Market Overview:

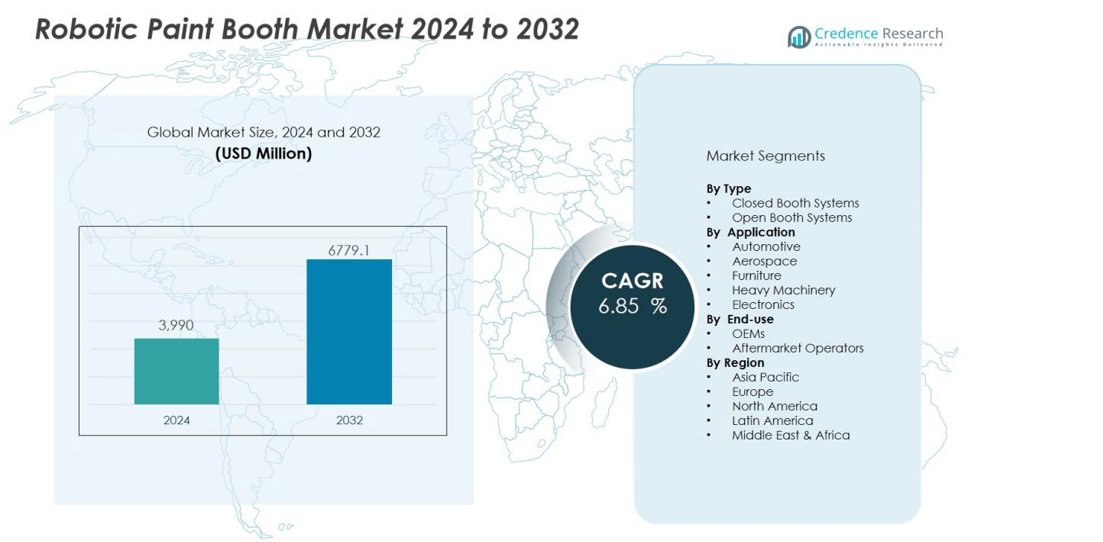

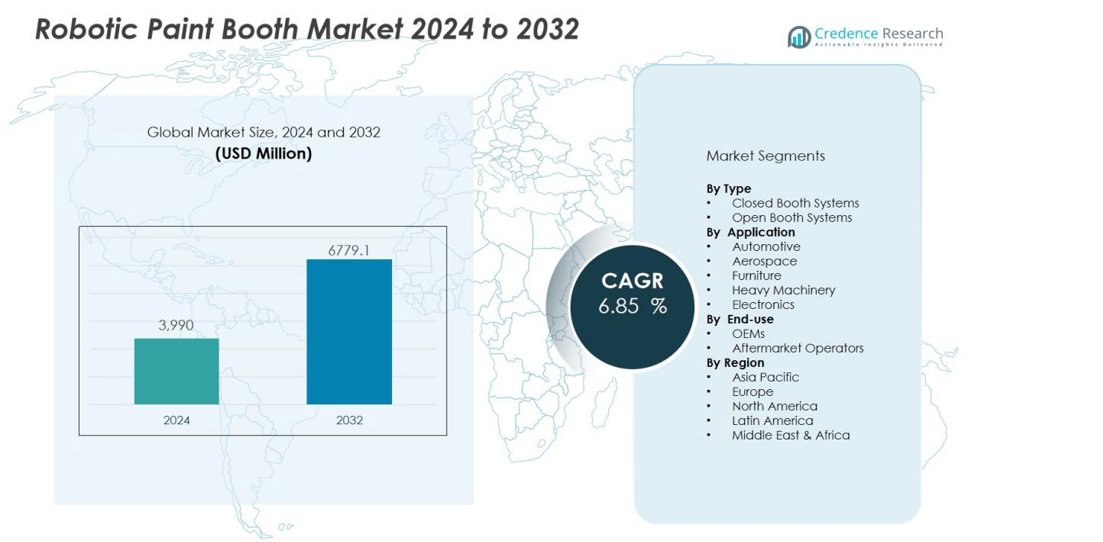

The robotic paint booth market size was valued at USD 3,990 million in 2024 and is anticipated to reach USD 6779.1 million by 2032, at a CAGR of 6.85 % during the forecast period (2024-2032).

