CHAPTER NO. 1 : INTRODUCTION ERROR! BOOKMARK NOT DEFINED.

1.1.1. Report Description Error! Bookmark not defined.

Purpose of the Report Error! Bookmark not defined.

USP & Key Offerings Error! Bookmark not defined.

1.1.2. Key Benefits for Stakeholders Error! Bookmark not defined.

1.1.3. Target Audience 20

1.1.4. Report Scope 20

CHAPTER NO. 2 : EXECUTIVE SUMMARY 21

2.1. Plastic Welding Equipment Market Snapshot 21

2.1.1. South Africa Plastic Welding Equipment Market, Volume (Units) & Revenue (USD Million) 2018 – 2032 23

2.2. Insights from Primary Respondents 23

CHAPTER NO. 3 : GEOPOLITICAL CRISIS IMPACT ANALYSIS 24

3.1. Russia-Ukraine and Israel-Palestine War Impacts 24

CHAPTER NO. 4 : PLASTIC WELDING EQUIPMENT MARKET – INDUSTRY ANALYSIS 25

4.1. Introduction 25

4.2. Market Drivers 26

4.2.1. Rising demand for lightweight and durable materials in automotive manufacturing 26

4.2.2. Increasing use of plastic welding equipment in medical device production 27

4.3. Market Restraints 28

4.3.1. High initial investment costs for advanced plastic welding equipment 28

4.4. Market Opportunities 29

4.4.1. Technological advancements in plastic welding techniques, such as laser welding 29

4.5. Porter’s Five Forces Analysis 30

4.6. Value Chain Analysis 31

4.7. Buying Criteria 32

CHAPTER NO. 5 : IMPORT EXPORT ANALYSIS 33

5.1. Import Analysis by South Africa 33

5.1.1. South Africa Plastic Welding Equipment Market Import Revenue, By South Africa, 2018 – 2023 33

5.2. Export Analysis by South Africa 34

5.2.1. South Africa Plastic Welding Equipment Market Export Revenue, By South Africa, 2018 – 2023 34

CHAPTER NO. 6 : DEMAND SUPPLY ANALYSIS 35

6.1. Demand Analysis by South Africa 35

6.1.1. South Africa Plastic Welding Equipment Market Demand Revenue, By South Africa, 2018 – 2023 35

6.2. Supply Analysis by South Africa 36

6.2.1. South Africa Plastic Welding Equipment Market Supply Revenue, By South Africa, 2018 – 2023 36

CHAPTER NO. 7 : PRICE ANALYSIS 37

7.1. Price Analysis by Type 37

7.1.1. South Africa Plastic Welding Equipment Market Price, By Type, 2018 – 2023 37

7.1.2. South Africa Type Market Price, By Type, 2018 – 2023 37

CHAPTER NO. 8 : RAW MATERIALS ANALYSIS 38

8.1. Key Raw Materials and Suppliers 38

8.2. Key Raw Materials Price Trend 38

CHAPTER NO. 9 : MANUFACTURING COST ANALYSIS 39

