Market Overview

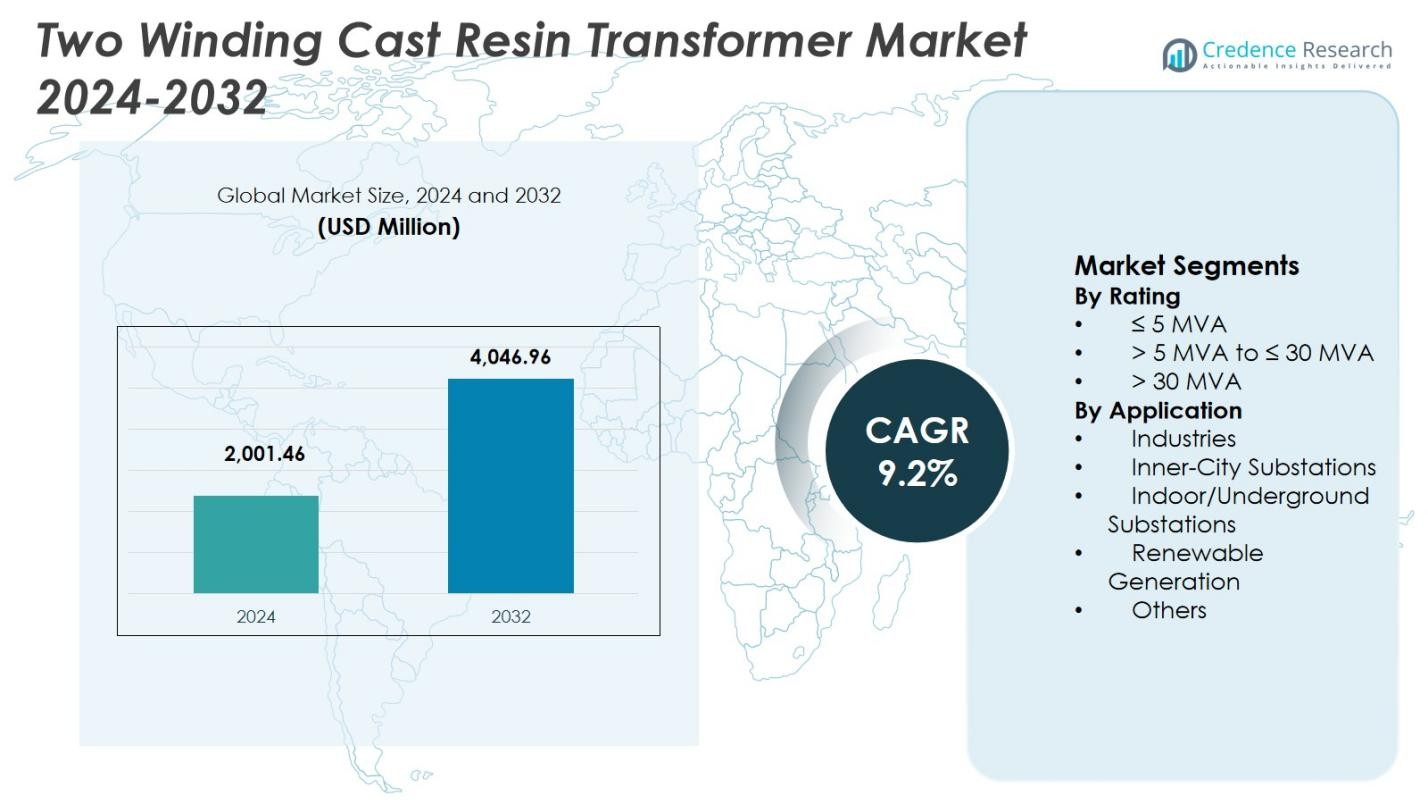

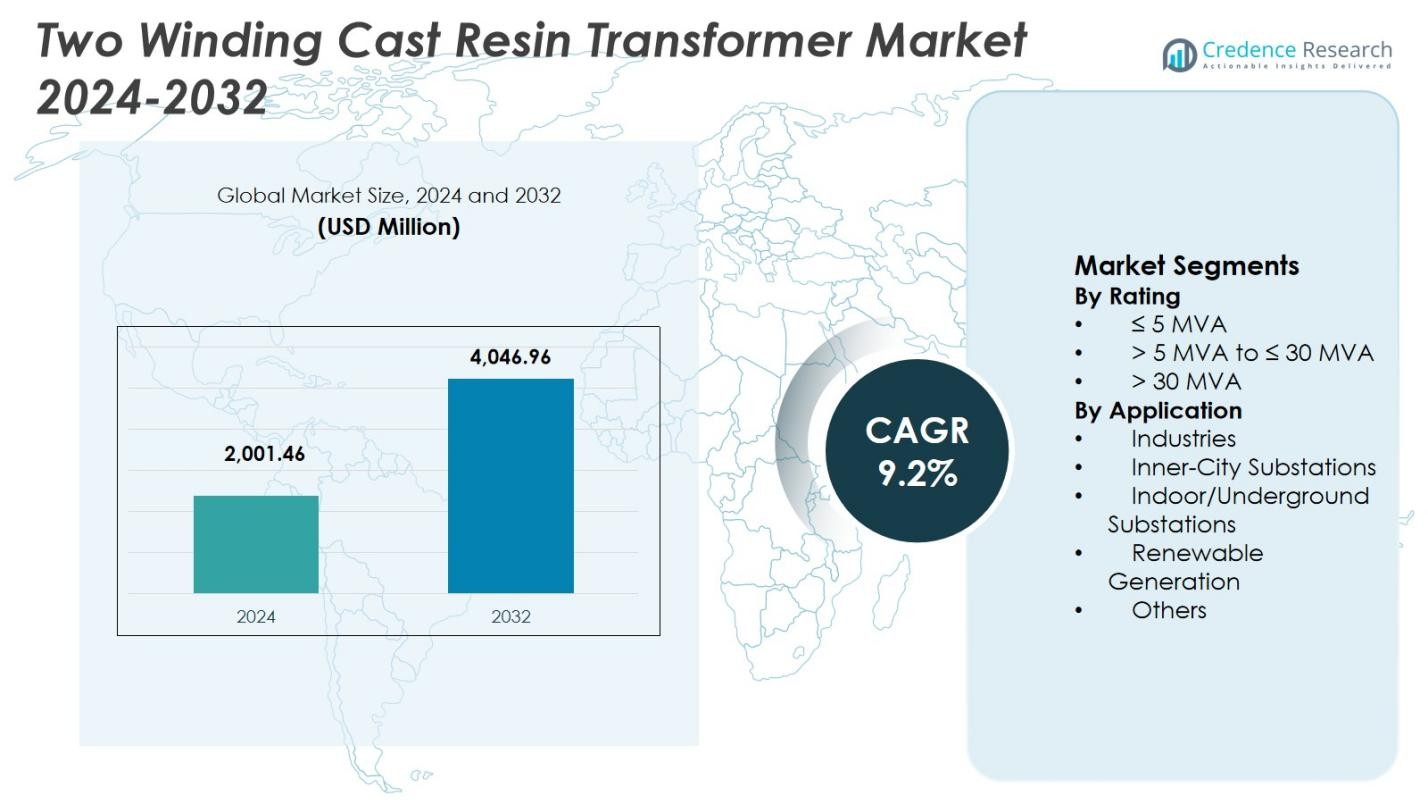

The Two Winding Cast Resin Transformer Market size was valued at USD 2,001.46 million in 2024 and is anticipated to reach USD 4,046.96 million by 2032, growing at a CAGR of 9.2% during the forecast period.

