Market Overview:

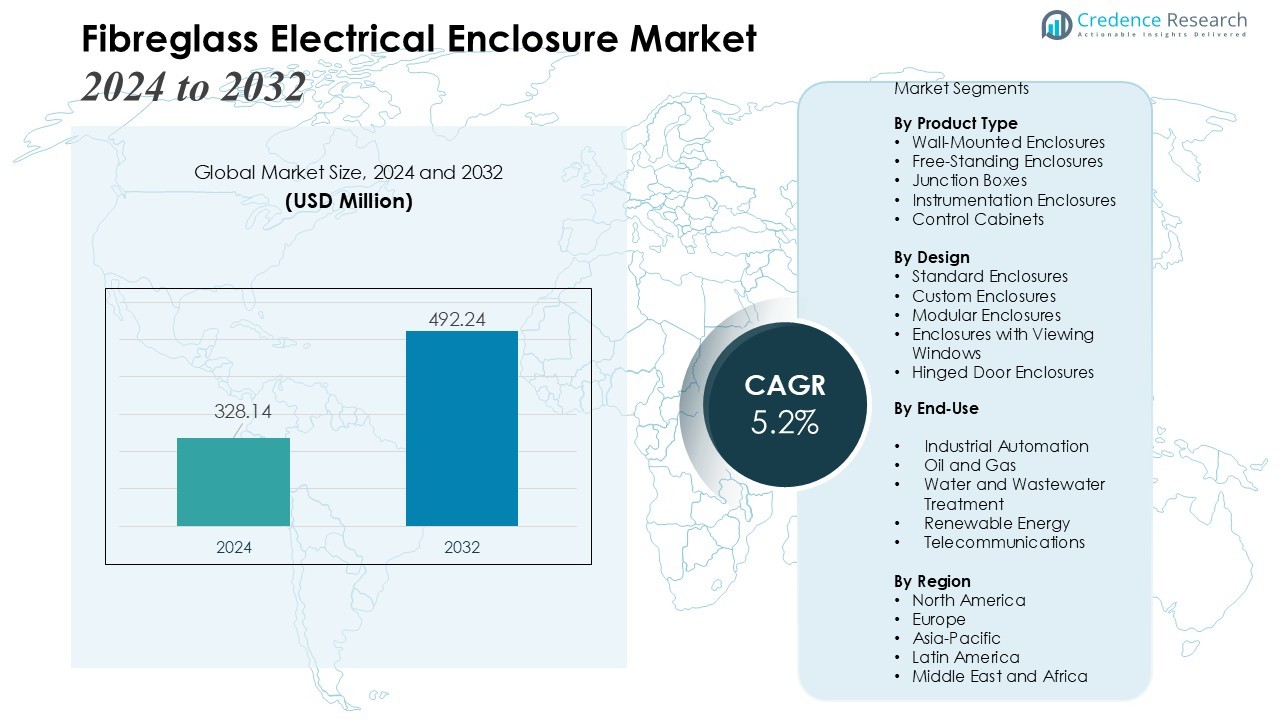

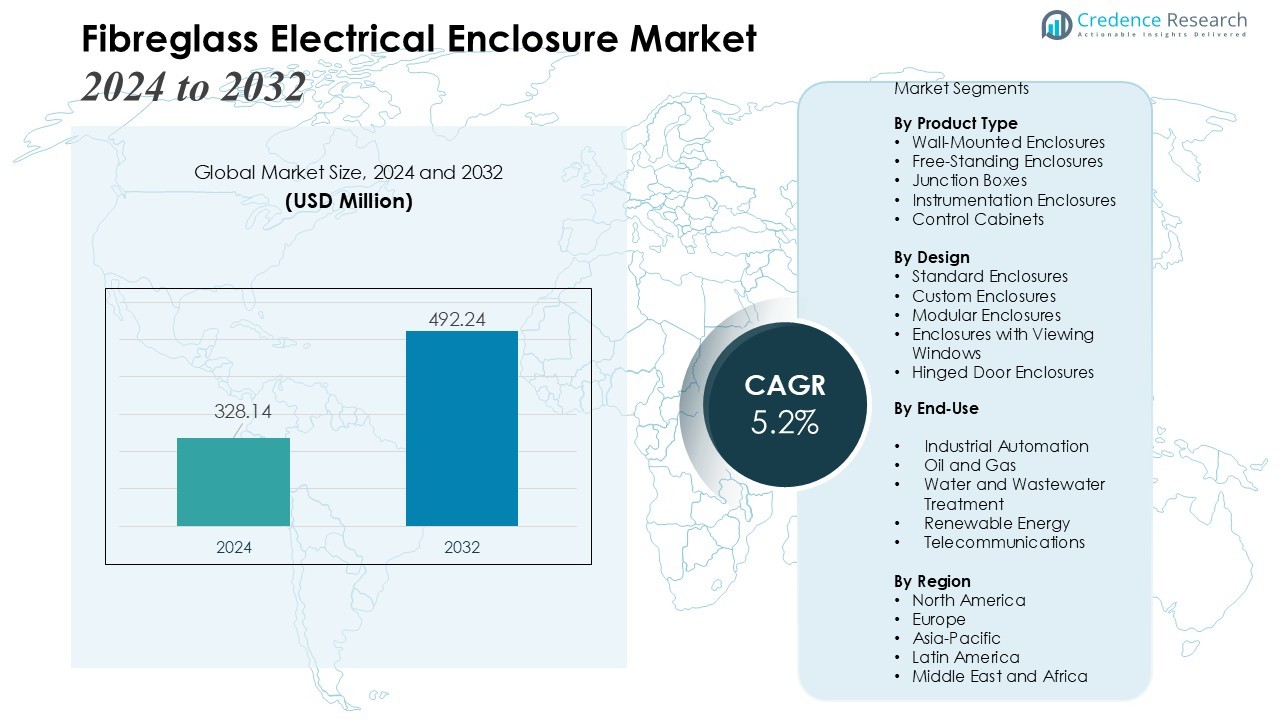

The Fibreglass Electrical Enclosure Market size was valued at USD 328.14 million in 2024 and is anticipated to reach USD 492.24 million by 2032, at a CAGR of 5.2% during the forecast period (2024-2032).

| REPORT ATTRIBUTE |

DETAILS |

| Historical Period |

2020-2023 |

| Base Year |

2024 |

| Forecast Period |

2025-2032 |

| Fibreglass Electrical Enclosure Market Size 2024 |

USD 328.14 Million |

| Fibreglass Electrical Enclosure Market, CAGR |

5.2% |

| Fibreglass Electrical Enclosure Market Size 2032 |

USD 492.24 Million |

Market expansion is primarily driven by the superior performance characteristics of fibreglass enclosures. These include high corrosion resistance, chemical resistance, non-conductive properties, and robust durability in harsh environments. Industries such as water and wastewater treatment, oil and gas, renewable energy, telecommunications and industrial automation increasingly favor fibreglass enclosures due to their low maintenance requirements and longer service life. Additionally, the global shift toward infrastructure modernization and stricter electrical safety regulations supports sustained market demand.

Regionally, the Asia-Pacific market is expected to witness the fastest growth, supported by rapid industrialization, expanding manufacturing activities, and increased investment in automation and energy infrastructure. North America and Europe retain significant market shares, driven by mature industrial sectors, stringent safety standards, and widespread adoption of renewable energy and smart grid technologies. Emerging markets in Latin America and the Middle East & Africa also contribute to future growth through ongoing infrastructure development and industrial expansion.

Access crucial information at unmatched prices!

