Market Overview:

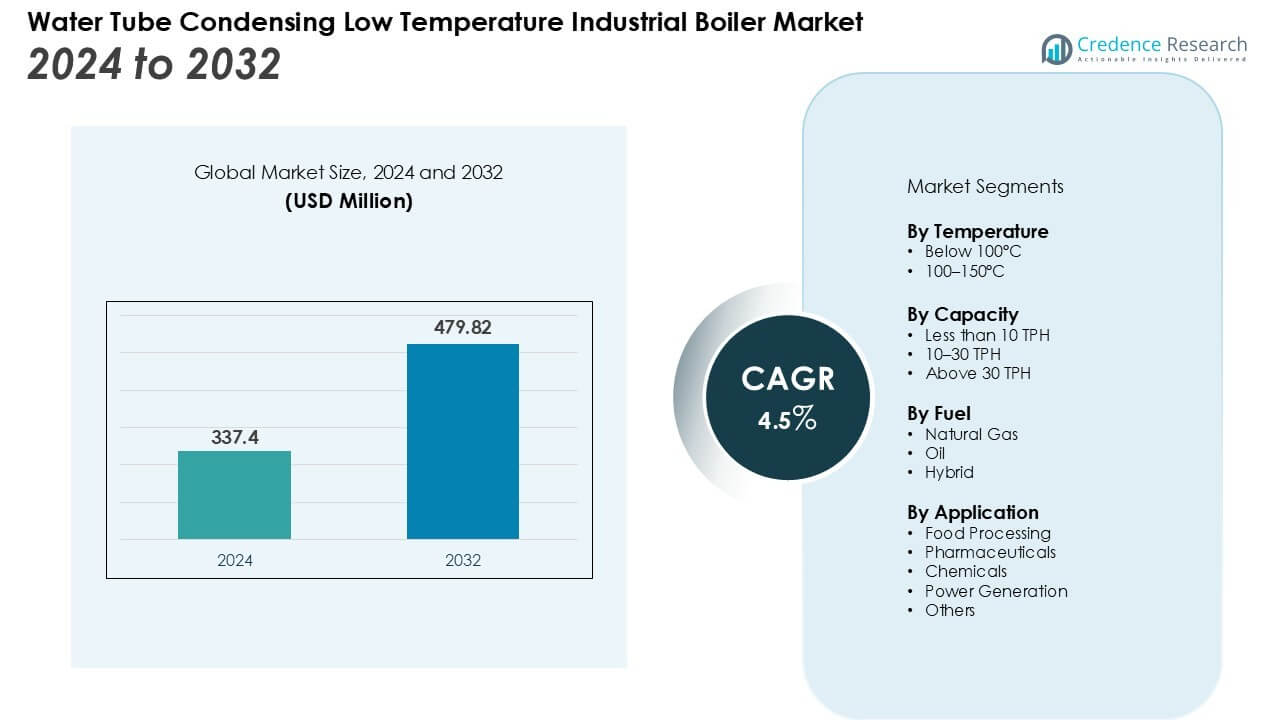

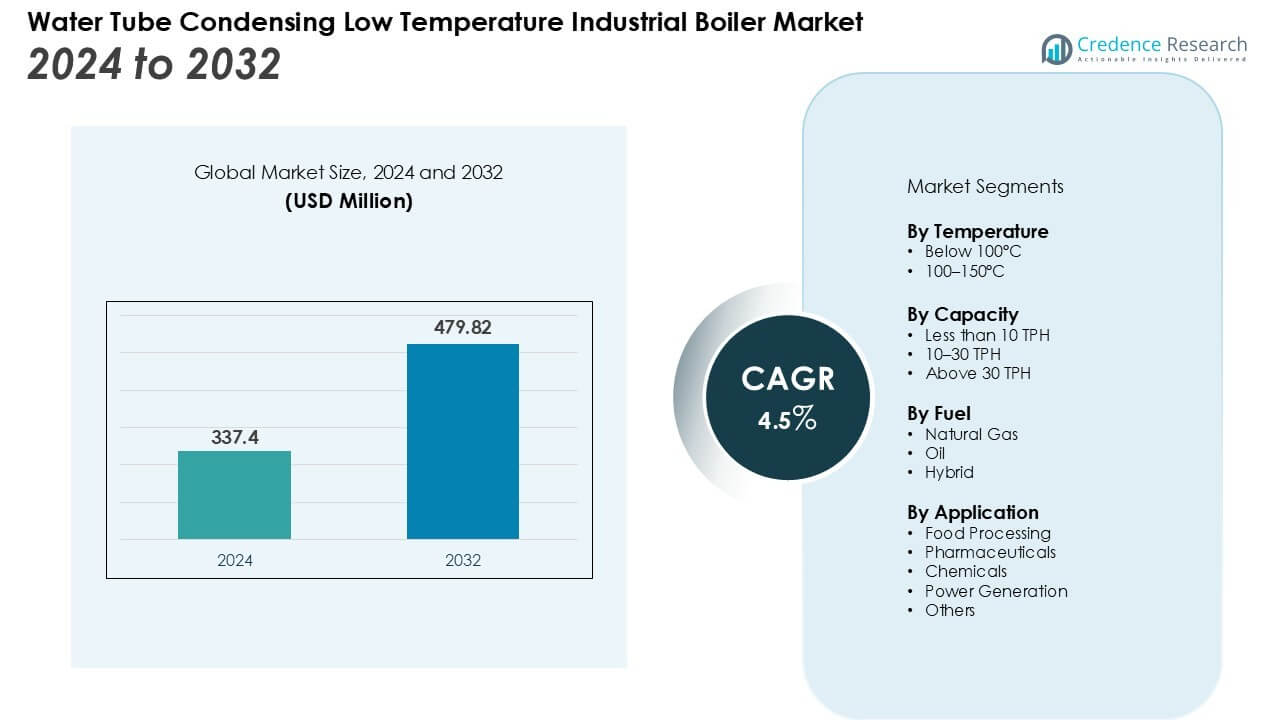

The Water Tube Condensing Low Temperature Industrial Boiler Market size was valued at USD 337.4 million in 2024 and is anticipated to reach USD 479.82 million by 2032, at a CAGR of 4.5% during the forecast period (2024-2032).

| REPORT ATTRIBUTE |

DETAILS |

| Historical Period |

2020-2023 |

| Base Year |

2024 |

| Forecast Period |

2025-2032 |

| Water Tube Condensing Low Temperature Industrial Boiler Market Size 2024 |

USD 337.4 Million |

| Water Tube Condensing Low Temperature Industrial Boiler Market, CAGR |

4.5% |

| Water Tube Condensing Low Temperature Industrial Boiler Market Size 2032 |

USD 479.82 Million |

Key drivers include the rising focus on sustainable manufacturing and compliance with stringent environmental standards. Industries such as food processing, pharmaceuticals, chemicals, and power generation are increasingly investing in condensing low temperature boilers to reduce operational costs and enhance energy performance. Technological advancements in automation and digital monitoring are also boosting adoption, as manufacturers seek improved process reliability and reduced downtime.

Regionally, Europe remains a leading market due to strict energy-efficiency directives and widespread adoption of green technologies. North America is experiencing solid growth, supported by modernization of industrial infrastructure and government incentives for clean energy solutions. Asia-Pacific is emerging as the fastest-growing region, driven by rapid industrialization, rising energy demand, and significant investment in manufacturing facilities. Collectively, these factors are shaping a competitive and innovation-driven market landscape, with global players focusing on R&D to strengthen product efficiency and regulatory compliance.