| REPORT ATTRIBUTE |

DETAILS |

| Historical Period |

2020-2023 |

| Base Year |

2024 |

| Forecast Period |

2025-2032 |

| Two Winding Cast Resin Transformer Market Size 2024 |

USD 2,001.46 Million |

| Two Winding Cast Resin Transformer Market, CAGR |

9.2% |

| Two Winding Cast Resin Transformer Market Size 2032 |

USD 4,046.96 Million |

The Two Winding Cast Resin Transformer Market is led by established global manufacturers such as ABB, Schneider Electric, Hitachi Energy, General Electric, CG Power & Industrial Solutions, Eaton, Bharat Heavy Electricals Limited, Fuji Electric Co. Ltd., SGB SMIT, and Raychem RPG Private Limited, which collectively shape product innovation, capacity expansion, and technology adoption. These companies focus on medium-voltage solutions, enhanced fire safety, and advanced insulation systems to meet rising demand from urban infrastructure, industrial facilities, and renewable energy projects. Regionally, Asia-Pacific dominates the Two Winding Cast Resin Transformer Market with a 41.3% share, driven by rapid urbanization, industrial expansion, and large-scale investments in power distribution and grid modernization across emerging and developed economies.

Access crucial information at unmatched prices!

Request your sample report today & start making informed decisions powered by Credence Research Inc.!

Download Sample

Market Insights

- The Two Winding Cast Resin Transformer Market was valued at USD 2,001.46 million in 2024 and is projected to reach USD 4,046.96 million by 2032, expanding at a CAGR of 9.2%, supported by rising demand for fire-safe, oil-free, and low-maintenance power distribution solutions across utilities and industries.

- Growth in the Two Winding Cast Resin Transformer Market is driven by accelerating urban infrastructure development, grid modernization programs, industrial electrification, and increasing adoption in indoor and underground substations, where safety, reliability, and compact design are critical requirements.

- Key trends shaping the Two Winding Cast Resin Transformer Market include increasing deployment in renewable energy projects, rising preference for medium-voltage transformers, and strong dominance of the > 5 MVA to ≤ 30 MVA segment, which accounted for 47.6% share in 2024 due to balanced capacity and flexibility.

- Leading manufacturers such as ABB, Schneider Electric, Hitachi Energy, General Electric, CG Power & Industrial Solutions, and Eaton focus on technology upgrades, insulation innovation, and regional expansion to strengthen positioning amid growing infrastructure and industrial demand.

- Regionally, Asia-Pacific led the Two Winding Cast Resin Transformer Market with a 41.3% share in 2024, followed by Europe at 27.6% and North America at 18.4%, while Latin America and the Middle East & Africa together represented steady growth potential supported by infrastructure expansion.

Market Segmentation Analysis:

By Rating:

In the Two Winding Cast Resin Transformer Market, the > 5 MVA to ≤ 30 MVA segment dominated in 2024, accounting for 47.6% market share. This dominance is driven by strong demand from medium-voltage distribution networks, industrial plants, commercial buildings, and urban infrastructure projects requiring reliable, fire-safe, and low-maintenance transformers. This rating range offers an optimal balance between capacity, efficiency, and installation flexibility, making it suitable for data centers, metro rail systems, and renewable energy substations. Rising urban electrification, grid modernization programs, and replacement of oil-filled transformers further strengthen demand for this segment.

- For instance, Hitachi Energy’s RESIBLOC cast resin transformers are supplied in medium-voltage ratings up to 30 MVA for heavy-duty industrial and infrastructure projects, combining flame-retardant design with low maintenance needs for harsh environments.

By Application:

By application, Industries emerged as the dominant sub-segment in the Two Winding Cast Resin Transformer Market, capturing 38.9% share in 2024. Industrial facilities increasingly adopt cast resin transformers due to their high thermal stability, enhanced safety in hazardous environments, and minimal maintenance requirements. Growth is supported by expansion of manufacturing units, processing plants, and automation-intensive industries requiring uninterrupted power supply. Additionally, stricter fire safety regulations and increasing preference for indoor installations accelerate adoption. Rising investments in industrial electrification across emerging and developed economies continue to reinforce this segment’s leadership.