Request your sample report today & start making informed decisions powered by Credence Research Inc.!

Download Sample

Market Insights:

- The Fibreglass Electrical Enclosure Market reached USD 328.14 million in 2024 and is set to reach USD 492.24 million by 2032, supported by a CAGR of 5.2% during 2024–2032.

- Market demand strengthens due to corrosion resistance, chemical resistance, non-conductive structure and high durability offered by fibreglass enclosures.

- Industries such as water treatment, oil and gas, renewable energy, telecom and industrial automation prefer fibreglass enclosures for long service life and low maintenance needs.

- Infrastructure modernization and stricter electrical safety regulations create strong adoption opportunities across global industrial and utility sectors.

- Asia-Pacific records the fastest growth pace due to industrial expansion, manufacturing development and investments in automation and energy systems.

- North America and Europe sustain strong market positions supported by advanced industrial bases, safety regulations and growing renewable energy deployment.

- Rising renewable energy installations, demand for corrosion-resistant materials and industry shift toward long-lasting enclosure solutions continue to support long-term market growth.

Market Drivers:

Market Drivers:

Rising Demand for Corrosion-Resistant and Durable Enclosure Solutions

The Fibreglass Electrical Enclosure Market benefits from strong demand for enclosures that withstand corrosive, humid and chemically aggressive environments. Industries such as oil and gas, water treatment and marine operations prefer fibreglass due to its resistance to rust, impact and UV exposure. The material supports long operational life, reduces maintenance frequency and improves system reliability. It offers a lightweight structure that simplifies handling and installation. These advantages strengthen its adoption across heavy-duty industrial applications.