Access crucial information at unmatched prices!

Request your sample report today & start making informed decisions powered by Credence Research Inc.!

Download Sample

Market Insights:

- The Water Tube Condensing Low Temperature Industrial Boiler Market reached USD 337.4 million and is projected to hit USD 479.82 million at a CAGR of 4.5%.

- Rising demand for energy-efficient and low-emission systems is driving steady adoption across industrial facilities.

- Automation improves combustion control, energy savings, and reliability, aligning with strict environmental regulations.

- Food processing, pharmaceutical, chemical, and power generation industries are leading end-use adopters.

- High upfront costs and integration challenges remain key barriers for small and mid-sized enterprises.

- Europe holds 38% share, North America 27%, and Asia-Pacific 22%, reflecting diverse regional strengths.

- Continuous investment in smart automation, IoT integration, and sustainable infrastructure shapes future market growth.

Market Drivers:

Growing Need for Energy-Efficient and Low-Emission Industrial Systems

The Water Tube Condensing Low Temperature Industrial Boiler Automation Market is expanding due to rising energy-efficiency requirements across industries. Companies face strict emission norms, which drive demand for condensing boilers capable of reducing fuel usage and carbon output. Automation enhances operational control, ensuring optimized combustion and heat transfer. Energy savings and sustainability goals are strengthening adoption in diverse industrial sectors.

