Market Overview:

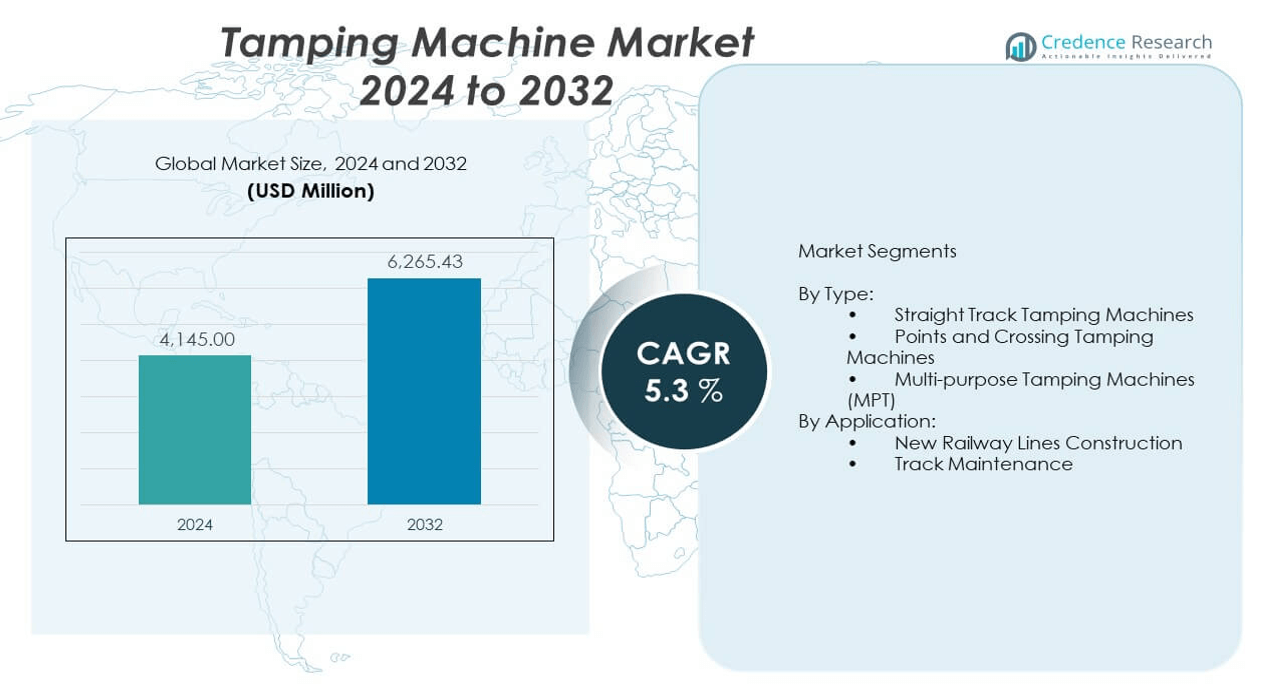

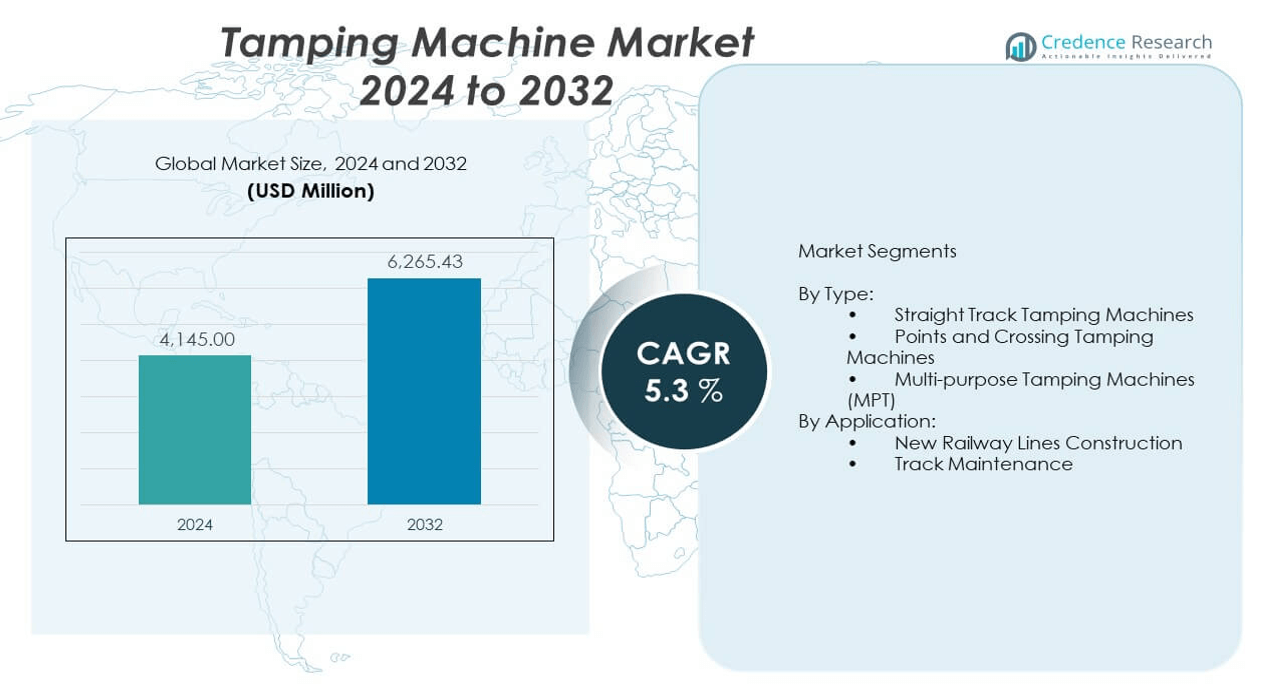

The tamping machine market is projected to grow from USD 4,145 million in 2024 to an estimated USD 6,265.43 million by 2032, expanding at a CAGR of 5.3% during the forecast period from 2024 to 2032. This growth reflects increasing investments in rail infrastructure modernization and maintenance activities globally, driven by rising demand for high-speed rail systems, metro expansions, and freight rail optimization.

| REPORT ATTRIBUTE |

DETAILS |

| Historical Period |

2020-2023 |

| Base Year |

2024 |

| Forecast Period |

2025-2032 |

| Tamping Machine Market Size 2024 |

USD 4,145 million |

| Tamping Machine Market, CAGR |

5.3% |

| Tamping Machine Market Size 2032 |

USD 6,265.43 million |

Market demand is strongly supported by the need for efficient track maintenance to ensure safety, ride comfort, and operational efficiency. Governments and railway authorities are deploying advanced tamping machines to automate and accelerate track leveling, alignment, and ballast compaction, reducing manual labor and downtime. Technological advancements, such as GPS-guided systems, smart diagnostics, and hybrid power solutions, are further improving machine productivity and appeal among end users.

Geographically, Europe leads the tamping machine market due to its extensive high-speed and conventional rail networks, coupled with consistent upgrades and automation. North America follows closely, supported by ongoing investments in railway infrastructure modernization. Meanwhile, Asia-Pacific is emerging as a high-growth region, particularly in countries like China and India, where rapid urbanization and government-led transportation reforms are fueling rail network expansion and maintenance needs

Market Insights:

- The tamping machine market was valued at USD 4,145 million in 2024 and is projected to reach USD 6,265.43 million by 2032, growing at a CAGR of 5.3% during the forecast period.

- Rising investments in high-speed rail networks, metro systems, and freight corridors continue to drive demand for advanced tamping machines.

- The need for automated and efficient track maintenance to ensure ride comfort, operational safety, and network uptime supports sustained market growth.

- High capital costs and long procurement cycles act as barriers, especially for small contractors and emerging markets.

- Limited availability of skilled operators and technical personnel hampers effective machine utilization and increases downtime risks.

- Europe leads the global market, supported by dense rail networks and ongoing modernization projects, accounting for the largest regional share.

