Market Overview

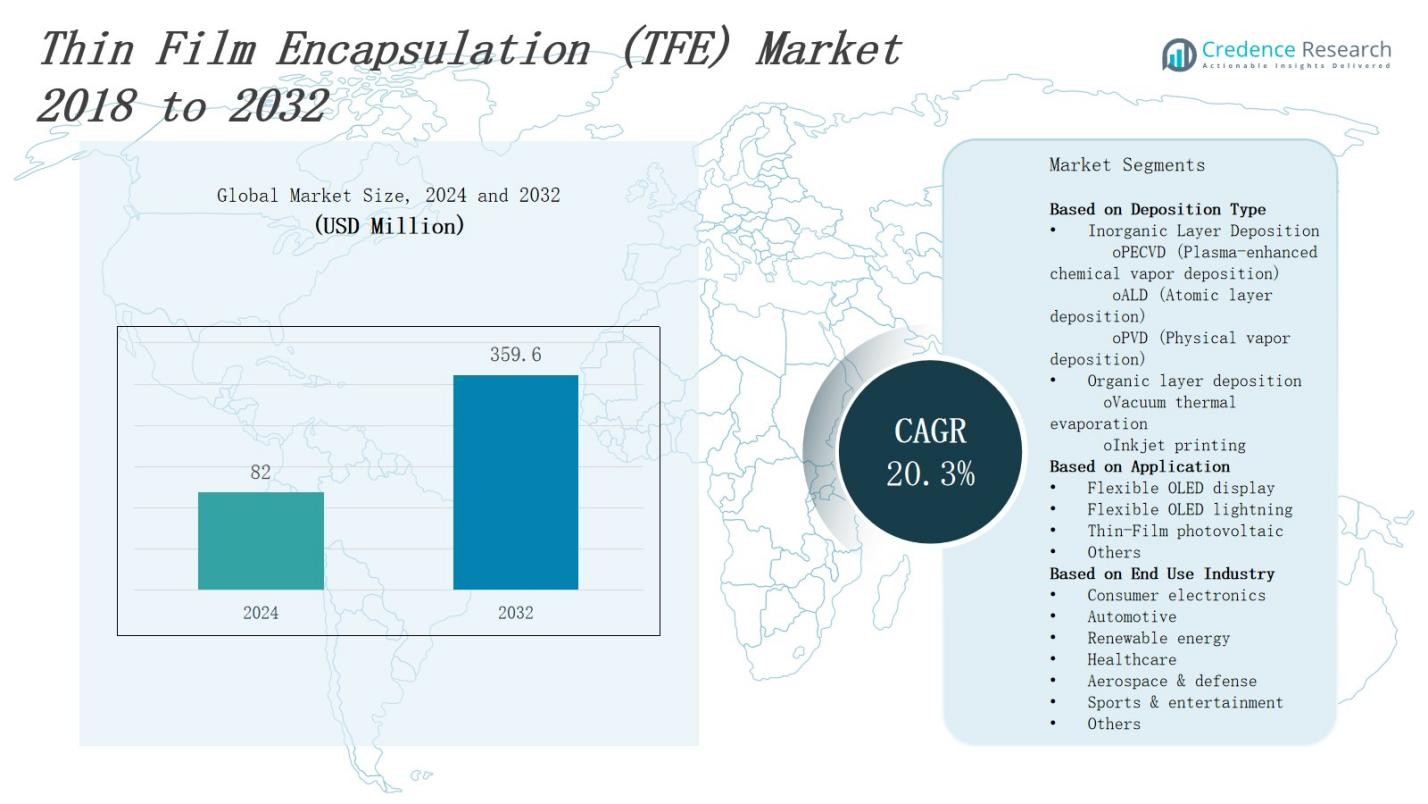

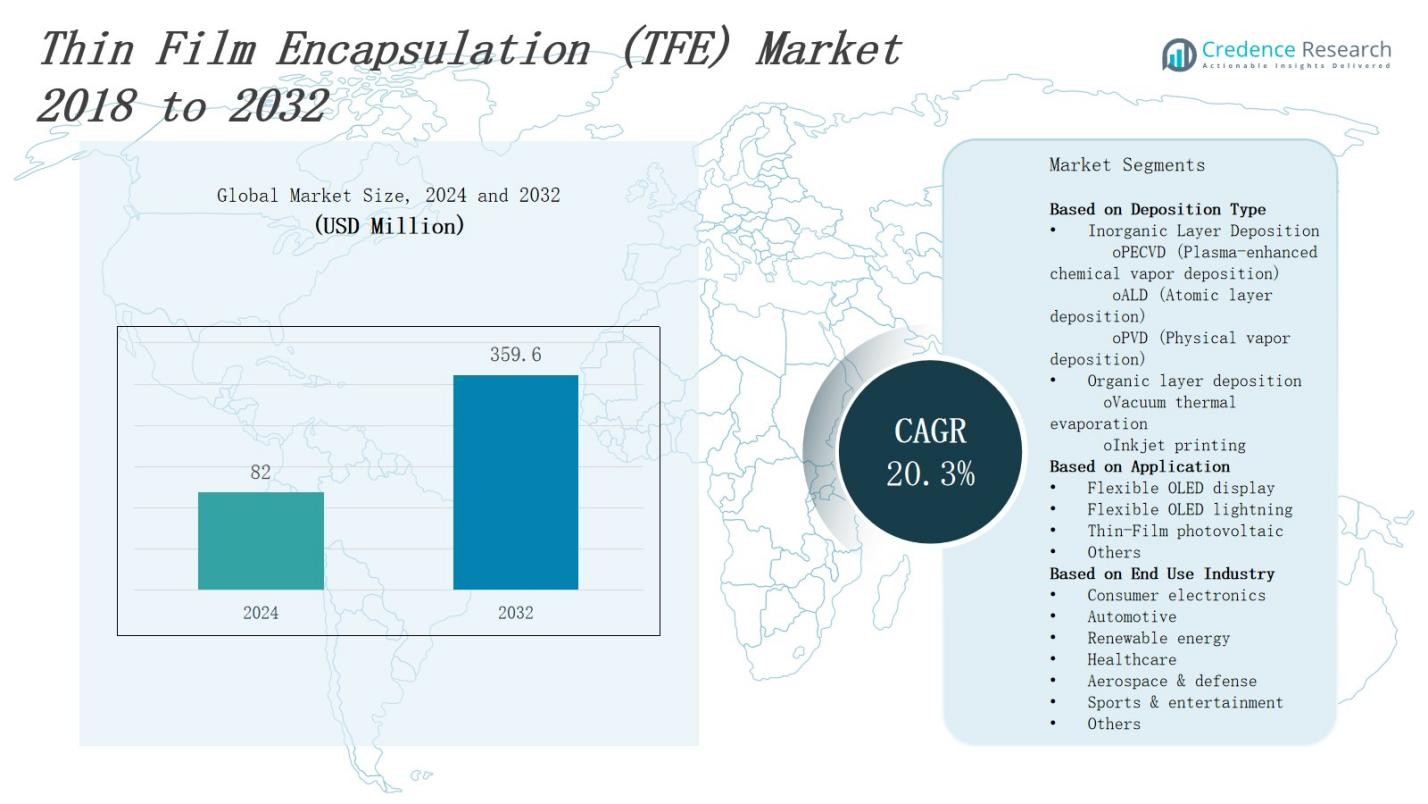

The Thin Film Encapsulation (TFE) market is projected to grow from USD 82 million in 2024 to USD 359.6 million by 2032, expanding at a CAGR of 20.3%.