- For instance, Eaton’s NEMA 4X-rated fibreglass enclosures are designed for corrosion resistance in harsh environments like offshore platforms and endure the required 200-hour (or 800-hour, depending on the exact standard applied) salt spray testing without degradation.

Growing Focus on Electrical Safety and Compliance Standards

Stricter global electrical safety regulations propel the Fibreglass Electrical Enclosure Market forward. Governments and industry bodies enforce standards that require non-conductive and high-strength enclosures. It provides excellent insulation performance, reducing risks of electrical faults and improving personnel safety. Demand increases in sectors dealing with high-voltage systems and critical electrical infrastructure. Compliance-driven procurement supports consistent market expansion.

- For instance, Saginaw develops custom fiberglass enclosures tailored for high-voltage utility sectors with NEMA Type 4X ratings for corrosion resistance.

Expansion of Industrial Automation and Power Infrastructure Projects

The Fibreglass Electrical Enclosure Market gains momentum from large-scale automation and electrification projects worldwide. Manufacturing plants, renewable energy sites and utilities require reliable enclosure solutions to protect advanced electronic components. It delivers stable housing for sensitive controls exposed to outdoor or harsh operational settings. Investments in smart grids, distributed energy systems and industrial modernization strengthen product deployment. Rising equipment complexity increases the need for resilient enclosure materials.

Growth in Renewable Energy Installations and Outdoor Applications

Increasing renewable energy installations support steady growth in the Fibreglass Electrical Enclosure Market. Solar farms, wind facilities and off-grid power systems operate in demanding outdoor locations. It fits such environments due to strong weather resistance, low thermal conductivity and long service performance. The shift toward sustainable power systems increases the need for durable enclosures that secure electrical balance-of-system components. Market traction improves with rising global clean energy commitments.

Market Trends:

Increasing Preference for Advanced Composite Materials and Customizable Enclosure Designs

The Fibreglass Electrical Enclosure Market reflects a clear trend toward advanced composite formulations that enhance strength, thermal stability and environmental resistance. Industries request tailored enclosures that meet application-specific requirements in size, mounting, ventilation and hardware compatibility. It supports this trend by offering high design flexibility without compromising structural integrity. Manufacturers focus on producing enclosures with improved UV protection, flame-retardant ratings and reinforced resin systems. Demand rises for lightweight designs that ease transportation and installation in remote or elevated locations. Product customization strengthens industry adoption across power distribution, telecom, marine and industrial automation sectors.

- For instance, nVent Hoffman (formerly Hoffman Engineering) offers a line of composite (fiberglass) enclosures with a flame spread rating per UL standards, which are significantly lighter than metallic options for easier handling.

Growing Integration of Smart Features and Digital Monitoring Capabilities

The Fibreglass Electrical Enclosure Market experiences increasing demand for enclosures designed to work with connected and intelligent systems. Industries introduce monitoring sensors, thermal management solutions and IoT-based components that require protective housings with consistent performance. It meets these expectations through designs that support cable routing, modular components and integrated access points. Manufacturers introduce enclosures compatible with predictive maintenance systems that track temperature, internal moisture and component performance. Growth in smart grids, outdoor communication networks and renewable energy facilities accelerates this trend. Rising investment in advanced electrical infrastructure strengthens the transition toward smarter, technologically capable enclosure solutions.

- For Instance, CamdenBoss offers smart plastic enclosures designed for users to integrate their own IoT sensors for real-time monitoring, with some product lines achieving IP67 ratings.

Market Challenges Analysis:

High Material Costs and Competitive Pressure from Alternative Enclosure Types

The Fibreglass Electrical Enclosure Market faces notable pressure due to higher material and production costs compared to steel and polycarbonate enclosures. Manufacturers encounter challenges in balancing performance benefits with cost-sensitive customer expectations. It often competes with metal enclosures that offer lower upfront pricing and strong mechanical durability. Variability in resin and composite material costs further affects pricing stability. Some end users hesitate to shift from traditional materials due to familiarity and existing procurement standards. These factors create a competitive environment that limits rapid market penetration in certain sectors.