9.1. Manufacturing Cost Analysis 39

9.2. Manufacturing Process 39

CHAPTER NO. 10 : ANALYSIS COMPETITIVE LANDSCAPE 40

10.1. Company Market Share Analysis – 2023 40

10.1.1. South Africa Plastic Welding Equipment Market: Company Market Share, by Revenue, 2023 40

10.1.2. South Africa Plastic Welding Equipment Market: Company Market Share, by Revenue, 2023 41

10.1.3. South Africa Plastic Welding Equipment Market: Top 6 Company Market Share, by Revenue, 2023 41

10.1.4. South Africa Plastic Welding Equipment Market: Top 3 Company Market Share, by Revenue, 2023 41

10.2. South Africa Plastic Welding Equipment Market Company Volume Market Share, 2023 43

10.3. South Africa Plastic Welding Equipment Market Company Revenue Market Share, 2023 43

10.4. Company Assessment Metrics, 2023 44

10.4.1. Stars 44

10.4.2. Emerging Leaders 44

10.4.3. Pervasive Players 44

10.4.4. Participants 44

10.5. Start-ups /SMEs Assessment Metrics, 2023 44

10.5.1. Progressive Companies 44

10.5.2. Responsive Companies 44

10.5.3. Dynamic Companies 44

10.5.4. Starting Blocks 44

10.6. Strategic Developments 45

10.6.1. Acquisitions & Mergers 45

New Product Launch 45

South Africa Expansion 45

10.7. Key Players Product Matrix 46

CHAPTER NO. 11 : PESTEL & ADJACENT MARKET ANALYSIS 47

11.1. PESTEL 47

11.1.1. Political Factors 47

11.1.2. Economic Factors 47

11.1.3. Social Factors 47

11.1.4. Technological Factors 47

11.1.5. Environmental Factors 47

11.1.6. Legal Factors 47

11.2. Adjacent Market Analysis 47

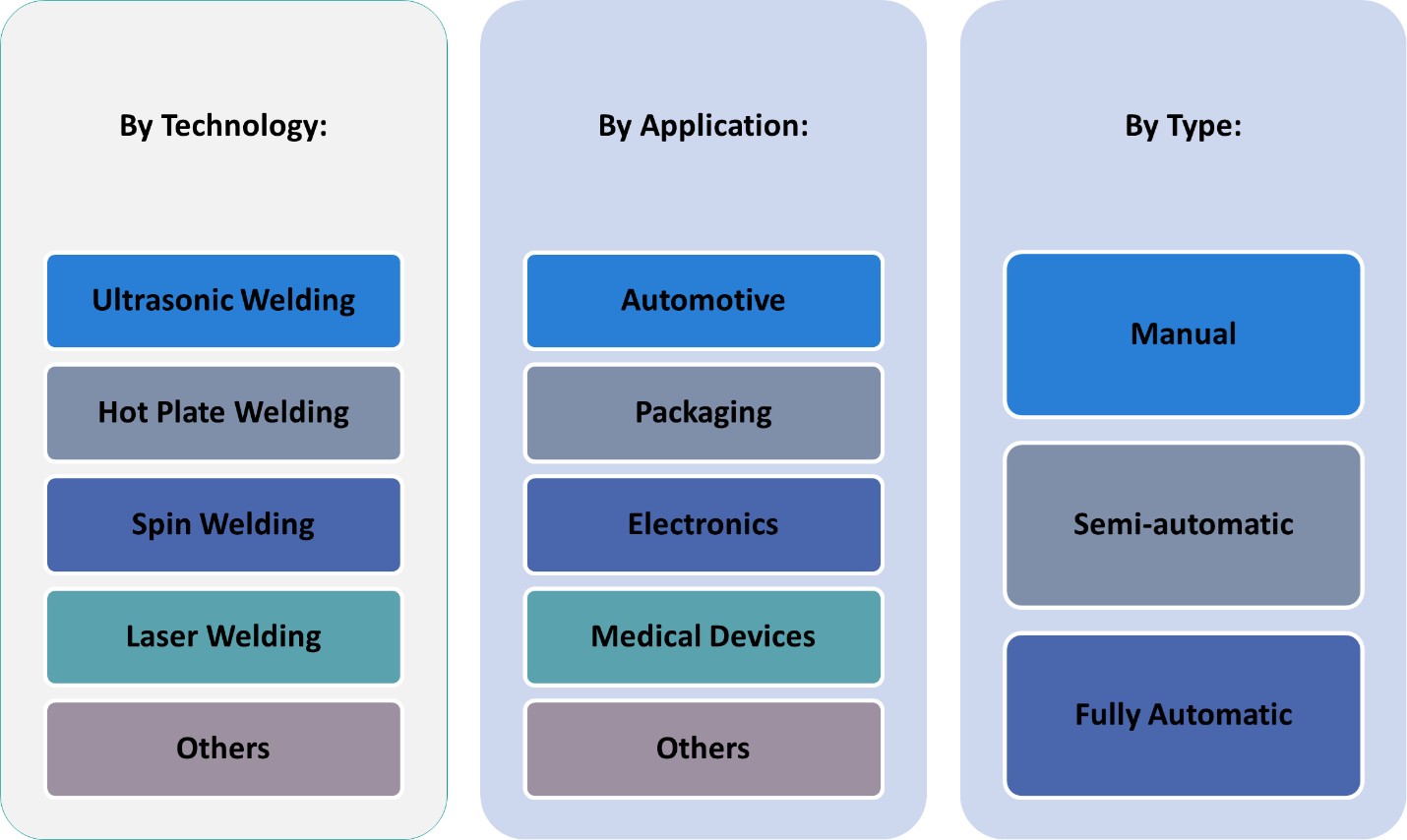

CHAPTER NO. 12 : PLASTIC WELDING EQUIPMENT MARKET – BY TYPE SEGMENT ANALYSIS 48

12.1. Plastic Welding Equipment Market Overview, by Type Segment 48

12.1.1. Plastic Welding Equipment Market Revenue Share, By Type, 2023 & 2032 49

12.1.2. Plastic Welding Equipment Market Attractiveness Analysis, By Type 50

12.1.3. Incremental Revenue Growth Opportunity, by Type, 2024 – 2032 50

12.1.4. Plastic Welding Equipment Market Revenue, By Type, 2018, 2023, 2027 & 2032 51

12.2. Manual 52

12.3. Semi-automatic 53

12.4. Fully Automatic 54

CHAPTER NO. 13 : PLASTIC WELDING EQUIPMENT MARKET – BY APPLICATION SEGMENT ANALYSIS 55

13.1. Plastic Welding Equipment Market Overview, by Application Segment 55

13.1.1. Plastic Welding Equipment Market Revenue Share, By Application, 2023 & 2032 56