| REPORT ATTRIBUTE |

DETAILS |

| Historical Period |

2020-2023 |

| Base Year |

2024 |

| Forecast Period |

2025-2032 |

| Robotic Paint Booth Market Size 2024 |

USD 3,990 million |

| Robotic Paint Booth Market, CAGR |

6.85% |

| Robotic Paint Booth Market Size 2032 |

USD 6779.1 million |

Key drivers include the need for consistent coating quality, reduced material wastage, and compliance with environmental regulations on emissions. Robotic paint booths improve productivity by minimizing human error and ensuring uniform application across complex surfaces. Industries such as automotive, aerospace, furniture, and heavy machinery are accelerating adoption to enhance efficiency, reduce operating costs, and meet sustainability goals.

Regionally, North America and Europe lead the robotic paint booth market due to advanced manufacturing infrastructure and high automation adoption. The Asia-Pacific region is projected to witness the fastest growth, supported by expanding automotive production in China, India, and Japan, along with government initiatives promoting industrial automation. Emerging economies in Latin America and the Middle East are also adopting robotic paint systems, particularly in automotive and industrial applications, offering new growth opportunities for market players.

Access crucial information at unmatched prices!

Request your sample report today & start making informed decisions powered by Credence Research Inc.!

Download Sample

Market Insights:

- The robotic paint booth market was valued at USD 3,990 million in 2024 and is projected to reach USD 6,779.1 million by 2032, growing at a CAGR of 6.85% during 2024–2032.

- Automotive remained the largest application segment in 2024, with strong demand for consistent coating quality and efficiency across complex vehicle parts.

- Rising environmental regulations are fueling adoption, as robotic paint booths reduce VOC emissions, overspray, and energy use, supporting sustainability goals.

- The market is advancing through AI, machine vision, and IoT integration, enabling higher precision, predictive maintenance, and digital manufacturing adaptability.

- High capital costs and integration challenges continue to limit adoption, especially among small and medium enterprises with budget constraints.

- North America led with 34% share in 2024, followed by Europe at 28%, driven by advanced infrastructure, emission control needs, and strong industrial bases.

- Asia-Pacific accounted for 26% share in 2024 and is the fastest-growing region, supported by expanding automotive production, automation initiatives, and rising export activities.

Market Drivers:

Growing Demand for Automation in Automotive and Industrial Manufacturing:

The automotive industry remains the largest end user of robotic paint booths, driven by the need for consistent quality and efficiency. Manufacturers are adopting automated systems to meet strict production standards while reducing cycle times. The robotic paint booth market benefits from its ability to deliver uniform coatings across complex vehicle parts. It also helps improve cost control by lowering rework and reducing paint usage.

- For instance, BMW’s Dingolfing plant has implemented the EcoPaintJet Pro system that eliminates overspray entirely and saves approximately 7,000 operating hours while reducing energy consumption by 6,000 megawatt-hours annually.

Rising Focus on Environmental Regulations and Sustainability Goals:

Stringent global environmental regulations encourage industries to use technologies that reduce emissions and overspray. Robotic paint booths limit volatile organic compound (VOC) emissions through precise application and controlled environments. The robotic paint booth market gains traction as companies aim to comply with eco-friendly manufacturing standards. It also supports sustainability goals by reducing waste and enhancing energy efficiency in painting operations.

- For instance, Mazda’s Ujina plant achieved a 17% reduction in paint usage using ABB’s RB1000i-S atomizers, equivalent to saving approximately 30,000 liters of paint annually.

Enhancing Productivity Through Consistency and Reduced Labor Dependency:

Companies are under constant pressure to improve output and reduce dependency on manual labor. Robotic paint booths deliver consistent coating quality with minimal errors, even in large-scale operations. The robotic paint booth market grows as firms adopt automation to address workforce shortages and rising labor costs. It also strengthens competitiveness by ensuring round-the-clock production capability and reducing operational downtime.

