Market Overview:

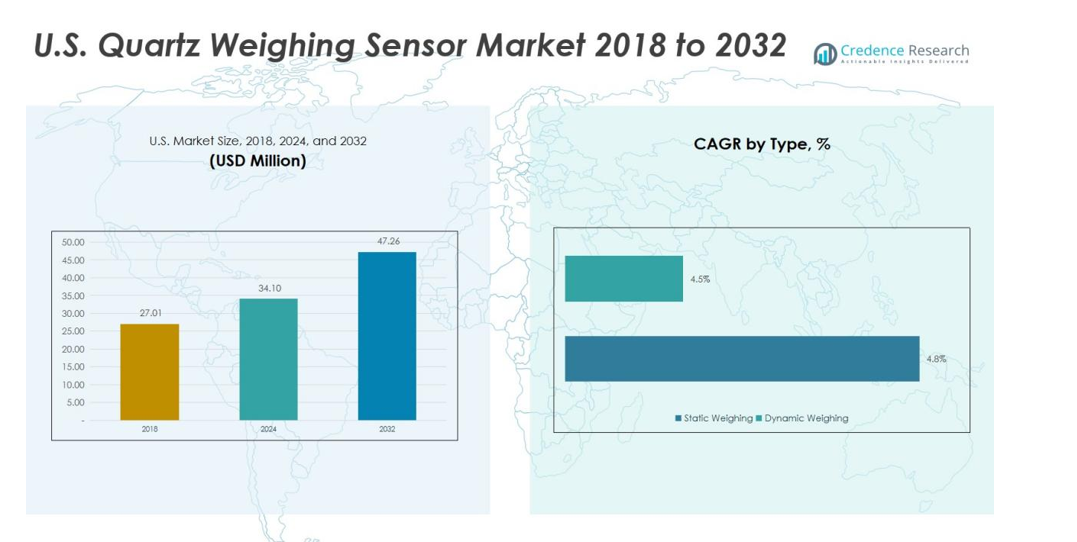

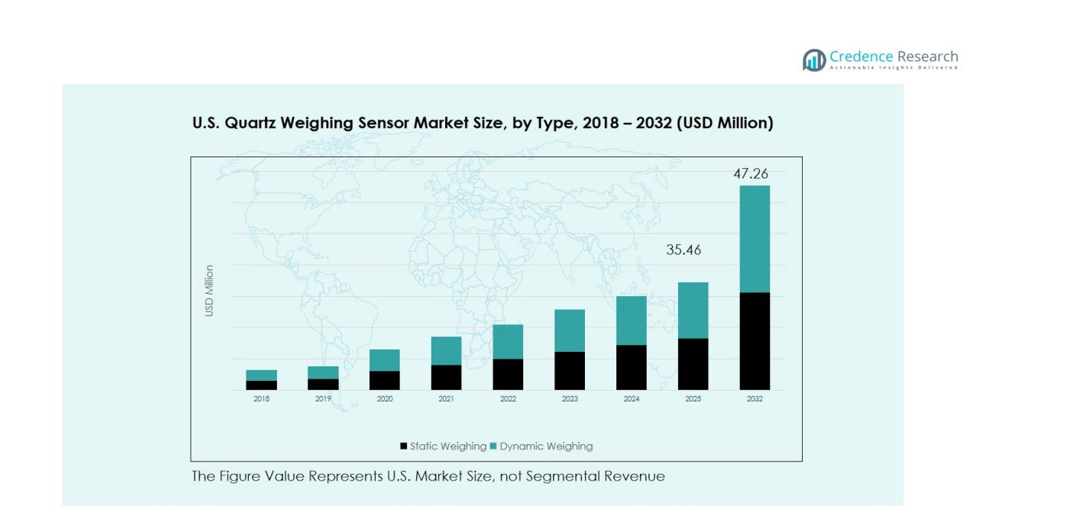

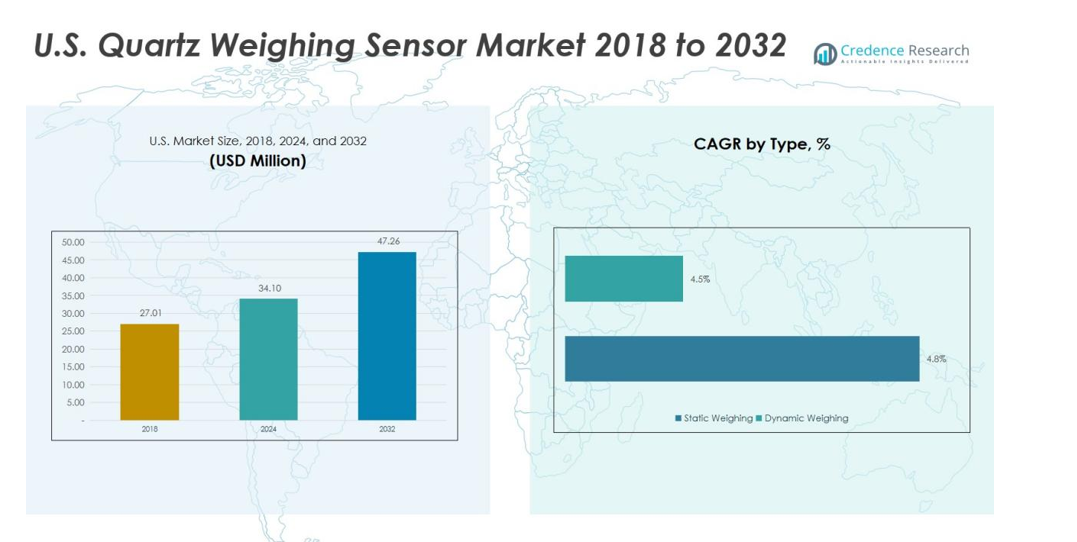

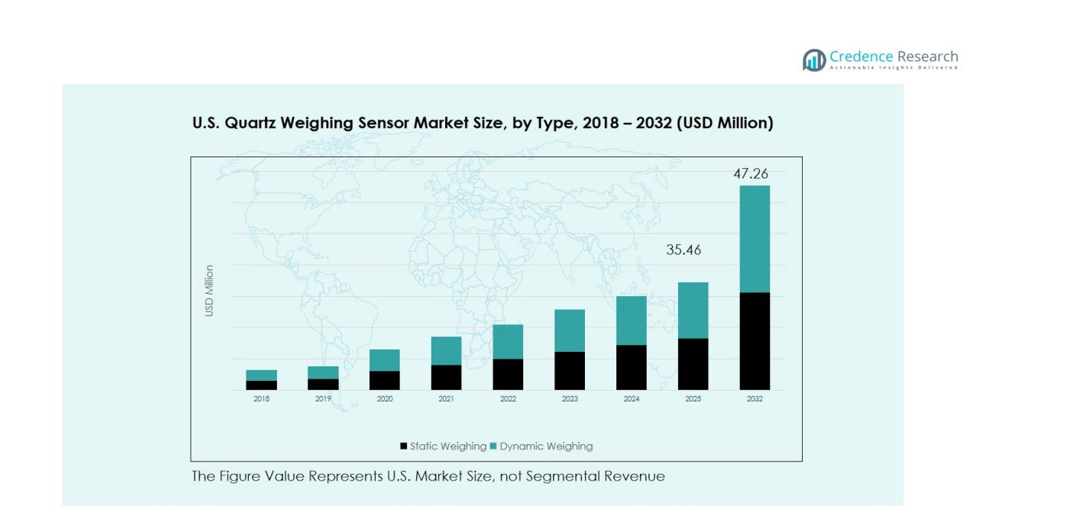

The U.S. Quartz Weighing Sensor Market size was valued at USD 27.01 million in 2018 to USD 34.10 million in 2024 and is anticipated to reach USD 47.26 million by 2032, at a CAGR of 4.10% during the forecast period.

| REPORT ATTRIBUTE |

DETAILS |

| Historical Period |

2020-2023 |

| Base Year |

2024 |

| Forecast Period |

2025-2032 |

| U.S. Quartz Weighing Sensor Market Size 2024 |

USD 34.10 million |

| U.S. Quartz Weighing Sensor Market, CAGR |

4.10% |

| U.S. Quartz Weighing Sensor Market Size 2032 |

USD 47.26 million |

Rising automation in manufacturing, advancements in micro-electromechanical systems (MEMS), and growing adoption in analytical instruments support market growth. The sensors’ ability to provide long-term reliability and fast response times enhances their use in pharmaceuticals, chemicals, and food processing sectors. The transition toward smart manufacturing and the integration of IoT-enabled weighing systems further boost their demand.

Regionally, the U.S. remains a leading market due to its strong industrial base, technological innovation, and presence of key sensor manufacturers. High R&D investments and a well-developed semiconductor ecosystem support product innovation and domestic production. Expanding use in aerospace, defense, and precision engineering sectors positions the U.S. as a key contributor to advancements in quartz-based weighing technologies.

