| REPORT ATTRIBUTE |

DETAILS |

| Historical Period |

2020-2023 |

| Base Year |

2024 |

| Forecast Period |

2025-2032 |

| 3D Printing Technology Market Size 2024 |

USD 14,633.48 million |

| 3D Printing Technology Market, CAGR |

14.60% |

| 3D Printing Technology Market Size 2032 |

USD 46,866.97 million |

Market Overview:

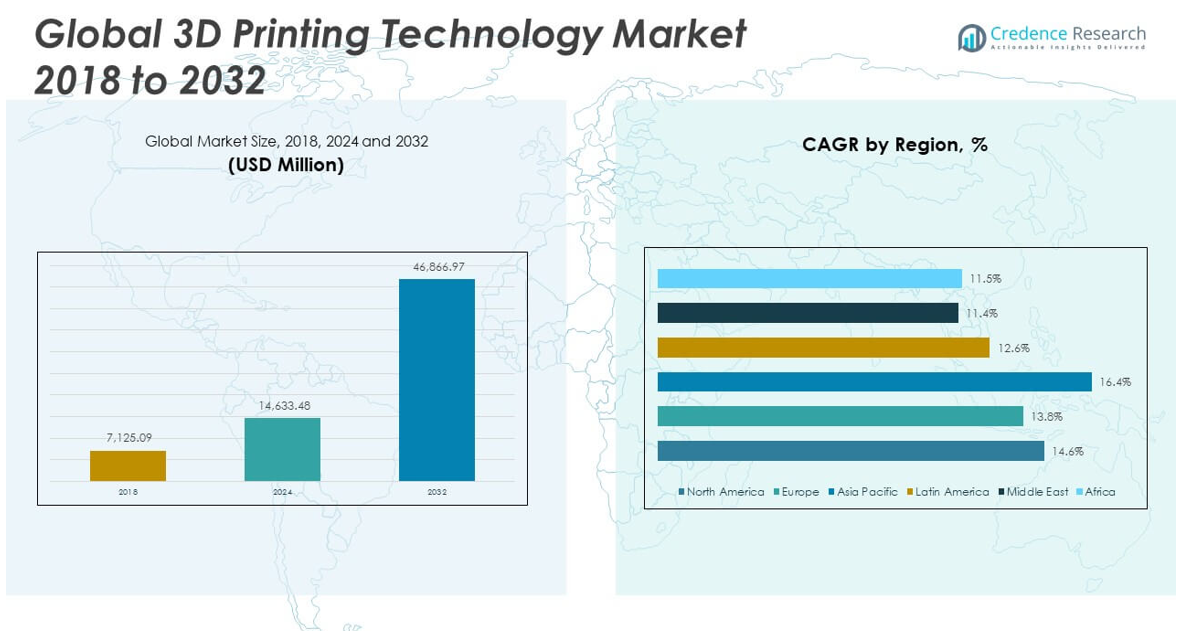

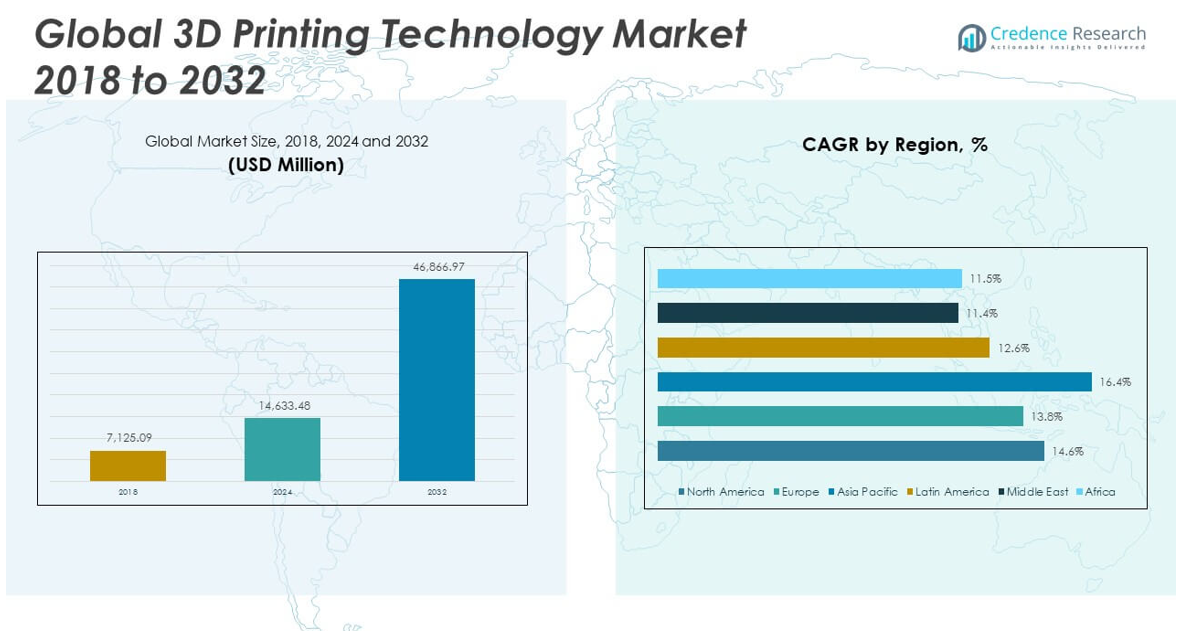

The Global 3D Printing Technology Market size was valued at USD 7,125.09 million in 2018 to USD 14,633.48 million in 2024 and is anticipated to reach USD 46,866.97 million by 2032, at a CAGR of 14.60% during the forecast period.

The global 3D printing technology market is being propelled by several key drivers. Technological advancements, such as improvements in printing speed, precision, and material compatibility, are enhancing the capabilities and applications of additive manufacturing. The ability to produce complex parts with minimal material waste and reduced tooling requirements is making 3D printing a cost-effective solution, particularly in prototyping and low-volume manufacturing. Furthermore, the demand for customized products tailored to specific requirements is driving the growth of 3D printing across industries such as healthcare, automotive, and fashion. Additionally, 3D printing offers supply chain resilience by decentralizing production and enabling on-demand manufacturing, which is increasingly valuable in mitigating supply chain disruptions.

Regionally, North America currently holds the largest market share, driven by significant investments in industries such as aerospace, automotive, and healthcare, particularly in the United States. Europe follows closely, with countries like Germany and the United Kingdom leading efforts to integrate 3D printing into traditional manufacturing processes for enhanced efficiency. The Asia-Pacific region is also showing rapid growth, with China and Japan making substantial