- Asia-Pacific emerges as the fastest-growing region, driven by rapid urbanization and expanding rail infrastructure in China, India, and Southeast Asia.

Access crucial information at unmatched prices!

Request your sample report today & start making informed decisions powered by Credence Research Inc.!

Download Sample

Market Drivers:

Expansion of Railway Infrastructure Projects Fuels Equipment Demand:

Governments across developing and developed countries continue to invest heavily in railway infrastructure expansion, driving significant demand in the tamping machine market. New high-speed rail lines, metro systems, and freight corridors require efficient track-laying and maintenance equipment. It supports large-scale construction programs by enhancing productivity and reducing manual labor dependency. Public-private partnerships and cross-border rail initiatives increase the pace of infrastructure development. High traffic density on existing routes necessitates both line expansion and regular maintenance. This infrastructure boom directly raises the need for advanced and multi-functional tamping machines. It enables faster commissioning of new lines and helps maintain operational efficiency. The market responds by offering purpose-built machines tailored for large projects and varying rail conditions.

- For instance, Plasser & Theurer’s 09-3X Dynamic Tamping Machine features a 3-sleeper tamping unit that allows tamping three sleepers simultaneously in one cycle, delivering a 30 to 40 percent increase in output compared to traditional 2-sleeper tamping units. This enhanced productivity supports substantial track maintenance and expansion tasks effectively.

Increasing Emphasis on Operational Efficiency and Track Safety:

Railway operators focus on maximizing operational uptime and ensuring passenger and cargo safety through consistent track geometry. The tamping machine market gains from this trend as it offers advanced solutions for leveling and aligning tracks efficiently. Irregular track geometry leads to derailments, poor ride quality, and excessive wear on rolling stock. It supports infrastructure reliability through automation and precision engineering. By reducing manual intervention, tamping machines improve worksite safety and speed up maintenance windows. Modern machines can handle complex track configurations with higher accuracy. Network owners adopt these systems to reduce long-term maintenance costs. It reflects a broader shift toward performance-based asset management in the rail sector.

- For instance, Plasser & Theurer’s SmartTamping technology integrates real-time measurement and tamping control systems that have supported over 30 billion tamping cycles globally since 1953.

Rapid Technological Advancements Elevate Machine Capabilities:

Automation, digital control systems, and GPS-integrated tamping machines transform the operational capabilities of modern railway maintenance fleets. It influences procurement decisions by delivering enhanced track precision and data-driven insights. Smart tamping machines collect and analyze real-time data to optimize tamping force and depth. These technologies reduce rework, material wastage, and total maintenance time. Remote diagnostics and predictive maintenance features further elevate equipment lifecycle performance. The tamping machine market experiences a transition from mechanical to intelligent systems. This evolution aligns with global smart rail initiatives. The integration of AI and telematics ensures continuous improvement in maintenance outcomes.

Aging Rail Networks Drive Sustained Maintenance Activities:

Mature railway networks in Europe, North America, and parts of Asia face increasing strain due to aging infrastructure. The tamping machine market benefits as recurring maintenance becomes critical for safety and performance. Frequent usage, environmental exposure, and insufficient upgrades lead to track instability. Governments allocate dedicated budgets for rehabilitation programs and life-cycle extensions. Tamping machines enable precise ballast compaction that restores geometric alignment and prolongs asset life. It helps reduce track downtime and supports uninterrupted rail services. Legacy infrastructure requires customized tamping approaches, often addressed through modular machine configurations. Demand for versatile and high-frequency tamping units grows in this context.

Market Trends:

Shift Toward Electrified and Hybrid Tamping Solutions:

Environmental regulations and sustainability goals encourage the shift away from diesel-powered machines. The tamping machine market witnesses a transition toward battery-electric and hybrid power units. Rail operators seek eco-friendly alternatives to meet emission reduction targets. It encourages manufacturers to redesign platforms that reduce fuel consumption and noise pollution. Electric tamping machines perform efficiently in tunnels and urban rail networks with minimal ventilation. These innovations enhance operator safety and reduce environmental impact. Countries in Europe and Asia lead adoption due to strict environmental compliance standards. The trend strengthens the market’s alignment with green infrastructure objectives.