Complex Installation Requirements and Limited Awareness in Emerging Markets

The Fibreglass Electrical Enclosure Market encounters challenges associated with installation practices that require proper handling to avoid surface stress or structural damage. It demands trained personnel who understand composite enclosure characteristics, which is not always available in developing regions. Limited awareness of long-term value and performance benefits reduces adoption in markets dominated by metal-based solutions. Environmental extremes in some regions require specialized enclosure grades, which increases procurement complexity. Inconsistent regulatory frameworks create uncertainty for suppliers planning entry into new geographies. These barriers slow expansion despite growing interest in corrosion-resistant enclosure technologies.

Market Opportunities:

Expansion in Renewable Energy and Harsh-Environment Applications

The Fibreglass Electrical Enclosure Market gains strong opportunities from rapid growth in solar, wind and off-grid power installations. Renewable energy sites require enclosures that maintain performance in extreme heat, moisture and corrosive coastal environments. It aligns well with these requirements due to its high resilience and long service capabilities. Governments and private developers increase investment in clean energy infrastructure, creating new demand channels. Industries seek reliable enclosures for outdoor power electronics and communication units. These conditions support growth in remote and environmentally challenging locations.

Rising Demand for Smart, Modular and Custom-Built Enclosure Solutions

The Fibreglass Electrical Enclosure Market benefits from rising interest in enclosures that support IoT devices, sensors and integrated monitoring systems. It offers flexibility for modular designs that accommodate evolving electrical and digital needs. Manufacturers develop customizable solutions for telecom networks, industrial automation systems and smart grid technologies. Growth in predictive maintenance practices increases the need for enclosures compatible with temperature and moisture monitoring tools. Industries look for lightweight and easy-to-install housing for advanced control equipment. These opportunities strengthen long-term adoption across high-tech and infrastructure-driven sectors.

Market Segmentation Analysis:

By Product Type

The Fibreglass Electrical Enclosure Market features a broad product range that includes junction boxes, wall-mounted enclosures and free-standing enclosures. Demand remains strong for junction boxes due to their wide use in electrical distribution and control systems. Wall-mounted enclosures secure significant adoption in industrial automation, renewable energy facilities and telecom installations that require space-efficient protective housing. Free-standing units support large electrical assemblies used in utilities and heavy industries. It continues to gain traction across sectors that prioritize corrosion resistance and extended service life.

- For instance, Pentair’s fiberglass junction boxes can achieve a NEMA 6P rating, which requires the enclosure to endure prolonged submersion under specific test conditions defined by UL-50, typically at a depth of 6 feet for a 24-hour period.

By Design

The Fibreglass Electrical Enclosure Market includes standard enclosures, custom-designed units and modular configurations. Standard designs maintain steady demand due to their suitability for general-purpose electrical protection. Custom-built enclosures gain interest among industries requiring specific dimensions, ventilation options or mounting structures. Modular enclosures support flexible installation needs in expanding automation and power distribution projects. It aligns with industries seeking adaptable and durable solutions for both indoor and outdoor environments.

By End-Use

The Fibreglass Electrical Enclosure Market serves sectors such as industrial automation, power and energy, oil and gas, water and wastewater treatment and telecommunications. Industrial automation holds a strong share due to extensive use of protective housings for PLCs, drives and control systems. Power and energy applications benefit from enclosures that withstand outdoor exposure and maintain insulation integrity. Water and wastewater facilities prefer fibreglass for its corrosion resistance and long-term stability. It supports end users that require reliable protection for critical electrical infrastructure.

Segmentations:

By Product Type

- Wall-Mounted Enclosures

- Free-Standing Enclosures

- Junction Boxes

- Instrumentation Enclosures

- Control Cabinets

By Design

- Standard Enclosures

- Custom Enclosures

- Modular Enclosures

- Enclosures with Viewing Windows

- Hinged Door Enclosures

By End-Use

- Industrial Automation

- Oil and Gas

- Water and Wastewater Treatment

- Renewable Energy

- Telecommunications

By Region

- North America

- Europe

- Germany

- France

- U.K.

- Italy

- Spain

- Rest of Europe

- Asia Pacific

- China

- Japan

- India

- South Korea

- South-east Asia

- Rest of Asia Pacific

- Latin America

- Brazil

- Argentina

- Rest of Latin America

- Middle East & Africa

- GCC Countries

- South Africa

- Rest of the Middle East and Africa

Regional Analysis:

Strong Demand in Asia-Pacific Driven by Industrial Expansion

Asia-Pacific holds 38% market share and stands as the leading regional contributor in the Fibreglass Electrical Enclosure Market. Rapid growth in manufacturing, power distribution and infrastructure development strengthens the region’s dominance. It benefits from strong investment in renewable energy, telecom networks and industrial automation. Governments support large-scale electrification programs that increase the need for durable enclosure systems. Rising deployment of outdoor electrical equipment creates sustained demand for weather-resistant and corrosion-resistant fibreglass units.