| REPORT ATTRIBUTE |

DETAILS |

| Historical Period |

2020-2024 |

| Base Year |

2024 |

| Forecast Period |

2025-2032 |

| Thin Film Encapsulation (TFE) market Size 2024 |

USD 82 Million |

| Thin Film Encapsulation (TFE) market, CAGR |

20.3% |

| Thin Film Encapsulation (TFE) market Size 2032 |

USD 359.6 Million |

The Thin Film Encapsulation (TFE) market grows driven by rising demand for flexible and durable protective coatings in electronics, particularly flexible displays and wearable devices. Increasing adoption of OLED and AMOLED technologies fuels the need for advanced encapsulation to enhance device longevity and performance. Manufacturers focus on developing ultra-thin, lightweight films that provide superior barrier properties against moisture and oxygen. Technological advancements in atomic layer deposition and plasma-enhanced chemical vapor deposition accelerate market growth. Rising consumer preference for bendable, foldable devices and expanding applications in healthcare and automotive sectors further support the adoption of TFE solutions worldwide.

The Thin Film Encapsulation (TFE) market spans key regions including North America, Europe, Asia-Pacific, and the Rest of the World. Asia-Pacific leads with the largest market share, driven by major electronics manufacturers in China, South Korea, and Japan. North America and Europe hold significant shares due to advanced technology adoption and strong R&D investments. The Rest of the World region shows emerging growth potential in healthcare and renewable energy sectors. Key players such as Meyer Burger Technology AG, SAMSUNG SDI CO., LTD., LG Chem, and SAES Getters S.p.A. drive innovation and competition across these regions.

Access crucial information at unmatched prices!

Request your sample report today & start making informed decisions powered by Credence Research Inc.!

Download Sample

Market Insights

- The Thin Film Encapsulation (TFE) market is projected to grow from USD 82 million in 2024 to USD 359.6 million by 2032, at a CAGR of 20.3%.

- Rising demand for flexible and durable protective coatings in electronics, especially flexible displays and wearables, drives market growth.

- Increasing adoption of OLED and AMOLED technologies creates strong need for advanced encapsulation to improve device longevity and performance.

- Manufacturers develop ultra-thin, lightweight films with superior moisture and oxygen barrier properties to meet application requirements.

- Technological advances in atomic layer deposition and plasma-enhanced chemical vapor deposition accelerate market expansion.

- Asia-Pacific leads with 38% market share due to major electronics manufacturers in China, South Korea, and Japan; North America holds 28%, Europe 22%, and Rest of the World 12%.

- Key players including Meyer Burger Technology AG, SAMSUNG SDI CO., LTD., LG Chem, and SAES Getters S.p.A. drive innovation and competition across regions.

Market Drivers

Growing Demand for Flexible and Wearable Electronics

The Thin Film Encapsulation (TFE) market benefits from the rapid adoption of flexible and wearable electronic devices. Consumers increasingly prefer lightweight, bendable, and durable gadgets such as foldable smartphones, smartwatches, and fitness trackers. These devices require robust encapsulation to protect sensitive components from moisture and oxygen exposure. Manufacturers invest heavily in TFE technologies to meet these durability and flexibility requirements. This rising demand fuels innovation and drives market expansion globally. It also pushes production capacities to accommodate growing volumes in consumer electronics.

- For instance, Samsung’s foldable smartphones use TFE to protect flexible OLED displays, which are bent thousands of times in testing while maintaining durability and visual performance.

Advancements in Display Technologies

The Thin Film Encapsulation (TFE) market gains momentum due to the widespread adoption of OLED and AMOLED display technologies. These displays demand superior barrier solutions to maintain brightness, color accuracy, and device lifespan. It plays a critical role in preventing degradation caused by environmental factors. Companies develop ultra-thin, transparent encapsulation films that integrate seamlessly with advanced display panels. Continuous research on improved deposition methods enhances product performance. The integration of TFE into next-generation displays supports sustained market growth.

- For instance, LG Display has developed transparent OLED panels featuring TFE for use in commercial digital signage and automotive augmented reality windshields, enhancing both flexibility and environmental stability in demanding contexts.