Market Insights:

- The U.S. Quartz Weighing Sensor Market was valued at USD 27.01 million in 2018, reached USD 34.10 million in 2024, and is projected to attain USD 47.26 million by 2032, registering a CAGR of 4.10% during the forecast period.

- North America accounted for nearly 42% of the total share in 2024, driven by strong industrial automation and advanced R&D capabilities, followed by Europe with 28% and Asia Pacific with 21%, supported by growing semiconductor and precision manufacturing sectors.

- Asia Pacific is expected to be the fastest-growing region, contributing over 25% of market expansion by 2032 due to rapid industrialization and increased demand for smart weighing systems across China, Japan, and South Korea.

- By type, static weighing sensors held about 60% of the total share, supported by their accuracy and wide use in laboratories and quality control systems.

- Dynamic weighing sensors accounted for the remaining 40%, gaining momentum in automated and continuous process monitoring applications within manufacturing and logistics industries.

Access crucial information at unmatched prices!

Request your sample report today & start making informed decisions powered by Credence Research Inc.!

Download Sample

Market Drivers:

Rising Demand for High-Precision Measurement in Industrial and Scientific Applications

The U.S. Quartz Weighing Sensor Market is driven by growing demand for high-precision measurement in research laboratories and industrial facilities. Industries such as pharmaceuticals, chemicals, and semiconductors require accurate mass measurement to maintain process quality and compliance. Quartz sensors provide exceptional frequency stability and low drift, improving consistency in automated weighing systems. Their superior precision enables reliable performance in critical applications like analytical balances and microgram-level testing.

- For Instance, Sartorius Cubis II Ultra-High Resolution Semi-Micro balance features a monolithic weighing system with electromagnetic force compensation. This system enables a stabilization time under 2 seconds and a minimum sample weight of 4.1 mg.

Growing Integration of Sensors in Smart Manufacturing and Automation Systems

Automation trends across the manufacturing sector continue to drive adoption of quartz weighing sensors. These sensors enable continuous process monitoring, ensuring accuracy in production lines and material handling operations. Their compatibility with digital control systems supports real-time data acquisition and predictive maintenance. It strengthens the transition toward Industry 4.0, where precision and reliability are vital for optimizing productivity and minimizing human error.

- For Instance, Siemens Milltronics MMI-3 dual belt scale system provides a measurement accuracy of ±0.125% over a 4:1 (25–100%) rate range in approved installations.

Advancements in Sensor Design and Microelectromechanical Technologies

Rapid technological innovation in microelectromechanical systems (MEMS) has improved the performance and miniaturization of quartz weighing sensors. New designs enhance sensitivity, reduce energy consumption, and extend operational lifespans. This evolution supports broader use across portable instruments, laboratory devices, and industrial scales. It also encourages manufacturers to develop cost-effective, high-performance solutions tailored for dynamic weighing and analytical processes.

Expanding Use Across Aerospace, Defense, and Precision Engineering Sectors

The aerospace and defense industries increasingly use quartz weighing sensors for their accuracy and stability under extreme conditions. Applications include fuel measurement, component calibration, and force detection. The precision engineering sector benefits from these sensors’ ability to maintain consistent readings across varying temperatures and vibrations. It enhances performance reliability, positioning quartz technology as a preferred solution for high-value and mission-critical operations.

Market Trends:

Integration of Smart Technologies and Digital Connectivity in Precision Weighing Systems

The U.S. Quartz Weighing Sensor Market is witnessing a strong shift toward smart and connected weighing systems. Industries are adopting sensors with integrated digital interfaces and IoT capabilities to enhance data accuracy and traceability. These technologies enable real-time monitoring, predictive maintenance, and automated calibration in production environments. It supports the transition to Industry 4.0, where precision and efficiency are key operational priorities. The inclusion of wireless communication modules and cloud-based analytics is helping industries achieve faster decision-making and improved system reliability. Growing demand for digital process optimization is encouraging manufacturers to introduce intelligent sensors that combine measurement accuracy with advanced connectivity features.

- For Instance, Kistler Instrumente AG introduced its 5074A digital charge amplifier in October 2017. A successor model, the 5074B, was later launched in November 2020. The 5074A achieves an acquisition rate of up to 50 kSps per channel through Industrial Ethernet connectivity, which enables real-time data transmission across multi-channel quartz-based piezoelectric systems.