Integration of Advanced Technologies Driving Competitive Advantage:

Innovations such as artificial intelligence, machine vision, and real-time monitoring enhance robotic paint booth performance. These advancements improve precision, adaptability, and efficiency, supporting industry-wide digital transformation. The robotic paint booth market is advancing as companies leverage smart systems to optimize workflows. It also fosters competitiveness by enabling manufacturers to customize solutions and maintain high-quality standards across diverse applications.

Market Trends:

Adoption of Smart and Connected Robotic Painting Solutions:

The robotic paint booth market is witnessing strong adoption of smart technologies that improve efficiency and accuracy. Integration of sensors, IoT platforms, and machine vision allows real-time monitoring and precise control of paint application. It helps manufacturers optimize paint consumption, reduce defects, and meet evolving customer expectations for high-quality finishes. Companies are also using predictive maintenance tools to lower downtime and extend equipment life. Automation providers are introducing AI-enabled systems that learn from production data and adapt to varied surfaces. This trend reflects the broader shift toward Industry 4.0 and connected manufacturing systems.

- For instance, ABB launched the RB 1000i-S paint atomizer that improves transfer efficiency by up to 10% while reducing paint waste by a minimum of 30% compared to its predecessor.

Rising Penetration in Emerging Economies and Non-Automotive Sectors:

The robotic paint booth market is expanding beyond automotive into aerospace, furniture, electronics, and heavy machinery. It supports industries that require high precision and consistent coating performance. Growth is also strong in Asia-Pacific, Latin America, and the Middle East, where industrial automation adoption is accelerating. Local manufacturers are investing in robotic painting systems to remain competitive in global supply chains. Sustainability targets and stricter workplace safety regulations are further boosting demand for automated solutions. Partnerships between global robotics firms and regional companies are enabling cost-effective deployment in new markets. This trend is strengthening the global reach of robotic paint booth solutions.

- For instance, at Audi’s Ingolstadt plant in 2024, Dürr deployed 28 EcoBell4 atomizers across its new topcoat line—achieving a clear-coat transfer efficiency of 98% and reducing paint loss to under 2% of total usage.

Market Challenges Analysis:

High Capital Investment and Integration Complexity Limiting Adoption:

The robotic paint booth market faces challenges due to high initial investment requirements and integration complexity. Small and medium enterprises struggle to justify the costs of automation compared to manual processes. It also requires advanced infrastructure, skilled technicians, and continuous maintenance, which add to expenses. Integration with existing production lines often demands customization, making deployment time-consuming and costly. These financial and technical barriers slow adoption in cost-sensitive industries. Vendors must address affordability and scalability to expand their market presence.

Shortage of Skilled Workforce and Operational Limitations:

The robotic paint booth market is constrained by a shortage of skilled operators capable of handling advanced systems. Training requirements for programming, monitoring, and troubleshooting robotic systems are high, creating a talent gap. It also faces challenges in handling highly customized or low-volume production, where manual painting can be more flexible. Limited awareness among traditional manufacturers further restricts demand in emerging regions. Downtime caused by system failures or software issues can disrupt entire production lines. Addressing workforce development and system adaptability is crucial for sustained growth.

Market Opportunities:

Expanding Applications Across Diverse Industrial Sectors:

The robotic paint booth market holds strong opportunities as adoption extends beyond automotive into aerospace, electronics, heavy equipment, and furniture manufacturing. These industries demand high-precision coating and uniform finishes, creating scope for advanced robotic systems. It supports production where quality, consistency, and efficiency are vital to maintain competitiveness. Growing construction and infrastructure projects also increase demand for painted machinery and equipment. Rising consumer preference for premium finishes in appliances and electronics further drives growth. Expanding applications across industries offer vendors significant opportunities to diversify revenue streams.