Technological Innovations in Encapsulation Processes

The Thin Film Encapsulation (TFE) market advances through continuous technological improvements in deposition techniques like atomic layer deposition (ALD) and plasma-enhanced chemical vapor deposition (PECVD). These methods allow precise control over film thickness and uniformity, enhancing barrier effectiveness. It enables manufacturers to produce highly reliable encapsulation solutions suitable for various applications. Innovations reduce manufacturing costs and improve scalability. Enhanced encapsulation quality increases product reliability, which attracts key end-users. This drives broader adoption of TFE across multiple industries.

Expanding Applications Beyond Consumer Electronics

The Thin Film Encapsulation (TFE) market experiences growth due to increasing applications in sectors such as healthcare, automotive, and aerospace. Protective films safeguard sensitive sensors, flexible solar panels, and medical devices from environmental damage. It facilitates the development of lightweight, compact components with extended operational life. Growing focus on miniaturization and high-performance materials creates new opportunities. Partnerships between material suppliers and device manufacturers promote innovation. These factors collectively boost demand for TFE solutions across diverse markets.

Market Trends

Rising Adoption of Flexible and Foldable Device Technologies

The Thin Film Encapsulation (TFE) market shows a strong trend toward supporting flexible and foldable electronic devices. Demand for smartphones, tablets, and wearables with bendable displays continues to grow rapidly. It provides essential moisture and oxygen barrier protection without compromising device flexibility. Manufacturers focus on developing ultra-thin, lightweight encapsulation films that conform to complex geometries. This trend encourages investments in new materials and advanced deposition techniques. It drives innovations that improve device durability and consumer appeal.

- For instance, Huawei Mate X6 incorporates TFE with advanced materials like carbon fiber inner screens and Kunlun Glass 2 to boost foldable screen durability while maintaining TÜV-certified color accuracy and robust environmental resistance.

Integration of Advanced Deposition Technologies for Superior Film Quality

The Thin Film Encapsulation (TFE) market experiences growth driven by advancements in deposition technologies such as atomic layer deposition (ALD) and plasma-enhanced chemical vapor deposition (PECVD). These techniques enable precise, uniform thin films with enhanced barrier properties. It supports production of highly reliable encapsulation layers that prevent degradation of sensitive components. Companies emphasize process optimization to reduce defects and improve yield. These technological trends allow TFE solutions to meet stringent performance demands across applications.

- For instance, Applied Materials innovated plasma-enhanced ALD systems to improve thin-film deposition quality in 3D NAND memory and logic chips, focusing on defect reduction and yield optimization critical for high-reliability encapsulation layers.

Shift Toward Sustainable and Environmentally Friendly Materials

The Thin Film Encapsulation (TFE) market increasingly incorporates eco-friendly materials and processes. Manufacturers pursue sustainable film substrates and low-impact coating methods to reduce environmental footprints. It reflects growing regulatory pressures and consumer demand for green electronics. The trend promotes the development of recyclable and biodegradable encapsulation options. Industry players collaborate on research to balance sustainability with performance. This focus on environmentally responsible solutions differentiates leading companies and drives market growth.

Expansion into Emerging Applications Beyond Consumer Electronics

The Thin Film Encapsulation (TFE) market broadens its scope by entering sectors such as healthcare, automotive, and renewable energy. Protective films support flexible sensors, medical implants, and lightweight solar panels, enhancing device reliability. It enables miniaturization and improved performance in these fields. Partnerships between TFE providers and original equipment manufacturers accelerate adoption. This diversification opens new revenue streams and reduces dependence on traditional electronics markets. It strengthens the market’s long-term growth potential.

