Market Overview:

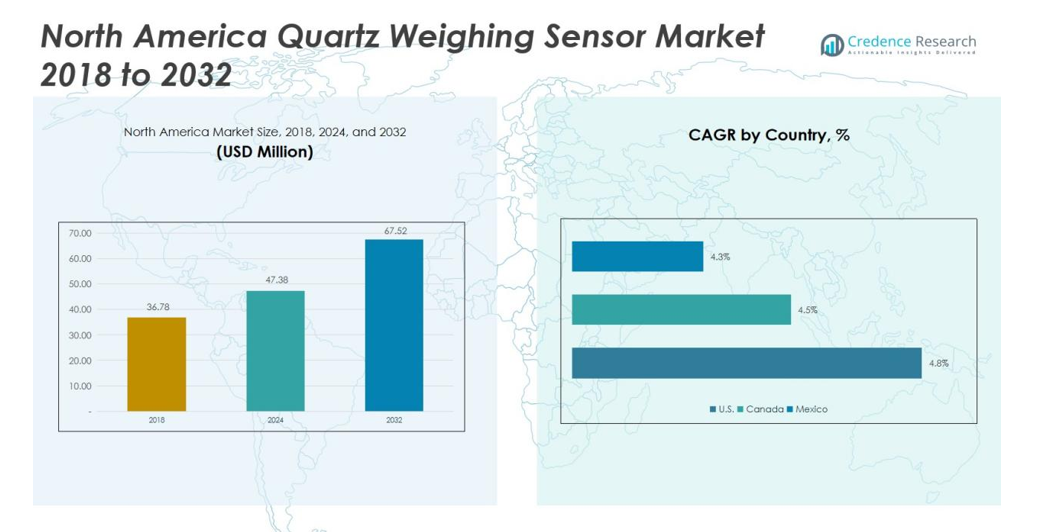

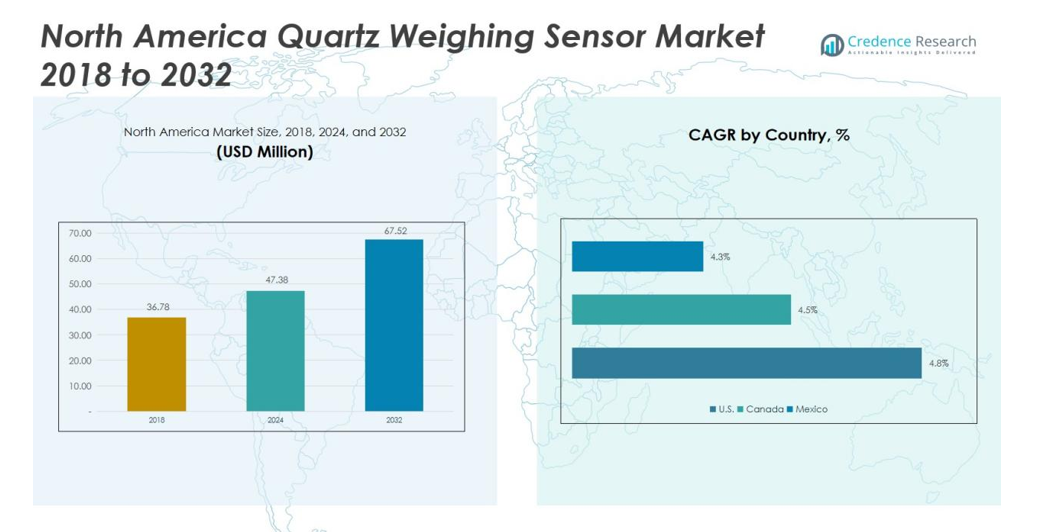

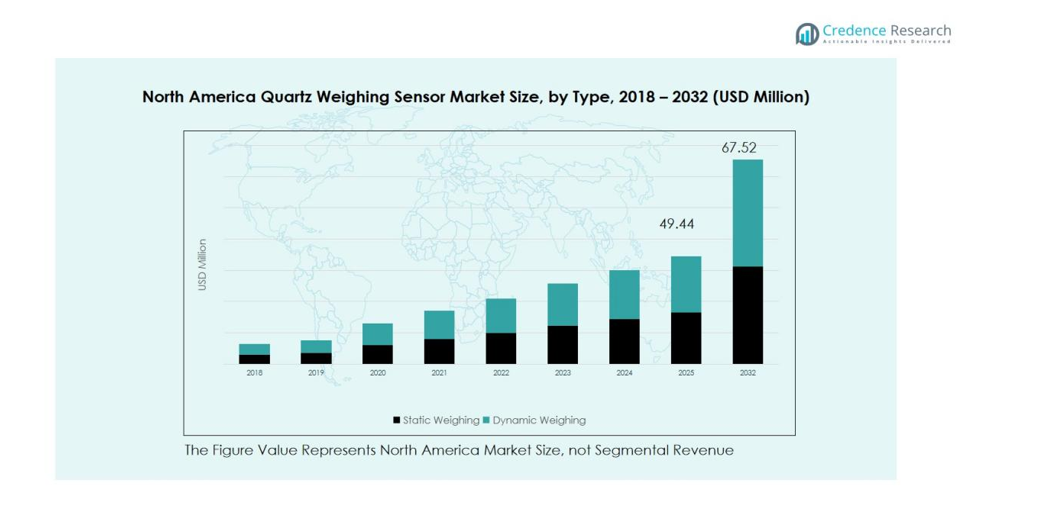

The North America Quartz Weighing Sensor Market size was valued at USD 36.78 million in 2018 to USD 47.38 million in 2024 and is anticipated to reach USD 67.52 million by 2032, at a CAGR of 4.54% during the forecast period.

| REPORT ATTRIBUTE |

DETAILS |

| Historical Period |

2020-2023 |

| Base Year |

2024 |

| Forecast Period |

2025-2032 |

| North America Quartz Weighing Sensor Market Size 2024 |

USD 47.38 million |

| North America Quartz Weighing Sensor Market, CAGR |

4.54% |

| North America Quartz Weighing Sensor Market Size 2032 |

USD 67.52 million |

Strong demand for high-accuracy and temperature-stable weighing solutions in pharmaceuticals, food processing, and chemical industries drives market expansion. The sensors’ ability to maintain measurement integrity under varying environmental conditions enhances their adoption in laboratory and manufacturing applications. Integration of IoT-enabled technologies and smart weighing systems is accelerating innovation, supporting process optimization and real-time data analysis across automated production environments.