- For instance, Superior Boiler’s Cheyenne High-Efficiency Condensing Boiler offers sub-7 ppm NOx emissions with capacities up to 7.0 MMBTU/hour, setting industry standards for low emissions and high capacity.

Increasing Focus on Cost Optimization and Operational Reliability

Industries prioritize solutions that reduce production costs while improving output quality. Automated condensing boiler systems provide consistent monitoring, reducing chances of equipment failure and unplanned downtime. It supports predictive maintenance, which lowers repair expenses and extends equipment life cycles. Businesses adopt these systems to secure competitive advantages and maintain profitability.

- For instance, AERCO’s Benchmark boilers come with a standard 5-year onAER predictive maintenance subscription that enables early fault detection and reduces unplanned downtime.

Integration of Digital Monitoring and Smart Control Platforms

Automation is evolving with advanced digital control platforms that allow real-time process management. Integration with IoT-enabled systems enables precise adjustments and remote operation. It ensures safety, efficiency, and transparency in boiler operations. Industrial plants adopt automation to gain data-driven insights, streamline production, and maintain compliance with evolving regulatory standards.

Expanding Adoption Across Key End-Use Industries

The market benefits from increasing investments in food processing, pharmaceuticals, chemicals, and power generation. These industries demand reliable steam generation to meet production targets and quality standards. Automated condensing low temperature boilers deliver consistent performance while addressing sustainability and safety concerns. It positions the market as a preferred choice for industries aiming for efficiency and regulatory alignment.

Market Trends:

Advancements in Smart Automation and Digital Connectivity

The Water Tube Condensing Low Temperature Industrial Boiler Automation Market is experiencing strong momentum through adoption of advanced automation and digital tools. Manufacturers integrate IoT platforms, smart sensors, and AI-driven analytics to enhance real-time monitoring. It enables predictive maintenance, remote operation, and optimized energy use in industrial environments. Demand for cloud-based control systems is also rising, allowing centralized management of multiple boiler units across facilities. Companies adopt automation not only for compliance but also to achieve higher efficiency in resource utilization. This trend strengthens the transition toward intelligent, connected, and fully optimized industrial operations.

- For instance, Cleaver-Brooks’ Prometha IoT system collects a minimum of 250 data points per boiler every six seconds, enabling real-time monitoring and actionable insights that enhance operational efficiency while preventing unplanned downtime.

Rising Focus on Sustainability and Industry-Specific Customization

The market is influenced by growing emphasis on sustainable solutions tailored to sector-specific needs. Food processing, pharmaceutical, and chemical industries require systems that align with strict regulatory standards while ensuring uninterrupted performance. It drives demand for automation that can regulate fuel efficiency, reduce emissions, and maintain stable output under varied load conditions. Growing investment in low-emission infrastructure supports wider adoption across emerging economies. Customization of automation solutions to match industrial workflows is gaining traction, allowing greater flexibility for users. This trend highlights a shift toward systems designed not only for compliance but also for industry-driven operational excellence.

- For instance, Siemens’ Amberg facility in Germany produces 12 million Simatic programmable logic controllers yearly through highly customized automated manufacturing processes, ensuring precision and efficiency.

Market Challenges Analysis:

High Initial Investment and Integration Barriers

The Water Tube Condensing Low Temperature Industrial Boiler Automation Market faces constraints from high upfront costs and integration complexity. Advanced automation systems require significant capital expenditure, which discourages small and mid-sized enterprises from adoption. It also demands compatibility with existing infrastructure, and retrofitting older plants often presents technical and financial challenges. Lack of skilled personnel to handle advanced control systems increases dependency on external expertise, raising operational costs. These factors slow the pace of automation in price-sensitive markets and limit broader adoption.

Regulatory Compliance and Maintenance Complexity

Evolving regulatory standards across regions create uncertainty for manufacturers and users. The market must adapt to varied environmental and safety requirements, which often differ between countries and industries. It increases the complexity of design and maintenance, requiring continuous updates in automation features. Frequent inspections and compliance audits add further pressure on operators. Technical challenges in maintaining performance consistency under strict efficiency targets also affect long-term adoption. This dynamic creates operational hurdles that influence investment decisions in several industries.