Market Challenges Analysis

High Manufacturing Costs and Complex Production Processes

The Thin Film Encapsulation (TFE) market faces significant challenges due to the high costs associated with advanced manufacturing techniques. It requires specialized equipment such as atomic layer deposition and plasma-enhanced chemical vapor deposition systems, which demand substantial capital investment. These processes involve precise control and cleanroom environments that increase operational expenses. Manufacturers struggle to balance cost-efficiency with maintaining the high quality and reliability standards needed for sensitive electronic devices. The complexity of scaling production while ensuring uniformity and defect-free films further complicates manufacturing. These factors limit widespread adoption, particularly among smaller players.

Material Limitations and Performance Reliability Concerns

The Thin Film Encapsulation (TFE) market encounters challenges related to material performance and long-term reliability. It relies on thin films that must provide effective barriers against moisture and oxygen without compromising flexibility or transparency. Some materials may degrade under mechanical stress or environmental exposure, impacting device lifespan. Achieving a perfect balance between barrier properties and mechanical durability remains difficult. Variations in film adhesion and compatibility with different substrates cause performance inconsistencies. These issues require continuous material innovation and rigorous testing to meet evolving application demands. Such challenges slow product development and market penetration.

Market Opportunities

Expanding Applications in Emerging Industries and Technologies

The Thin Film Encapsulation (TFE) market presents significant opportunities by expanding into emerging industries such as healthcare, automotive, and renewable energy. It supports the development of flexible sensors, wearable medical devices, and lightweight solar panels that require robust protection from environmental factors. Growing demand for miniaturized, durable components drives adoption in these sectors. Collaborations between TFE providers and original equipment manufacturers accelerate innovation and product integration. This diversification reduces reliance on traditional consumer electronics and opens new revenue streams, enhancing market resilience and growth potential.

Advancements in Sustainable and High-Performance Materials

The Thin Film Encapsulation (TFE) market benefits from ongoing innovations in sustainable and high-performance materials. It enables manufacturers to develop eco-friendly, recyclable, and biodegradable encapsulation films that meet increasing environmental regulations and consumer expectations. Enhanced material formulations improve barrier properties while maintaining flexibility and transparency. These advancements reduce environmental impact and production costs, making TFE solutions more attractive across industries. Investment in research and development drives breakthroughs that can capture new market segments and strengthen competitive positioning.

Market Segmentation Analysis:

By Deposition Type

The Thin Film Encapsulation (TFE) market segments primarily into inorganic and organic layer deposition techniques. Inorganic deposition includes PECVD, ALD, and PVD, which provide superior barrier properties and durability. It serves applications demanding high reliability, such as flexible OLED displays. Organic layer deposition utilizes vacuum thermal evaporation and inkjet printing, offering cost-effective, scalable solutions with good flexibility. It supports emerging flexible electronics where lightweight encapsulation is crucial. Manufacturers invest in optimizing these methods to balance performance, cost, and production efficiency, driving technological advancement across segments.

- For instance, Samsung Electronics and LG Display utilize Atomic Layer Deposition (ALD) for barrier films on flexible OLED displays due to its precise control and uniform, pinhole-free coatings that enhance durability on thermally fragile substrates.

By Application

The Thin Film Encapsulation (TFE) market caters to flexible OLED displays, flexible OLED lighting, thin-film photovoltaics, and other applications. Flexible OLED displays dominate due to rising demand in smartphones, tablets, and wearables requiring protection without sacrificing flexibility. It also addresses the growing flexible OLED lighting sector with its energy efficiency and design advantages. Thin-film photovoltaics benefit from TFE’s moisture barrier capabilities, enhancing solar panel longevity. Other applications include flexible sensors and electronic textiles, which broaden market scope and innovation potential.

- For instance, BOE Technology Group employs a multi-layer TFE structure that has enabled their flexible OLED devices to resist moisture and oxygen, maintaining performance after 20,000 hours in high humidity conditions.