investments in research and development. The large-scale manufacturing capabilities and expansive consumer markets in this region are accelerating the adoption of additive manufacturing technologies. Meanwhile, Latin America and the Middle East & Africa are emerging markets where interest in 3D printing is growing, particularly in sectors like construction and healthcare, where the technology offers cost-effective and innovative solutions.

Market Insights:

- The Global 3D Printing Technology Market was valued at USD 7,125.09 million in 2018 and is expected to reach USD 46,866.97 million by 2032, with a CAGR of 14.60%.

- Technological advancements in 3D printing, including faster printing speeds, higher precision, and improved material compatibility, are fueling the growth of the market across industries like aerospace, automotive, and healthcare.

- The ability to minimize material waste and reduce tooling costs is driving the adoption of 3D printing, particularly in prototyping and low-volume manufacturing.

- The demand for customized and on-demand products is a key factor driving the expansion of 3D printing, enabling manufacturers to produce tailored solutions without the need for extensive production line modifications.

- Sustainability concerns are pushing industries toward 3D printing, as it reduces waste, conserves material, and allows for localized production, contributing to lower carbon footprints.

- Despite the benefits, high initial investment costs and operational expenses remain a challenge, particularly for small and medium-sized enterprises (SMEs) looking to adopt 3D printing technologies.

- The lack of standardized protocols and regulatory frameworks for 3D printing poses challenges in industries like aerospace and healthcare, where product safety and compliance are critical.

Access crucial information at unmatched prices!

Request your sample report today & start making informed decisions powered by Credence Research Inc.!