- For instance, Plasser & Theurer introduced the Unimat 09-2X 4×4/4S E³ universal tamping machine featuring their E³ concept, combining high performance with low emissions and noise, specifically engineered to provide sustainable operation while complying with stringent ecological standards.

Integration of Remote Monitoring and Telematics:

Machine connectivity and real-time diagnostics play an expanding role in predictive maintenance. The tamping machine market adopts telematics to monitor machine health and usage remotely. Operators leverage cloud-based platforms to track productivity, fuel efficiency, and wear patterns. It enables proactive maintenance scheduling and reduces equipment downtime. Remote access to performance data aids fleet optimization and operator training. Integrated control systems also offer automated tamping cycles, improving consistency across shifts. This trend aligns with smart infrastructure investments and digital railway frameworks. Manufacturers incorporate IoT and advanced sensors to deliver scalable digital features.

- For instance, since 2020, all new Plasser & Theurer machines come equipped with the Datamatic IoT Edge device as standard. This system continuously monitors machine components, enabling early detection of service needs and supporting predictive maintenance strategies, thus increasing machine availability and operational reliability.

Rising Demand for Multi-Functional Tamping Equipment:

Rail operators prefer machines that can handle multiple track types and maintenance activities. The tamping machine market expands its multi-purpose product lines to address this requirement. These machines support straight track tamping, switch tamping, and lifting-aligning functions in a single unit. It reduces machine deployment cost and eliminates the need for multiple specialized fleets. Modular design options allow configuration changes based on site needs. Contractors gain operational flexibility and improved ROI through multi-capability machines. Demand from emerging rail markets accelerates this trend, particularly where budget constraints exist. It signals a growing need for versatile and cost-effective solutions.

Increasing OEM Focus on Aftermarket and Lifecycle Services:

Manufacturers diversify their business models by expanding after-sales support and lifecycle management offerings. The tamping machine market now includes service contracts, spare parts packages, and condition-based maintenance programs. Long-term agreements support customers through the entire machine lifecycle. It builds customer loyalty and ensures performance consistency. OEMs offer operator training, on-site support, and software updates to extend machine utility. This services-led approach aligns with evolving customer expectations. It also reflects the industry’s shift toward value-added partnerships. The growing installed base of machines drives recurring revenue through aftermarket services.

Market Challenges Analysis:

High Initial Investment and Complex Procurement Process Limit Adoption:

The capital-intensive nature of tamping machines presents a significant barrier for smaller contractors and developing countries. The tamping machine market faces adoption hurdles due to high upfront equipment costs and limited financing options. Public rail agencies often require lengthy procurement cycles involving detailed technical evaluations and budget approvals. It delays equipment deployment and slows project timelines. Lack of awareness and training among operators in emerging markets further restricts usage. Customization requirements based on regional rail standards raise costs and engineering complexity. These challenges affect the ability of smaller players to compete or scale. Financing solutions, equipment leasing, and used-machine markets attempt to address the affordability gap.

Shortage of Skilled Operators and Maintenance Technicians:

Operating modern tamping machines requires specialized training and experience. The tamping machine market encounters operational delays due to a shortage of qualified personnel. High automation levels demand both digital and mechanical skillsets. Many regions struggle to retain trained technicians, affecting machine uptime and productivity. It leads to increased reliance on OEM support, driving up operational costs. Rapid technology upgrades also outpace training infrastructure, especially in low-resource areas. Machine misuse and inadequate maintenance cause unplanned breakdowns and reduced machine life. These workforce challenges can compromise the effectiveness of rail maintenance schedules.

Market Opportunities:

Emerging Railway Projects in Asia and Africa Offer Growth Potential:

Developing nations invest in new railway corridors to boost regional trade and connectivity. The tamping machine market gains opportunities from large-scale rail infrastructure programs in India, Southeast Asia, and parts of Africa. Governments prioritize modernization, urban transit, and cross-border networks. It creates consistent demand for both construction-phase and long-term maintenance tamping solutions. The market can expand by offering cost-effective, modular, and hybrid machines suitable for these growth regions.