By End Use Industry

The Thin Film Encapsulation (TFE) market serves diverse industries, including consumer electronics, automotive, renewable energy, healthcare, aerospace & defense, sports & entertainment, and others. Consumer electronics represent the largest segment, driven by demand for flexible, durable devices. It finds increasing use in automotive displays and sensors, enhancing vehicle safety and user experience. Renewable energy benefits from TFE protection in solar panels, while healthcare leverages it for wearable medical devices. Aerospace, defense, and sports sectors explore TFE for lightweight, reliable protective films, expanding market reach and application diversity.

Segments:

Based on Deposition Type

- Inorganic Layer Deposition

- PECVD (Plasma-enhanced chemical vapor deposition)

- ALD (Atomic layer deposition)

- PVD (Physical vapor deposition)

- Organic layer deposition

-

- Vacuum thermal evaporation

- Inkjet printing

Based on Application

- Flexible OLED display

- Flexible OLED lightning

- Thin-Film photovoltaic

- Others

Based on End Use Industry

- Consumer electronics

- Automotive

- Renewable energy

- Healthcare

- Aerospace & defense

- Sports & entertainment

- Others

Based on the Geography:

- North America

- Europe

- Germany

- France

- U.K.

- Italy

- Spain

- Rest of Europe

- Asia Pacific

- China

- Japan

- India

- South Korea

- South-east Asia

- Rest of Asia Pacific

- Latin America

- Brazil

- Argentina

- Rest of Latin America

- Middle East & Africa

- GCC Countries

- South Africa

- Rest of the Middle East and Africa

Regional Analysis

North America

The Thin Film Encapsulation (TFE) market in North America holds a significant share of 28%. It benefits from the presence of advanced electronics manufacturing hubs and strong demand for flexible displays and wearable devices. Leading technology companies invest in research and development to enhance encapsulation solutions tailored to consumer and industrial needs. It supports diverse applications, including healthcare and automotive sectors, driving regional growth. Robust infrastructure and favorable government policies encourage innovation and adoption. The focus on miniaturization and smart device integration further accelerates market expansion across the region.

Europe

Europe accounts for 22% of the Thin Film Encapsulation (TFE) market, driven by growing investments in flexible electronics and renewable energy technologies. It houses several key players specializing in advanced encapsulation materials and deposition processes. Strict environmental regulations promote the development of sustainable and eco-friendly TFE solutions. It finds increasing use in automotive displays, medical devices, and flexible lighting applications. Collaborative research initiatives and government support enhance technological advancement. The emphasis on product quality and reliability sustains steady market growth in Europe.

Asia-Pacific

The Asia-Pacific region dominates the Thin Film Encapsulation (TFE) market with a 38% share, propelled by rapid industrialization and expanding consumer electronics manufacturing. It hosts major electronics and display panel manufacturers adopting flexible and foldable device technologies. Rising demand from countries like China, South Korea, and Japan fuels market growth. It supports diverse applications, including smartphones, wearables, and thin-film photovoltaics. Government initiatives promoting innovation and smart manufacturing accelerate adoption. Competitive pricing and large-scale production capacity position Asia-Pacific as the fastest-growing region.

Rest of the World

The Rest of the World region captures 12% of the Thin Film Encapsulation (TFE) market, encompassing Latin America, the Middle East, and Africa. It witnesses growing interest in advanced electronic devices and renewable energy applications. It faces challenges due to limited manufacturing infrastructure but benefits from increasing imports and technology transfers. Emerging markets show potential for growth in healthcare wearables and flexible sensors. Investments in research and partnerships with global players stimulate market development. The region offers opportunities for expanding TFE adoption in untapped sectors.

Shape Your Report to Specific Countries or Regions & Enjoy 30% Off!