Regionally, the United States dominates the North America Quartz Weighing Sensor Market due to its strong industrial base, technological leadership, and presence of major sensor manufacturers. Canada follows with growing demand from advanced manufacturing and research laboratories, supported by supportive government policies promoting smart industry development. Mexico is emerging as a high-potential market, driven by expanding industrial automation and increasing investments in precision-based manufacturing systems, strengthening regional market dynamics.

Market Insights:

- The North America Quartz Weighing Sensor Market was valued at USD 36.78 million in 2018, reached USD 47.38 million in 2024, and is projected to attain USD 67.52 million by 2032, registering a CAGR of 4.54%.

- The United States accounted for around 68% of the regional market in 2024, driven by its strong industrial infrastructure, high R&D investment, and early adoption of smart manufacturing technologies.

- Canada held nearly 20% of the market share, supported by its growing research and industrial automation sectors, while Mexico contributed around 12%, benefiting from rapid industrial modernization and increased foreign investments.

- Mexico is expected to be the fastest-growing market with expanding manufacturing activities, favorable trade policies, and increasing demand for precision-based automation systems.

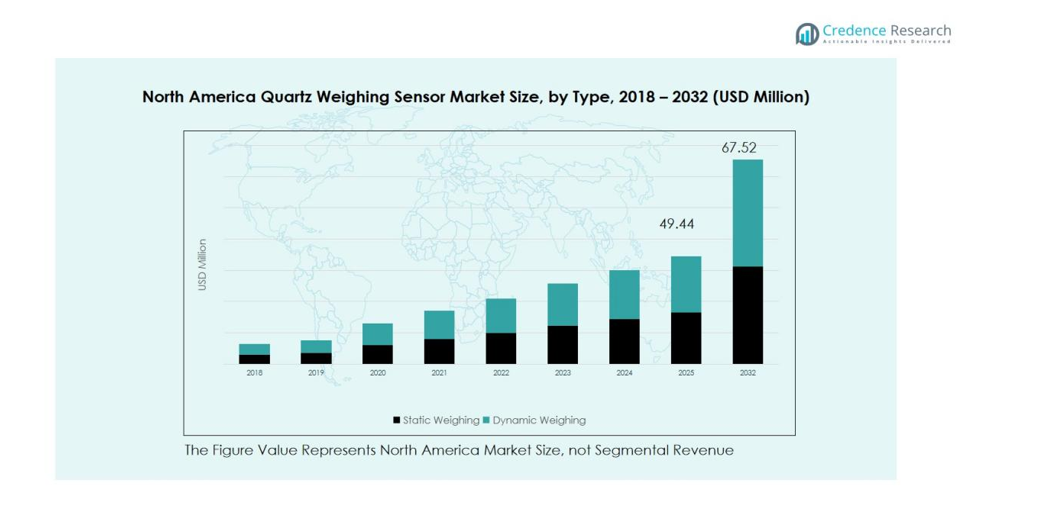

- Static weighing accounted for about 60% of total revenue in 2024 due to high use in laboratories, while dynamic weighing held 40%, gaining traction in automated production lines and continuous industrial processes.