Market Opportunities:

Rising Demand for Sustainable and Digitally Controlled Solutions

The Water Tube Condensing Low Temperature Industrial Boiler Automation Market is positioned to benefit from the global push toward sustainable and energy-efficient systems. Governments promote cleaner industrial operations through incentives, creating strong opportunities for advanced condensing automation. It supports industries in meeting emission goals while lowering operational costs. Expanding digital ecosystems with IoT and AI-driven control platforms enhance performance and transparency. Growing emphasis on remote monitoring and predictive maintenance will drive adoption across manufacturing hubs. These developments create favorable ground for wider integration of automated condensing boilers in both developed and emerging markets.

Expansion Across Emerging Economies and Industry-Specific Applications

Strong growth potential exists in Asia-Pacific, Latin America, and the Middle East, where industrialization and infrastructure development continue to accelerate. Industries in these regions require reliable steam solutions that balance cost efficiency with sustainability. It enables automation providers to introduce scalable and customizable systems tailored to local demands. Increasing adoption in food processing, chemicals, and power generation presents opportunities for sector-focused innovation. Partnerships between global technology firms and regional manufacturers can strengthen market presence. This expansion pathway highlights the long-term potential for advanced automation systems to become integral to industrial energy strategies.

Market Segmentation Analysis:

By Temperature

The Water Tube Condensing Low Temperature Industrial Boiler Automation Market is segmented into below 100°C and 100–150°C systems. Demand for below 100°C units is rising in industries requiring low-pressure steam with high energy efficiency. It finds strong use in food processing and pharmaceuticals where precise thermal control is critical. Systems in the 100–150°C range serve power generation and heavy chemical sectors that require higher thermal output. Both segments gain traction as industries emphasize emission compliance and efficiency.

- For instance, the Cleaver-Brooks ClearFire®-CE (CFC-E) condensing hydronic boiler features dual-return connections, a design that significantly increases energy savings compared to a conventional single-return boiler by enhancing its condensing capability.

By Capacity

The market is divided into less than 10 TPH, 10–30 TPH, and above 30 TPH boilers. Less than 10 TPH units are widely adopted by small and mid-sized industries for cost-effective operations. It offers reliable solutions for moderate steam demand while optimizing energy use. The 10–30 TPH range dominates large manufacturing facilities, balancing higher output with sustainable operation. Above 30 TPH units are preferred in power generation and petrochemicals, where large-scale steam requirements drive investment.

- For instance, a Cleaver-Brooks D-Type watertube boiler was engineered for a power plant with a steam capacity of 214,000 pounds per hour and a design pressure of 450 PSI.

By Fuel

Fuel segmentation includes natural gas, oil, and hybrid alternatives. Natural gas-based systems lead adoption due to cleaner combustion and regulatory support for low-emission technologies. It remains the preferred choice in regions promoting decarbonization. Oil-based systems serve industries with limited natural gas infrastructure, though demand is declining under emission constraints. Hybrid systems integrating renewable sources are gaining interest, highlighting long-term opportunities for sustainable industrial automation.

Segmentations:

By Temperature

By Capacity

- Less than 10 TPH

- 10–30 TPH

- Above 30 TPH

By Fuel

By Application

- Food Processing

- Pharmaceuticals

- Chemicals

- Power Generation

- Others

By Region

- North America

- Europe

- UK

- France

- Germany

- Italy

- Spain

- Russia

- Belgium

- Netherlands

- Austria

- Sweden

- Poland

- Denmark

- Switzerland

- Rest of Europe

- Asia Pacific

- China

- Japan

- South Korea

- India

- Australia

- Thailand

- Indonesia

- Vietnam

- Malaysia

- Philippines

- Taiwan

- Rest of Asia Pacific

- Latin America

- Brazil

- Argentina

- Peru

- Chile

- Colombia

- Rest of Latin America

- Middle East

- UAE

- KSA

- Israel

- Turkey

- Iran

- Rest of Middle East

- Africa

- Egypt

- Nigeria

- Algeria

- Morocco

- Rest of Africa

Regional Analysis:

Strong Market Presence in Europe

Europe accounted for 38% of the Water Tube Condensing Low Temperature Industrial Boiler Automation Market. The region is projected to maintain a leading position through the forecast period. Industrial facilities across Germany, France, and the United Kingdom are early adopters of condensing automation systems, driven by energy-efficiency directives. It benefits from strong government support for low-emission equipment and advanced manufacturing practices. The presence of established boiler manufacturers and technology providers further strengthens regional growth. Continuous investment in smart industrial infrastructure ensures Europe remains a key hub for innovation in automated boiler systems.