Download Sample

Market Drivers:

Technological Advancements and Innovations Driving Growth in 3D Printing Technology

The rapid pace of technological advancements in 3D printing is a primary driver of market growth. Continuous improvements in printing speed, material compatibility, and precision are significantly enhancing the capabilities of additive manufacturing. These innovations enable 3D printers to produce complex structures and fine details that were once impossible with traditional methods. The development of new materials, including metals, polymers, and ceramics, is broadening the scope of applications, allowing industries such as aerospace, automotive, and healthcare to adopt this technology more effectively. These advancements are making 3D printing more versatile and competitive in various manufacturing processes, further accelerating its adoption globally.

- For example, Lynx’s industrial 3D printing system can produce approximately 50 small engine cases in just three days, compared to a traditional manufacturing timeline of about one month.

Cost Efficiency and Reduction in Manufacturing Waste

One of the key drivers of the Global 3D Printing Technology Market is its ability to reduce manufacturing costs, especially in prototyping and small-scale production. Traditional manufacturing methods often require costly tooling, molds, and significant material waste. 3D printing eliminates many of these costs by producing parts directly from digital models without the need for specialized tooling. The additive nature of the technology also minimizes material waste, contributing to more sustainable production. This makes it an attractive solution for companies aiming to streamline production costs while improving material efficiency and sustainability.

Customization and On-Demand Manufacturing Solutions

The demand for personalized and on-demand products has significantly increased the adoption of 3D printing technology. It allows manufacturers to create customized solutions tailored to the specific needs of their customers without requiring extensive retooling or production line modifications. Industries such as healthcare benefit from this feature, as 3D printing enables the production of patient-specific implants and prosthetics, improving treatment outcomes. In other sectors, like fashion and automotive, it empowers companies to deliver unique, customized products that meet growing consumer demands. The flexibility offered by 3D printing for low-volume and highly specialized production is a major factor driving its widespread use.

Sustainability and Environmental Benefits

Sustainability concerns are pushing industries toward adopting 3D printing technology. Traditional manufacturing methods often generate significant waste, whereas 3D printing uses only the material necessary to build the desired object, significantly reducing waste. This method aligns with global sustainability goals and eco-conscious practices. 3D printing can also support the creation of more energy-efficient products and reduce the carbon footprint by enabling local production, thus minimizing transportation emissions. With growing emphasis on reducing environmental impacts, 3D printing offers a more sustainable alternative to conventional manufacturing, increasing its appeal among companies seeking greener solutions.

- For instance, Arburg Plastic Freeforming (APF) technology enables the production of bioresorbable, patient-specific implantswith wall thicknesses as low as 8 mm, fabricated within 5–60 minutes per part.

Market Trends:

Integration of 3D Printing with Industry 4.0 and Automation

The integration of 3D printing with Industry 4.0 technologies is a significant trend in the Global 3D Printing Technology Market. Manufacturers are increasingly adopting automation, data analytics, and Internet of Things (IoT) technologies alongside 3D printing to create more efficient and connected production environments. This integration enables real-time monitoring and optimization of manufacturing processes, resulting in improved quality control and operational efficiency. Companies are using predictive analytics to assess the performance of 3D printers, reducing downtime and ensuring consistent output. The synergy between 3D printing and automation allows businesses to streamline operations and stay competitive in a fast-evolving market.

Adoption of 3D Printing in End-Use Production Applications

Another key trend is the growing use of 3D printing for end-use production applications. Initially, 3D printing was primarily employed for rapid prototyping and concept models. However, its role in the production of functional parts and components is expanding. Industries such as aerospace, automotive, and healthcare are increasingly relying on 3D printing to manufacture end-use parts due to its ability to produce highly complex, lightweight, and durable products. The trend towards end-use production reflects the technology’s growing maturity and its ability to meet stringent industry standards. As 3D printing becomes more reliable, companies are scaling its use for mass production, further solidifying its position in the manufacturing ecosystem.

Expansion of 3D Printing Material Options

The expansion of 3D printing material options is another prominent trend shaping the Global 3D Printing Technology Market. The development of new materials—such as metal alloys, high-strength polymers, and biocompatible materials—has broadened the application of 3D printing across various sectors. Manufacturers are no longer limited to basic plastics but can now use advanced materials suited for specific end-use applications. These materials provide the necessary durability, strength, and performance characteristics required in critical industries like healthcare, aerospace, and automotive. The growing range of material choices is enhancing the versatility and efficiency of 3D printing, allowing it to fulfill more complex and demanding production needs.

- For instance, Fictiv has introduced 10 new 3D printing materials compatible with SLA, SLS, FDM, and MJF technologies, allowing for larger bed sizes and faster production—parts can be delivered in as little as 24 hours.

Rise in Collaborative 3D Printing Ecosystems and Partnerships

Collaborative 3D printing ecosystems and partnerships are emerging as a significant trend in the market. Companies are increasingly forming alliances to share knowledge, resources, and technology to drive innovation in 3D printing. These collaborations often involve partnerships between 3D printing technology providers, material manufacturers, and end-user industries. By working together, businesses can address technical challenges, develop new applications, and accelerate the adoption of 3D printing across different sectors. Such ecosystems foster faster innovation cycles and create more robust and scalable solutions for industries seeking to leverage 3D printing for enhanced production capabilities.

- For example, practical collaborations, such as the Materialise and PAL Robotics partnership, have enabled the production of 50 unique robot parts ranging from 20 mm to 1,200 mm, optimizing weight and cost for robotics application.

Market Challenges Analysis:

High Initial Investment and Operational Costs

One of the primary challenges faced by the Global 3D Printing Technology Market is the high initial investment and operational costs associated with the technology. While 3D printing offers long-term cost benefits, the upfront capital required for purchasing high-quality 3D printers and advanced materials can be prohibitive, especially for small and medium-sized enterprises (SMEs). The need for specialized equipment, skilled labor, and regular maintenance further adds to the operational expenses. Despite the decreasing prices of certain 3D printers, the high costs of industrial-grade machines and specialized materials continue to limit the widespread adoption of the technology, especially in cost-sensitive industries. Overcoming these financial barriers remains a critical challenge for expanding 3D printing adoption across a broader range of industries.

Lack of Standardization and Regulatory Frameworks

The absence of established standards and regulatory frameworks also poses significant challenges for the growth of the Global 3D Printing Technology Market. Variability in material properties, machine capabilities, and printing techniques often complicates the integration of 3D printing into existing production processes. In sectors like aerospace, automotive, and healthcare, where precision and compliance with strict quality standards are paramount, the lack of standardized protocols can hinder the reliability and consistency of 3D printed components. The absence of a global regulatory framework also raises concerns about the safety and quality of 3D printed products, which can affect consumer confidence and adoption. The development of universally accepted standards is crucial to addressing these concerns and facilitating broader market acceptance.

Market Opportunities:

Growing Demand for Customized Products and Solutions

A significant opportunity in the Global 3D Printing Technology Market lies in the growing demand for customized products and solutions. Consumers increasingly seek personalized items, ranging from healthcare products like implants and prosthetics to fashion and automotive components. 3D printing allows for the efficient production of these customized solutions at scale, enabling manufacturers to meet specific customer needs without high setup costs. This trend is particularly evident in industries like healthcare, where patient-specific solutions are in high demand. As customization becomes more prevalent across various sectors, the ability to provide on-demand, bespoke products will offer manufacturers a competitive advantage.

Expanding Applications in Sustainable Manufacturing

The shift toward sustainability presents another opportunity for the 3D printing market. As industries seek to minimize waste and reduce environmental impact, 3D printing offers an efficient solution by using only the material required for production, significantly cutting down on waste. Its ability to use recycled or eco-friendly materials further enhances its appeal in sustainability-driven sectors. Industries such as construction, automotive, and packaging are increasingly looking to integrate 3D printing to meet environmental regulations and corporate sustainability goals. This growing focus on green manufacturing is expected to drive the adoption of 3D printing across multiple industries.

Market Segmentation Analysis:

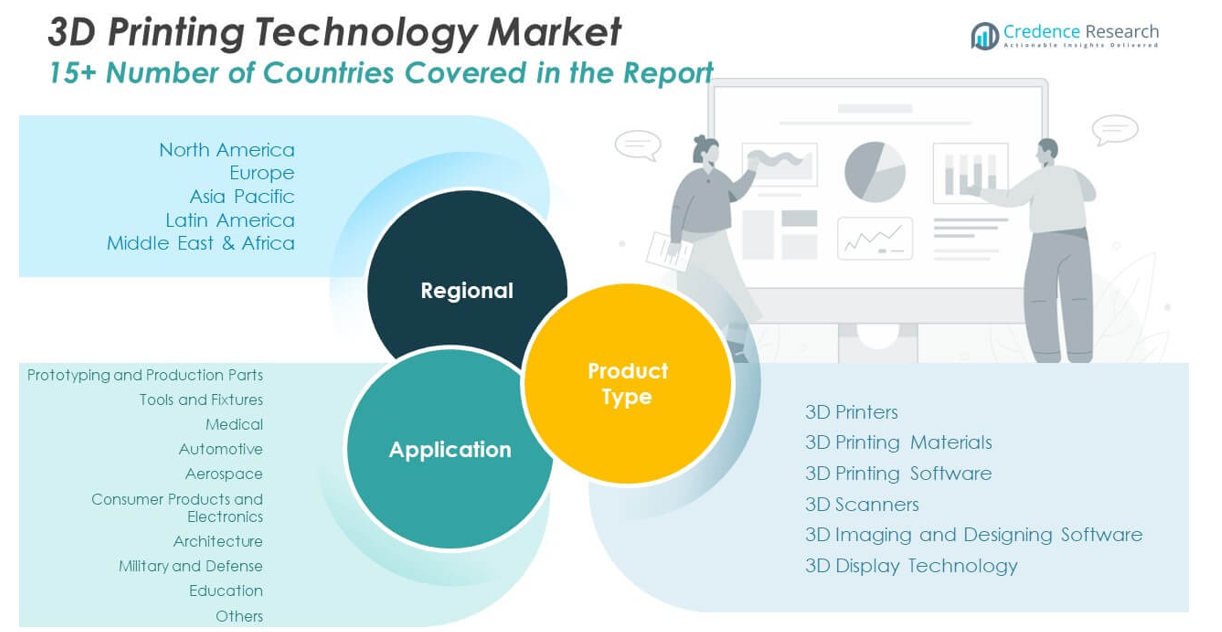

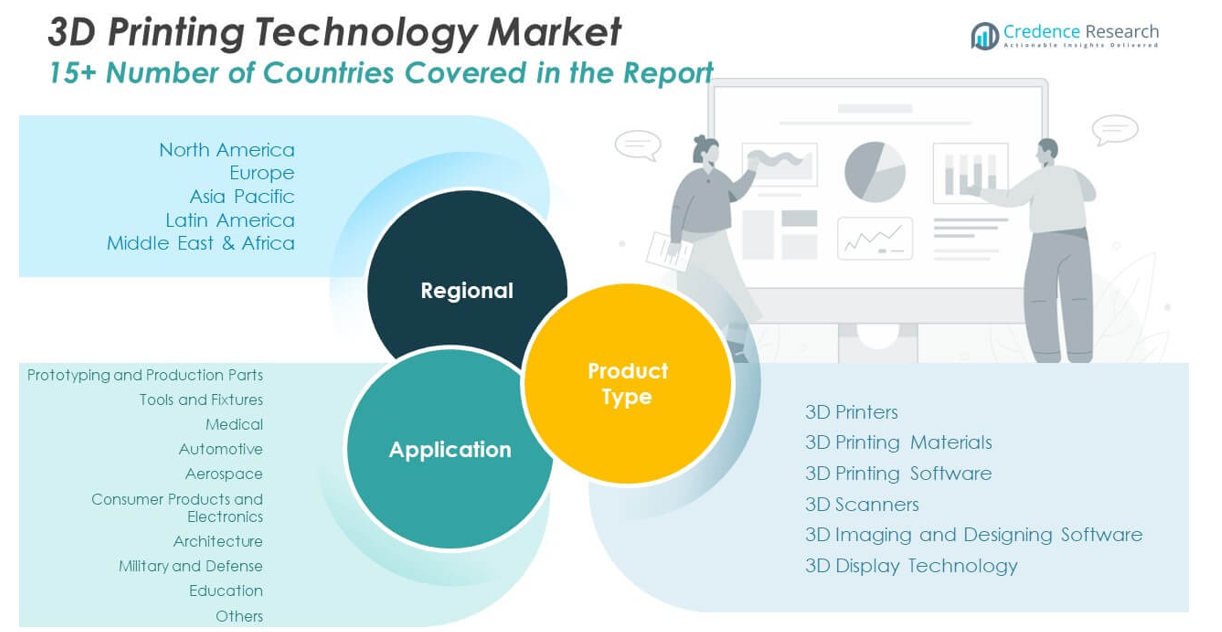

The Global 3D Printing Technology Market is segmented into product types and applications, each contributing to its expansion across diverse industries.

By Product Type, the market includes 3D Printers, 3D Printing Materials, 3D Printing Software, 3D Scanners, 3D Imaging and Designing Software, and 3D Display Technology. 3D printers hold the largest share, driven by technological advancements in precision and speed. 3D printing materials, such as metals, plastics, and ceramics, are crucial to its growth, enabling the production of complex parts across industries. 3D printing software enables users to design and simulate objects, while 3D scanners are essential for capturing real-world objects for digital reproduction. 3D imaging and designing software, along with 3D display technology, facilitate accurate design processes and visualization, enhancing the capabilities of 3D printing.

- For example, the Prusa CORE One, launched in 2025, exemplifies the latest in high-speed, high-precision 3D printing. This fully enclosed CoreXY printer features active temperature control and the upgraded Nextruder with 360° cooling, enabling flawless printing of 75° overhangs and supporting over 200 filament types.

By Application, key segments include Prototyping and Production Parts, Tools and Fixtures, Medical, Automotive, Aerospace, Consumer Products and Electronics, Architecture, Military and Defense, Education, and Others. Prototyping remains the leading application, with 3D printing providing cost-effective solutions for rapid development. The medical sector utilizes 3D printing for customized implants and prosthetics, while automotive and aerospace industries leverage it for lightweight, durable components. In consumer products, it enables personalization and mass customization. Military and defense applications focus on rapid prototyping and advanced material development. As industries across the board explore these applications, the demand for tailored solutions is expanding the overall market.

- For example, Mooji Meats uses 3D-printed prototypes to develop plant-based products that mimic whole cuts of meat, enabling rapid iteration and proof-of-concept development. 3D-printed prototypes allow manufacturers to turn around new designs in less than a day, accelerating innovation and reducing costs.

Segmentation:

By Product Type:

- 3D Printers

- 3D Printing Materials

- 3D Printing Software

- 3D Scanners

- 3D Imaging and Designing Software

- 3D Display Technology

By Application:

- Prototyping and Production Parts

- Tools and Fixtures

- Medical

- Automotive

- Aerospace

- Consumer Products and Electronics

- Architecture

- Military and Defense

- Education

- Others

By Region:

- North America

- Europe

- Germany

- France

- U.K.

- Italy

- Spain

- Rest of Europe

- Asia Pacific

- China

- Japan

- India

- South Korea

- South-east Asia

- Rest of Asia Pacific

- Latin America

- Brazil

- Argentina

- Rest of Latin America

- Middle East & Africa

- GCC Countries

- South Africa

- Rest of the Middle East and Africa

Regional Analysis:

North America 3D Printing Technology Market

The North America 3D Printing Technology Market size was valued at USD 2,974.37 million in 2018, and it is anticipated to reach USD 19,408.31 million by 2032, at a CAGR of 14.6% during the forecast period. The region dominates the global market with a strong presence of key players and high technological adoption across industries such as aerospace, automotive, and healthcare. The United States is particularly a major contributor, owing to its advanced manufacturing infrastructure, significant investments in R&D, and the rising demand for customized products. The market is also driven by increasing automation and the integration of 3D printing with Industry 4.0 technologies. Its substantial market share reflects the significant growth opportunities driven by innovations in material sciences and expanding applications in production.