Access crucial information at unmatched prices!

Request your sample report today & start making informed decisions powered by Credence Research Inc.!

Download Sample

Market Drivers:

Rising Demand for High-Precision Measurement Solutions

The North America Quartz Weighing Sensor Market benefits from increasing demand for precision measurement systems in industries such as pharmaceuticals, food processing, and chemical manufacturing. These sectors require sensors with superior accuracy, stability, and durability to ensure process consistency and regulatory compliance. The ability of quartz sensors to deliver precise readings under temperature and vibration variations supports their adoption. It continues to gain traction as manufacturers emphasize product quality and traceability across production lines.

- For Instance, Anritsu Corporation produces a range of high-speed, high-accuracy, and IoT-enabled SSV checkweighers for pharmaceutical production lines, designed to improve batch consistency and inspection reliability in facilities across North America.

Growing Adoption of Automation and Smart Manufacturing

Industry 4.0 initiatives across North America are driving rapid integration of automated weighing systems. The sensors’ compatibility with smart factory frameworks enables real-time data collection, predictive maintenance, and process optimization. Their role in enabling seamless communication between machines and control systems enhances efficiency in production facilities. It is increasingly used across automated environments to achieve higher throughput and operational accuracy.

- For Instance, Mettler-Toledo’s SPC high-precision weigh module incorporates high-precision electromagnetic force restoration (EMFR) technology with a readability of 0.01 mg, repeatability of 0.02 mg, and linearity deviation less than 0.05 mg across capacities up to 21 grams, supporting pharmaceutical formulation processes requiring tight tolerance control

Technological Advancements in Sensor Design and Performance

Continuous innovations in quartz sensing technologies are fueling market growth. Developments such as miniaturized components, improved frequency stability, and enhanced digital interfaces expand their application scope. These advancements improve performance in harsh or variable conditions, allowing integration into both laboratory and industrial setups. It supports manufacturers in achieving better accuracy, response speed, and long-term reliability.

Expanding Application in Research and Analytical Laboratories

Rising investments in scientific research, healthcare, and testing facilities are strengthening the demand for quartz-based weighing instruments. Laboratories across North America prefer quartz sensors for their high sensitivity and resistance to environmental drift. The increasing focus on precision analytics in biotechnology and material testing further enhances adoption. It continues to find growing relevance in research domains requiring trace-level accuracy and repeatable measurement results.

Market Trends:

Integration of IoT and Smart Manufacturing Technologies

The North America Quartz Weighing Sensor Market is witnessing a steady shift toward IoT-enabled and data-driven industrial operations. Manufacturers are embedding smart weighing sensors into automated production lines to enable real-time monitoring, predictive maintenance, and process optimization. These connected sensors improve operational transparency by transmitting accurate weight and performance data across digital platforms. It enhances quality control and supports faster decision-making in industrial and laboratory environments. The growing focus on digital transformation and Industry 4.0 adoption across sectors such as pharmaceuticals, food processing, and chemicals further supports sensor deployment. Continuous improvement in wireless communication protocols and edge computing integration is strengthening the adoption of advanced quartz-based weighing systems.

- For instance, the Mettler-Toledo IO-Link load cell provides weight data updates at 200 Hz (200 updates per second), supporting high-speed weighing applications with sophisticated signal filtering that optimizes machine design for increased throughput.

Advancements in Miniaturization and Material Engineering

Ongoing innovations in sensor materials and compact designs are shaping the competitive landscape. Manufacturers are developing smaller, thermally stable quartz sensors capable of operating under extreme industrial conditions without sacrificing precision. It supports product expansion in portable laboratory devices, compact analytical instruments, and automated inspection systems. The growing demand for lightweight, energy-efficient, and durable sensors is influencing R&D investments across major regional companies. Advanced coating technologies and improved vibration isolation mechanisms are enhancing product longevity and reliability. Continuous evolution in material science and electronic design is setting new standards for performance, accuracy, and application flexibility within the regional market.