Consistent Adoption in North America Supported by Regulatory Standards

North America holds 27% market share and maintains steady growth driven by strict safety and performance regulations. The region implements advanced industrial automation and smart grid modernization, which increases demand for high-performance enclosure solutions. It supports industries that prioritize non-conductive materials for critical applications in energy, transportation and utilities. Strong presence of technology-driven sectors encourages the use of enclosures compatible with digital monitoring systems. Infrastructure refurbishment programs strengthen long-term adoption across commercial and industrial facilities.

Stable Growth in Europe Backed by Renewable Energy and Industrial Modernization

Europe holds 23% market share and demonstrates stable expansion supported by rising investment in clean energy projects. The region increases deployment of solar, wind and grid-connected systems that require durable enclosure solutions for outdoor environments. It benefits from stringent environmental and safety directives that encourage the shift toward non-corrosive enclosure materials. Industrial modernization across Germany, France, Italy and the Nordics enhances product demand. Strong focus on energy efficiency and advanced electrical protection technologies supports consistent market traction.

Key Player Analysis:

- Schneider Electric

- ABB

- Eaton

- Siemens

- Legrand

- Hoffman (nVent)

- Fibox

- Allied Moulded Products

- Rittal

- Adalet

- Saginaw Control & Engineering

- Bud Industries

Competitive Analysis:

The Fibreglass Electrical Enclosure Market reflects strong competition driven by product innovation, material enhancements and expanding industrial applications. Leading companies focus on designing corrosion-resistant and durable enclosures tailored for harsh environments. It encourages manufacturers to strengthen portfolios with UV-stable, flame-retardant and impact-resistant grades that support diverse end-use sectors. Market participants invest in advanced molding technologies and improved resin systems to achieve higher structural performance. Partnerships with distributors and system integrators improve market reach across industrial, utility and commercial installations. Competition intensifies as global and regional players target sectors such as renewable energy, telecommunications and water treatment that require long-life enclosure solutions. Firms differentiate offerings through customization, certified safety standards and competitive pricing strategies that align with customer requirements.

Recent Developments:

- In February 2025, Legrand, Schneider Electric, and Siemens launched an interest group to support the NR+ connectivity standard for wireless infrastructure.

- In November 2025, Schneider Electric and Switch expanded their partnership with a $1.9 billion supply capacity agreement to power AI factories, including prefabricated power modules and the largest data center cooling initiative in North America.

Shape Your Report to Specific Countries or Regions & Enjoy 30% Off!

Report Coverage:

The research report offers an in-depth analysis based on Product Type, Design, End-Use and Region. It details leading market players, providing an overview of their business, product offerings, investments, revenue streams, and key applications. Additionally, the report includes insights into the competitive environment, SWOT analysis, current market trends, as well as the primary drivers and constraints. Furthermore, it discusses various factors that have driven market expansion in recent years. The report also explores market dynamics, regulatory scenarios, and technological advancements that are shaping the industry. It assesses the impact of external factors and ITALY economic changes on market growth. Lastly, it provides strategic recommendations for new entrants and established companies to navigate the complexities of the market.

Future Outlook:

- The Fibreglass Electrical Enclosure Market is expected to experience steady expansion driven by rising adoption across industries that require corrosion-resistant and long-life enclosure solutions.

- Demand will strengthen as utilities upgrade power distribution networks and integrate advanced monitoring technologies that require durable protective housings.

- Growth in renewable energy installations will create strong opportunities for enclosures capable of operating in harsh outdoor environments.

- Manufacturers will prioritize product innovation focused on improved impact strength, UV stability and thermal performance to support emerging application requirements.

- Smart infrastructure projects will increase the need for enclosures compatible with IoT devices, sensors and digital control systems.

- Telecom network expansion, particularly in developing economies, will elevate demand for weatherproof and non-conductive enclosure systems.

- Increased automation in manufacturing plants will drive procurement of enclosures designed to protect sensitive electrical and electronic assemblies.

- Sustainability-focused industries will shift toward fibreglass solutions that offer longer service life with reduced maintenance demands.

- Investments in industrial modernization and energy transition initiatives will support consistent deployment of composite-based enclosure technologies.

- Market participants will expand global footprints to address rising demand in Asia-Pacific, Latin America and the Middle East, creating a competitive environment centered on reliability, customization and performance enhancement.

Market Drivers:

Market Drivers: