Market Overview:

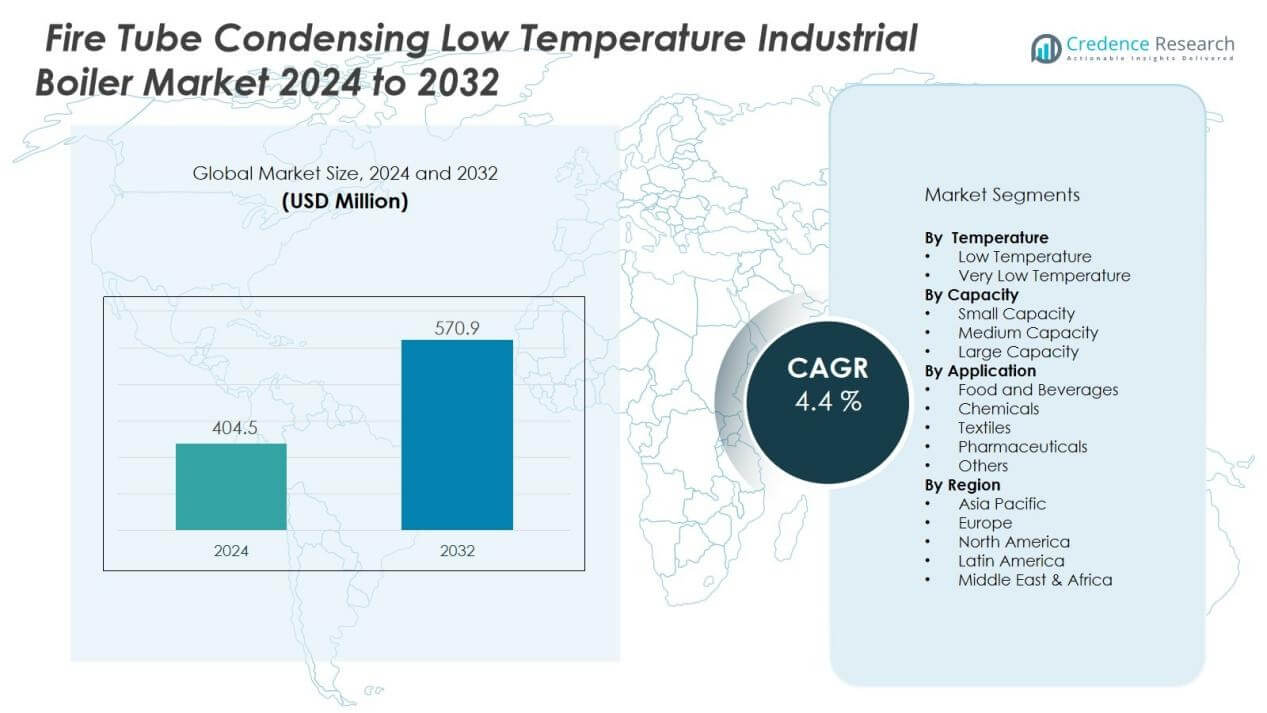

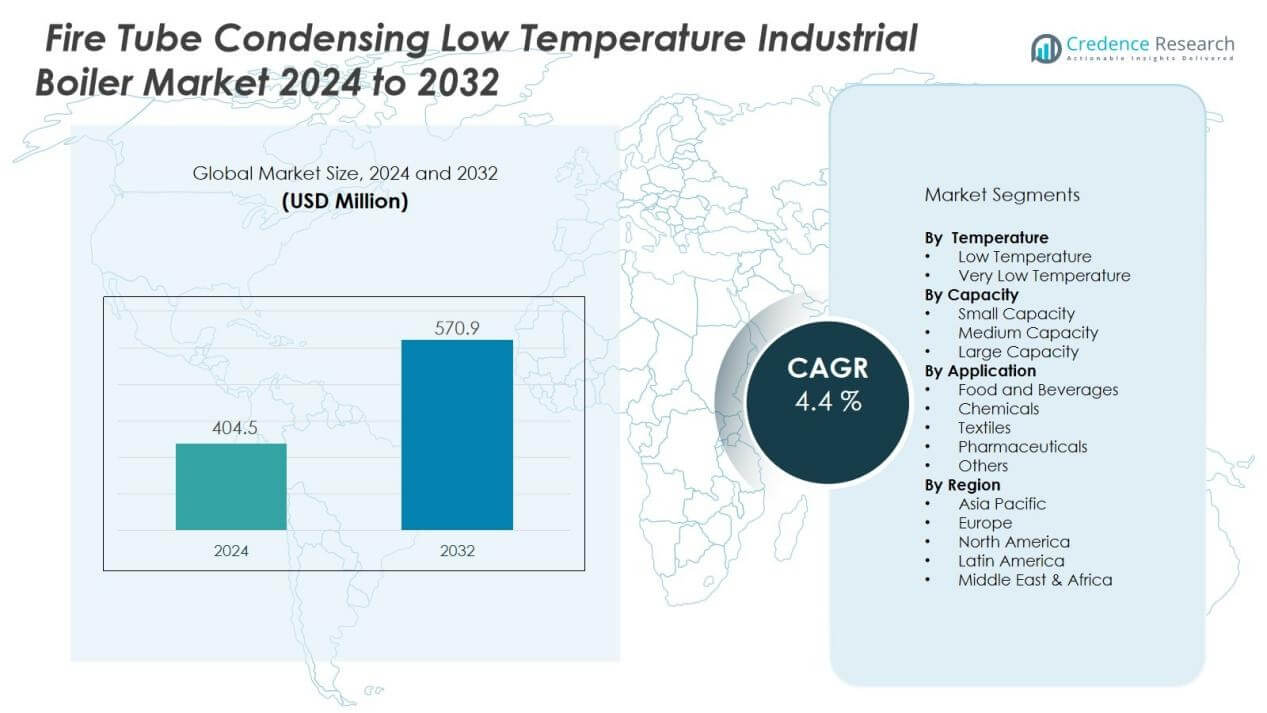

The fire tube condensing low temperature industrial boiler market size was valued at USD 404.5 million in 2024 and is anticipated to reach USD 570.9 million by 2032, at a CAGR of 4.4 % during the forecast period (2024-2032).

| REPORT ATTRIBUTE |

DETAILS |

| Historical Period |

2020-2023 |

| Base Year |

2024 |

| Forecast Period |

2025-2032 |

| Fire Tube Condensing Low Temperature Industrial Boiler Market, Size 2024 |

USD 404.5 Million |

| Fire Tube Condensing Low Temperature Industrial Boiler Market, CAGR |

4.4% |

| Fire Tube Condensing Low Temperature Industrial Boiler Market Size 2032 |

USD 570.9 Million |

Market drivers include the global shift toward sustainability and the need for reduced carbon footprints. The boilers’ high efficiency, reduced fuel consumption, and ability to operate under low temperatures make them ideal for industries focusing on cost optimization and emission control. Technological advancements, including smart monitoring systems and modular boiler designs, are strengthening product performance while meeting safety and environmental standards. Growing replacement of conventional boilers with condensing models also accelerates market penetration.

Regionally, Europe leads the market, supported by stringent emission regulations and early adoption of green technologies. North America follows, benefiting from industrial automation and regulatory incentives for energy efficiency. Asia-Pacific is projected to grow at the fastest rate, fueled by rapid industrialization, expanding manufacturing capacity, and rising demand for sustainable heating solutions in China, India, and Southeast Asia. Latin America and the Middle East & Africa also show promising potential with increasing infrastructure investments and energy diversification strategies.

Access crucial information at unmatched prices!

Request your sample report today & start making informed decisions powered by Credence Research Inc.!

Download Sample

Market Insights:

- The fire tube condensing low temperature industrial boiler market was valued at USD 404.5 million in 2024 and is projected to reach USD 570.9 million by 2032.

- Energy-efficient and cost-saving heating solutions drive strong demand across food processing, chemical, and textile industries.

- Stringent government regulations on emissions push industries to replace conventional boilers with condensing models.

- Technological advancements such as smart monitoring systems and modular designs enhance performance and reliability.

- High initial investment and complex maintenance requirements remain key challenges for small and mid-sized enterprises.

- Europe leads with 38% market share, supported by strict environmental policies and established manufacturers.

- Asia-Pacific, holding 24% market share, is projected to record the fastest growth due to industrial expansion and clean energy adoption.

Market Drivers:

Rising Demand for Energy-Efficient and Cost-Effective Heating Solutions:

The fire tube condensing low temperature industrial boiler market is strongly driven by the need for energy-efficient systems that reduce operational costs. Industries are seeking solutions that minimize fuel consumption while delivering consistent heat output. These boilers achieve high thermal efficiency, lowering utility expenses for manufacturers. The growing focus on long-term cost savings is increasing demand across food processing, chemical, and textile industries.

- For instance, Bosch’s Buderus SB615-640 fire tube condensing boiler achieved an output of 2,104 MBtu/h from a rated input of 2,228 MBtu/h in industrial food processing applications, allowing users to operate efficiently while minimizing fuel consumption.

Stringent Environmental Regulations and Emission Reduction Targets:

Tighter government policies on carbon emissions and industrial pollution are boosting adoption of advanced boiler systems. It provides a sustainable solution by reducing greenhouse gas emissions and meeting regulatory compliance standards. Companies are compelled to upgrade legacy systems to condensing models with lower environmental impact. These regulations push industries toward eco-friendly technologies, ensuring steady market expansion.

- For instance, in 2024, CordenPharma Colorado upgraded its two fire-tube steam boilers to low-NOx burners with parallel positioning control and oxygen trim; this modernization saved 311 MWh of energy annually and reduced NOx emissions by 1.6 tons per year at their facility.

Technological Advancements in Boiler Design and Performance:

Ongoing innovation in boiler technology is enhancing efficiency, safety, and operational flexibility. Features such as smart controls, modular configurations, and improved heat exchangers make boilers more attractive for industrial users. It enables industries to optimize energy use while improving overall system reliability. These advancements also support integration with renewable energy sources, creating new growth opportunities.

Expanding Industrialization and Infrastructure Development in Emerging Regions:

Rapid industrial growth in Asia-Pacific and parts of Latin America is a major driver of market demand. The fire tube condensing low temperature industrial boiler market benefits from rising manufacturing activities, construction projects, and energy diversification programs. It supports industries that require reliable and efficient heating systems for production. Expanding infrastructure and modernization efforts in these regions ensure a strong outlook for adoption.

Market Trends:

Growing Integration of Smart Technologies and Digital Monitoring Solutions:

The fire tube condensing low temperature industrial boiler market is witnessing strong adoption of smart controls and IoT-enabled monitoring systems. Manufacturers are incorporating advanced sensors, real-time performance tracking, and predictive maintenance tools into boiler designs. It allows industries to reduce downtime, extend equipment life, and optimize fuel efficiency. Digital solutions also improve compliance by offering detailed emission data for regulatory reporting. Remote monitoring and automation features are making operations safer and less labor-intensive. This trend aligns with the global move toward Industry 4.0 practices and digital transformation in industrial processes.

- For instance, Cleaver-Brooks launched its Prometha® Connected Boiler Solutions platform, which provides real-time remote monitoring and analytics for over 250 critical boiler data points, aiding operators in achieving up to 96% operating efficiency in industrial applications as of 2024.

Shift Toward Sustainable Designs and Renewable Energy Compatibility:

Another major trend shaping the market is the development of eco-friendly and renewable-compatible boiler solutions. Companies are designing models that integrate with biomass, biofuels, and hybrid heating systems to reduce environmental impact. It supports industries looking to align operations with sustainability goals while lowering long-term energy costs. The adoption of modular and compact boiler designs also reflects the growing need for space-efficient solutions in urban industrial settings. Materials with higher durability and corrosion resistance are being used to extend product life cycles. This shift demonstrates how the fire tube condensing low temperature industrial boiler market is adapting to the dual demand for efficiency and sustainability.

- For Instance, The Viessmann Vitocrossal 300 CT3 (or CT3B, depending on the specific model) is a gas-condensing boiler that can be integrated into a heating system alongside other technologies, including biomass systems for larger applications. Certain models within the Vitocrossal 300 family are capable of achieving a seasonal efficiency of up to 98% in industrial heating applications.

Market Challenges Analysis:

High Initial Investment and Maintenance Complexity:

The fire tube condensing low temperature industrial boiler market faces challenges related to high upfront costs and maintenance requirements. Advanced condensing models demand greater capital investment compared to traditional boilers, which can discourage small and mid-sized enterprises. It also requires skilled technicians for installation and ongoing servicing, increasing operational expenses. The complexity of parts such as heat exchangers and smart monitoring systems raises repair costs when breakdowns occur. Limited access to trained service providers in developing regions further intensifies the barrier for adoption. This cost-related challenge slows down replacement of conventional systems in price-sensitive markets.

Fluctuating Fuel Prices and Limited Awareness in Emerging Regions:

Volatile fuel prices create uncertainty for industries evaluating long-term savings from boiler upgrades. It affects purchasing decisions, especially in markets dependent on imported fuels. Another obstacle is the lack of awareness in emerging economies about the efficiency and environmental benefits of condensing boiler systems. Companies often continue using outdated technologies due to limited knowledge of lifecycle cost savings. Insufficient promotional activities by manufacturers and weak regulatory enforcement in some regions hinder adoption. These challenges restrict the overall growth pace of the fire tube condensing low temperature industrial boiler market despite its proven advantages.

Market Opportunities:

Expansion of Sustainable and Renewable-Compatible Boiler Solutions:

The fire tube condensing low temperature industrial boiler market presents strong opportunities in the transition toward sustainable energy systems. Manufacturers are focusing on designing boilers compatible with biofuels, biomass, and hybrid energy sources. It allows industries to align with global decarbonization goals while reducing dependency on fossil fuels. Demand is growing in sectors seeking greener heating technologies to meet corporate sustainability targets. Government incentives and stricter emission policies further encourage the adoption of renewable-ready boiler solutions. This creates a favorable environment for companies offering innovative, low-emission product lines.

Rising Industrialization and Modernization in Emerging Economies:

Expanding industrial sectors in Asia-Pacific, Latin America, and the Middle East open significant opportunities for adoption. The fire tube condensing low temperature industrial boiler market benefits from rising demand in food processing, chemicals, and textiles where efficient heating is essential. It also gains traction from infrastructure growth and the modernization of outdated boiler systems in these regions. Increasing investments in smart factories and energy-efficient equipment provide a strong growth pathway. Local governments are introducing stricter efficiency standards, which push industries toward condensing models. These developments create long-term opportunities for global and regional manufacturers to expand their presence.

Market Segmentation Analysis:

By Temperature:

The fire tube condensing low temperature industrial boiler market is segmented by operating temperature into low and very low ranges. Low temperature boilers dominate due to their balance of efficiency and cost-effectiveness. It offers reliable performance across industries that require consistent but not extreme heating. Very low temperature models are gaining traction in specialized applications where precise control and reduced emissions are priorities. Industries focused on sustainability prefer these options for their ability to meet strict environmental standards.

- For Instance, Viessmann’s Vitocrossal 300 condensing boilers are highly efficient, with company specifications citing thermal efficiency figures up to 98.4% (and sometimes slightly higher or lower depending on the model and standard).

By Capacity:

Capacity segmentation includes small, medium, and large boilers. Medium-capacity units hold a strong position because they meet the needs of mid-scale industries such as textiles, food processing, and manufacturing. It provides a balance between energy efficiency and output. Large-capacity boilers are increasingly demanded in heavy industries and large plants where continuous operations are critical. Small-capacity systems attract adoption in small-scale industries and facilities that prioritize compact solutions.

- For instance, the discontinued CMB series compact steam boilers, sold by Omega Engineering, were manufactured by Chromalox. They were used in laboratories and small-scale jewelry manufacturing. They provided point-of-use steam output up to 45 lbs/hr (approximately 20.4 kg/h), ensuring safe and reliable operation for critical applications.

By Application:

Key applications include food and beverages, chemicals, textiles, pharmaceuticals, and others. The food and beverage sector leads due to the need for reliable steam and hot water generation. It supports continuous processing and strict hygiene requirements. Chemical and textile industries also contribute significantly with growing modernization and energy-saving initiatives. Pharmaceutical plants prefer these boilers for precise heating control required in sensitive production processes. Expanding industrial bases worldwide will ensure broad application growth across multiple sectors.

Segmentations:

By Temperature:

- Low Temperature

- Very Low Temperature

By Capacity:

- Small Capacity

- Medium Capacity

- Large Capacity

By Application:

- Food and Beverages

- Chemicals

- Textiles

- Pharmaceuticals

- Others

By Region:

- North America

- Europe

- UK

- France

- Germany

- Italy

- Spain

- Russia

- Belgium

- Netherlands

- Austria

- Sweden

- Poland

- Denmark

- Switzerland

- Rest of Europe

- Asia Pacific

- China

- Japan

- South Korea

- India

- Australia

- Thailand

- Indonesia

- Vietnam

- Malaysia

- Philippines

- Taiwan

- Rest of Asia Pacific

- Latin America

- Brazil

- Argentina

- Peru

- Chile

- Colombia

- Rest of Latin America

- Middle East

- UAE

- KSA

- Israel

- Turkey

- Iran

- Rest of Middle East

- Africa

- Egypt

- Nigeria

- Algeria

- Morocco

- Rest of Africa

Regional Analysis:

Europe:

Europe holds 38% market share in the fire tube condensing low temperature industrial boiler market, making it the leading region. Strict emission standards and carbon reduction targets drive industries to adopt advanced boiler technologies. It benefits from early adoption of green energy initiatives and government incentives for sustainable equipment. Demand is high across food processing, manufacturing, and chemical sectors. Investments in smart factory infrastructure also encourage integration of digital monitoring with boiler systems. The presence of established boiler manufacturers in Germany, the UK, and Italy further strengthens regional dominance.