Leasing and Rental Business Models Expand Market Accessibility:

Rising interest in machine leasing and rental services provides an alternative path for market entry. The tamping machine market benefits as contractors reduce capital burden through short-term equipment use. It supports flexible deployment and adapts to varying project sizes. OEMs and third-party providers offer scalable leasing packages, enabling smaller players to participate in large contracts. This model increases utilization and improves machine availability across regions.

Market Segmentation Analysis:

By Type

The tamping machine market segments by type into Straight Track Tamping Machines, Points and Crossing Tamping Machines, and Multi-purpose Tamping Machines (MPT). Straight track machines are commonly used for high-speed track alignment and leveling in long, uninterrupted sections of rail. Points and crossing machines are designed for precision tamping in complex track areas such as switches, turnouts, and crossings. Multi-purpose tamping machines dominate the market due to their operational flexibility across various track conditions. It enables railway operators to reduce downtime and enhance asset utilization by consolidating multiple functions into a single unit.

- For instance, Plasser & Theurer offers specialized tamping units for different track applications, including multi-purpose machines featuring hydraulic non-synchronous constant pressure tamping technology, which ensures effective ballast compaction and stable geometry maintenance across a variety of track types.

By Application

By application, the tamping machine market is categorized into New Railway Lines Construction and Track Maintenance. New railway construction requires advanced tamping systems to ensure high-quality ballast compaction and alignment for long-term stability. This segment continues to grow with expanding railway networks and infrastructure projects worldwide. Track maintenance represents a major share of the market, driven by the need for routine upkeep to ensure safety, ride quality, and efficiency. It remains a consistent revenue contributor due to the cyclical nature of railway maintenance and the global push for infrastructure modernization.

- For instance, the Unimat Combi 08-275 by Plasser & Theurer, which is their 16,000th machine produced, is engineered for spot fault repairs and routine maintenance, providing reliable and versatile performance essential for both new line construction and sustained track upkeep.

Segmentation:

By Type:

- Straight Track Tamping Machines

- Points and Crossing Tamping Machines

- Multi-purpose Tamping Machines (MPT)

By Application:

- New Railway Lines Construction

- Track Maintenance

Regional Analysis:

Europe Dominates with Established Rail Networks and Technological Advancements

Europe holds the largest share of the tamping machine market, accounting for approximately 34% of the global revenue. Strong investments in rail modernization, automation, and sustainability continue to drive demand across the region. Countries such as Germany, France, and the UK maintain dense, aging rail networks that require frequent track maintenance and upgrades. It benefits from advanced manufacturing hubs and well-established OEM presence, ensuring rapid deployment of high-performance tamping solutions. EU-level directives promoting low-emission rail transport also boost the adoption of hybrid and electric tamping machines. The region’s focus on safety, efficiency, and digitalization supports steady market growth.

Asia-Pacific Emerges as the Fastest Growing Regional Market

Asia-Pacific commands around 29% of the tamping machine market and is projected to witness the highest growth rate over the forecast period. Rapid rail infrastructure development in China, India, and Southeast Asia drives significant equipment demand. It supports major railway expansion projects, including high-speed rail, urban metro systems, and freight corridors. Government initiatives like India’s Gati Shakti plan and China’s Belt and Road Initiative further accelerate deployment. Local manufacturing capabilities and competitive pricing make the region attractive for both domestic consumption and exports. Rising adoption of automation and smart maintenance systems enhances long-term market prospects in this region.

North America Shows Steady Demand Driven by Maintenance Needs

North America represents nearly 22% of the tamping machine market, primarily driven by the need to maintain and rehabilitate extensive rail freight and passenger networks. The United States and Canada invest in track infrastructure upgrades to enhance safety, reduce delays, and meet federal standards. It focuses on lifecycle extension of aging rail assets rather than new construction. Demand centers around multi-purpose tamping machines capable of high-frequency deployment. OEMs target the region with service contracts, leasing models, and digital integration support. Technological adoption remains high, though procurement cycles can be prolonged due to regulatory and budgetary frameworks.