Focus on Miniaturization, Energy Efficiency, and Advanced Material Engineering

Market participants are focusing on developing compact and energy-efficient quartz weighing sensors to meet evolving industrial and research needs. Advances in microelectromechanical systems (MEMS) technology enable miniaturized designs without compromising accuracy or performance. It enhances integration flexibility in analytical instruments, portable devices, and automated weighing systems. Manufacturers are also investing in advanced materials and surface treatments to improve durability and resistance to temperature and vibration. The trend toward sustainable manufacturing and longer product lifecycles is driving demand for sensors that reduce energy use and maintenance frequency. Continuous innovation in sensor structure and packaging technology is expected to redefine performance standards across high-precision measurement applications.

- For Instance, In July 2025, STMicroelectronics agreed to acquire NXP Semiconductors’ MEMS sensor business for up to $950 million.

Market Challenges Analysis:

High Manufacturing Costs and Complex Production Processes Limiting Scalability

The U.S. Quartz Weighing Sensor Market faces challenges due to high manufacturing costs and complex fabrication requirements. Producing high-precision quartz sensors involves advanced cutting, polishing, and frequency calibration, which demand specialized equipment and expertise. These factors increase production expenses and limit large-scale manufacturing capabilities. Smaller manufacturers often struggle to compete with established players that possess advanced process infrastructure. It also impacts pricing flexibility and slows adoption in cost-sensitive sectors such as consumer electronics and general manufacturing.

Technological Limitations and Competition from Alternative Sensing Technologies

The market also faces pressure from alternative sensing technologies like piezoelectric, strain gauge, and capacitive sensors. These alternatives offer adequate accuracy at lower costs, attracting industrial users seeking economical solutions. Integration challenges with digital systems and temperature sensitivity under extreme environments further restrict quartz sensor applications. Continuous innovation is necessary to maintain competitive performance and adaptability to modern automation platforms. It demands consistent R&D investment, which can burden smaller firms. The need for standardization and improved interoperability remains a critical hurdle for expanding market reach.

Market Opportunities:

Emerging Adoption in Smart Weighing Systems and IoT-Enabled Devices

The U.S. Quartz Weighing Sensor Market is witnessing strong opportunities through integration with smart weighing systems and IoT-enabled platforms. Demand for connected industrial systems that provide real-time weight data and diagnostics is rising rapidly. Quartz sensors’ precision and stability make them ideal for automated and remote monitoring applications. It enables predictive maintenance and process optimization in sectors such as pharmaceuticals, logistics, and food production. Growing use of data analytics in weight measurement systems enhances decision-making efficiency and operational transparency, creating a favorable growth environment.

Rising Demand Across Healthcare, Aerospace, and Advanced Manufacturing Sectors

Expanding applications across healthcare and aerospace are opening new revenue avenues for quartz sensor manufacturers. High sensitivity and temperature resilience make quartz sensors suitable for medical dosing, laboratory instruments, and aircraft system calibration. The shift toward lightweight and energy-efficient components in advanced manufacturing further supports adoption. It encourages innovation in compact and energy-optimized sensor designs that meet regulatory and performance standards. Collaborations between OEMs and sensor developers are expected to accelerate commercialization and strengthen market competitiveness across specialized industries.

Market Segmentation Analysis:

By Type

The U.S. Quartz Weighing Sensor Market is segmented into static weighing and dynamic weighing types. Static weighing sensors dominate due to their extensive use in laboratory balances, precision measurement systems, and quality control processes. They provide consistent accuracy and stability, making them ideal for applications requiring fixed-load measurement. Dynamic weighing sensors are gaining traction in automated and high-speed production environments. It offers advantages in continuous monitoring, vehicle weighing, and process control systems where rapid data acquisition is essential. The growing adoption of automated weighing systems in industrial operations is expected to strengthen demand for both sensor types.

- For instance, Sartorius’ Cubis® II ultra-high resolution laboratory balance achieves 0.0001 mg (0.1 microgram) readability with a maximum capacity of 2.1 grams, delivering repeatability tolerance of 0.0002 mg at 5% load and demonstrating superior precision for pharmaceutical and research applications requiring highest accuracy standards.

By Application

The market is classified into industrial applications, aerospace, scientific research, and others. Industrial applications hold the largest share due to widespread use in process control, manufacturing automation, and material testing. Aerospace applications are expanding rapidly due to the need for high-precision force and mass measurement in component calibration and aircraft systems. Scientific research laboratories use quartz sensors for microgram-level precision and analytical studies. It also finds niche use in healthcare and defense for critical mass detection and monitoring tasks. Continuous innovation and integration with smart systems are expected to enhance performance across all application segments.

- For Instance, a research team developed a prototype quartz resonant pressure sensor with a sensitivity of 46.32 Hz/MPa and 0.0266% comprehensive accuracy across a 120 MPa pressure range, suitable for ultra-high-pressure applications like deep-sea exploration.