13.1.2. Plastic Welding Equipment Market Attractiveness Analysis, By Application 57

13.1.3. Incremental Revenue Growth Opportunity, by Application, 2024 – 2032 57

13.1.4. Plastic Welding Equipment Market Revenue, By Application, 2018, 2023, 2027 & 2032 58

13.2. Automotive 59

13.3. Packaging 60

13.4. Electronics 61

13.5. Medical Devices 62

13.6. Others 63

CHAPTER NO. 14 : PLASTIC WELDING EQUIPMENT MARKET – BY TECHNOLOGY SEGMENT ANALYSIS 64

14.1. Plastic Welding Equipment Market Overview, by Technology Segment 64

14.1.1. Plastic Welding Equipment Market Revenue Share, By Technology, 2023 & 2032 65

14.1.2. Plastic Welding Equipment Market Attractiveness Analysis, By Technology 66

14.1.3. Incremental Revenue Growth Opportunity, by Technology, 2024 – 2032 66

14.1.4. Plastic Welding Equipment Market Revenue, By Technology, 2018, 2023, 2027 & 2032 67

14.2. Ultrasonic Welding 68

14.3. Hot Plate Welding 69

14.4. Spin Welding 70

14.5. Laser Welding 71

14.6. Others 72

CHAPTER NO. 15 : COMPANY PROFILES 73

15.1. Leister Technologies AG 73

15.1.1. Company Overview 73

15.1.2. Product Portfolio 73

15.1.3. Swot Analysis 73

15.1.4. Business Strategy 73

15.1.5. Financial Overview 74

15.2. RITMO S.p.A. 75

15.3. Emerson Electric Co. 75

15.4. Herrmann Ultraschalltechnik GmbH & Co. KG 75

15.5. Frimo Group GmbH 75

15.6. Bielomatik Leuze GmbH & Co. KG 75

15.7. Mecasonic Group 75

15.8. CEMAS Elettra 75

15.9. CHN-TOP Machinery Group 75

15.10. Haitian International Holdings Ltd. 75

List of Figures

FIG NO. 1. South Africa Plastic Welding Equipment Market, Volume (Units) & Revenue (USD Million) 2018 – 2032 23

FIG NO. 2. Porter’s Five Forces Analysis for South Africa Plastic Welding Equipment Market 30

FIG NO. 3. Value Chain Analysis for South Africa Plastic Welding Equipment Market 31

FIG NO. 4. South Africa Plastic Welding Equipment Market Import Revenue, By South Africa, 2018 – 2023 33

FIG NO. 5. South Africa Plastic Welding Equipment Market Export Revenue, By South Africa, 2018 – 2023 34

FIG NO. 6. South Africa Plastic Welding Equipment Market Demand Revenue, By South Africa, 2018 – 2023 35

FIG NO. 7. South Africa Plastic Welding Equipment Market Supply Revenue, By South Africa, 2018 – 2023 36

FIG NO. 8. South Africa Plastic Welding Equipment Market Price, By Type, 2018 – 2023 37