- For instance, SiTime’s Titan MEMS resonator platform introduced in September 2025 achieves up to 7× smaller PCB area and 50× higher shock tolerance compared to legacy quartz components, marking a measurable leap in miniaturization and resilience for industrial and IoT sensors.

Market Challenges Analysis:

High Production Costs and Complex Manufacturing Processes

The North America Quartz Weighing Sensor Market faces challenges related to high production costs and intricate manufacturing requirements. Quartz sensors demand precision fabrication, advanced calibration, and high-purity materials, which increase operational expenses. The cost of maintaining accuracy and stability across varying temperatures further adds to production complexity. It restricts smaller manufacturers from competing with established players that possess advanced fabrication capabilities. Limited economies of scale and dependency on imported components can also affect pricing flexibility and profit margins. These factors collectively hinder the mass adoption of quartz-based weighing systems in cost-sensitive applications.

Competition from Alternative Sensing Technologies

The growing availability of alternative sensing technologies presents a key challenge to market expansion. Capacitive, piezoelectric, and strain gauge sensors offer competitive pricing and simpler integration, attracting users seeking lower-cost solutions. It pressures quartz sensor manufacturers to innovate and differentiate through enhanced performance or digital connectivity. The pace of technological substitution in certain industrial segments may slow demand for traditional quartz systems. Limited awareness of long-term performance benefits also impacts adoption in smaller enterprises. Maintaining market share requires continuous technological evolution and strategic positioning against emerging sensor technologies.

Market Opportunities:

Expansion of Smart and Connected Industrial Ecosystems

The North America Quartz Weighing Sensor Market holds strong growth potential with the expansion of smart factories and connected manufacturing ecosystems. Integration of IoT and AI-driven systems in production facilities creates demand for intelligent weighing sensors capable of real-time data transmission. These technologies enable process automation, energy efficiency, and improved quality assurance across diverse industries. It supports innovation in predictive maintenance and digital twins, enhancing operational efficiency and reducing downtime. Growing investments in industrial automation across the U.S. and Canada strengthen the business case for advanced quartz-based weighing technologies. Collaborations between sensor manufacturers and software providers will further unlock new application opportunities.

Rising Demand in Emerging End-Use Industries

Increasing adoption in biotechnology, healthcare, and precision engineering industries presents major growth avenues for market players. The sensors’ ability to deliver accurate and repeatable measurements supports critical applications such as laboratory testing, material research, and pharmaceutical production. It benefits from rising R&D expenditure and the region’s focus on precision-based manufacturing. Expansion of cleanroom and high-tech manufacturing facilities further amplifies demand for stable and contamination-resistant sensors. Growing emphasis on quality assurance and regulatory compliance across these sectors fosters continuous product innovation. These trends position quartz weighing sensors as essential components in the next generation of analytical and industrial systems.

Market Segmentation Analysis:

By Type

The North America Quartz Weighing Sensor Market is segmented into static weighing and dynamic weighing types. Static weighing systems dominate the market due to their high precision and stability in fixed measurement environments such as laboratories and calibration facilities. These sensors provide consistent results for applications requiring low-frequency or stationary measurements. Dynamic weighing systems are gaining traction in automated and high-speed industrial applications that demand real-time monitoring. It offers enhanced performance in continuous production lines, packaging units, and material handling systems. Growing automation in manufacturing and process industries is expected to expand demand for dynamic weighing solutions across North America.

- For instance, Kistler’s Lineas quartz piezoelectric sensors for Weigh-In-Motion (WIM) systems in North America can accurately record vehicle weights at speeds exceeding 100 km/h, maintaining installation depths as low as 55 mm for high data precision and minimal surface disruption.

By Application

The market is categorized into industrial applications, aerospace, scientific research, and others. Industrial applications lead the market, driven by strong adoption in manufacturing, process control, and quality inspection systems. Aerospace applications are expanding with increasing use in precision component testing and load measurement. Scientific research facilities rely on quartz sensors for their high accuracy and temperature resistance in analytical instruments. It continues to see emerging demand from biotechnology, materials science, and semiconductor industries. The growing emphasis on precision engineering and R&D activities reinforces the adoption of quartz weighing sensors across multiple sectors.

- For Instance, Airbus employs advanced load-monitoring systems, such as those used for the A350 family, during the joining of major airframe sections like the fuselage and wings to precisely measure and control applied forces.