Europe 3D Printing Technology Market

The Europe 3D Printing Technology Market size was valued at USD 2,261.11 million in 2018 and is projected to reach USD 13,643.80 million by 2032, growing at a CAGR of 13.8% during the forecast period. Europe’s market is expanding due to the increased adoption of additive manufacturing in industries like automotive, healthcare, and consumer goods. Germany and the UK are key contributors to market growth, with a focus on integrating 3D printing into traditional manufacturing processes. The region also benefits from favorable government policies that support innovation and sustainable manufacturing. European countries’ emphasis on research and development in 3D printing technologies is accelerating market expansion, with increasing demand for customized products and end-use production.

Asia Pacific 3D Printing Technology Market

The Asia Pacific 3D Printing Technology Market size was valued at USD 1,319.78 million in 2018, and it is expected to reach USD 10,732.77 million by 2032, growing at a CAGR of 16.4% during the forecast period. This region is witnessing the fastest growth in the 3D printing market, fueled by countries such as China, Japan, and India. The region benefits from a large manufacturing base and rising demand for innovative production technologies in automotive, electronics, and healthcare. China, in particular, is a major driver of this growth due to its vast industrial base and increasing investment in 3D printing technologies. The Asia Pacific market is characterized by rapid advancements in R&D, affordable material costs, and expanding production capabilities, driving its high market share.

Latin America 3D Printing Technology Market

The Latin America 3D Printing Technology Market size was valued at USD 293.77 million in 2018 and is expected to reach USD 1,653.60 million by 2032, growing at a CAGR of 12.6% during the forecast period. This market is emerging, with Brazil and Mexico leading the adoption of 3D printing technologies. The growing demand for customized products, particularly in sectors such as healthcare and automotive, is driving market growth. The increasing focus on sustainability and cost-efficient manufacturing solutions is further pushing the demand for 3D printing in the region. Although smaller than other regions, Latin America presents significant opportunities for growth as local industries increasingly turn to additive manufacturing for innovation and production efficiency.

Middle East 3D Printing Technology Market

The Middle East 3D Printing Technology Market size was valued at USD 159.17 million in 2018 and is anticipated to reach USD 746.75 million by 2032, at a CAGR of 11.4% during the forecast period. The Middle East is embracing 3D printing for its potential to reduce costs, improve supply chains, and foster local production. Countries like the UAE and Saudi Arabia are investing heavily in 3D printing, particularly for applications in construction, healthcare, and aerospace. With an increasing focus on innovation and smart manufacturing, the Middle East is leveraging 3D printing to improve efficiency and develop sustainable solutions. The market is expected to grow steadily as industries look to incorporate 3D printing for end-use production and customization.

Africa 3D Printing Technology Market

The Africa 3D Printing Technology Market size was valued at USD 116.89 million in 2018, and it is projected to reach USD 681.73 million by 2032, growing at a CAGR of 11.5% during the forecast period. Africa’s 3D printing market is still in its nascent stages, but the growth potential is significant. Key countries such as South Africa are leading the adoption of 3D printing technology, particularly in sectors like healthcare, education, and industrial manufacturing. The increasing interest in reducing production costs, as well as improving access to customized solutions, is driving market growth. The region’s growing innovation hubs and investment in local manufacturing capabilities present promising opportunities for the 3D printing market to expand in the coming years.

Shape Your Report to Specific Countries or Regions & Enjoy 30% Off!

Key Player Analysis:

- Stratasys Ltd.

- 3D Systems Corporation

- EOS GmbH

- SLM Solutions GmbH

- ExOne GmbH

- Concept Laser GmbH

- Arcam AB

- Voxeljet Technology GmbH

- Solidscape, Inc.

- HP Inc.