Rising Demand in Emerging Economies and Sustainable Manufacturing:

The robotic paint booth market is set to benefit from industrial expansion in Asia-Pacific, Latin America, and the Middle East. Rapid urbanization, rising vehicle ownership, and growth in manufacturing sectors drive automation investments. It also aligns with sustainability targets, as robotic booths reduce waste and limit VOC emissions. Governments promoting cleaner production practices create additional opportunities for adoption. Partnerships with local integrators and manufacturers support cost-effective deployments in these regions. Growing focus on sustainable manufacturing and global supply chain competitiveness will continue to fuel market expansion.

Market Segmentation Analysis:

By Type:

The robotic paint booth market by type is segmented into closed booth systems and open booth systems. Closed booth systems dominate due to their ability to control emissions, reduce overspray, and ensure consistent quality. It offers better compliance with environmental standards and supports high-volume production in automotive and industrial applications. Open booth systems, while cost-effective, are used in small-scale operations requiring flexibility. Manufacturers prefer advanced closed booth solutions to improve efficiency and reduce waste. The growing demand for automated, eco-friendly solutions drives the adoption of closed systems globally.

- For Instance, Industrial finishing companies can use advanced systems like Wagner’s E-Line with the QuickCube powder coating booth for automated processes. The QuickCube’s efficient PVC sandwich wall design allows for exceptionally fast color changes, which is ideal for shops that handle frequent small-batch orders.

By Application:

The robotic paint booth market by application includes automotive, aerospace, furniture, heavy machinery, and electronics. Automotive remains the largest application segment, supported by demand for consistent finishes and productivity gains. It continues to expand in aerospace and electronics where precision and durability are critical. Furniture and heavy machinery sectors are also embracing robotic paint booths to enhance product quality. Increasing preference for high-quality finishes in consumer appliances further supports adoption. Growth across applications highlights the versatility of robotic paint solutions in diverse industries.

By End User:

The robotic paint booth market by end user is categorized into OEMs and aftermarket operators. OEMs lead the segment due to large-scale production requirements and strict quality standards. It benefits from OEM adoption in automotive, aerospace, and heavy equipment industries. The aftermarket segment is expanding with demand for cost-effective upgrades and retrofits. Service providers and smaller manufacturers use aftermarket solutions to enhance efficiency. Both segments contribute significantly to sustained market growth.

- For instance, BMW Group’s Plant Regensburg has implemented a world-first end-to-end digitalized and automated surface processing system using AI-controlled robots, processing up to 1,300 BMW X2 vehicles per working day.

Shape Your Report to Specific Countries or Regions & Enjoy 30% Off!

Segmentations:

By Type:

- Closed Booth Systems

- Open Booth Systems

By Application:

- Automotive

- Aerospace

- Furniture

- Heavy Machinery

- Electronics

By End User:

- OEMs

- Aftermarket Operators

By Region:

North America

Europe

- UK

- France

- Germany

- Italy

- Spain

- Russia

- Rest of Europe

Asia Pacific

- China

- Japan

- South Korea

- India

- Australia

- Southeast Asia

- Rest of Asia Pacific

Latin America

- Brazil

- Argentina

- Rest of Latin America

Middle East

- GCC Countries

- Israel

- Turkey

- Rest of Middle East

Africa

- South Africa

- Egypt

- Rest of Africa

Regional Analysis:

North America:

North America held 34% market share in 2024, supported by advanced automation adoption. The region benefits from strong automotive and aerospace industries that prioritize high-precision coating solutions. The robotic paint booth market grows steadily here as manufacturers focus on efficiency, emission control, and sustainable production. It also gains traction from increasing labor shortages, pushing companies to automate painting operations. Investments in Industry 4.0 technologies further support integration of smart robotic systems. U.S. and Canada remain central to growth due to well-established manufacturing bases and technology providers.

Europe:

Europe captured 28% market share in 2024, driven by strict environmental regulations and sustainability goals. The robotic paint booth market in this region benefits from demand for reduced VOC emissions and energy-efficient operations. It also advances as industries modernize production facilities to meet evolving quality standards. Germany, France, and the U.K. are leading adopters due to strong automotive and industrial bases. Rising collaborations between robotics firms and coating technology providers further enhance system efficiency. The focus on green manufacturing and digital transformation strengthens regional demand.