- For instance, Kel established a 1,350 sq. m. semi-automated plant in 2015 with 300 MVA annual capacity, producing dry-type cast resin transformers tailored for heavy industrial loads in processing and automation setups.

Key Growth Drivers

Rising Urban Infrastructure and Grid Modernization Investments

The Two Winding Cast Resin Transformer Market benefits significantly from accelerating urban infrastructure development and large-scale grid modernization programs. Rapid urbanization increases demand for compact, fire-safe, and environmentally friendly transformers suitable for indoor and underground installations. Governments and utilities are investing in upgrading aging electrical infrastructure to improve efficiency, reliability, and safety. Cast resin transformers support these objectives through low maintenance requirements, high overload capability, and reduced fire risk, making them ideal for densely populated urban environments and smart city projects worldwide.

- For instance, Hammond Power Solutions supplied eight custom cast-resin transformers to a leading global financial firm’s headquarters in Manhattan.

Expansion of Industrial and Commercial Power Demand

Growing industrialization and commercial construction strongly drive demand in the Two Winding Cast Resin Transformer Market. Manufacturing facilities, data centers, hospitals, and commercial complexes require stable and uninterrupted power supply with high safety standards. Cast resin transformers provide superior thermal performance, moisture resistance, and operational reliability in harsh environments. Increasing automation, electrification of industrial processes, and capacity expansion across process industries further accelerate adoption, particularly in medium-voltage distribution applications where operational continuity and safety are critical.

- For instance, Hanley Energy deploys cast resin transformers in data centers for their flame-retardant insulation and self-extinguishing properties, reducing fire hazards and enabling close proximity to loads without toxic gas risks.

Increasing Integration of Renewable Energy Systems

The rapid expansion of renewable energy generation significantly contributes to growth in the Two Winding Cast Resin Transformer Market. Solar and wind projects increasingly deploy cast resin transformers for step-up and distribution functions due to their low fire hazard, environmental compatibility, and suitability for indoor and confined installations. Grid integration of decentralized renewable sources requires reliable and efficient transformers capable of handling variable loads. Supportive government policies, energy transition initiatives, and rising investments in renewable infrastructure continue to strengthen demand.

Key Trends & Opportunities

Shift Toward Indoor and Underground Substation Installations

A prominent trend in the Two Winding Cast Resin Transformer Market is the increasing preference for indoor and underground substations. Space constraints, urban safety regulations, and aesthetic considerations drive utilities and developers to adopt compact, dry-type transformers. Cast resin transformers eliminate oil leakage risks and reduce fire hazards, making them ideal for enclosed environments. This trend creates strong opportunities for manufacturers to develop space-efficient designs with higher power density, noise reduction features, and advanced insulation technologies.

- For instance, Hitachi Energy’s RESIBLOC dry-type transformers feature glass fiber-reinforced epoxy resin insulation for superior mechanical strength and moisture resistance, ideal for indoor high-rise and underground installations like skyscrapers and stadiums.

Technological Advancements in Insulation and Thermal Management

Ongoing advancements in insulation materials and thermal management systems present key opportunities in the Two Winding Cast Resin Transformer Market. Manufacturers are improving epoxy resin formulations, cooling efficiency, and digital monitoring capabilities to enhance performance and extend service life. Integration of sensors for temperature and load monitoring supports predictive maintenance and operational optimization. These innovations increase transformer reliability, reduce lifecycle costs, and appeal to utilities and industrial users seeking smarter and more efficient power distribution solutions.

- For instance, SGB-SMIT employs double-layer winding technology with epoxy resin casting under vacuum, incorporating multiple cooling ducts in high-voltage coils to achieve uniform temperature distribution and reduce overheating risks.