Expanding Opportunities in North America

North America represented 27% of the Water Tube Condensing Low Temperature Industrial Boiler Automation Market. The region continues to expand with steady adoption across industrial sectors. The United States and Canada witness rising adoption of automated condensing boiler systems in food, pharmaceutical, and chemical industries. It is further supported by government incentives that encourage energy-efficient industrial technologies. Growing focus on digital transformation in industrial operations accelerates adoption of IoT-enabled automation platforms. Strong R&D investment and the presence of leading automation firms ensure steady progress in the region.

Rapid Growth Across Asia-Pacific

Asia-Pacific held 22% of the Water Tube Condensing Low Temperature Industrial Boiler Automation Market. The region is expected to record the fastest growth during the forecast period. Industrial users in China, India, and Southeast Asia invest in advanced automation to improve reliability, efficiency, and compliance with evolving emission norms. It benefits from growing demand for energy-efficient solutions amid rising fuel costs. Governments encourage sustainable energy practices, creating favorable conditions for adoption of condensing boiler automation. Local manufacturing expansion and foreign direct investments further enhance market potential.

Shape Your Report to Specific Countries or Regions & Enjoy 30% Off!

Key Player Analysis:

- Fulton

- Hurst Boiler & Welding

- Thermax

- Babcock & Wilcox

- Rentech Boilers

- Babcock Wanson

- Thermodyne Boilers

- Burnham Commercial Boilers

- Clayton Industries

- IHI Corporation

- Miura America

- Cleaver-Brooks

- Johnston Boiler

- EPCB Boiler

Competitive Analysis:

The Water Tube Condensing Low Temperature Industrial Boiler Automation Market is highly competitive, with global and regional players focusing on efficiency, innovation, and compliance. Leading companies emphasize advanced automation, IoT-enabled monitoring, and energy-saving technologies to strengthen their portfolios. It drives continuous investment in research and development aimed at improving fuel flexibility and system reliability. Manufacturers are also expanding partnerships and service networks to enhance customer reach and provide tailored solutions. Competition is shaped by strict regulatory standards that encourage differentiation through sustainability and performance. Regional players focus on cost-effective solutions, while multinational firms prioritize large-scale industrial applications. The competitive landscape highlights a shift toward digital integration, predictive maintenance, and environmentally aligned solutions that reinforce long-term growth potential.

Recent Developments:

- In May 2025, Babcock & Wilcox announced its plan to utilize the proceeds from the sale of its Danish subsidiary, Babcock & Wilcox A/S, to advance its BrightLoop hydrogen production facility in Massillon, Ohio.

- In June 2025, Babcock & Wilcox first announced the agreement to sell its Diamond Power International business.

- In May 2024, Miura’s parent company, MIURA CO., LTD., finalized its acquisition of CBE ENTERPRISES, INC., the parent company of Cleaver-Brooks.

Report Coverage:

The research report offers an in-depth analysis based on Temperature, Capacity, Fuel, Application and Region. It details leading market players, providing an overview of their business, product offerings, investments, revenue streams, and key applications. Additionally, the report includes insights into the competitive environment, SWOT analysis, current market trends, as well as the primary drivers and constraints. Furthermore, it discusses various factors that have driven market expansion in recent years. The report also explores market dynamics, regulatory scenarios, and technological advancements that are shaping the industry. It assesses the impact of external factors and global economic changes on market growth. Lastly, it provides strategic recommendations for new entrants and established companies to navigate the complexities of the market.

Future Outlook:

- The Water Tube Condensing Low Temperature Industrial Boiler Automation Market will expand through rising demand for sustainable and energy-efficient solutions.

- Industries will adopt advanced automation systems to ensure operational reliability and reduce downtime.

- It will gain momentum from increasing integration of IoT-enabled monitoring and smart control platforms.

- Governments will continue to enforce strict environmental standards, encouraging adoption of low-emission boiler systems.

- Food processing, pharmaceutical, and chemical industries will remain key end-use sectors driving adoption.

- Power generation and large-scale manufacturing will invest in high-capacity units to improve efficiency.

- It will see strong growth opportunities in emerging economies with rapid industrialization and infrastructure expansion.

- Research and development will focus on hybrid systems and renewable fuel integration.

- Digital transformation will support predictive maintenance, real-time monitoring, and enhanced safety compliance.

- Global competition will intensify as companies prioritize innovation, regulatory alignment, and customer-focused solutions.