Asia-Pacific:

Asia-Pacific accounted for 26% market share in 2024, making it the fastest-growing regional market. The robotic paint booth market here is expanding rapidly due to rising vehicle production in China, India, and Japan. It also benefits from government initiatives promoting automation in manufacturing sectors. Growing consumer demand for high-quality finishes in vehicles and appliances drives accelerated adoption. Local manufacturers are investing in advanced painting solutions to remain globally competitive. The region’s expanding industrial base and rising export activities position it as a key growth hub.

Key Player Analysis:

- ABB Ltd.

- b m surface systems GmbH

- Arnold Machine Inc.

- Blowtherm USA

- Eisenmann GmbH

- Durr AG

- FANUC Corp.

- Graco Inc.

- GIFFIN Inc.

- Junair Spraybooths Ltd..

- KUKA AG

- MEXX Engineering Pty Ltd.

- Kawasaki Heavy Industries Ltd

- Nordson Corp.

Competitive Analysis:

The robotic paint booth market is highly competitive with global players focusing on advanced technologies and sustainability. Key companies include ABB Ltd., b m surface systems GmbH, Arnold Machine Inc., Blowtherm USA, Eisenmann GmbH, Dürr AG, FANUC Corp., Graco Inc., and GIFFIN Inc. It is shaped by innovations in automation, energy efficiency, and compliance with environmental standards. Leading firms invest heavily in R&D to integrate AI, machine vision, and IoT for precision and efficiency. Strategic partnerships and acquisitions strengthen their global reach and expand product portfolios. OEM-focused solutions dominate, but demand from aftermarket operators is creating new opportunities. It continues to evolve as manufacturers adopt flexible systems to address diverse industrial applications while enhancing productivity and reducing emissions.

Recent Developments:

- In August 2025, Dongguan Mentech Optical & Magnetic acquired a majority stake in ABB E-mobility’s ChargeDot, providing ABB with global expansion opportunities in EV charging solutions.

- In August 2025, ABB entered into a long-term supply partnership with Noveon Magnetics to source American-made rare earth magnets for its North American manufacturing operations and industrial motors.

- In June 2025, Dürr introduced its new “X.Cellify” brand for its range of battery cell technologies, uniting its products for electrode coating and electrolyte filling under this new name.

Report Coverage:

The research report offers an in-depth analysis based on Type, Application, End User and Region. It details leading Market players, providing an overview of their business, product offerings, investments, revenue streams, and key applications. Additionally, the report includes insights into the competitive environment, SWOT analysis, current Market trends, as well as the primary drivers and constraints. Furthermore, it discusses various factors that have driven Market expansion in recent years. The report also explores Market dynamics, regulatory scenarios, and technological advancements that are shaping the industry. It assesses the impact of external factors and global economic changes on Market growth. Lastly, it provides strategic recommendations for new entrants and established companies to navigate the complexities of the Market.

Future Outlook:

- The robotic paint booth market will witness strong demand from automotive, aerospace, and electronics sectors.

- It will continue to evolve with AI, machine vision, and predictive maintenance integration.

- Manufacturers will prioritize energy-efficient and low-emission painting technologies to meet sustainability goals.

- It will expand in emerging economies, supported by rising industrial automation and infrastructure development.

- Demand for customized robotic booths will increase as industries focus on flexible production lines.

- Strategic partnerships between robotics firms and coating technology providers will strengthen innovation pipelines.

- The market will benefit from growing labor shortages, pushing companies to automate painting operations.

- Digital transformation and Industry 4.0 adoption will accelerate the deployment of connected robotic paint booths.

- It will gain traction in non-automotive industries such as furniture, appliances, and heavy equipment.

- Continuous investments in R&D will ensure higher precision, efficiency, and adaptability of robotic paint booth systems.