Key Player Analysis

- SAMSUNG SDI CO., LTD. (South Korea)

- Meyer Burger Technology AG (Switzerland)

- Kyoritsu Chemical & Co., Ltd. (Japan)

- AMS Technologies AG (Germany)

- SAES Getters S.p.A. (Italy)

- BYSTRONIC GLASS (Switzerland)

- Picosun Oy (Finland)

- KANEKA CORPORATION (Japan)

- SNU Precision Co., Ltd. (South Korea)

- Angstrom Engineering Inc. (Canada)

- ROLIC Technologies (Switzerland)

- LG Chem (South Korea)

Competitive Analysis

The Thin Film Encapsulation (TFE) market features intense competition among established players and emerging innovators. Leading companies focus on advancing deposition technologies and developing high-performance, flexible encapsulation materials. It drives product differentiation and enhances barrier properties to meet growing demand for flexible displays and wearable devices. Key players invest heavily in research and development to optimize cost-efficiency and manufacturing scalability. Strategic partnerships and collaborations with electronics manufacturers accelerate technology adoption and market penetration. Competitive pricing and regional expansion remain critical factors for securing market share. It challenges companies to continuously innovate and adapt to evolving application requirements, ensuring sustained growth in a rapidly changing landscape.

Recent Developments

- In March 2025, Samsung Display announced a partnership with multiple OLED manufacturers to advance thin-film encapsulation technology, aiming to enhance durability, reduce costs, and improve flexible display performance for smartphones and wearables.

- In December 2024, Applied Materials, Inc. unveiled new advancements in thin-film encapsulation technologies designed to boost efficiency and lower production costs for OLED and photovoltaic applications.

- In November 2024, Picosun Oy launched a new atomic layer deposition (ALD) system specifically for thin-film encapsulation of flexible OLED displays, improving manufacturing efficiency and quality for high-volume production.

- In October 2024, Meyer Burger Technology AG introduced a new thin-film encapsulation solution for photovoltaic applications, enhancing efficiency and longevity for thin-film solar cells.

Market Concentration & Characteristics

The Thin Film Encapsulation (TFE) market exhibits a moderately concentrated structure dominated by key players with strong technological capabilities and global reach. It features several leading companies that invest heavily in research and development to innovate advanced deposition techniques and high-performance encapsulation materials. These firms focus on developing ultra-thin, flexible films that meet stringent barrier requirements for emerging flexible electronics and wearable devices. The market’s complexity requires significant capital expenditure, creating high entry barriers for new competitors. It fosters collaboration between technology providers and electronics manufacturers to accelerate product integration. Regional dominance by Asia-Pacific manufacturers emphasizes large-scale production capabilities and cost competitiveness. The market demands continuous innovation to address challenges such as material durability and manufacturing scalability. It encourages strategic partnerships and mergers to strengthen market positioning and expand application portfolios. This competitive environment drives sustained growth and technological advancement within the Thin Film Encapsulation (TFE) market.

Report Coverage

The research report offers an in-depth analysis based on Deposition Type, Application, End-User Industry and Geography. It details leading market players, providing an overview of their business, product offerings, investments, revenue streams, and key applications. Additionally, the report includes insights into the competitive environment, SWOT analysis, current market trends, as well as the primary drivers and constraints. Furthermore, it discusses various factors that have driven market expansion in recent years. The report also explores market dynamics, regulatory scenarios, and technological advancements that are shaping the industry. It assesses the impact of external factors and global economic changes on market growth. Lastly, it provides strategic recommendations for new entrants and established companies to navigate the complexities of the market.

Future Outlook

- Demand for flexible and foldable electronic devices will drive Thin Film Encapsulation (TFE) market growth.

- Innovations in deposition technologies will enhance film quality and manufacturing efficiency.

- Manufacturers will focus on developing environmentally friendly and recyclable encapsulation materials.

- Expansion of applications in healthcare and automotive sectors will create new market opportunities.

- Collaboration between material suppliers and device manufacturers will accelerate product adoption.

- Miniaturization of electronic components will increase the need for advanced encapsulation solutions.

- Asia-Pacific will continue to lead due to its strong electronics manufacturing base.

- Improvements in barrier performance will extend the lifespan of flexible displays and sensors.

- Investments in research and development will support breakthrough innovations.

- Market players will pursue strategic partnerships to strengthen their competitive position globally.