Competitive Analysis:

The Global 3D Printing Technology Market is highly competitive, with several key players striving for market dominance. Leading companies such as Stratasys Ltd., 3D Systems Corporation, and HP Inc. have a significant share, driven by their continuous innovation in product offerings and advancements in 3D printing technologies. These companies focus on expanding their product portfolios, which include industrial-grade 3D printers, advanced materials, and software solutions for various industries like aerospace, automotive, and healthcare. Smaller players and regional companies are also emerging, contributing to the market’s diversity. Strategic partnerships, acquisitions, and collaborations are common in this space, allowing firms to enhance their technological capabilities and expand their customer base. The increasing demand for customized and cost-effective solutions pushes companies to innovate and offer more specialized 3D printing applications. The competitive landscape is dynamic, with market leaders investing heavily in R&D to maintain a technological edge and cater to evolving consumer needs.

Recent Developments:

- In April 2025, Stratasys unveiled the Neo®800+, a high-speed, large-format stereolithography 3D printer. The Neo800+ offers up to 50% faster throughput and is designed for high-value applications such as wind tunnel testing and tooling. The launch was announced at the Additive Manufacturer’s User Group conference on March 31, 2025, with a subsequent event at RAPID + TCT on April 8, 2025.

- In April 2025, 3D Systems announced the successful completion of the sale of its Geomagic® software portfolio to Hexagon’s Manufacturing Intelligence Division for $123 million.This strategic move allows 3D Systems to focus on advancing its core additive manufacturing software platforms.

- In April 2025, Raise3D introduced its RMS220 selective laser sintering (SLS) 3D printer at the RAPID 2025 event.Designed for batch production, the RMS220 features a large build volume and is capable of printing up to 5 kg of parts from PA12, offering enterprises a cost-effective solution for producing large parts.

Market Concentration & Characteristics:

The Global 3D Printing Technology Market is moderately concentrated, with a few key players holding a significant share, while numerous smaller companies contribute to its diversity. Leading firms such as Stratasys Ltd., 3D Systems Corporation, and HP Inc. dominate the market due to their advanced technological capabilities, large-scale production, and extensive customer bases. These companies focus on high-end industrial solutions and cater to specialized applications in sectors like aerospace, automotive, and healthcare. At the same time, smaller and regional players offer niche solutions, often targeting specific industries or providing affordable options for small-scale production. The market is characterized by rapid technological advancements, ongoing innovation, and an increasing emphasis on customization and sustainability. Firms are investing heavily in research and development to differentiate themselves and meet the growing demand for cost-effective, high-performance 3D printing technologies.

Report Coverage:

The research report offers an in-depth analysis based on product types and applications. It details leading market players, providing an overview of their business, product offerings, investments, revenue streams, and key applications. Additionally, the report includes insights into the competitive environment, SWOT analysis, current market trends, as well as the primary drivers and constraints. Furthermore, it discusses various factors that have driven market expansion in recent years. The report also explores market dynamics, regulatory scenarios, and technological advancements that are shaping the industry. It assesses the impact of external factors and global economic changes on market growth. Lastly, it provides strategic recommendations for new entrants and established companies to navigate the complexities of the market.

Future Outlook:

- The Global 3D Printing Technology Market is expected to continue its robust growth, driven by innovations in materials and printing technologies.

- The increasing demand for customized and on-demand products across industries will further accelerate adoption, particularly in healthcare and automotive.

- 3D printing will see expanded use in end-use production, not just prototyping, in industries like aerospace and electronics.

- Advancements in multi-material and composite 3D printing technologies will unlock new opportunities in sectors requiring complex parts.

- The integration of 3D printing with Industry 4.0, including AI and IoT, will enhance automation and efficiency in manufacturing.

- Sustainability concerns will drive further demand for 3D printing, as it offers waste reduction and energy efficiency.

- The growth of localized production via 3D printing will help mitigate supply chain vulnerabilities.

- Smaller businesses and startups will increasingly adopt 3D printing for cost-effective, low-volume production.

- The rise of eco-friendly and recyclable materials will make 3D printing a more sustainable option.

- Regulatory frameworks and standardization efforts will create a more reliable environment for mass adoption across industries.