Segmentations:

By Type:

- Static Weighing

- Dynamic Weighing

By Application:

- Industrial Applications

- Aerospace

- Scientific Research

- Others

Regional Analysis:

Strong Industrial Base and High Demand for Precision Technologies Across North America

The U.S. Quartz Weighing Sensor Market benefits from the country’s advanced industrial infrastructure and strong focus on technological precision. Manufacturing, aerospace, and research industries rely heavily on high-accuracy weighing systems for production and testing. The presence of established players and advanced R&D centers supports rapid product innovation and customization. It enables faster adoption of smart weighing systems integrated with digital and IoT-based monitoring tools. Continuous investments in automation and industrial modernization sustain the country’s leadership within the North American region.

Rising Adoption Across Key Manufacturing and Research Hubs

Key manufacturing states, including California, Texas, and Michigan, exhibit strong demand for quartz weighing sensors due to their concentration of industrial and research activities. The pharmaceutical and semiconductor industries across these regions are increasingly deploying quartz sensors for precision-controlled processes. It enhances measurement reliability and process optimization in high-value manufacturing environments. Research laboratories and calibration centers in Massachusetts and New York also contribute significantly to market expansion. Government support for innovation and domestic production strengthens the regional ecosystem for advanced sensing technologies.

Growing Opportunities Through Technological Partnerships and Export Potential

The U.S. is emerging as a hub for sensor design, testing, and system integration partnerships. Collaboration between sensor manufacturers, OEMs, and research institutions continues to drive next-generation product development. It enhances export potential to global markets seeking advanced weighing technologies. The country’s strong intellectual property framework and investment in digital manufacturing create a favorable environment for innovation. Expanding opportunities in defense, aerospace, and industrial automation are expected to reinforce the U.S. position as a global leader in precision weighing solutions.

Shape Your Report to Specific Countries or Regions & Enjoy 30% Off!

Key Player Analysis:

Competitive Analysis:

The U.S. Quartz Weighing Sensor Market features strong competition among global and domestic manufacturers focused on precision measurement technologies. Key players include TE Connectivity, Kistler Group, PCB Piezotronics, and ChampionX, each emphasizing innovation, product reliability, and advanced sensor integration. Companies are expanding their portfolios with digital and IoT-compatible quartz sensors designed for industrial, aerospace, and research applications. It focuses on developing compact, durable, and high-sensitivity sensors that meet evolving performance and accuracy standards. Strategic collaborations with OEMs and automation firms strengthen market presence and application diversity. Continuous R&D investment and technological refinement remain critical for maintaining competitive differentiation and market leadership across specialized weighing and measurement segments.

Recent Developments:

- In October 2025, TE Connectivity announced it will host its 2025 Investor Day on November 20, 2025, in Philadelphia, where executive leadership will present strategic growth plans across global markets.

- In August 2025, The company announced India’s first real-time road quality assessment system, implemented on the Ganga Expressway project through smart measurement technologies supplied by Kistler.

Report Coverage:

The research report offers an in-depth analysis based on Type and Application. It details leading market players, providing an overview of their business, product offerings, investments, revenue streams, and key applications. Additionally, the report includes insights into the competitive environment, SWOT analysis, current market trends, as well as the primary drivers and constraints. Furthermore, it discusses various factors that have driven market expansion in recent years. The report also explores market dynamics, regulatory scenarios, and technological advancements that are shaping the industry. It assesses the impact of external factors and global economic changes on market growth. Lastly, it provides strategic recommendations for new entrants and established companies to navigate the complexities of the market.

Future Outlook:

- The U.S. Quartz Weighing Sensor Market will experience sustained growth driven by rising automation across industrial sectors.

- Adoption of precision weighing systems in pharmaceutical, semiconductor, and food industries will continue to expand.

- Technological advancements will enhance sensor durability, accuracy, and digital connectivity for smart manufacturing applications.

- Integration of IoT and AI-enabled analytics will improve process efficiency and real-time monitoring capabilities.

- Aerospace and defense sectors will increase use of quartz sensors for calibration, fuel measurement, and component testing.

- Research institutions will drive innovation in high-sensitivity sensor designs for advanced analytical applications.

- Partnerships between sensor manufacturers and OEMs will accelerate customized product development for specific industrial needs.

- Sustainability and energy-efficient production processes will encourage the use of long-life, low-maintenance quartz sensors.

- Domestic manufacturing initiatives and government support for technology innovation will strengthen supply chain resilience.

- Growing global demand for precision sensing solutions will enhance export opportunities and reinforce U.S. technological leadership.