Shape Your Report to Specific Countries or Regions & Enjoy 30% Off!

Key Player Analysis:

- Plasser & Theurer

- MATISA

- Harsco Rail

- Robel

- China Railway Construction Corporation (CRCC)

- RPM Group

- Gemac Engineering Machinery Co. Ltd

- System 7

- Sinara-Transport Machines

- New Sorema Ferroviaria SpA

- Strukton

- Leonhard Weiss Group

- Remputmash Group

- Kalugaputmash

- Schweerbau

Competitive Analysis:

The tamping machine market is moderately consolidated, with a few global players dominating revenue and innovation. Companies such as Plasser & Theurer, MATISA, and Harsco Rail lead in technology integration, global reach, and product variety. It remains competitive due to rising demand from both mature and emerging markets. Players focus on product innovation, modular designs, and digital systems to differentiate their offerings. Regional firms like CRCC and Gemac Engineering strengthen their domestic presence through cost-effective solutions and public sector contracts. Strategic partnerships, service agreements, and leasing models help expand their customer base. The competitive landscape reflects a balance between high-end global providers and price-sensitive regional players.

Recent Developments:

- In 2025, Plasser & Theurer secured its largest contract to supply ÖBB Infrastruktur with a fleet of 56 modular maintenance vehicles equipped with hybrid traction drives, with an option for an additional 46 vehicles; the first deliveries are anticipated by the end of the year.

- In 2025, MATISA celebrated its 80th anniversary emphasizing innovation in railway infrastructure. The company remains a global leader in renewal trains, with flagship products including the P 95 renewal trains and C 75 ballast cleaners known for high productivity and modularity.

- China Railway Construction Corporation (CRCC) continues its presence as a major tamping machine manufacturer but without recent specific new product or partnership announcements readily available in current sources.

- In March 2023, Harsco Rail partnered with Wabtec Corporation to integrate advanced telematics and predictive diagnostics into its rail maintenance equipment portfolio.

- In January 2024, Plasser & Theurer launched its new Unimat 09-8×4/4S Dynamic E³ tamping machine, equipped with hybrid drive technology and digital maintenance tools to support eco-efficient rail operations.

Market Concentration & Characteristics:

The tamping machine market exhibits moderate to high market concentration, with established OEMs holding strong technological and distribution advantages. It features a mix of global and regional players competing across innovation, pricing, and service capabilities. Barriers to entry remain high due to capital intensity, regulatory standards, and after-sales service requirements. It is characterized by long product lifecycles, high customization needs, and rising demand for digital integration. Customers seek reliable performance, multi-functionality, and lifecycle cost efficiency, shaping vendor strategies.

Report Coverage:

The research report offers an in-depth analysis based on by Type and By Application segments. It details leading market players, providing an overview of their business, product offerings, investments, revenue streams, and key applications. Additionally, the report includes insights into the competitive environment, SWOT analysis, current market trends, as well as the primary drivers and constraints. Furthermore, it discusses various factors that have driven market expansion in recent years. The report also explores market dynamics, regulatory scenarios, and technological advancements that are shaping the industry. It assesses the impact of external factors and global economic changes on market growth. Lastly, it provides strategic recommendations for new entrants and established companies to navigate the complexities of the market.

Future Outlook:

- Demand for hybrid and electric tamping machines will grow to meet global emissions targets.

- Emerging economies in Asia and Africa will fuel new machine deployments.

- Predictive maintenance solutions will become standard in machine offerings.

- Leasing and rental models will widen access for small and mid-sized contractors.

- Multi-purpose machines will dominate procurement due to cost-efficiency.

- OEMs will strengthen aftermarket and lifecycle services to drive recurring revenue.

- Digitization of tamping operations will enhance productivity and data integration.

- Regional customization will increase due to varying rail specifications.

- Partnerships between OEMs and infrastructure companies will support long-term contracts.

- Investments in smart rail networks will align closely with machine modernization efforts.