North America:

North America accounts for 28% market share, supported by industrial modernization and regulatory policies promoting efficiency. It reflects strong demand from sectors such as chemicals, textiles, and pharmaceuticals. The region is focusing on replacing outdated boilers with condensing models to reduce fuel use and emissions. Smart controls and IoT-enabled systems see high adoption, aligning with digital transformation trends. It benefits from a robust aftermarket service network and government-backed energy programs. The United States leads regional growth due to large-scale industrial investments and sustainability-driven procurement practices.

Asia-Pacific:

Asia-Pacific captures 24% market share and is projected to record the fastest growth. Rising industrialization in China, India, and Southeast Asia creates strong demand for efficient heating systems. It gains traction from expanding manufacturing bases and government policies supporting clean energy adoption. Local industries are transitioning from conventional boilers to advanced condensing models for cost and efficiency benefits. Regional infrastructure projects and rapid urbanization further expand application scope. Strong opportunities exist for global manufacturers to expand through partnerships and localized production facilities.

Shape Your Report to Specific Countries or Regions & Enjoy 30% Off!

Key Player Analysis:

- Babcock Wanson

- Clayton Industries

- Burnham Commercial Boilers

- Cleaver-Brooks

- Ferroli

- EPCB Boiler

- Fulton

- Hurst Boiler & Welding

- Hoval

- Miura America

- IHI Corporation

Competitive Analysis:

The fire tube condensing low temperature industrial boiler market is highly competitive with global and regional players driving innovation and adoption. Key companies include Babcock Wanson, Clayton Industries, Burnham Commercial Boilers, Cleaver-Brooks, Ferroli, EPCB Boiler, Fulton, and Hurst Boiler & Welding. These firms focus on energy efficiency, advanced heat recovery, and compliance with emission standards to strengthen their market presence. It emphasizes product differentiation through smart monitoring systems, modular designs, and renewable-compatible solutions. Strategic partnerships, mergers, and localized manufacturing facilities help companies expand their reach across diverse geographies. Strong aftersales support and customized offerings also play a critical role in sustaining customer loyalty and building long-term relationships. The market remains dynamic, with competition centered on cost-effectiveness, technological advancements, and the ability to meet evolving environmental regulations.

Recent Developments:

- In June 2025, Babcock Wanson acquired Danish company Chr. Møller A/S to expand its pan-European industrial boiler service network and strengthen its turnkey decarbonisation offering.

- In May 2025, Burnham Holdings, parent of Burnham Commercial Boilers, announced the divestiture of its Thermo Pride and Norwood Manufacturing subsidiaries to R.W. Beckett Corporation for $27.6 million in cash, reinforcing the focus on its commercial and industrial boiler portfolio.

- In Feb 2025, Ferroli became an official Event Partner for the Italian National Rugby Team during the prestigious 2025 Six Nations, strengthening its brand presence in the sports arena.

Report Coverage:

The research report offers an in-depth analysis based on Temperature, Capacity, Application and Region. It details leading Market players, providing an overview of their business, product offerings, investments, revenue streams, and key applications. Additionally, the report includes insights into the competitive environment, SWOT analysis, current Market trends, as well as the primary drivers and constraints. Furthermore, it discusses various factors that have driven Market expansion in recent years. The report also explores Market dynamics, regulatory scenarios, and technological advancements that are shaping the industry. It assesses the impact of external factors and global economic changes on Market growth. Lastly, it provides strategic recommendations for new entrants and established companies to navigate the complexities of the Market.

Future Outlook:

- The fire tube condensing low temperature industrial boiler market will experience steady adoption supported by energy efficiency regulations.

- It will see increasing demand in food processing, textile, and chemical industries seeking reliable heating solutions.

- Technological advancements will focus on digital monitoring, automation, and integration with renewable energy sources.

- The market will benefit from stricter carbon emission targets imposed by governments across developed economies

- .Asia-Pacific will continue to emerge as the fastest-growing region due to industrial expansion and infrastructure development.

- It will face rising opportunities through modernization of outdated boiler systems in developing countries.

- Manufacturers will emphasize modular and compact designs to address space constraints in industrial facilities.

- Global players will expand partnerships and joint ventures to strengthen regional presence and distribution networks.

- Sustainability-driven procurement will influence purchasing decisions, boosting adoption of eco-friendly and low-emission boilers.

- It will remain highly competitive, with innovation and aftersales services playing a key role in differentiation.