Segmentations:

By Type:

- Static Weighing

- Dynamic Weighing

By Application:

- Industrial Applications

- Aerospace

- Scientific Research

- Others

By Country (North America):

Regional Analysis:

Dominance of the United States in Technological Innovation and Adoption

The North America Quartz Weighing Sensor Market is strongly led by the United States, driven by its advanced industrial infrastructure and strong focus on automation. The presence of leading sensor manufacturers, R&D centers, and electronics companies supports continuous technological development. Industries such as pharmaceuticals, aerospace, and food processing extensively adopt quartz sensors for their accuracy and reliability. It benefits from high investments in smart manufacturing and digital transformation initiatives across multiple sectors. The country’s leadership in integrating IoT-enabled weighing systems further strengthens its market position. Strong collaboration between manufacturers and research institutions continues to promote innovation in sensor performance and design.

Canada’s Expanding Role in Precision Manufacturing and Research

Canada holds a growing share in the regional market, supported by increasing adoption of high-precision instruments across laboratories and industrial sectors. The country’s manufacturing industry is gradually shifting toward smart and automated production, driving demand for accurate weighing solutions. Government initiatives promoting clean technologies and research excellence are enhancing sensor deployment across scientific and industrial environments. It benefits from strong partnerships between universities, technology firms, and process industries focusing on advanced measurement systems. Canada’s emphasis on innovation and sustainability is fostering steady market expansion in precision instrumentation and automation.

Mexico’s Growing Industrial Automation and Export Potential

Mexico is emerging as a promising market, supported by expanding manufacturing operations and rising demand for automation technologies. Growing foreign investments in automotive, electronics, and industrial equipment sectors are stimulating the adoption of quartz-based weighing systems. It benefits from improving infrastructure, skilled labor, and favorable trade policies that attract technology-driven industries. Local manufacturers are integrating precision measurement systems to meet international production standards. Increasing industrial modernization and cross-border collaborations with U.S. manufacturers are enhancing Mexico’s role as a competitive hub within the regional sensor supply chain.

Shape Your Report to Specific Countries or Regions & Enjoy 30% Off!

Key Player Analysis:

Competitive Analysis:

The North America Quartz Weighing Sensor Market is characterized by the presence of global and regional manufacturers focusing on precision, reliability, and advanced sensor technology. Key players include TE Connectivity, Kistler Group, PCB Piezotronics, ChampionX, Enviko, and Zhengzhou Hengliang Tech Co., Ltd. Competition centers on innovation in miniaturization, temperature stability, and real-time data capabilities to meet the evolving needs of industrial and laboratory applications. It emphasizes continuous R&D investment and collaboration with automation and electronics companies to enhance sensor performance. Companies are also expanding their product portfolios to address diverse application requirements in industrial, aerospace, and scientific research sectors. Strategic partnerships and product differentiation remain critical to strengthening market positioning and capturing emerging opportunities across the region.

Recent Developments:

- In October 2025, TE Connectivity announced it will host its 2025 Investor Day on November 20, 2025, in Philadelphia, where executive leadership will present strategic growth plans across global markets.

- In August 2025, The company announced India’s first real-time road quality assessment system, implemented on the Ganga Expressway project through smart measurement technologies supplied by Kistler.S

Report Coverage:

The research report offers an in-depth analysis based on Type, Application and Country (North America). It details leading market players, providing an overview of their business, product offerings, investments, revenue streams, and key applications. Additionally, the report includes insights into the competitive environment, SWOT analysis, current market trends, as well as the primary drivers and constraints. Furthermore, it discusses various factors that have driven market expansion in recent years. The report also explores market dynamics, regulatory scenarios, and technological advancements that are shaping the industry. It assesses the impact of external factors and global economic changes on market growth. Lastly, it provides strategic recommendations for new entrants and established companies to navigate the complexities of the market.

Future Outlook:

- The North America Quartz Weighing Sensor Market is expected to experience steady growth driven by automation and digital transformation across industries.

- Rising adoption of IoT-integrated weighing systems will enhance operational efficiency and predictive maintenance capabilities.

- Increased investment in smart manufacturing and process optimization will strengthen demand for advanced quartz sensors.

- Continuous innovation in sensor materials and miniaturization will expand application in compact and portable instruments.

- Growing use in precision-driven sectors such as pharmaceuticals, aerospace, and semiconductors will support market expansion.

- Integration of AI and data analytics with weighing technologies will improve real-time monitoring and accuracy.

- Expansion of R&D activities across the U.S. and Canada will encourage product advancements and local manufacturing.

- Manufacturers will focus on developing cost-efficient, energy-saving designs to improve competitiveness in industrial markets.

- Rising focus on clean technologies and environmental monitoring will create new opportunities for quartz-based sensing solutions.

- Collaborations between industry players and research institutes will drive technological innovation and strengthen North America’s leadership in precision measurement solutions.