Key Challenges

Higher Initial Cost Compared to Oil-Filled Transformers

The Two Winding Cast Resin Transformer Market faces challenges related to higher upfront costs compared to conventional oil-filled transformers. Advanced insulation materials, specialized manufacturing processes, and quality control requirements increase capital expenditure. Price-sensitive customers, particularly in developing regions, may delay adoption despite long-term operational benefits. Budget constraints in public infrastructure projects and industrial facilities can limit short-term market penetration, requiring manufacturers to emphasize lifecycle cost advantages and safety benefits.

Limitations in High-Capacity and Outdoor Applications

Performance constraints in very high-capacity and extreme outdoor applications pose challenges for the Two Winding Cast Resin Transformer Market. Cast resin transformers face thermal dissipation limitations at higher power ratings and may require additional cooling systems. Exposure to harsh weather conditions can also affect long-term performance without adequate enclosure protection. These limitations restrict adoption in large utility-scale substations and high-voltage transmission networks, where oil-filled transformers remain preferred due to higher load-handling capability.

Regional Analysis

Asia-Pacific

Asia-Pacific led the Two Winding Cast Resin Transformer Market in 2024, accounting for 41.3% market share. Strong growth is driven by rapid urbanization, expanding industrial bases, and large-scale investments in power distribution infrastructure across China, India, Southeast Asia, and South Korea. Rising construction of metros, commercial complexes, and indoor substations increases demand for fire-safe and low-maintenance transformers. In addition, aggressive renewable energy deployment and grid expansion programs support adoption. Government-led electrification initiatives and replacement of aging oil-filled transformers further reinforce Asia-Pacific’s leadership position.

Europe

Europe represented 27.6% market share in the Two Winding Cast Resin Transformer Market in 2024, supported by strict fire safety regulations and strong emphasis on sustainable power infrastructure. Widespread adoption in inner-city and underground substations, rail networks, and commercial buildings drives demand. European utilities prioritize environmentally friendly and oil-free transformer solutions to meet decarbonization goals. Increasing renewable energy integration, especially wind and solar, further boosts installations. Continuous grid modernization and refurbishment of aging electrical assets across Germany, France, Italy, and the Nordics sustain steady regional growth.

North America

North America accounted for 18.4% market share in the Two Winding Cast Resin Transformer Market in 2024. Demand is driven by grid resilience investments, data center expansion, and rising adoption of indoor substations in urban areas. Utilities and industrial users increasingly favor cast resin transformers for their safety, reliability, and low maintenance. Growth is further supported by renewable energy projects, smart grid initiatives, and replacement of aging transformers in commercial and institutional facilities. The United States dominates regional demand, supported by infrastructure upgrades and stringent safety compliance standards.

Latin America

Latin America captured 7.1% market share in the Two Winding Cast Resin Transformer Market in 2024, driven by expanding industrial activity and gradual modernization of power distribution networks. Countries such as Brazil, Mexico, and Chile invest in renewable energy projects and urban infrastructure, supporting adoption of cast resin transformers. Growth is also aided by increasing focus on fire safety in commercial buildings and indoor substations. Although price sensitivity remains a constraint, rising awareness of lifecycle benefits and regulatory alignment strengthens long-term market potential.

Middle East & Africa

The Middle East & Africa held 5.6% market share in the Two Winding Cast Resin Transformer Market in 2024. Demand is supported by infrastructure development, urban construction, and growing renewable energy investments, particularly in the Gulf countries. Indoor and underground substations in commercial complexes, airports, and metro projects drive adoption. In Africa, electrification programs and grid expansion initiatives contribute to gradual growth. Harsh climatic conditions increase preference for dry-type transformers with enhanced safety and reliability, supporting steady regional uptake.

