024 and is expected to reach USD 553.83 million by 2032, registering a CAGR of 4.4%. Asia Pacific dominates with a 43% market share. China, Japan, and India represent the largest markets, driven by rapid urbanization, population growth, and expanding food processing and pharmaceutical industries. The region experiences rising consumer demand for packaged goods, propelling investment in high-speed, automated machinery. Local manufacturers focus on cost-effective, scalable solutions, while multinational companies strengthen regional supply chains. Strong export activity from China and Japan further accelerates technology adoption.

Latin America Thermoform Form Fill Seal Machine Market

Latin America Thermoform Form Fill Seal Machine Market grew from USD 33.31 million in 2018 to USD 41.86 million in 2024 and is forecast to reach USD 49.67 million by 2032, posting a CAGR of 1.9%. Latin America holds a 4% market share. Brazil and Mexico lead regional growth, supported by developments in packaged food, beverage, and pharmaceutical production. Regional industries adopt automation to improve product quality and operational efficiency. Governments focus on food safety standards and modernization, creating new opportunities for packaging technology providers. Challenges include variable economic conditions, yet demand for flexible packaging solutions remains stable across key markets.

Middle East Thermoform Form Fill Seal Machine Market

Middle East Thermoform Form Fill Seal Machine Market grew from USD 27.30 million in 2018 to USD 32.47 million in 2024 and is set to reach USD 38.72 million by 2032, achieving a CAGR of 2.0%. The Middle East accounts for a 3% market share. Saudi Arabia and the United Arab Emirates drive demand, with investments in food production and healthcare infrastructure. Market growth aligns with rising demand for packaged foods, pharmaceuticals, and consumer goods. Companies focus on quality control and advanced packaging to support both local consumption and export requirements. The regional push toward economic diversification and industrialization continues to support new machinery adoption.

Africa Thermoform Form Fill Seal Machine Market

Africa Thermoform Form Fill Seal Machine Market grew from USD 17.26 million in 2018 to USD 23.53 million in 2024 and is projected to reach USD 27.31 million by 2032, with a CAGR of 1.6%. Africa represents a 2% market share. South Africa, Nigeria, and Egypt are key countries supporting the gradual expansion of packaging technology adoption. Growth remains steady as urban populations and consumer packaged goods demand increase. The food, beverage, and pharmaceutical sectors invest in modern machinery to improve shelf life and product quality. Infrastructure limitations and investment constraints challenge rapid adoption, yet the region offers long-term opportunities for market players targeting untapped potential.

Key Player Analysis

- Amcor PLC

- Anchor Packaging, Inc.

- Barry-Wehmiller Group

- Bosch Packaging Technology

- Coesia Group

- DS Smith

- Huhtamaki Oyj

- Mondi Group

- Paccor Packaging Corporation

- Placon Corporation

Competitive Analysis

The Thermoform Form Fill Seal Machine Market features a competitive landscape shaped by global leaders such as Amcor PLC, Bosch Packaging Technology, Huhtamaki Oyj, Coesia Group, DS Smith, and Mondi Group. These companies leverage advanced research and development capabilities to introduce innovative packaging solutions that cater to the evolving needs of food, pharmaceutical, and consumer goods industries. The market rewards players that can provide solutions aligned with evolving customer demands, such as machines compatible with biodegradable materials or those featuring Industry 4.0 capabilities like IoT connectivity and predictive maintenance. Competitors strive to differentiate themselves through comprehensive product portfolios, after-sales service, and technical support. Strategic mergers, acquisitions, and collaborations enable companies to expand their global footprint and enhance supply chain resilience. The ability to respond quickly to regulatory changes and new industry standards further distinguishes market leaders. Intense rivalry ensures rapid technological advancements, high product quality, and greater value for end users across all regions and sectors.

Recent Developments

- In November 2023, Coveris introduced Formpeel P at the COMPAMED trade show in Düsseldorf. Formpeel P is a recyclable thermoforming film as well as Coveris’s eco-friendly packaging portfolio. It is meant for medical clients using form-fill-seal machines.

- In November 2023, Liquibox and Cryovac integrated their strategic resources to accelerate the delivery of sustainable packaging solutions for the global fluids and liquids market, which is valued at approximately USD 3 trillion. The newly formed entity, SEE, aims to become a digitally advanced, automated leader in sustainable packaging.

- In August 2023, Ahlstrom teamed up with The Paper People LLC to create packages for frozen foods that are kinder to the environment. This new fiber-based, certified recyclable packaging is designed to eliminate the use of plastic and films made from fossil fuels in frozen food packaging.

Market Concentration & Characteristics

The Thermoform Form Fill Seal Machine Market exhibits a moderately concentrated structure, with a few large multinational companies accounting for a significant share alongside several specialized regional players. It is characterized by high barriers to entry, including substantial capital investment, advanced technical expertise, and the need for ongoing innovation to meet evolving industry standards. Leading participants maintain competitive advantages through expansive product portfolios, global service networks, and continuous research and development. The market favors companies that can deliver reliability, customization, and operational efficiency while supporting sustainable packaging solutions. Product differentiation centers on automation, material flexibility, and integration with digital technologies. Rapid technological progress and shifting regulatory requirements shape industry dynamics, encouraging market leaders to prioritize compliance and adaptability. End users expect machines that provide high output, consistent quality, and easy integration into existing production lines, driving ongoing demand for tailored, high-performance solutions.

Shape Your Report to Specific Countries or Regions & Enjoy 30% Off!

Report Coverage

The research report offers an in-depth analysis based on Packaging Type, Material Type, End Use Industry and Geography. It details leading market players, providing an overview of their business, product offerings, investments, revenue streams, and key applications. Additionally, the report includes insights into the competitive environment, SWOT analysis, current market trends, as well as the primary drivers and constraints. Furthermore, it discusses various factors that have driven market expansion in recent years. The report also explores market dynamics, regulatory scenarios, and technological advancements that are shaping the industry. It assesses the impact of external factors and global economic changes on market growth. Lastly, it provides strategic recommendations for new entrants and established companies to navigate the complexities of the market.

Future Outlook

- Market adoption will accelerate in emerging economies due to rising consumer goods production.

- Manufacturers will prioritize integration of IoT and automation for predictive maintenance and real-time analytics.

- Sustainability pressures will push widespread use of biodegradable and recyclable packaging materials.

- Flexible machinery capable of quick format changeovers will gain preference among diverse product lines.

- Demand for improved sealing performance and contamination control will increase in pharmaceutical and food sectors.

- Machine learning applications will enhance quality control and defect detection on production lines.

- Remote monitoring and cloud-based diagnostics will become standard features in advanced systems.

- Collaborative robotics will support human-machine interaction, improving safety and efficiency.

- Customization options will expand to meet specialized packaging needs in niche markets.

- Strategic partnerships between machinery manufacturers and material suppliers will drive innovation in compatible film technologies.