FIG NO. 9. Raw Materials Price Trend Analysis, 2018 – 2023 38

FIG NO. 10. Manufacturing Cost Analysis 39

FIG NO. 11. Manufacturing Process 39

FIG NO. 12. Company Share Analysis, 2023 40

FIG NO. 13. Company Share Analysis, 2023 41

FIG NO. 14. Company Share Analysis, 2023 41

FIG NO. 15. Company Share Analysis, 2023 41

FIG NO. 16. Plastic Welding Equipment Market – Company Volume Market Share, 2023 43

FIG NO. 17. Plastic Welding Equipment Market – Company Revenue Market Share, 2023 43

FIG NO. 18. Plastic Welding Equipment Market Revenue Share, By Type, 2023 & 2032 49

FIG NO. 19. Market Attractiveness Analysis, By Type 50

FIG NO. 20. Incremental Revenue Growth Opportunity by Type, 2024 – 2032 50

FIG NO. 21. Plastic Welding Equipment Market Revenue, By Type, 2018, 2023, 2027 & 2032 51

FIG NO. 22. South Africa Plastic Welding Equipment Market for Manual, Volume (Units) & Revenue (USD Million) 2018 – 2032 52

FIG NO. 23. South Africa Plastic Welding Equipment Market for Semi-automatic, Volume (Units) & Revenue (USD Million) 2018 – 2032 53

FIG NO. 24. South Africa Plastic Welding Equipment Market for Fully Automatic, Volume (Units) & Revenue (USD Million) 2018 – 2032 54

FIG NO. 25. Plastic Welding Equipment Market Revenue Share, By Application, 2023 & 2032 56

FIG NO. 26. Market Attractiveness Analysis, By Application 57

FIG NO. 27. Incremental Revenue Growth Opportunity by Application, 2024 – 2032 57

FIG NO. 28. Plastic Welding Equipment Market Revenue, By Application, 2018, 2023, 2027 & 2032 58

FIG NO. 29. South Africa Plastic Welding Equipment Market for Automotive, Volume (Units) & Revenue (USD Million) 2018 – 2032 59

FIG NO. 30. South Africa Plastic Welding Equipment Market for Packaging, Volume (Units) & Revenue (USD Million) 2018 – 2032 60

FIG NO. 31. South Africa Plastic Welding Equipment Market for Electronics, Volume (Units) & Revenue (USD Million) 2018 – 2032 61

FIG NO. 32. South Africa Plastic Welding Equipment Market for Medical Devices, Volume (Units) & Revenue (USD Million) 2018 – 2032 62

FIG NO. 33. South Africa Plastic Welding Equipment Market for Others, Volume (Units) & Revenue (USD Million) 2018 – 2032 63

FIG NO. 34. Plastic Welding Equipment Market Revenue Share, By Technology, 2023 & 2032 65

FIG NO. 35. Market Attractiveness Analysis, By Technology 66

FIG NO. 36. Incremental Revenue Growth Opportunity by Technology, 2024 – 2032 66

FIG NO. 37. Plastic Welding Equipment Market Revenue, By Technology, 2018, 2023, 2027 & 2032 67

FIG NO. 38. South Africa Plastic Welding Equipment Market for Ultrasonic Welding, Volume (Units) & Revenue (USD Million) 2018 – 2032 68

FIG NO. 39. South Africa Plastic Welding Equipment Market for Hot Plate Welding, Volume (Units) & Revenue (USD Million) 2018 – 2032 69

FIG NO. 40. South Africa Plastic Welding Equipment Market for Spin Welding, Volume (Units) & Revenue (USD Million) 2018 – 2032 70

FIG NO. 41. South Africa Plastic Welding Equipment Market for Laser Welding, Volume (Units) & Revenue (USD Million) 2018 – 2032 71

FIG NO. 42. South Africa Plastic Welding Equipment Market for Others, Volume (Units) & Revenue (USD Million) 2018 – 2032 72

List of Tables

TABLE NO. 1. : South Africa Plastic Welding Equipment Market: Snapshot 21

TABLE NO. 2. : Drivers for the Plastic Welding Equipment Market: Impact Analysis 26

TABLE NO. 3. : Restraints for the Plastic Welding Equipment Market: Impact Analysis 28

TABLE NO. 4. : South Africa Plastic Welding Equipment Market Revenue, By Type, 2018 – 2023 37

TABLE NO. 5. : Key Raw Materials & Suppliers 38