Market Segmentations:

By Rating

- ≤ 5 MVA

- > 5 MVA to ≤ 30 MVA

- > 30 MVA

By Application

- Industries

- Inner-City Substations

- Indoor/Underground Substations

- Renewable Generation

- Others

By Geography

- North America

- Europe

- Germany

- France

- U.K.

- Italy

- Spain

- Rest of Europe

- Asia Pacific

- China

- Japan

- India

- South Korea

- South-east Asia

- Rest of Asia Pacific

- Latin America

- Brazil

- Argentina

- Rest of Latin America

- Middle East & Africa

- GCC Countries

- South Africa

- Rest of the Middle East and Africa

Competitive Landscape

ABB, Schneider Electric, Hitachi Energy, General Electric, CG Power & Industrial Solutions, Eaton, Bharat Heavy Electricals Limited, Fuji Electric Co. Ltd., SGB SMIT, and Raychem RPG Private Limited lead the Two Winding Cast Resin Transformer Market. The market exhibits moderate to high competition, driven by technological innovation, product reliability, and global service capabilities. Key players focus on expanding medium-voltage portfolios, improving thermal performance, and enhancing fire-safety features to address urban and industrial demand. Strategic investments in manufacturing capacity, regional expansion, and digital monitoring integration strengthen competitive positioning. Companies also emphasize compliance with international efficiency and safety standards to secure utility and infrastructure contracts. Partnerships with utilities, renewable developers, and EPC firms support market penetration, while aftersales service and lifecycle cost optimization remain critical differentiators in competitive bidding environments.

Shape Your Report to Specific Countries or Regions & Enjoy 30% Off!

Key Player Analysis

- Schneider Electric

- CG Power & Industrial Solutions

- Hitachi Energy

- Raychem RPG Private Limited

- Eaton

- SGB SMIT

- Bharat Heavy Electricals Limited

- Fuji Electric Co. Ltd.

- General Electric

- ABB

Recent Developments

- In November 2025, Tesla Transformadores launched the Cast Resin-Encapsulated Transformer 1.1 kV Series at the Eleventh FISE 2025 Fair in Medellín.

- In May 2025, GE Vernova announced an order to supply over 70 extra high-voltage transformers and shunt reactors to India’s POWERGRID to support renewable power corridors, with manufacturing at its Vadodara facility.

- In May 2024, Sudhir Power Limited introduced its cast resin transformers up to 4 MVA, 33 kV class, emphasizing safety and reliability.

Report Coverage

The research report offers an in-depth analysis based on Rating, Application and Geography. It details leading market players, providing an overview of their business, product offerings, investments, revenue streams, and key applications. Additionally, the report includes insights into the competitive environment, SWOT analysis, current market trends, as well as the primary drivers and constraints. Furthermore, it discusses various factors that have driven market expansion in recent years. The report also explores market dynamics, regulatory scenarios, and technological advancements that are shaping the industry. It assesses the impact of external factors and global economic changes on market growth. Lastly, it provides strategic recommendations for new entrants and established companies to navigate the complexities of the market.

Future Outlook

- The Two Winding Cast Resin Transformer Market will continue to benefit from sustained investments in urban power infrastructure and grid modernization programs.

- Increasing adoption of indoor and underground substations will drive demand for fire-safe and oil-free transformer solutions.

- Industrial electrification and expansion of data centers will strengthen medium-voltage transformer requirements.

- Renewable energy integration will accelerate deployment of cast resin transformers across solar and wind installations.

- Technological advancements in insulation materials will enhance thermal performance and operational efficiency.

- Digital monitoring and smart diagnostics will gain importance for predictive maintenance and reliability improvement.

- Stricter fire safety and environmental regulations will support replacement of conventional oil-filled transformers.

- Compact and high power-density designs will see higher adoption in space-constrained urban environments.

- Emerging economies will create new growth opportunities through electrification and infrastructure development.

- Competitive intensity will increase as manufacturers focus on innovation, localization, and lifecycle cost optimization.